Documente Academic

Documente Profesional

Documente Cultură

QCF312 WPQR

Încărcat de

minhnnDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

QCF312 WPQR

Încărcat de

minhnnDrepturi de autor:

Formate disponibile

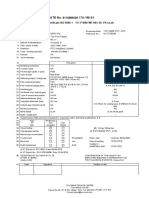

CLIENT

VIETNAM OIL AND GAS CORPORATION

Subcontractor Name & Logo

PROJECT

DUNG QUAT REFINERY (DQR) PROJECT

WELDING PROCEDURE QUALIFICATION RECORD (WPQR) 1/2

PROJ. NO

8474L QCF312

QUALITY CONTROL FORM:

Welder's Name Procedure Qualification Record ( PQR ) No. Welding Process(es) Types (Manual, Automatic, Semi-automatic)

Stamp No. JOINTS Date

Welding Procedure Specification No.

BASE METALS Material Specification Type or Grade Gr/P No. Thickness Size Other FILLER METALS F No. A No. SFA No. AWS Class Elect/Filler Dia Elect/ Filler Trade Name Electrode-Flux (Class) Flux Trade Name Non-Consumable Elect Non-Consumable Elect Dia Weld metal deposit: POSITION Position of Groove Weld Progression (Uphill, Downhill) Other

to Gr/P No.

POSTWELD HEAT TREATMENT Temperature Time Other ELECTRICAL CHARACTERISTICS Current Polarity Amperes (Range) Volts (Range) GAS Shielding Gas(es) Percent Composition (Mixtures) Flow Rate Gas Backing Trailing Shielding Gas Composition TECHNIQUE String or Weave Bead Orifice or Gas Cup Size Interpass Cleaning (Brushing, Grinding, etc.) Method of Back Gouging Oscillation Contact Tube to Work Distance Multiple or Single Pass (per Side) Multiple or Single Electrodes

PREHEAT Preheat Temperature Interpass Temperature Other

WELDING PARAMETER

No Layer/ Pass No Process Elect/Filler AWS Class Dia Amperage Polarity A Voltage V T.Speed mm/min H.Input Kj/mm

Depth of Weld Width of Interpass Tem'p Deposit Weld Bead

mm

mm

WFS (mm/min)

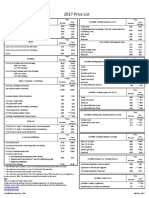

CLIENT

VIETNAM OIL AND GAS CORPORATION

Subcontractor Name & Logo

PROJECT

DUNG QUAT REFINERY (DQR) PROJECT

WELDING PROCEDURE QUALIFICATION RECORD (WPQR) 2/2

PROJ. NO

8474L QCF312

QUALITY CONTROL FORM:

Specimen No.

Width

Thickness

TENSILE TEST Ultimate Area Total Load

Ultimate

Unit Stress

Character of Failure and Location

GUIDE BEND TEST Type and Figure No. Result

Specimen No.

Notch Location

Notch Type

TOUGHNESS TESTS Test Impact % Shear Temperature Values

Lateral Expansion Measurement

Drop Weight Break No Break

Judgment Type and Character of Failure

Satisfactory Unsatisfactory

FILLET WELD TEST Penetration into Parent Metal Macro-result OTHER TESTS

Satisfactory Unsatisfactory

Type of Test Deposit Analysis Other

CERTIFICATE OF COMPLIANCE Test Conducted by: Laboratory Test No.

We certify that the statements made in this record are correct and that preparation, welding and testing of the test welds conform to the requirements of the project specification. Subcontractor: Third Party Rep: TPC Rep: Client/PMC Rep: Name: Name: Name: Name: Signature: Signature: Signature: Signature: Date Date Date Date

(Detail of record of tests are illustrative only and may be modified to conform to the type and number of tests required by the project specification.)

S-ar putea să vă placă și

- Aws Qc5-91 - Standard For Certification of Welding EducatorsDocument12 paginiAws Qc5-91 - Standard For Certification of Welding Educatorscamelod555Încă nu există evaluări

- Aci 304.2R-96Document25 paginiAci 304.2R-96minhnnÎncă nu există evaluări

- Safety in Manufacturing: Ergonomics: Awkward PosturesDocument2 paginiSafety in Manufacturing: Ergonomics: Awkward PosturesprashanthÎncă nu există evaluări

- MCQs on Defence Audit Code Chapter 9 and 10Document2 paginiMCQs on Defence Audit Code Chapter 9 and 10Rustam SalamÎncă nu există evaluări

- 19013 MTC【CY】 PDFDocument1 pagină19013 MTC【CY】 PDFConstruction ProjectsÎncă nu există evaluări

- Make $50 A Day Autopilot MethodDocument4 paginiMake $50 A Day Autopilot MethodJadon BoytonÎncă nu există evaluări

- WPS List For Piping: (Asme Section Ix)Document2 paginiWPS List For Piping: (Asme Section Ix)Ali MoosaviÎncă nu există evaluări

- Aci 117 - 90 Concrete Construction PDFDocument16 paginiAci 117 - 90 Concrete Construction PDFcessare08100% (4)

- Welding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateDocument2 paginiWelding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateAmjad PathanÎncă nu există evaluări

- NPCIL Tube Fitting SpecificationsDocument22 paginiNPCIL Tube Fitting Specificationssumant.c.singh1694100% (1)

- QCF007 Post Pour Inspection and Concrete RepairDocument1 paginăQCF007 Post Pour Inspection and Concrete Repairminhnn100% (1)

- ACI 304R-00 Guide For Measuring, Mixing, Transporting, and Placing ConcreteDocument41 paginiACI 304R-00 Guide For Measuring, Mixing, Transporting, and Placing Concretebonnico75% (4)

- Standard Specification FOR High Frequency Welded (HFW) Line Pipe (Onshore)Document31 paginiStandard Specification FOR High Frequency Welded (HFW) Line Pipe (Onshore)Agniva DuttaÎncă nu există evaluări

- Welding EngineerDocument10 paginiWelding EngineerNnamdi Celestine NnamdiÎncă nu există evaluări

- BPVC Ix QW-482Document2 paginiBPVC Ix QW-482ganesh82Încă nu există evaluări

- Astm A106 Ts EnglDocument4 paginiAstm A106 Ts EnglxaviereduardoÎncă nu există evaluări

- ACI 304 (1) .3R-96 - Heavyweight Concrete. Measuring, Mixing, TraDocument12 paginiACI 304 (1) .3R-96 - Heavyweight Concrete. Measuring, Mixing, TrawilsonschmittÎncă nu există evaluări

- 03SA0S04Document5 pagini03SA0S04Jhonny RinconesÎncă nu există evaluări

- A1X3R1 - 2d - EPI-08-WP5-TW PDFDocument10 paginiA1X3R1 - 2d - EPI-08-WP5-TW PDFJose Anisio SilvaÎncă nu există evaluări

- EIL - Formats - PMI PDFDocument53 paginiEIL - Formats - PMI PDFABHISHEK SINGHÎncă nu există evaluări

- Aws PQR FormDocument3 paginiAws PQR Formndi101Încă nu există evaluări

- Quality Oriented and ISO Approved Stainless Steel 904L Buttweld Pipe Fittings Manufacturer in IndiaDocument5 paginiQuality Oriented and ISO Approved Stainless Steel 904L Buttweld Pipe Fittings Manufacturer in IndiaPetromat Oil and Gas Equipment Pvt. Ltd.Încă nu există evaluări

- QCF102 Concrete Pouring RecordDocument1 paginăQCF102 Concrete Pouring RecordminhnnÎncă nu există evaluări

- ASTM F1545 Plastic Lined Pipe 0803Document6 paginiASTM F1545 Plastic Lined Pipe 0803JabranYounasÎncă nu există evaluări

- EIL - Specification Sheet123Document1 paginăEIL - Specification Sheet123Dinesh ChouguleÎncă nu există evaluări

- S275JR PDFDocument1 paginăS275JR PDFEmrahCayboylu100% (1)

- Qcf305 Ut ReportDocument1 paginăQcf305 Ut ReportminhnnÎncă nu există evaluări

- QW 442 A Number PDFDocument1 paginăQW 442 A Number PDFMadidj_2014Încă nu există evaluări

- Aci 304.6R-91Document14 paginiAci 304.6R-91minhnnÎncă nu există evaluări

- What Is PID - TutorialDocument5 paginiWhat Is PID - Tutorialsocrates19582405Încă nu există evaluări

- Aci 304.3R-96Document8 paginiAci 304.3R-96minhnnÎncă nu există evaluări

- Civil Boq AiiapDocument170 paginiCivil Boq AiiapMuhammad ArslanÎncă nu există evaluări

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 paginăQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345Încă nu există evaluări

- Wps GT 9b Cvn90 Rev 1 PDFDocument6 paginiWps GT 9b Cvn90 Rev 1 PDFM. Zaki RahmaniÎncă nu există evaluări

- Astm A 450Document10 paginiAstm A 450Telmo VianaÎncă nu există evaluări

- 6-15-0001 Rev 2 Gen Spec For Heat Exchanger PDFDocument20 pagini6-15-0001 Rev 2 Gen Spec For Heat Exchanger PDFsumit kumarÎncă nu există evaluări

- TDC-10A Rev 3 Upgradation by Welding of C12A Steel CastingsDocument3 paginiTDC-10A Rev 3 Upgradation by Welding of C12A Steel CastingsGohilakrishnan ThiagarajanÎncă nu există evaluări

- IRCLASS Systems and Solutions Pvt. Ltd. (A Wholy Owned Subsidiary of Indian Register of Shipping)Document4 paginiIRCLASS Systems and Solutions Pvt. Ltd. (A Wholy Owned Subsidiary of Indian Register of Shipping)Mostafizur RahmanÎncă nu există evaluări

- WPS PQR-05Document10 paginiWPS PQR-05Ranjan KumarÎncă nu există evaluări

- SURIA ENGINEERING WELDING PROCEDURE SPECIFICATION (WPS) FOR GTAW & SMAWDocument1 paginăSURIA ENGINEERING WELDING PROCEDURE SPECIFICATION (WPS) FOR GTAW & SMAWsuria qaqcÎncă nu există evaluări

- Astm A179 PDFDocument1 paginăAstm A179 PDFgaminÎncă nu există evaluări

- Data Sheet Material 2.4819Document3 paginiData Sheet Material 2.4819BoberÎncă nu există evaluări

- Wps For Aluminium WeldingDocument8 paginiWps For Aluminium WeldingMohammed MusaÎncă nu există evaluări

- Highlights On ASME Essential VariablesDocument8 paginiHighlights On ASME Essential VariableschowhkÎncă nu există evaluări

- Madina Trading WPS No. 017Document12 paginiMadina Trading WPS No. 017MAT-LIONÎncă nu există evaluări

- GMAWDocument12 paginiGMAWsushant47Încă nu există evaluări

- WPS & PQR (E Co Cr-E)Document3 paginiWPS & PQR (E Co Cr-E)HossamSAshourÎncă nu există evaluări

- API 2H50 Data Sheet 2012 04 02Document2 paginiAPI 2H50 Data Sheet 2012 04 02alvaedison00Încă nu există evaluări

- Astm A529 1972Document5 paginiAstm A529 1972dharlanuctcom0% (1)

- Welder Certificate ISO 9606-1 QualificationDocument1 paginăWelder Certificate ISO 9606-1 QualificationDeepak Das100% (1)

- Wps PQRDocument7 paginiWps PQRsobariÎncă nu există evaluări

- Welding Rod For c5 & f5 - Er 80s-b6Document1 paginăWelding Rod For c5 & f5 - Er 80s-b6SatyamEngÎncă nu există evaluări

- ASTM A573-A573M-93a-1998Document2 paginiASTM A573-A573M-93a-1998NadhiraÎncă nu există evaluări

- Baosteel hot rolled steel plate quality certificateDocument3 paginiBaosteel hot rolled steel plate quality certificateDang TranÎncă nu există evaluări

- Er 100 S 1Document1 paginăEr 100 S 1Oliver Quezada Inostroza100% (1)

- dpvc-09 Petrobras PDFDocument47 paginidpvc-09 Petrobras PDFBilly TanÎncă nu există evaluări

- Nip Material ComparsionDocument1 paginăNip Material ComparsionRob WillestoneÎncă nu există evaluări

- Nikopol Steel Pipe Plant Yutist Seamless Steel TubesDocument2 paginiNikopol Steel Pipe Plant Yutist Seamless Steel Tubesvishal.nitham100% (1)

- Thermal Power Project Weld Inspection ReportDocument1 paginăThermal Power Project Weld Inspection ReportAshwani DograÎncă nu există evaluări

- Procedure For: J164 (Rev 11/02)Document21 paginiProcedure For: J164 (Rev 11/02)tomcanÎncă nu există evaluări

- Aisi 4130Document2 paginiAisi 4130Marcos CarreroÎncă nu există evaluări

- Spec Grade Number Symbol Number Symbol Asme (Astm) KS JISDocument50 paginiSpec Grade Number Symbol Number Symbol Asme (Astm) KS JISVinay TrivediÎncă nu există evaluări

- PQR For 32 MM PlateDocument1 paginăPQR For 32 MM PlateMuhammed MubeenÎncă nu există evaluări

- Pressure Vessel RT TestDocument3 paginiPressure Vessel RT TestAriq FauzanÎncă nu există evaluări

- 02 Samss 011Document36 pagini02 Samss 011OMER ELFADILÎncă nu există evaluări

- Ewf - Technical Sheet - Calculation of Preheat Temperature For Butt WeldsDocument1 paginăEwf - Technical Sheet - Calculation of Preheat Temperature For Butt WeldsDries VandezandeÎncă nu există evaluări

- Graycor WPS 19 SampleDocument5 paginiGraycor WPS 19 SampleRaul SebastiamÎncă nu există evaluări

- Technical Requirements for hot dip galvanizingDocument7 paginiTechnical Requirements for hot dip galvanizingArun SharmaÎncă nu există evaluări

- Project:OLMTP Project No:16-PSS-002 Client:ZKB-RELIABLE: Daily Welding Inspection ReportDocument4 paginiProject:OLMTP Project No:16-PSS-002 Client:ZKB-RELIABLE: Daily Welding Inspection ReportEngr Saeed AnwarÎncă nu există evaluări

- Pressure Vessel Material Selection GuidelinesDocument3 paginiPressure Vessel Material Selection Guidelinesarjun SinghÎncă nu există evaluări

- Industrial radiography A Complete Guide - 2019 EditionDe la EverandIndustrial radiography A Complete Guide - 2019 EditionÎncă nu există evaluări

- Dung Quat Refinery Project: Welder & Welding Operator Qualification Test CertificateDocument2 paginiDung Quat Refinery Project: Welder & Welding Operator Qualification Test CertificateminhnnÎncă nu există evaluări

- Dung Quat Refinery Project: Welder & Welding Operator Qualification Test Certificate (Asme Ix / Aws D 1.1)Document2 paginiDung Quat Refinery Project: Welder & Welding Operator Qualification Test Certificate (Asme Ix / Aws D 1.1)minhnnÎncă nu există evaluări

- AWS QC 10-95 Spec 4 Qualification Certification Entry Level WelderDocument25 paginiAWS QC 10-95 Spec 4 Qualification Certification Entry Level WelderminhnnÎncă nu există evaluări

- AWS QC 11-96 Spec 4 Qualification Certification Advanced Level WelderDocument38 paginiAWS QC 11-96 Spec 4 Qualification Certification Advanced Level Welderminhnn50% (2)

- 124 2R-94 PDFDocument1 pagină124 2R-94 PDFfarhadamÎncă nu există evaluări

- Aci 117 R90Document11 paginiAci 117 R90Rafael Elgueta Aravena100% (1)

- 2236 Price List 2017 20170306Document1 pagină2236 Price List 2017 20170306minhnn100% (1)

- ACI 303.1-97 Standard Specification For Cast-In-Place Architectural ConcreteDocument10 paginiACI 303.1-97 Standard Specification For Cast-In-Place Architectural ConcreteZaki 'Eki' MuliawanÎncă nu există evaluări

- 126 3R-99 PDFDocument50 pagini126 3R-99 PDFfarhadamÎncă nu există evaluări

- ACI 304R-89. Guide For Measuring, Mixing, Transporting, andDocument54 paginiACI 304R-89. Guide For Measuring, Mixing, Transporting, andminhnnÎncă nu există evaluări

- QCF012 Authorisation To BackfillDocument1 paginăQCF012 Authorisation To BackfillminhnnÎncă nu există evaluări

- Batching, Mixing and Job-Control of Lightweight ConcreteDocument9 paginiBatching, Mixing and Job-Control of Lightweight ConcreteRonaldo HertezÎncă nu există evaluări

- CQC008Document1 paginăCQC008minhnnÎncă nu există evaluări

- QCF006 Placement & Compaction of Fill MaterialDocument1 paginăQCF006 Placement & Compaction of Fill MaterialminhnnÎncă nu există evaluări

- QCF005 Survey LogDocument2 paginiQCF005 Survey LogminhnnÎncă nu există evaluări

- QCF011 Asphalt Concrete Site ControlDocument3 paginiQCF011 Asphalt Concrete Site ControlminhnnÎncă nu există evaluări

- QC Form Dung Quat Refinery ProjectDocument1 paginăQC Form Dung Quat Refinery ProjectminhnnÎncă nu există evaluări

- QCF009 Insp Report-Precast ConcreteDocument1 paginăQCF009 Insp Report-Precast ConcreteminhnnÎncă nu există evaluări

- Dung Quat Refinery Project: Works Inspection ReportDocument1 paginăDung Quat Refinery Project: Works Inspection ReportminhnnÎncă nu există evaluări

- QCF010 Works Inspection Report GeotextileDocument1 paginăQCF010 Works Inspection Report GeotextileminhnnÎncă nu există evaluări

- QCF013 Materials Inspection ReportDocument1 paginăQCF013 Materials Inspection ReportminhnnÎncă nu există evaluări

- QCF101 Compaction Test ReportDocument1 paginăQCF101 Compaction Test ReportminhnnÎncă nu există evaluări

- 2014 Chevrolet Cruze maintenance schedule guideDocument2 pagini2014 Chevrolet Cruze maintenance schedule guidericardo rodriguezÎncă nu există evaluări

- MBA Stats Essentials: Measures, Prob, Hypothesis TestsDocument4 paginiMBA Stats Essentials: Measures, Prob, Hypothesis TestsIbrahim JawedÎncă nu există evaluări

- COA (Odoo Egypt)Document8 paginiCOA (Odoo Egypt)menams2010Încă nu există evaluări

- Caf 8 Aud Spring 2022Document3 paginiCaf 8 Aud Spring 2022Huma BashirÎncă nu există evaluări

- Ermac vs. MedeloDocument1 paginăErmac vs. MedeloJessa F. Austria-CalderonÎncă nu există evaluări

- Sahrudaya Health Care Private Limited: Pay Slip For The Month of May-2022Document1 paginăSahrudaya Health Care Private Limited: Pay Slip For The Month of May-2022Rohit raagÎncă nu există evaluări

- G.R. No. 122039 May 31, 2000 VICENTE CALALAS, Petitioner, Court of Appeals, Eliza Jujeurche Sunga and Francisco Salva, RespondentsDocument56 paginiG.R. No. 122039 May 31, 2000 VICENTE CALALAS, Petitioner, Court of Appeals, Eliza Jujeurche Sunga and Francisco Salva, RespondentsJayson AbabaÎncă nu există evaluări

- GFRDDocument9 paginiGFRDLalit NagarÎncă nu există evaluări

- VectorsDocument9 paginiVectorsdam_allen85Încă nu există evaluări

- Practice Questions & Answers: Made With by SawzeeyyDocument141 paginiPractice Questions & Answers: Made With by SawzeeyyPhake CodedÎncă nu există evaluări

- Application Tracking System: Mentor - Yamini Ma'AmDocument10 paginiApplication Tracking System: Mentor - Yamini Ma'AmBHuwanÎncă nu există evaluări

- Term Paper Mec 208Document20 paginiTerm Paper Mec 208lksingh1987Încă nu există evaluări

- 22 Caltex Philippines, Inc. vs. Commission On Audit, 208 SCRA 726, May 08, 1992Document36 pagini22 Caltex Philippines, Inc. vs. Commission On Audit, 208 SCRA 726, May 08, 1992milkteaÎncă nu există evaluări

- Best Practices For SAP-PM History DocumentationDocument8 paginiBest Practices For SAP-PM History DocumentationLaammeem Noon100% (1)

- Grid Xtreme VR Data Sheet enDocument3 paginiGrid Xtreme VR Data Sheet enlong bạchÎncă nu există evaluări

- DX DiagDocument31 paginiDX DiagJose Trix CamposÎncă nu există evaluări

- Torta de Riso Business PlanDocument25 paginiTorta de Riso Business PlanSalty lÎncă nu există evaluări

- Kooltherm PipeDocument8 paginiKooltherm Pipenaseema1Încă nu există evaluări

- Private Copy of Vishwajit Mishra (Vishwajit - Mishra@hec - Edu) Copy and Sharing ProhibitedDocument8 paginiPrivate Copy of Vishwajit Mishra (Vishwajit - Mishra@hec - Edu) Copy and Sharing ProhibitedVISHWAJIT MISHRAÎncă nu există evaluări

- Expert Java Developer with 10+ years experienceDocument3 paginiExpert Java Developer with 10+ years experienceHaythem MzoughiÎncă nu există evaluări

- Panameterics GF 868 Flare Gas Meter PDFDocument8 paginiPanameterics GF 868 Flare Gas Meter PDFDaniel DamboÎncă nu există evaluări

- Computer Science Practical File WorkDocument34 paginiComputer Science Practical File WorkArshdeep SinghÎncă nu există evaluări

- JuliaPro v0.6.2.1 Package API ManualDocument480 paginiJuliaPro v0.6.2.1 Package API ManualCapitan TorpedoÎncă nu există evaluări

- Presenting India's Biggest NYE 2023 Destination PartyDocument14 paginiPresenting India's Biggest NYE 2023 Destination PartyJadhav RamakanthÎncă nu există evaluări

- (Unit) Title of The Chapter Name of FacilitatorDocument35 pagini(Unit) Title of The Chapter Name of FacilitatorDipesh BasnetÎncă nu există evaluări