Documente Academic

Documente Profesional

Documente Cultură

Anaerobic Co Digestion of Poultry Manure and Waste Kitchen Oil

Încărcat de

Anonymous MVHQ97KEoPDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Anaerobic Co Digestion of Poultry Manure and Waste Kitchen Oil

Încărcat de

Anonymous MVHQ97KEoPDrepturi de autor:

Formate disponibile

Slovak Society of Chemical Engineering Institute of Chemical and Environmental Engineering Slovak University of Technology in Bratislava

PROCEEDINGS

37

th

International Conference of Slovak Society of Chemical Engineering

Hotel Hutnk Tatransk Matliare, Slovakia May 24 28, 2010

Editor: J. Marko

ISBN 978-80-227-3290-1 Lazor, M., Hut nan, M., Sedl cek, S., Kolesrov, N., palkov, V.: Anaerobic co-digestion of poultry manure and waste kitchen oil, Editor: Marko, J., In Proceedings of the 37th International Conference of Slovak Society of Chemical Engineering, Tatransk Matliare, Slovakia, 13991406, 2010.

37th International Conference of SSCHE May 2428, 2010, Tatransk e Matliare, Slovakia

Po-Th-6, 113p.pdf

Anaerobic co-digestion of poultry manure and waste kitchen oil

Lazor, M., Hutan, M., Sedlek, S., Kolesrov, N., palkov, V. Institute of Chemical and Environmental Engineering, Faculty of Chemical and Food Technology, Slovak University of Technology, Radlinskho 9, 812 37 Bratislava, Slovak Republic

Keywords: poultry manure, waste kitchen oil, biogas, co-digestion

1.0

Introduction

Agro food industry is a huge producent of wastes that can be for energetic purposes used. Excrements of animals as poultry, swines, livestocks are one of them. Their energetic content is still sufficient for composting or anaerobic digestion. Annual animal excrement production in Slovak Republic is about 13 700 000 t what can be used for 1,03 TWhe (3,7.1015 J) electric energy and 2,8 PJt (2,8.1015 J) heat energy production. For this aim 258 biogas stations are needed. Tab.1Basic technologic parametres for different animal excrements anaerobic digestion [1]

Parameter Minimal digestion time Temperature Maximal loading of biosludge Biogas production Dimension d

0

Swine 13 17 38 42 5 0,35

Beef 16 21 38 42 4 0,20

Poultry 25 30 38 42 3 0,40

kg VS/m3/d m /kg VS/d

3

Very perspective method of agro food wastes utilization is co-digestion, where different biodegradable wastes are together anaerobic treated. At choice of treated wastes many factors take into account is needed. The most important are price and access of wastes, their composition (organic mass and mineral content), methane yield from organic mass, price of needed digestion technology etc. Co-digestion has in comparison with single anaerobic fermentation several advantages. increased biogas production with single fermentation of wastes comparison minimal green house gases producing disposition of wastes, which occupy large planes contaminations restraint of ground waters destruction of pathogenous germs in raw waste smell removal digested waste is perfect bio-organic fertilizer In this presented work poultry manure as a animal waste and waste kitchen oil as a restaurant waste were chosen. Poultry manure was chosen due to its biggest methane yield related to 1 kg volatile solids (VS) (Tab.1) and waste kitchen oil due to its high energetic content (Tab.3). This experiment is only part of big study where intensification methods to anaerobic process are aplicated.

1399

37th International Conference of SSCHE May 2428, 2010, Tatransk e Matliare, Slovakia

Po-Th-6, 113p.pdf

2.0

Experimental

Aim of this work was monitoring of biogas production and its composition from agro-food wastes. The first of all, anaerobic digestion of poultry manure and wasted kitchen oil was investigated. Organic fraction ratio of poultry manure and wasted oil in this presented work was 9:1.. Temperature value of this anaerobic process was maintaining in mesophilic scale i.e. 37oC. As an anaerobic laboratory apparatus, semicontinuous reactor was used. Substrates feeding and excess sludge removal was every day and biosludge loading by volatile solids was inceasing gradually untill fermentation colaps . Periodically biogas composition by the mobile IR spectrophotometer was measured. As an anaerobic stabilized inoculum waste water sludge was used. Average input substrates parameters, resp. inoculum like COD, ammonia concentration, pH and organic fraction (OF) is in table2.

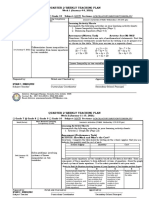

Tab 2. Basic parameters of inocculum stabilized waste water anaerobic sludge

COD [mg/l] NH4 [mg/l] VFA [mg/l] Xc [g/l] pH

+

1370 231 369 7,5 7,8

Pic.1 1-isolated laboratory reactor, 2-stirrer with electromotor, 3-time switch, 4-electric heating with regulation, 5-drum gas gauge, 6-feeding open

Total reactor volume was approximately 17 l, where anaerobic mixture occupied 15 l. Therefore, remaining space about 2 l as an improvised gasholder serviented. From there, excess gas through the bubbler to flow-meter was led away. Mixing of anaerobic mixture by propeller blender was secured. Process temperature was measured by thermometer, which the mixtures heating was regulating.

1400

37th International Conference of SSCHE May 2428, 2010, Tatransk e Matliare, Slovakia

Po-Th-6, 113p.pdf

3. Results and discussions 3.1. Poultry manure waste kitchen oil anaerobic digestion

Aim of this experiment was monitoring biogas production and its composition at graduated organic mass loading and also measuring of processing parameters that characterize anaerobic processes (pH, NH4+, VFA (volatile fat acids), Xc (dry mass content)). For anaerobic systems these parameters are indical and change one of them cause change the other. Experiment was running until system began be collapsing. Poultry manure and waste kitchen oil as a cofermentation system was chosen. Co-digestion started with initial organic mass (VS) loading on the level 0.3 kg VS/m3/d and gradually was increased until final value 1.2 kg VS/m3/d. Feeding by manure and oil was at every loading to constant VS ratio both substrates , it means 9:1. First 12 days organic mass loading was 0.3 kg VS/m3/d, 13 23. day 0.5 VS/m3/d, 24 120. day 0.7 VS/m3/d, 121 143. day 1 VS/m3/d and finally 144 305 day 1.2 VS/m3/d. In generally anaerobic system stabilization is long time process that take several weeks till months. It depends on many factors ( intensity of organic mass loading, temperature and composition of input substrates).

18 000,0 16 000,0 14 000,0 12 000,0 10 000,0 8 000,0 6 000,0 4 000,0 2 000,0 0,0 0 50 100 150 200 250 300

time[ d ]

C O D [mg/] V F A [mg/l] NH4+ [mg/l]

Fig.1 Anaerobic process parameters time development (COD, VFA, NH4+)

Organic mass loading is mostly expressed two ways loading by volatile solids (VS) and loading by COD. Because different substrates has different organic mass composition, it means different COD related to 1 kg VS , better and for anaerobic processes more valuable parameter COD should be. Typical example studied co-digestion system poultry manure waste kitchen oil was. Chemical oxygen demand (COD) for poultry manure was 0.9 g COD/kg VS, eventually 2340 COD/kg VS for waste kitchen oil (Tab. 3). Poultry manure was periodically taken from near farm and subsequently stored in fridge. Waste kitchen oil was taken from university canteen and also stored in fridge. Average stored time for poultry manure was 2 3 weeks. If stored time overreached 3 weeks, manure started decompose. It was indicated by ammonia smell. If so particularly decomposed manure was dosing, always unstability in anaerobic process was happened. As can be shown in Fig.1, every dosing of particularly decompose manure caused increasing COD, NH4+ and VFA. After 125th co-digestion days stored time of manure was decreasing to 10 days. As a result was stabilizing of anaerobic process.

1401

37th International Conference of SSCHE May 2428, 2010, Tatransk e Matliare, Slovakia

Po-Th-6, 113p.pdf

Tab.3 Organic mass and COD biosludge loading through the anaerobic digestion poultry manure waste kitchen oil

Total organic mass Organic mass loading loading - manure 3 3 [kg VS/m /d] [kg VS/m /d] 0,3 0,27 0,5 0,45 0,7 0,63 1 0,9 1,2 1,08 COD - manure 0,9 COD - oil 2340 Organic mass loading - oil COD loading - manure 3 3 [kg VS/m /d] [g COD/m /d] 0,03 0,243 0,05 0,405 0,07 0,567 0,1 0,81 0,12 0,972 g COD/kg VS g COD/kg VS COD loading - oil 3 [g COD/m /d] 70,2 117 163,8 234 280,8

Optimal pH value for anaerobic process is in interval 6.5 7.5. For holding this value existence of acid basic buffer system is needed. In anaerobic system co-exist two basic buffer system (ammoniac NH3 + H+ NH4+ and carbonate CO32- + H+ HCO3- ). However if substrate with high total nitrogen content is digested (poultry manure), inhibition of anaerobic processes can happen. For example if swine manure is digested, upper limit free ammonia value is 1,1 g NH3 N/l. Ammonia is generated from nitrogenous matters as proteins and urea [3]. Free ammonia and NH4+ are two main inorganic nitrogenous forms in aqueous solutions. Free ammonia toxicity is caused its freely membrane-permeability and consequently causing proton imbalance or potassium deficiency [4]. From all anaerobic types of microorganisms, the methanogens are the least tolerant and the most likely to cease growth due to ammonia inhibition [5]. There are many different maximum free ammonia concentrations for methanogens on literatures. For example , as ammonia concentrations were increased in the range of 40515734 mg NH3N/l, acidogenic populations in the granular sludge were hardly affected while the methanogenic population lost 56.5% of its activity [6]. In our present work , after 175th digestion day free ammonia inhibition started be significant, if concentration 4000 mg NH4+/l was overreached (Fig.1). According [11] free ammonia if concentration of NH4+ is known can be counted as follows: pH = (TAN/(1+10(pKa pH)). In 175th day pH = 8,4, pKa = 8,95 [11] a therefore concentration of free ammonia NH3 = 1130 mg/l.

8,8 8,6 8,4 8,2 pH 8 7,8 7,6 7,4 0 50 100 150 200 250 300 350 time[ d ]

Fig.2 pH development during anaerobic digestion of poultry manure waste kitchen oil

1402

37th International Conference of SSCHE May 2428, 2010, Tatransk e Matliare, Slovakia

Po-Th-6, 113p.pdf

During treatment of waste containing high concentrations of TAN (total ammonia nitrogen), pH affects the growth of microorganisms as well as the composition of TAN [7]. Process instability due to ammonia often results in volatile fatty acids (VFA) accumulation, which again leads to a decrease in pH and thereby declining concentration of free ammonia FA. The interaction between FA, VFAs and pH may lead to an inhibited steady state, a condition where the process is running stably but with a lower methane yield [8]. In our presented work this situation occurred after 175th co-digestion day, where pH value due to free ammonia started increase (Fig.2) and consequential rise of COD and VFA concentration (Fig.1).

Biogas production [m3/ kg VS/ d] 1200,00 1000,00 800,00 600,00 400,00 200,00 0,00 0 50 100 150 200 250 300 350 time [ d ]

Fig.3 Biogas production related to 1 kg added VS

This free ammonia inhibition caused decrease of biogas production (Fig.3). System was pseudo stable, it means that biogas production was stabilized and oscillated between 200 300 m3/kg VS/d. However in comparison with biogas production before inhibition (before 175th day , 400 - 600 m3/kg VS/d) it was only 50 % yield (Fig.3). Toxic influent of free ammonia caused also decrease in methane content in biogas (Tab.4). Therefore the most important if substrates with high nitrogenous matters are anaerobic digested (poultry manure) is decrease of free ammonia concentration. There are two main physicalchemical methods to free ammonia removal, air stripping and chemical precipitation [9]. For ammonia precipitation magnesium ammonium phosphate can be used. Another posibility is dilution of manure to a total solid level of 0.53.0% . This approach is joined with economic unattractivity due to high waste volume [10]. Various types of inhibition can be counteracted by increasing the biomass retention in the reactor. It was found that the methane yield in a CSTR could be increased by switching off the stirrer half an hour before and after substrate addition [11]. Ammonia inhibition can be reduced using different types of inert material (clay, activated carbon, zeolite) or adding of ionic exchanger or adsorbants (natural zeolite, glauconite) [12]. Another parameter that can affects to free ammonia concentration temperature is. As is known , higher temperature has positive impact to microorganisms growth and metabolic rate, on the other side higher temperature leads to higher free ammonia concentration, thus to inhibition. Several authors have found that anaerobic treatment of waste with high ammonia is less stable in thermophilic conditions in comparison with mesophilic digestion [13]. It was discovered that some ions as Na+, K+, Ca2+ and K+ have anti inhibition effects, mainly joined with free ammonia inhibition.

1403

37th International Conference of SSCHE May 2428, 2010, Tatransk e Matliare, Slovakia

Po-Th-6, 113p.pdf

Tab.4 Biogas composition (poultry manure waste kitchen oil)

Digestion 14 day Organic mass 0,3 loading [kg 3 VS/m /d] componets CH4 [%] CO2 [%] O2 [%] H 2S [ppm] H2 [ppm] 22 34 41 57 71 83 91 111 127 147 165 187 210 235 251 270 294

0,5 0,7 0,7 0,7 0,7 0,7 0,7 0,7

1,2

1,2

1,2 1,2

1,2

1,2 1,2

1,2

Biogas composition 60,4 56,6 53,9 45,2 70,7 58,8 55,8 57,8 56,2 55,5 52,3 51,4 52,4 50,3 49,8 50,1 46,4 48,3 33,3 36,8 40,1 48,7 24,4 33 38,9 37,1 37,5 37,6 40,1 41,6 43,1 45,3 44,3 42,3 47,3 45,9 1,1 1,4 1,3 1,6 0,9 1,2 1 1 1,1 1 0,9 1,1 1,2 1,1 1 0,9 1,1 1,2

104 137 740 1210 515 169 806 455 1069 1152 1005 1054 1003 989 1052 1035 989 1105 165 42 55 51 85 100 80 80 68 80 95 101 125 114 131 145 167 195

4.0 1.

Conclusions Co - digestion of poultry manure and waste kitchen oil was occurred. Initial organic mass loading was 0,3 kg VS/m3/d and consequently gradually increased up to 1,2 VS/m3/d. Organic mass ratio between poultry manure and waste kitchen oil was during all co-digestion on constant level 9:1. It was found that high concentration of free ammonia has very negative influence to anaerobic process and for co-digestion of poultry manure waste kitchen oil upper limit concentration of free ammonia on level 1130 mg NH3/l was detected. Free ammonia inhibition caused decrease in biogas production, where from origin production before inhibition (up to 175th co-digestion day) 400 600 m3/kg VS/d declined to 200 300 m3/kg VS/d (after 175th co-digestion day) It was discovered, that if storage time of poultry manure is very long (2 weeks and longer), its decomposition happened to ammonia production. It led to high concentration of ammonia in dosing batch and subsequently to inhibition of anaerobic process. The most important if substrates with high nitrogen content are digested is reduce concentration of free ammonia. However maximum acceptable free ammonia concentration is for various anaerobic microorganisms different and for every substrate individual. Determination of this concentration by experiment is necessary Free ammonia remove by different methods can be reached. The most important are air striping and chemical precipitation by magnesium ammonium phosphate.

2.

3.

4.

5.

6.

1404

37th International Conference of SSCHE May 2428, 2010, Tatransk e Matliare, Slovakia

Po-Th-6, 113p.pdf

5.0 [1]

Literature Hirl P.J., Irvine R.L.: In: Proc. First IAWO Spec. Conf. Sequencing Batch Technology, 41 48, Munchen, 1996 Anaerobic digestion of swine manure: Inhibition by ammonia Water Research, Volume 32, Issue 1, January 1998, Pages 5-12 Kaare Hvid Hansen, Irini Angelidaki, Birgitte Kiaer Ahring Ammonia Inhibition in High-Solids Biogasification: An Overview and Practical Solutions,M. Kayhanian , Environmental Technology, 1479-487X, Volume 20, Issue 4, 1999, Pages 355 365 Gallert et al., 1998 C. Gallert, S. Bauer and J. Winter, Effect of ammonia on the anaerobic degradation of protein by a mesophilic and thermophilic biowaste population, Appl. Microbiol. Biotechnol. 50 (1998), pp. 495501 Kayhanian, 1994 M. Kayhanian, Performance of a high-solids anaerobic digestion process under various ammonia concentrations, J. Chem. Tech. Biotechnol. 59 (1994), pp. 349352 Koster and Lettinga, 1988 I.W. Koster and G. Lettinga, Anaerobic digestion at extreme ammonia concentrations, Biol. Wastes 25 (1988), pp. 5159. Hansen et al., 1999 K.H. Hansen, I. Angelidaki and B.K. Ahring, Improving thermophilic anaerobic digestion of swine manure, Water Res. 33 (1999), pp. 1805 1810 Angelidaki and Ahring, 1993 I. Angelidaki and B.K. Ahring, Thermophilic digestion of livestock waste: the effect of ammonia, Appl. Microbiol. Biotechnol. 38 (1993), pp. 560564 Kabdasli et al., 2000 I. Kabdasli, O. Tnay, I. ztrk, S. Yilmaz and O. Arikan, Ammonia removal from young landfill leachate by magnesium ammonium phosphate precipitation and air stripping, Water Sci. Technol. 41 (2000), pp. 237240. Callaghan et al., 1999 F.J. Callaghan, D.A.J. Wase, K. Thayanithy and C.F. Forster, Co-digestion of waste organic solids: batch studies, Bioresour. Technol. 67 (1999), pp. 117122 Hansen et al., 1998 K.H. Hansen, I. Angelidaki and B.K. Ahring, Anaerobic digestion of swine manure: inhibition by ammonia, Water Res. 32 (1998), pp. 512 Angelidaki et al., 1990 I. Angelidaki, S.P. Petersen and B.K. Ahring, Effects of lipids on thermophilic anaerobic digestion and reduction of lipid inhibition upon addition of bentonite, Appl. Microbiol. Biotechnol. 33 (1990), pp. 469472 Parkin and Miller, 1983 Parkin, G.F., Miller, S.W., 1983. Response of methane fermentation to continuous addition of selected industrial toxicants. In: Proceedings of the 37th Purdue Industrial Waste Conference, West Lafayette, Ind.

[2]

[3]

[4]

[5]

[6]

[7]

[8]

[9]

[10]

[11]

[12]

[13]

1405

37th International Conference of SSCHE May 2428, 2010, Tatransk e Matliare, Slovakia

Po-Th-6, 113p.pdf

6.0

Acknowledgements

The presented contribution was created as a part of project SK00023 financed by Norwegian Financial Mechanism, Financial Mechanism of EEA and the State Budget of the Slovak Republic (www.eeagrants.com).

1406

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- Little: PrinceDocument18 paginiLittle: PrinceNara Serrano94% (18)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Organic Orchard, Vineyard, and Berry Crop Documentation FormsDocument22 paginiOrganic Orchard, Vineyard, and Berry Crop Documentation FormsAnonymous MVHQ97KEoPÎncă nu există evaluări

- Hydrangea CareDocument2 paginiHydrangea CareAnonymous MVHQ97KEoPÎncă nu există evaluări

- Triple Standards:: Quick Reference Guide To Private Environmental, Quality, and Social StandardsDocument9 paginiTriple Standards:: Quick Reference Guide To Private Environmental, Quality, and Social StandardsAnonymous MVHQ97KEoPÎncă nu există evaluări

- Livestock FormsDocument37 paginiLivestock FormsddpuruliaÎncă nu există evaluări

- NOSB Processing Materials Decisions June 2001Document11 paginiNOSB Processing Materials Decisions June 2001Anonymous MVHQ97KEoPÎncă nu există evaluări

- Home & Garden Information Center: JasmineDocument2 paginiHome & Garden Information Center: JasmineAnonymous MVHQ97KEoPÎncă nu există evaluări

- What Are The Basic Requirements For Organic Certification?Document2 paginiWhat Are The Basic Requirements For Organic Certification?Anonymous MVHQ97KEoPÎncă nu există evaluări

- What Are The Basic Requirements For Organic Certification?Document2 paginiWhat Are The Basic Requirements For Organic Certification?Anonymous MVHQ97KEoPÎncă nu există evaluări

- ChapatiDocument11 paginiChapatiAnonymous MVHQ97KEoPÎncă nu există evaluări

- Cold Protection For Nursery CropsDocument9 paginiCold Protection For Nursery CropsAnonymous MVHQ97KEoPÎncă nu există evaluări

- Guide To Production Information For Commercial Floriculture GrowersDocument13 paginiGuide To Production Information For Commercial Floriculture GrowersAnonymous MVHQ97KEoPÎncă nu există evaluări

- Home & Garden Information Center: VinesDocument4 paginiHome & Garden Information Center: VinesAnonymous MVHQ97KEoPÎncă nu există evaluări

- Muesli SML PDFDocument4 paginiMuesli SML PDFAnonymous MVHQ97KEoPÎncă nu există evaluări

- Nettle SoupDocument2 paginiNettle SoupAnonymous MVHQ97KEoPÎncă nu există evaluări

- SAWG Organic Farmer Network - EquipmentDocument4 paginiSAWG Organic Farmer Network - EquipmentAnonymous MVHQ97KEoPÎncă nu există evaluări

- Ishi in Two Worlds A Biography of The Last Wild Indian in North AmericaDocument6 paginiIshi in Two Worlds A Biography of The Last Wild Indian in North AmericaAnonymous MVHQ97KEoPÎncă nu există evaluări

- PopoversDocument1 paginăPopoversAnonymous MVHQ97KEoPÎncă nu există evaluări

- Popovers Recipe - Food NetworkDocument1 paginăPopovers Recipe - Food NetworkAnonymous MVHQ97KEoPÎncă nu există evaluări

- Popovers - King Arthur Flour PDFDocument1 paginăPopovers - King Arthur Flour PDFAnonymous MVHQ97KEoPÎncă nu există evaluări

- Popovers - King Arthur FlourDocument1 paginăPopovers - King Arthur FlourAnonymous MVHQ97KEoPÎncă nu există evaluări

- Muesli SML PDFDocument4 paginiMuesli SML PDFAnonymous MVHQ97KEoPÎncă nu există evaluări

- HTTP 301Document2 paginiHTTP 301Anonymous MVHQ97KEoPÎncă nu există evaluări

- Arduino Tutorial - Learn Electronics and Microcontrollers Using Arduino!Document3 paginiArduino Tutorial - Learn Electronics and Microcontrollers Using Arduino!Anonymous MVHQ97KEoPÎncă nu există evaluări

- The Problems and Possible Solutions in The Development of A Chinese Deaf IdentityDocument15 paginiThe Problems and Possible Solutions in The Development of A Chinese Deaf IdentityAnonymous MVHQ97KEoPÎncă nu există evaluări

- A Model of Safe Levels For Electrical Stimulation Shannon 1992Document3 paginiA Model of Safe Levels For Electrical Stimulation Shannon 1992Anonymous MVHQ97KEoPÎncă nu există evaluări

- Engaging in A Conversation About Race - Louhelen Compilation - 2010Document44 paginiEngaging in A Conversation About Race - Louhelen Compilation - 2010Anonymous MVHQ97KEoPÎncă nu există evaluări

- Pitch Discrimination in The Cat Through Electrical Stimulation of The Terminal Auditory Nerve FiberDocument6 paginiPitch Discrimination in The Cat Through Electrical Stimulation of The Terminal Auditory Nerve FiberAnonymous MVHQ97KEoPÎncă nu există evaluări

- BT Style Guide July 2018Document9 paginiBT Style Guide July 2018Anonymous MVHQ97KEoPÎncă nu există evaluări

- A Matched Pairs Comparison of Single and Multichannel Cochlear Implants in Children Chute 1990Document4 paginiA Matched Pairs Comparison of Single and Multichannel Cochlear Implants in Children Chute 1990Anonymous MVHQ97KEoPÎncă nu există evaluări

- Bioresource Technology: Su Yun Xu, Obuli P. Karthikeyan, Ammaiyappan Selvam, Jonathan W.C. WongDocument6 paginiBioresource Technology: Su Yun Xu, Obuli P. Karthikeyan, Ammaiyappan Selvam, Jonathan W.C. WongAnonymous MVHQ97KEoPÎncă nu există evaluări

- Chapter 12Document15 paginiChapter 12kk5522Încă nu există evaluări

- BRENTON TarrantDocument4 paginiBRENTON TarrantSayyidÎncă nu există evaluări

- Financial Statement AnalysisDocument18 paginiFinancial Statement AnalysisAbdul MajeedÎncă nu există evaluări

- D15 Hybrid P1 QPDocument6 paginiD15 Hybrid P1 QPShaameswary AnnadoraiÎncă nu există evaluări

- STD Specification For Design and Integration of Fuel Energy Storage F3063Document7 paginiSTD Specification For Design and Integration of Fuel Energy Storage F3063Kobus PretoriusÎncă nu există evaluări

- Enzyme Immobilization - Advances in Industry, Agriculture, Medicine, and The Environment-Springer International Publishing (2016)Document141 paginiEnzyme Immobilization - Advances in Industry, Agriculture, Medicine, and The Environment-Springer International Publishing (2016)Komagatae XylinusÎncă nu există evaluări

- Final Notice To Global Girls Degree CollgeDocument2 paginiFinal Notice To Global Girls Degree CollgeIbn E AdamÎncă nu există evaluări

- Microbial Diseases of The Different Organ System and Epidem.Document36 paginiMicrobial Diseases of The Different Organ System and Epidem.Ysabelle GutierrezÎncă nu există evaluări

- 3.2.1 The Role of Market Research and Methods UsedDocument42 pagini3.2.1 The Role of Market Research and Methods Usedsana jaleelÎncă nu există evaluări

- Book Review Fiction New HereDocument7 paginiBook Review Fiction New HereFILZAH SYAUQINA BINTI SUBLY Pelajar KPTM IpohÎncă nu există evaluări

- Andromeda: Druid 3 Warborn06Document5 paginiAndromeda: Druid 3 Warborn06AlanÎncă nu există evaluări

- Vignyapan 18-04-2024Document16 paginiVignyapan 18-04-2024adil1787Încă nu există evaluări

- Advanced Statistical Approaches To Quality: INSE 6220 - Week 4Document44 paginiAdvanced Statistical Approaches To Quality: INSE 6220 - Week 4picalaÎncă nu există evaluări

- Technical and Business WritingDocument3 paginiTechnical and Business WritingMuhammad FaisalÎncă nu există evaluări

- Ioi Group - Capric Acid 98%Document7 paginiIoi Group - Capric Acid 98%Wong MjÎncă nu există evaluări

- Tanque: Equipment Data SheetDocument1 paginăTanque: Equipment Data SheetAlonso DIAZÎncă nu există evaluări

- Name: Mercado, Kath DATE: 01/15 Score: Activity Answer The Following Items On A Separate Sheet of Paper. Show Your Computations. (4 Items X 5 Points)Document2 paginiName: Mercado, Kath DATE: 01/15 Score: Activity Answer The Following Items On A Separate Sheet of Paper. Show Your Computations. (4 Items X 5 Points)Kathleen MercadoÎncă nu există evaluări

- 2011 - Papanikolaou E. - Markatos N. - Int J Hydrogen EnergyDocument9 pagini2011 - Papanikolaou E. - Markatos N. - Int J Hydrogen EnergyNMarkatosÎncă nu există evaluări

- ENG 102 Essay PromptDocument2 paginiENG 102 Essay Promptarshia winÎncă nu există evaluări

- The Fluency Course Teacher Instructions PDFDocument9 paginiThe Fluency Course Teacher Instructions PDFGabriel da RochaÎncă nu există evaluări

- Polyembryony &its ImportanceDocument17 paginiPolyembryony &its ImportanceSURIYA PRAKASH GÎncă nu există evaluări

- Planning Effective Advertising and Promotion Strategies For A Target AudienceDocument16 paginiPlanning Effective Advertising and Promotion Strategies For A Target Audiencebakhoo12Încă nu există evaluări

- Demand Determinants EEMDocument22 paginiDemand Determinants EEMPrabha KaranÎncă nu există evaluări

- Abacus 1 PDFDocument13 paginiAbacus 1 PDFAli ChababÎncă nu există evaluări

- Previous Year Questions Tnusrb S. I - 2010: Part - A': General KnowledgeDocument21 paginiPrevious Year Questions Tnusrb S. I - 2010: Part - A': General Knowledgemohamed AzathÎncă nu există evaluări

- Teaching Plan - Math 8 Week 1-8 PDFDocument8 paginiTeaching Plan - Math 8 Week 1-8 PDFRYAN C. ENRIQUEZÎncă nu există evaluări

- What Is Terrorism NotesDocument3 paginiWhat Is Terrorism NotesSyed Ali HaiderÎncă nu există evaluări

- Hydropneumatic Booster Set MFDocument5 paginiHydropneumatic Booster Set MFdonchakdeÎncă nu există evaluări

- My Activities in Module 2Document7 paginiMy Activities in Module 2Devine Gabat100% (6)