Documente Academic

Documente Profesional

Documente Cultură

MDMW Gold02

Încărcat de

miningnovaTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

MDMW Gold02

Încărcat de

miningnovaDrepturi de autor:

Formate disponibile

MINE OF THE MONTH – BODDINGTON

New beginning

Minimising the environmental impact is a high

priority of the Boddington expansion project

At the start of March, the partners in the Boddington

project in Western Australia gave the go-ahead for an

operation costing US$1.5 billion

T

Boddington Gold Mine, PO Box 48

HE development decision at Boddington just over 11.6 Moz and 480,000 t of copper. Newmont Boddington WA 6390

follows the acquisition in mid-February anticipates a copper recovery of 83%. There are Tel: +61 (0)8 9883 8260

by Newmont Mining Corp of the 22.22% additional resources of 144 Mt measured and indi- Fax: +61 (0)8 9883 4208

share in Boddington Gold Mine (BGM) held cated, at 0.58 g/t Au and 0.08% Cu.

by Newcrest Mining Ltd for A$225 million Under the management of Worsley Alumina had meanwhile acquired original owner Normandy

(US$1=A$1.36). This lifted the US company’s equity to (which operates the nearby Worsley bauxite mine), Mining) in late 2002. Newmont recently took over

66.7% (South African-based AngloGold Ashanti Ltd the overlying oxide mineralisation at Boddington was project management.

holds the remaining 33.3% of Boddington). The mine exploited from 1987 until the end of 2001. Product- Announcing the go-ahead, Wayne Murdy,

and processing plant are expected to take two years ion in 2001 totalled 234,000 oz. The project was taken Newmont’s chief executive, said: “We believe the

to construct. over by AngloGold, Newcrest and Newmont (which exploration opportunities at Boddington hold the

The operation, which lies potential to ultimately double reserves.”

130 km southeast of Perth, will

be based on an update to a five- GEOLOGY

year-old feasibility study that was Over the past few years, BGM’s exploration efforts

presented to the joint-venture have focused on identifying all remaining oxide ore

partners last December. The mine for the current milling facility and resource develop-

is expected to produce 1 Moz/y ment for the Boddington expansion project. Mining

over the first five years of opera- operations ceased at the end of November 2001,

tions, with an overall average after all known economic oxide gold resources had

over the 15-year-plus mine life been processed. However, exploration has success-

of 850,000 oz/y. The life-of-mine fully identified a 19.6 Moz gold bedrock resource, the

operating cost is put at US$210/ basis of the expansion project.

oz, net of by-product credits. The Boddington mine lies within the Saddleback

The expansion project will Greenstone Belt (SGB), a fault-bounded sliver of

exploit basement rock from Archaean volcanic and shallow level intrusive

underneath the existing oxide pit. rocks, surrounded by granitic

The initial mine plan is based on proven and prob- and gneissic rocks. The

able reserves totalling 403 Mt, at an average grade of Darwin SGB has produced over

0.90 g/t Au and 0.12% Cu, for contained reserves of Newmont 6 Moz of gold and is

Tanami operations

a highly prospective

ORIGINAL PROJECT exploration area

Tanami

Construction of the original operation at Yandal Pajingo for further gold

Boddington was managed by Hatch in a Northern mineralisation in

Territory

project which began in October 1986 and was Western both large-tonnage

completed in July 1989. The orebody was mined Australia AUSTRALIA stock-work gold resourc-

by open-pit methods, with a 3 Mt/y throughput es and high-grade

for an expected mine life of 15 years. The water Brisbane lode-type gold

requirements were met by a dam built on Thirty- Kalgoorie resources.

four Mile Brook, supplemented by water pumped BGM owners are

from the Hotham River. Perth committed to a continuing

The extraction process involved primary and Canberra Sydney exploration presence in the

Adelaide

secondary crushing, ball milling, carbon-in-leach Super Pit area and have substantial

extraction, elution of the loaded carbon, elec- Boddington Melbourne tenement holdings avail-

trowinning of gold, then smelting and casting as able, including that

bullion. Tasmania 0 800km managed on behalf

of the BGM-Alcoa

10 Mining Magazine May 2006

10-11MM0605.indd 10 21/4/06 4:39:14 pm

ENVIRONMENT

One of the objectives of the project has been to not being tied up by the copper in the process, and monitoring procedures will remain in place

minimise the environmental impact. the total cyanide usage for the increased throughout the life of this project.

■ Transport: Trucks will be used to carry supplies project size is only half that of what would ■ Noise: Disturbances from mining and process-

from Perth to the mine via the Albany Highway, have been required under the original project ing will increase from previous levels. However,

while others will transport copper concentrate to a design. Additionally, the new project design modelling shows that noise limits will be beneath

port for shipping. A number of options for transport includes a cyanide destruction process which the regulatory level of 35 dB(A) at the nearest

of concentrate for shipping are being considered, effectively decreases the cyanide concentrations residences. This is a conservative estimate based on

including truck delivery to Bunbury Port via Dwell- to negligible levels. worst-case scenarios.

ingup or Arthur River & Collie, or to Kwinana Port via ■ Vegetation: In the past, the spread of dieback ■ Rehabilitation: Consideration is being given for

Albany Hwy. and other weeds has been minimal due to the the mine to be rehabilitated to a range of land uses,

■ Cyanide: Under the new project parameters, stringent forest hygiene procedures in place. to the extent they are practicable. This will need

total cyanide usage will be greatly reduced as a Dieback mapping is conducted every three years considerable investigation from both a technical

consequence of the earlier removal of copper from and no increase in dieback affected areas, other and community perspective and will form a com-

the mineral-extraction process. Since cyanide is than natural spread, has been noted. The hygiene ponent of the upcoming consultation discussions.

Manual cleandown at Boddington gold mine.

Left: signs restrict vehicle movement

in infected areas

joint venture covering the greenstone

belt immediately north of the BGM

mine. An approved exploration pro-

gramme is in progress during the care

and maintenance period with an an-

nual budget of about US$2.5 million.

Exploration activities are now

focusing on the poorly-explored areas

of the greenstone belt outside the EXPANSION PROJECT

already-identified Boddington expansion resource. The Boddington project relates to the large-scale

The exploration strategy is to identify the resource mining and processing of basement rock from under

potential of the rest of the greenstone belt, with the the existing oxide pits. These investigations began

emphasis on high-grade lode-type deposits. in 1995 and an interim report was tabled in 2000. An

updated feasibility study was completed at the end

of last year.

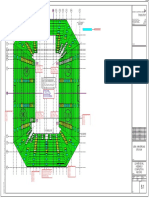

The expansion includes the construction of a new

processing plant, which will include a three-stage

ore-crushing process, single-stage ball mill grinding

and a copper/gold flotation method followed by gold

leaching of the flotation residue by the carbon-in-

leach (CIL) process. Mining will take place from two

open pits at a rate of more than 80 Mt/y, and a milling

rate of about 35 Mt/y.

A joint venture between Aka Kvaerner and

Clough Murray Roberts has won the engineering,

procurement and construction management (EPCM)

contract, and initial equipment orders have already

The expansion includes the construction of a new been placed. This contract, worth A$115 million, was

processing plant signed on April 10.

May 2006 Mining Magazine 11

10-11MM0605.indd 11 21/4/06 4:39:16 pm

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Detail Design Drawings: OCTOBER., 2017 Date Span Carriage WayDocument26 paginiDetail Design Drawings: OCTOBER., 2017 Date Span Carriage WayManvendra NigamÎncă nu există evaluări

- Zomato Restaurant Clustering & Sentiment Analysis - Ipynb - ColaboratoryDocument27 paginiZomato Restaurant Clustering & Sentiment Analysis - Ipynb - Colaboratorybilal nagoriÎncă nu există evaluări

- Sample REVISION QUESTION BANK. ACCA Paper F5 PERFORMANCE MANAGEMENTDocument43 paginiSample REVISION QUESTION BANK. ACCA Paper F5 PERFORMANCE MANAGEMENTAbayneh Assefa75% (4)

- DGMS - Tech - Circular No 03. 2009 Qualitative and Quantitative Assessment of Fire FightingDocument3 paginiDGMS - Tech - Circular No 03. 2009 Qualitative and Quantitative Assessment of Fire FightingminingnovaÎncă nu există evaluări

- MDMW Zircon04Document10 paginiMDMW Zircon04miningnovaÎncă nu există evaluări

- 3 Day MBA in MiningDocument4 pagini3 Day MBA in MiningminingnovaÎncă nu există evaluări

- Fundamentals of MiningDocument19 paginiFundamentals of Miningminingnova0% (1)

- Design, Control and Monitoring of Pit and Dump Slopes in Opencast MinesDocument5 paginiDesign, Control and Monitoring of Pit and Dump Slopes in Opencast MinesminingnovaÎncă nu există evaluări

- MDMW Zinc&Lead12Document3 paginiMDMW Zinc&Lead12miningnovaÎncă nu există evaluări

- Trends in Zircon Processing: A.C. Bidaye and I.G. SharmaDocument5 paginiTrends in Zircon Processing: A.C. Bidaye and I.G. SharmaminingnovaÎncă nu există evaluări

- MDMW Zinc&Lead01Document127 paginiMDMW Zinc&Lead01miningnovaÎncă nu există evaluări

- MDMW Zircon02Document9 paginiMDMW Zircon02miningnovaÎncă nu există evaluări

- Galvanized For Action: World Zinc ReportDocument16 paginiGalvanized For Action: World Zinc ReportminingnovaÎncă nu există evaluări

- Process Mineralogical Investigations in Concentrator at Rampura AguchaDocument4 paginiProcess Mineralogical Investigations in Concentrator at Rampura AguchaminingnovaÎncă nu există evaluări

- Iran Zinc Mines Development Company: Industry Overview and R&D Center Research ActivitiesDocument5 paginiIran Zinc Mines Development Company: Industry Overview and R&D Center Research ActivitiesminingnovaÎncă nu există evaluări

- Lead Metal Processing TechnologyDocument4 paginiLead Metal Processing TechnologyminingnovaÎncă nu există evaluări

- Determination of Grinding Rate Constant of Lakan Lead and Zinc DepositDocument4 paginiDetermination of Grinding Rate Constant of Lakan Lead and Zinc DepositminingnovaÎncă nu există evaluări

- MDMW Zinc&Lead05Document4 paginiMDMW Zinc&Lead05miningnovaÎncă nu există evaluări

- Enduring Value Through: Values ValuesDocument37 paginiEnduring Value Through: Values ValuesminingnovaÎncă nu există evaluări

- MDMW Zinc&Lead03Document2 paginiMDMW Zinc&Lead03miningnovaÎncă nu există evaluări

- Use of Wollastonite For Tailing Waste Management Enriched in MN (II) and ZN (II)Document5 paginiUse of Wollastonite For Tailing Waste Management Enriched in MN (II) and ZN (II)miningnovaÎncă nu există evaluări

- Vanadium Market in The World Vanadium Market in The World: FeatureDocument4 paginiVanadium Market in The World Vanadium Market in The World: FeatureminingnovaÎncă nu există evaluări

- MDMW Wollastonite05Document2 paginiMDMW Wollastonite05miningnovaÎncă nu există evaluări

- Preliminary Design Concentration of Talc by Emphasis On Mineralogy in The Malhamdar Index Mine in IranDocument5 paginiPreliminary Design Concentration of Talc by Emphasis On Mineralogy in The Malhamdar Index Mine in IranminingnovaÎncă nu există evaluări

- Oration: Occupational Pneumoconiosis and TuberculosisDocument4 paginiOration: Occupational Pneumoconiosis and TuberculosisminingnovaÎncă nu există evaluări

- 2007 Minerals Yearbook: Vanadium (Advance Release)Document11 pagini2007 Minerals Yearbook: Vanadium (Advance Release)miningnovaÎncă nu există evaluări

- MDMW Wollastonite03Document3 paginiMDMW Wollastonite03miningnovaÎncă nu există evaluări

- Dicaperl Perlite Mine, Near Socorro, Socorro County, NMDocument6 paginiDicaperl Perlite Mine, Near Socorro, Socorro County, NMminingnovaÎncă nu există evaluări

- MDMW Slate&Sandstone05Document87 paginiMDMW Slate&Sandstone05miningnovaÎncă nu există evaluări

- Activation of Sphalerite by Cu Ions Produced by Cyanide Action On ChalcopyriteDocument5 paginiActivation of Sphalerite by Cu Ions Produced by Cyanide Action On ChalcopyriteminingnovaÎncă nu există evaluări

- Properties: This Steel Can Is Coated With Tin For Corrosion ProtectionDocument4 paginiProperties: This Steel Can Is Coated With Tin For Corrosion ProtectionminingnovaÎncă nu există evaluări

- Preconcentration of Tungsten Mineral Fines On Multi-Gravity SeparatorDocument5 paginiPreconcentration of Tungsten Mineral Fines On Multi-Gravity SeparatorminingnovaÎncă nu există evaluări

- Utilization of Slate Mine Waste: A Study: Dr. A. K. SoniDocument10 paginiUtilization of Slate Mine Waste: A Study: Dr. A. K. SoniminingnovaÎncă nu există evaluări

- The Linguistic Colonialism of EnglishDocument4 paginiThe Linguistic Colonialism of EnglishAdriana MirandaÎncă nu există evaluări

- Crypto Wall Crypto Snipershot OB Strategy - Day Trade SwingDocument29 paginiCrypto Wall Crypto Snipershot OB Strategy - Day Trade SwingArete JinseiÎncă nu există evaluări

- Federalist Papers 10 51 ExcerptsDocument2 paginiFederalist Papers 10 51 Excerptsapi-292351355Încă nu există evaluări

- Five Reasons Hazards Are Downplayed or Not ReportedDocument19 paginiFive Reasons Hazards Are Downplayed or Not ReportedMichael Kovach100% (1)

- China Training WCDMA 06-06Document128 paginiChina Training WCDMA 06-06ryanz2009Încă nu există evaluări

- CURRICULUM PharmasubDocument10 paginiCURRICULUM PharmasubZE Mart DanmarkÎncă nu există evaluări

- Industrial ExperienceDocument30 paginiIndustrial ExperienceThe GridLockÎncă nu există evaluări

- Toh736 - 84000 The Dharani of Parnasavari PDFDocument24 paginiToh736 - 84000 The Dharani of Parnasavari PDFJames LeeÎncă nu există evaluări

- Modular Q1 WK3-4Document3 paginiModular Q1 WK3-4JENIFFER DE LEONÎncă nu există evaluări

- BiografijaDocument36 paginiBiografijaStjepan ŠkalicÎncă nu există evaluări

- Evidence Prove DiscriminationDocument5 paginiEvidence Prove DiscriminationRenzo JimenezÎncă nu există evaluări

- Boom-Block Gambit: Redemption'S RiseDocument44 paginiBoom-Block Gambit: Redemption'S RiseNone OfyourbuisnessÎncă nu există evaluări

- Galgotias University Uttar Pradesh School of Computing Science & Engineering B.Tech. (CSE) 2018-19 Semester Wise Breakup of CoursesDocument2 paginiGalgotias University Uttar Pradesh School of Computing Science & Engineering B.Tech. (CSE) 2018-19 Semester Wise Breakup of CoursesRohit Singh BhatiÎncă nu există evaluări

- Research FinalDocument55 paginiResearch Finalkieferdem071908Încă nu există evaluări

- Smartfind E5 g5 User ManualDocument49 paginiSmartfind E5 g5 User ManualdrewlioÎncă nu există evaluări

- Coding Rubric Unifix XXXX 75Document2 paginiCoding Rubric Unifix XXXX 75api-287660266Încă nu există evaluări

- Contemporary Strategic ManagementDocument2 paginiContemporary Strategic ManagementZee Dee100% (1)

- The Ovation E-Amp: A 180 W High-Fidelity Audio Power AmplifierDocument61 paginiThe Ovation E-Amp: A 180 W High-Fidelity Audio Power AmplifierNini Farribas100% (1)

- The Mooring Pattern Study For Q-Flex Type LNG Carriers Scheduled For Berthing at Ege Gaz Aliaga LNG TerminalDocument6 paginiThe Mooring Pattern Study For Q-Flex Type LNG Carriers Scheduled For Berthing at Ege Gaz Aliaga LNG TerminalMahad Abdi100% (1)

- Claim of FactDocument11 paginiClaim of FactXeb UlritzÎncă nu există evaluări

- XII CS Material Chap7 2012 13Document21 paginiXII CS Material Chap7 2012 13Ashis PradhanÎncă nu există evaluări

- Highlights ASME Guides Preheat PWHT IDocument4 paginiHighlights ASME Guides Preheat PWHT IArul Edwin Vijay VincentÎncă nu există evaluări

- AE Notification 2015 NPDCLDocument24 paginiAE Notification 2015 NPDCLSuresh DoosaÎncă nu există evaluări

- SDSSSSDDocument1 paginăSDSSSSDmirfanjpcgmailcomÎncă nu există evaluări

- Engleza Referat-Pantilimonescu IonutDocument13 paginiEngleza Referat-Pantilimonescu IonutAilenei RazvanÎncă nu există evaluări

- Boundary Value Analysis 2Document13 paginiBoundary Value Analysis 2Raheela NasimÎncă nu există evaluări

- JCP4 XDOBursting EngineDocument13 paginiJCP4 XDOBursting Enginesubhash221103Încă nu există evaluări