Documente Academic

Documente Profesional

Documente Cultură

Mix Design - 30-11-12 - vmr-70 - For W.C.R 0.25 With PF

Încărcat de

venkat_nsnDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Mix Design - 30-11-12 - vmr-70 - For W.C.R 0.25 With PF

Încărcat de

venkat_nsnDrepturi de autor:

Formate disponibile

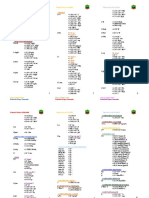

MIX DESIGN FOR M70 CONCRETE Size of Coarse Aggregate in mm = Specific Gravity of Coarse Aggregate = Bulk Density of Coarse

Aggregate in kg/m3 = Specific Gravity of Fine Aggregate = Bulk Density of Fine Aaggregate in kg/m3 = Specific Gravity of Cement = Specific Gravity of Water = Specific Gravity of GGBS = Volume ratio of FineAggregate to Coarse Aggregate = Specific Gravity of Super Plasticiser = Air content in SCC= PROCEDURE: Characterisic Strength in MPa = Target mean strength in MPa = fck + (K*S) =Refer table 10.4 & 10.3 for K & S values 1.Determine the amount of FA & CA : Let Packing Factor(PF) = Amount of Fine Aggregate needed per unit volume of SCC in kg/m3= Ws =B.D of FA*PF*%of FA= Amount of Coarse Aggregate needed per unit volume of SCC in kg/m3= Wg =B.D of CA*PF*%of CA= 2.Determine the Cement content @ 7.14 kg per Mpa =C=(7.14* Target mean strength)= 3. Mixing Water content required by Cement : W/C ratio of SCC produced with GGBS for obtaining 80.395 MPa. Is = Amount of mixing water in kg/m3 = Wwc = 4. Determine the GGBS content: Ratio of Weight of Water and GGBS = W/S= Ratio of Water and Cement = W/C= Vpf + Vpb = 1- ((Wg/(1000*SG of CA)) +(Ws/(1000*SG of FA)) +(C/(1000*SG of C)) + (Wwc/(1000*SG of W))+ Air content)= (((1*Wpm)/(1000*SG of GGBS)) + ((1*Ratio of W/GGBS*Wpm)/(1000*SG of W))) =0.0006Wpm . From this Wpm in kg/m3 = Weight of GGBS in kg/m3= Wggbs= 5. Determine the mixing water content required for GGBS: Water content for GGBS in kg/m3 = Wwb = 6. Determine the SP dosage: General dosage of SP based on previous engineering experience is 1.8%. Wsp=0.018*(C+Wggbs) in kg/m3 7. Adjustment of mixing water content needed in SCC: Let Solid content of SP is 30% = Amount of Water in SP=Wwsp= (1-0.30)*Wsp in kg/m3 = Amount of mixing water needed in SCC in kg/m3 = W =(Wwc+Wwb-Wwsp) MIX PROPORTION: QUANTITY(kg/m3) PROPORTION CEMENT GGBS FA 574.02 19.27 859.56 1 0.03 1.50 CA SP 819.71 1.43 10.68 0.019 WATER/BINDER M.SILICA VMA 141.81 40.18 1.722 0.247 0.07 0.003 10 2.631 1498 2.61 1450 3.01 1 2.91 52/48 1.09 1.25% 70 80.395 1.14 859.56 819.71 574.02 0.25 143.51 0.3 0.25 0.0124

19.27 19.27 5.78

10.68 0.30 7.48 141.81

MIX DESIGN FOR M70 CONCRETE Size of Coarse Aggregate in mm = Specific Gravity of Coarse Aggregate = Bulk Density of Coarse Aggregate in kg/m3 = Specific Gravity of Fine Aggregate = Bulk Density of Fine Aaggregate in kg/m3 = Specific Gravity of Cement = Specific Gravity of Water = Specific Gravity of GGBS = Volume ratio of FineAggregate to Coarse Aggregate = Specific Gravity of Super Plasticiser = Air content in SCC= PROCEDURE: Characterisic Strength in MPa = Target mean strength in MPa = fck + (K*S) =Refer table 10.4 & 10.3 for K & S values 1.Determine the amount of FA & CA : Let Packing Factor(PF) = Amount of Fine Aggregate needed per unit volume of SCC in kg/m3= Ws =B.D of FA*PF*%of FA= Amount of Coarse Aggregate needed per unit volume of SCC in kg/m3= Wg =B.D of CA*PF*%of CA= 2.Determine the Cement content @ 7.14 kg per Mpa =C=(7.14* Target mean strength)= 3. Mixing Water content required by Cement : W/C ratio of SCC produced with GGBS for obtaining 80.395 MPa. Is = Amount of mixing water in kg/m3 = Wwc = 4. Determine the GGBS content: Ratio of Weight of Water and GGBS = W/S= Ratio of Water and Cement = W/C= Vpf + Vpb = 1- ((Wg/(1000*SG of CA)) +(Ws/(1000*SG of FA)) +(C/(1000*SG of C)) + (Wwc/(1000*SG of W))+ Air content)= (((1*Wpm)/(1000*SG of GGBS)) + ((1*Ratio of W/GGBS*Wpm)/(1000*SG of W))) =0.0006Wpm . From this Wpm in kg/m3 = Weight of GGBS in kg/m3= Wggbs= 5. Determine the mixing water content required for GGBS: Water content for GGBS in kg/m3 = Wwb = 6. Determine the SP dosage: General dosage of SP based on previous engineering experience is 1.8%. Wsp=0.018*(C+Wggbs) in kg/m3 7. Adjustment of mixing water content needed in SCC: Let Solid content of SP is 30% = Amount of Water in SP=Wwsp= (1-0.30)*Wsp in kg/m3 = Amount of mixing water needed in SCC in kg/m3 = W =(Wwc+Wwb-Wwsp) MIX PROPORTION: QUANTITY(kg/m3) PROPORTION CEMENT GGBS FA 574.02 28.00 852.02 1 0.05 1.48 CA SP 812.52 1.42 10.84 0.019 WATER/BINDER M.SILICA VMA 144.32 40.18 1.722 0.251 0.07 0.003 10 2.631 1498 2.61 1450 3.01 1 2.91 52/48 1.09 1.25% 70 80.395 1.13 852.02 812.52 574.02 0.25 143.51 0.3 0.25 0.0180

28.00 28.00 8.40

10.84 0.30 7.59 144.32

MIX DESIGN FOR M70 CONCRETE Size of Coarse Aggregate in mm = Specific Gravity of Coarse Aggregate = Bulk Density of Coarse Aggregate in kg/m3 = Specific Gravity of Fine Aggregate = Bulk Density of Fine Aaggregate in kg/m3 = Specific Gravity of Cement = Specific Gravity of Water = Specific Gravity of GGBS = Volume ratio of FineAggregate to Coarse Aggregate = Specific Gravity of Super Plasticiser = Air content in SCC= PROCEDURE: Characterisic Strength in MPa = Target mean strength in MPa = fck + (K*S) =Refer table 10.4 & 10.3 for K & S values 1.Determine the amount of FA & CA : Let Packing Factor(PF) = Amount of Fine Aggregate needed per unit volume of SCC in kg/m3= Ws =B.D of FA*PF*%of FA= Amount of Coarse Aggregate needed per unit volume of SCC in kg/m3= Wg =B.D of CA*PF*%of CA= 2.Determine the Cement content @ 7.14 kg per Mpa =C=(7.14* Target mean strength)= 3. Mixing Water content required by Cement : W/C ratio of SCC produced with GGBS for obtaining 80.395 MPa. Is = Amount of mixing water in kg/m3 = Wwc = 4. Determine the GGBS content: Ratio of Weight of Water and GGBS = W/S= Ratio of Water and Cement = W/C= Vpf + Vpb = 1- ((Wg/(1000*SG of CA)) +(Ws/(1000*SG of FA)) +(C/(1000*SG of C)) + (Wwc/(1000*SG of W))+ Air content)= (((1*Wpm)/(1000*SG of GGBS)) + ((1*Ratio of W/GGBS*Wpm)/(1000*SG of W))) =0.0006Wpm . From this Wpm in kg/m3 = Weight of GGBS in kg/m3= Wggbs= 5. Determine the mixing water content required for GGBS: Water content for GGBS in kg/m3 = Wwb = 6. Determine the SP dosage: General dosage of SP based on previous engineering experience is 1.8%. Wsp=0.018*(C+Wggbs) in kg/m3 7. Adjustment of mixing water content needed in SCC: Let Solid content of SP is 30% = Amount of Water in SP=Wwsp= (1-0.30)*Wsp in kg/m3 = Amount of mixing water needed in SCC in kg/m3 = W =(Wwc+Wwb-Wwsp) MIX PROPORTION: QUANTITY(kg/m3) PROPORTION CEMENT GGBS FA 574.02 36.73 844.48 1 0.06 1.47 CA SP 805.32 1.40 10.99 0.019 WATER/BINDER M.SILICA VMA 146.83 40.18 1.722 0.256 0.07 0.003 10 2.631 1498 2.61 1450 3.01 1 2.91 52/48 1.09 1.25% 70 80.395 1.12 844.48 805.32 574.02 0.25 143.51 0.3 0.25 0.0236

36.73 36.73 11.02

10.99 0.30 7.70 146.83

MIX DESIGN FOR M70 CONCRETE Size of Coarse Aggregate in mm = Specific Gravity of Coarse Aggregate = Bulk Density of Coarse Aggregate in kg/m3 = Specific Gravity of Fine Aggregate = Bulk Density of Fine Aaggregate in kg/m3 = Specific Gravity of Cement = Specific Gravity of Water = Specific Gravity of GGBS = Volume ratio of FineAggregate to Coarse Aggregate = Specific Gravity of Super Plasticiser = Air content in SCC= PROCEDURE: Characterisic Strength in MPa = Target mean strength in MPa = fck + (K*S) =Refer table 10.4 & 10.3 for K & S values 1.Determine the amount of FA & CA : Let Packing Factor(PF) = Amount of Fine Aggregate needed per unit volume of SCC in kg/m3= Ws =B.D of FA*PF*%of FA= Amount of Coarse Aggregate needed per unit volume of SCC in kg/m3= Wg =B.D of CA*PF*%of CA= 2.Determine the Cement content @ 7.14 kg per Mpa =C=(7.14* Target mean strength)= 3. Mixing Water content required by Cement : W/C ratio of SCC produced with GGBS for obtaining 80.395 MPa. Is = Amount of mixing water in kg/m3 = Wwc = 4. Determine the GGBS content: Ratio of Weight of Water and GGBS = W/S= Ratio of Water and Cement = W/C= Vpf + Vpb = 1- ((Wg/(1000*SG of CA)) +(Ws/(1000*SG of FA)) +(C/(1000*SG of C)) + (Wwc/(1000*SG of W))+ Air content)= (((1*Wpm)/(1000*SG of GGBS)) + ((1*Ratio of W/GGBS*Wpm)/(1000*SG of W))) =0.0006Wpm . From this Wpm in kg/m3 = Weight of GGBS in kg/m3= Wggbs= 5. Determine the mixing water content required for GGBS: Water content for GGBS in kg/m3 = Wwb = 6. Determine the SP dosage: General dosage of SP based on previous engineering experience is 1.8%. Wsp=0.018*(C+Wggbs) in kg/m3 7. Adjustment of mixing water content needed in SCC: Let Solid content of SP is 30% = Amount of Water in SP=Wwsp= (1-0.30)*Wsp in kg/m3 = Amount of mixing water needed in SCC in kg/m3 = W =(Wwc+Wwb-Wwsp) MIX PROPORTION: QUANTITY(kg/m3) PROPORTION CEMENT GGBS FA 574.02 45.47 836.94 1 0.08 1.46 CA SP 798.13 1.39 11.15 0.019 WATER/BINDER M.SILICA VMA 149.34 40.18 1.722 0.260 0.07 0.003 10 2.631 1498 2.61 1450 3.01 1 2.91 52/48 1.09 1.25% 70 80.395 1.11 836.94 798.13 574.02 0.25 143.51 0.3 0.25 0.0293

45.47 45.47 13.64

11.15 0.30 7.81 149.34

MIX DESIGN FOR M70 CONCRETE Size of Coarse Aggregate in mm = Specific Gravity of Coarse Aggregate = Bulk Density of Coarse Aggregate in kg/m3 = Specific Gravity of Fine Aggregate = Bulk Density of Fine Aaggregate in kg/m3 = Specific Gravity of Cement = Specific Gravity of Fly Ash = Specific Gravity of Water = Volume ratio of FineAggregate to Coarse Aggregate = Specific Gravity of Super Plasticiser = Air content in SCC= PROCEDURE: Characterisic Strength in MPa = Target mean strength in MPa = fck + (K*S) =Refer table 10.4 & 10.3 for K & S values 1.Determine the amount of FA & CA : Let Packing Factor(PF) = Amount of Fine Aggregate needed per unit volume of SCC in kg/m3= Ws =B.D of FA*PF*%of FA= Amount of Coarse Aggregate needed per unit volume of SCC in kg/m3= Wg =B.D of CA*PF*%of CA= 2.Determine the Cement content @ 7.14 kg per Mpa =C=(7.14* Target mean strength)= 3. Mixing Water content required by Cement : W/C ratio of SCC produced with Fly Ash for obtaining 80.395 MPa. Is = Amount of mixing water in kg/m3 = Wwc = 4. Determine the Fly Ash content: Ratio of Weight of Water and Fly Ash = W/F= Ratio of Water and Cement = W/C= Vpf + Vpb = 1- ((Wg/(1000*SG of CA)) +(Ws/(1000*SG of FA)) +(C/(1000*SG of C)) + (Wwc/(1000*SG of W))+ Air content)= (((1*Wpm)/(1000*SG of F)) + ((1*Ratio of W/F* Wpm)/(1000*SG of W))) =0.0008Wpm. From this Wpm in kg/m 3 = Weight of Fly Ash in kg/m3= Wf = 5. Determine the mixing water content required for Fly Ash: Water content for Fly Ash in kg/m3 = Wwf= 6. Determine the SP dosage: General dosage of SP based on previous engineering experience is 1.8%. Wsp=0.018*(C+Wf+Wggbs) in kg/m 3 7. Adjustment of mixing water content needed in SCC: Let Solid content of SP is 30% = Amount of Water in SP=Wwsp= (1-0.30)*Wsp in kg/m3 = Amount of mixing water needed in SCC in kg/m3 = W =(Wwc+Wwf-Wwsp) MIX PROPORTION: QUANTITY(kg/m3) PROPORTION CEMENT FLY ASH FA 574.02 14.48 859.56 1 0.03 1.50 CA SP 819.71 1.43 10.59 0.018 WATER/BINDER M.SILICA VMA 142.94 40.18 1.722 0.249 0.07 0.003 10 2.631 1498 2.61 1450 3.01 2.19 1 52/48 1.09 1.25% 70 80.395 1.14 859.56 819.71 574.02 0.25 143.51 0.4 0.25 0.012

14.5 14.5 5.79

10.59 0.30 6.36 142.94

MIX DESIGN FOR M70 CONCRETE Size of Coarse Aggregate in mm = Specific Gravity of Coarse Aggregate = Bulk Density of Coarse Aggregate in kg/m3 = Specific Gravity of Fine Aggregate = Bulk Density of Fine Aaggregate in kg/m3 = Specific Gravity of Cement = Specific Gravity of Fly Ash = Specific Gravity of Water = Volume ratio of FineAggregate to Coarse Aggregate = Specific Gravity of Super Plasticiser = Air content in SCC= PROCEDURE: Characterisic Strength in MPa = Target mean strength in MPa = fck + (K*S) =Refer table 10.4 & 10.3 for K & S values 1.Determine the amount of FA & CA : Let Packing Factor(PF) = Amount of Fine Aggregate needed per unit volume of SCC in kg/m3= Ws =B.D of FA*PF*%of FA= Amount of Coarse Aggregate needed per unit volume of SCC in kg/m3= Wg =B.D of CA*PF*%of CA= 2.Determine the Cement content @ 7.14 kg per Mpa =C=(7.14* Target mean strength)= 3. Mixing Water content required by Cement : W/C ratio of SCC produced with Fly Ash for obtaining 80.395 MPa. Is = Amount of mixing water in kg/m3 = Wwc = 4. Determine the Fly Ash content: Ratio of Weight of Water and Fly Ash = W/F= Ratio of Water and Cement = W/C= Vpf + Vpb = 1- ((Wg/(1000*SG of CA)) +(Ws/(1000*SG of FA)) +(C/(1000*SG of C)) + (Wwc/(1000*SG of W))+ Air content)= (((1*Wpm)/(1000*SG of F)) + ((1*Ratio of W/F* Wpm)/(1000*SG of W))) =0.0008Wpm. From this Wpm in kg/m 3 = Weight of Fly Ash in kg/m3= Wf = 5. Determine the mixing water content required for Fly Ash: Water content for Fly Ash in kg/m3 = Wwf= 6. Determine the SP dosage: General dosage of SP based on previous engineering experience is 1.8%. Wsp=0.018*(C+Wf+Wggbs) in kg/m 3 7. Adjustment of mixing water content needed in SCC: Let Solid content of SP is 30% = Amount of Water in SP=Wwsp= (1-0.30)*Wsp in kg/m3 = Amount of mixing water needed in SCC in kg/m3 = W =(Wwc+Wwf-Wwsp) MIX PROPORTION: QUANTITY(kg/m3) PROPORTION CEMENT FLY ASH FA 574.02 21.04 852.02 1 0.04 1.48 CA SP 812.52 1.42 10.71 0.019 WATER/BINDER M.SILICA VMA 145.49 40.18 1.722 0.253 0.07 0.003 10 2.631 1498 2.61 1450 3.01 2.19 1 52/48 1.09 1.25% 70 80.395 1.13 852.02 812.52 574.02 0.25 143.51 0.4 0.25 0.018

21.0 21.0 8.42

10.71 0.30 6.43 145.49

MIX DESIGN FOR M70 CONCRETE Size of Coarse Aggregate in mm = Specific Gravity of Coarse Aggregate = Bulk Density of Coarse Aggregate in kg/m3 = Specific Gravity of Fine Aggregate = Bulk Density of Fine Aaggregate in kg/m3 = Specific Gravity of Cement = Specific Gravity of Fly Ash = Specific Gravity of Water = Volume ratio of FineAggregate to Coarse Aggregate = Specific Gravity of Super Plasticiser = Air content in SCC= PROCEDURE: Characterisic Strength in MPa = Target mean strength in MPa = fck + (K*S) =Refer table 10.4 & 10.3 for K & S values 1.Determine the amount of FA & CA : Let Packing Factor(PF) = Amount of Fine Aggregate needed per unit volume of SCC in kg/m3= Ws =B.D of FA*PF*%of FA= Amount of Coarse Aggregate needed per unit volume of SCC in kg/m3= Wg =B.D of CA*PF*%of CA= 2.Determine the Cement content @ 7.14 kg per Mpa =C=(7.14* Target mean strength)= 3. Mixing Water content required by Cement : W/C ratio of SCC produced with Fly Ash for obtaining 80.395 MPa. Is = Amount of mixing water in kg/m3 = Wwc = 4. Determine the Fly Ash content: Ratio of Weight of Water and Fly Ash = W/F= Ratio of Water and Cement = W/C= Vpf + Vpb = 1- ((Wg/(1000*SG of CA)) +(Ws/(1000*SG of FA)) +(C/(1000*SG of C)) + (Wwc/(1000*SG of W))+ Air content)= (((1*Wpm)/(1000*SG of F)) + ((1*Ratio of W/F* Wpm)/(1000*SG of W))) =0.0008Wpm. From this Wpm in kg/m 3 = Weight of Fly Ash in kg/m3= Wf = 5. Determine the mixing water content required for Fly Ash: Water content for Fly Ash in kg/m3 = Wwf= 6. Determine the SP dosage: General dosage of SP based on previous engineering experience is 1.8%. Wsp=0.018*(C+Wf+Wggbs) in kg/m 3 7. Adjustment of mixing water content needed in SCC: Let Solid content of SP is 30% = Amount of Water in SP=Wwsp= (1-0.30)*Wsp in kg/m3 = Amount of mixing water needed in SCC in kg/m3 = W =(Wwc+Wwf-Wwsp) MIX PROPORTION: QUANTITY(kg/m3) PROPORTION CEMENT FLY ASH FA 574.02 27.60 844.48 1 0.05 1.47 CA SP 805.32 1.40 10.83 0.019 WATER/BINDER M.SILICA VMA 148.05 40.18 1.722 0.258 0.07 0.003 10 2.631 1498 2.61 1450 3.01 2.19 1 52/48 1.09 1.25% 70 80.395 1.12 844.48 805.32 574.02 0.25 143.51 0.4 0.25 0.024

27.6 27.6 11.04

10.83 0.30 6.50 148.05

MIX DESIGN FOR M70 CONCRETE Size of Coarse Aggregate in mm = Specific Gravity of Coarse Aggregate = Bulk Density of Coarse Aggregate in kg/m3 = Specific Gravity of Fine Aggregate = Bulk Density of Fine Aaggregate in kg/m3 = Specific Gravity of Cement = Specific Gravity of Fly Ash = Specific Gravity of Water = Volume ratio of FineAggregate to Coarse Aggregate = Specific Gravity of Super Plasticiser = Air content in SCC= PROCEDURE: Characterisic Strength in MPa = Target mean strength in MPa = fck + (K*S) =Refer table 10.4 & 10.3 for K & S values 1.Determine the amount of FA & CA : Let Packing Factor(PF) = Amount of Fine Aggregate needed per unit volume of SCC in kg/m3= Ws =B.D of FA*PF*%of FA= Amount of Coarse Aggregate needed per unit volume of SCC in kg/m3= Wg =B.D of CA*PF*%of CA= 2.Determine the Cement content @ 7.14 kg per Mpa =C=(7.14* Target mean strength)= 3. Mixing Water content required by Cement : W/C ratio of SCC produced with Fly Ash for obtaining 80.395 MPa. Is = Amount of mixing water in kg/m3 = Wwc = 4. Determine the Fly Ash content: Ratio of Weight of Water and Fly Ash = W/F= Ratio of Water and Cement = W/C= Vpf + Vpb = 1- ((Wg/(1000*SG of CA)) +(Ws/(1000*SG of FA)) +(C/(1000*SG of C)) + (Wwc/(1000*SG of W))+ Air content)= (((1*Wpm)/(1000*SG of F)) + ((1*Ratio of W/F* Wpm)/(1000*SG of W))) =0.0008Wpm. From this Wpm in kg/m 3 = Weight of Fly Ash in kg/m3= Wf = 5. Determine the mixing water content required for Fly Ash: Water content for Fly Ash in kg/m3 = Wwf= 6. Determine the SP dosage: General dosage of SP based on previous engineering experience is 1.8%. Wsp=0.018*(C+Wf+Wggbs) in kg/m 3 7. Adjustment of mixing water content needed in SCC: Let Solid content of SP is 30% = Amount of Water in SP=Wwsp= (1-0.30)*Wsp in kg/m3 = Amount of mixing water needed in SCC in kg/m3 = W =(Wwc+Wwf-Wwsp) MIX PROPORTION: QUANTITY(kg/m3) PROPORTION CEMENT FLY ASH FA 574.02 34.16 836.94 1 0.06 1.46 CA SP 798.13 1.39 10.95 0.019 WATER/BINDER M.SILICA VMA 150.60 40.18 1.722 0.262 0.07 0.003 10 2.631 1498 2.61 1450 3.01 2.19 1 52/48 1.09 1.25% 70 80.395 1.11 836.94 798.13 574.02 0.25 143.51 0.4 0.25 0.029

34.2 34.2 13.67

10.95 0.30 6.57 150.60

MIX DESIGN FOR M70 CONCRETE Size of Coarse Aggregate in mm = Specific Gravity of Coarse Aggregate = Bulk Density of Coarse Aggregate in kg/m3 = Specific Gravity of Fine Aggregate = Bulk Density of Fine Aaggregate in kg/m3 = Specific Gravity of Cement = Specific Gravity of Fly Ash = Specific Gravity of Water = Volume ratio of FineAggregate to Coarse Aggregate = Specific Gravity of Super Plasticiser = Air content in SCC= PROCEDURE: Characterisic Strength in MPa = Target mean strength in MPa = fck + (K*S) =Refer table 10.4 & 10.3 for K & S values 1.Determine the amount of FA & CA : Let Packing Factor(PF) = Amount of Fine Aggregate needed per unit volume of SCC in kg/m3= Ws =B.D of FA*PF*%of FA= Amount of Coarse Aggregate needed per unit volume of SCC in kg/m3= Wg =B.D of CA*PF*%of CA= 2.Determine the Cement content @ 7.14 kg per Mpa =C=(7.14* Target mean strength)= 3. Mixing Water content required by Cement : W/C ratio of SCC produced with Fly Ash for obtaining 80.395 MPa. Is = Amount of mixing water in kg/m3 = Wwc = 4. Determine the Fly Ash content: Ratio of Weight of Water and Fly Ash = W/F= Ratio of Water and Cement = W/C= Vpf + Vpb = 1- ((Wg/(1000*SG of CA)) +(Ws/(1000*SG of FA)) +(C/(1000*SG of C)) + (Wwc/(1000*SG of W))+ Air content)= (((1*Wpm)/(1000*SG of F)) + ((1*Ratio of W/F* Wpm)/(1000*SG of W))) =0.0008Wpm. From this Wpm in kg/m 3 = Weight of Fly Ash in kg/m3= Wf = 5. Determine the mixing water content required for Fly Ash: Water content for Fly Ash in kg/m3 = Wwf= 6. Determine the SP dosage: General dosage of SP based on previous engineering experience is 1.8%. Wsp=0.018*(C+Wf+Wggbs) in kg/m 3 7. Adjustment of mixing water content needed in SCC: Let Solid content of SP is 30% = Amount of Water in SP=Wwsp= (1-0.30)*Wsp in kg/m3 = Amount of mixing water needed in SCC in kg/m3 = W =(Wwc+Wwf-Wwsp) MIX PROPORTION: QUANTITY(kg/m3) PROPORTION CEMENT FLY ASH FA 574.02 40.73 829.40 1 0.07 1.44 CA SP 790.94 1.38 11.07 0.019 WATER/BINDER M.SILICA 153.16 40.18 0.267 0.07 10 2.631 1498 2.61 1450 3.01 2.19 1.1 52/48 1.09 1.25% 70 80.395 1.1 829.40 790.94 574.02 0.25 143.51 0.4 0.25 0.035

40.7 40.7 16.29

11.07 0.30 6.64 153.16

VMA 1.722 0.003

MIX DESIGN FOR M70 CONCRETE Size of Coarse Aggregate in mm = Specific Gravity of Coarse Aggregate = Bulk Density of Coarse Aggregate in kg/m3 = Specific Gravity of Fine Aggregate = Bulk Density of Fine Aaggregate in kg/m3 = Specific Gravity of Cement = Specific Gravity of Water = Specific Gravity of GGBS = Volume ratio of FineAggregate to Coarse Aggregate = Specific Gravity of Super Plasticiser = Air content in SCC= PROCEDURE: Characterisic Strength in MPa = Target mean strength in MPa = fck + (K*S) =Refer table 10.4 & 10.3 for K & S values 1.Determine the amount of FA & CA : Let Packing Factor(PF) = Amount of Fine Aggregate needed per unit volume of SCC in kg/m3= Ws =B.D of FA*PF*%of FA= Amount of Coarse Aggregate needed per unit volume of SCC in kg/m3= Wg =B.D of CA*PF*%of CA= 2.Determine the Cement content @ 7.14 kg per Mpa =C=(7.14* Target mean strength)= 3. Mixing Water content required by Cement : W/C ratio of SCC produced with GGBS for obtaining 80.395 MPa. Is = Amount of mixing water in kg/m3 = Wwc = 4. Determine the GGBS content: Ratio of Weight of Water and GGBS = W/S= Ratio of Water and Cement = W/C= Vpf + Vpb = 1- ((Wg/(1000*SG of CA)) +(Ws/(1000*SG of FA)) +(C/(1000*SG of C)) + (Wwc/(1000*SG of W))+ Air content)= (((1*Wpm)/(1000*SG of GGBS)) + ((1*Ratio of W/GGBS*Wpm)/(1000*SG of W))) =0.0006Wpm . From this Wpm in kg/m3 = Weight of GGBS in kg/m3= Wggbs= 5. Determine the mixing water content required for GGBS: Water content for GGBS in kg/m3 = Wwb = 6. Determine the SP dosage: General dosage of SP based on previous engineering experience is 1.8%. Wsp=0.018*(C+Wggbs) in kg/m3 7. Adjustment of mixing water content needed in SCC: Let Solid content of SP is 30% = Amount of Water in SP=Wwsp= (1-0.30)*Wsp in kg/m3 = Amount of mixing water needed in SCC in kg/m3 = W =(Wwc+Wwb-Wwsp) MIX PROPORTION: QUANTITY(kg/m3) PROPORTION CEMENT GGBS FA 574.02 54.20 829.40 1 0.09 1.44 CA SP 790.94 1.38 11.31 0.020 WATER/BINDER M.SILICA VMA 151.85 40.18 1.722 0.265 0.07 0.003 10 2.631 1498 2.61 1450 3.01 1 2.91 52/48 1.09 1.25% 70 80.395 1.1 829.40 790.94 574.02 0.25 143.51 0.3 0.25 0.0349

54.20 54.20 16.26

11.31 0.30 7.92 151.85

SCC TEST RESULTS FOR M70 GRADE CONCRETE(WITH DIFFERENT W/C) W/C W/B F.ASH/m3 S.Flow(mm) T50(sec) V.Funnel(SEC) T-5min(sec) L-Box U-Box(mm) C.Strength(7days) 0.23 0.246 44.03 600x600 610x610 0.24 0.251 36.45 0.25 0.26 0.27 0.257 0.265 0.278 28.89 21.32 13.75 660x660 680x680 700x700 3.82 3.32 2.5 8 7.95 6.89 10.66 10.23 9.95 0.97 0.97 0.98 6 5 4

3.94 3.88 8.5 8.35 11.89 10.92 0.96 0.96 9 7 53.11N/mm2 52.44N/mm2

Range

650to800 2to5 6to12 6to15 0.8to1 0to30

S-ar putea să vă placă și

- Concrete Mix Design M25 PDFDocument8 paginiConcrete Mix Design M25 PDFJEFFY JACOBÎncă nu există evaluări

- 325.10R - 95 Roller Compacted Concrete PavementDocument32 pagini325.10R - 95 Roller Compacted Concrete PavementMike Feist100% (2)

- Mix Design M60 PDFDocument3 paginiMix Design M60 PDFGreeshma KajolÎncă nu există evaluări

- An Investigation Into The Issues Influencing The Use of Interlocking Stabilized Soil Blocks in Kenya A Case Study of Siaya CountyDocument77 paginiAn Investigation Into The Issues Influencing The Use of Interlocking Stabilized Soil Blocks in Kenya A Case Study of Siaya CountyManish Shashikant DharekÎncă nu există evaluări

- Concrete Mix Design GuideDocument7 paginiConcrete Mix Design GuideChathura ChamikaraÎncă nu există evaluări

- M20 Mix DesignDocument5 paginiM20 Mix Designakshay patelÎncă nu există evaluări

- Concrete Mix Design C30 - MDocument7 paginiConcrete Mix Design C30 - MMitendra Kumar ChauhanÎncă nu există evaluări

- Mix Design M-40 GradeDocument2 paginiMix Design M-40 GradePruthvi TejaÎncă nu există evaluări

- Concrete Mix Design Example - M50 Grade Concrete: 2. Selection of Water Cement Ratio: 3. Calculation of Water ContentDocument5 paginiConcrete Mix Design Example - M50 Grade Concrete: 2. Selection of Water Cement Ratio: 3. Calculation of Water ContentDattatreya DattuÎncă nu există evaluări

- Mix Design M25 Grade Designed As Per Is 10262 - 2009 & Is 456 - 2000Document4 paginiMix Design M25 Grade Designed As Per Is 10262 - 2009 & Is 456 - 2000narasimha salihundamÎncă nu există evaluări

- Hollow Block Machine TypesDocument36 paginiHollow Block Machine TypesmkulgeorgeÎncă nu există evaluări

- Concrete Mix Design ExplainedDocument21 paginiConcrete Mix Design ExplainedPratyush Kumar DoraÎncă nu există evaluări

- Types of CementDocument3 paginiTypes of CementAllan DeGuzman Dela VegaÎncă nu există evaluări

- Concrete Mix Design ExampleDocument2 paginiConcrete Mix Design ExampleMohamed Naheeb Aboobucker100% (1)

- Mix Design M20 Grade ConcreteDocument13 paginiMix Design M20 Grade ConcreteJaime Manalili LandinginÎncă nu există evaluări

- Design of The Concrete Mixture..FinalDocument51 paginiDesign of The Concrete Mixture..FinalCharisse Ann Arado Badoria100% (1)

- CONCRETE MIX DESIGN GUIDEDocument7 paginiCONCRETE MIX DESIGN GUIDEJaime Manalili Landingin0% (1)

- Design and Analysis of Screw Conveyor at Inlet of Ash/Dust ConditionerDocument6 paginiDesign and Analysis of Screw Conveyor at Inlet of Ash/Dust ConditionerMohd HafizzÎncă nu există evaluări

- Use of Plastic Fibre in Fly Ash BrickDocument66 paginiUse of Plastic Fibre in Fly Ash BrickSwapnil Battise25% (4)

- Mix Design MDocument3 paginiMix Design MPrabhakar Kumar BarnwalÎncă nu există evaluări

- New Microsoft Word DocumentDocument5 paginiNew Microsoft Word DocumentDattatreya DattuÎncă nu există evaluări

- New Microsoft Word DocumentDocument5 paginiNew Microsoft Word DocumentDattatreya Dattu0% (1)

- CH6 - Mix Design - Part2Document16 paginiCH6 - Mix Design - Part2Hamza Mo.Încă nu există evaluări

- Parameters For Mix Design M40Document6 paginiParameters For Mix Design M40Kumkum MukherjeeÎncă nu există evaluări

- COST COMPARISON OF CONCRETE MIXESDocument13 paginiCOST COMPARISON OF CONCRETE MIXESAkshit thakurÎncă nu există evaluări

- Mix Design CalculationsDocument3 paginiMix Design CalculationsaakalimÎncă nu există evaluări

- Comparative Analysis of Concrete Mix Proportioning As Per BS, ACI and BISDocument21 paginiComparative Analysis of Concrete Mix Proportioning As Per BS, ACI and BISiftikhar AhmadÎncă nu există evaluări

- Mix Design As Per Is 10262Document5 paginiMix Design As Per Is 10262Sonia MohapatraÎncă nu există evaluări

- Concrete Mix DesignDocument4 paginiConcrete Mix DesignZakir AliÎncă nu există evaluări

- Concrete Mix DesignDocument7 paginiConcrete Mix DesignUma MaheshwaraÎncă nu există evaluări

- Concrete Mix Design: by K.ShahDocument48 paginiConcrete Mix Design: by K.ShahBùi Quang MinhÎncă nu există evaluări

- ACI Concrete Mix Design ExampleDocument3 paginiACI Concrete Mix Design ExampleyunseyunÎncă nu există evaluări

- Mix Design With SuperplasticizersDocument8 paginiMix Design With SuperplasticizerskwameÎncă nu există evaluări

- Concrete Mix Design M20 - MMRDocument9 paginiConcrete Mix Design M20 - MMRMitendra Kumar ChauhanÎncă nu există evaluări

- Pervious Concrete Mix Design (M35) 1. Data For Mix ProportioningDocument4 paginiPervious Concrete Mix Design (M35) 1. Data For Mix ProportioningRashmi PleaseÎncă nu există evaluări

- Concrete Mix Design M-60 PDFDocument2 paginiConcrete Mix Design M-60 PDFSravan Kumar AnumoluÎncă nu există evaluări

- ACI MethodDocument57 paginiACI MethodashoknrÎncă nu există evaluări

- CHEMICAL SUPPLIERS CONCRETE MIX DESIGNDocument7 paginiCHEMICAL SUPPLIERS CONCRETE MIX DESIGNMitendra Kumar ChauhanÎncă nu există evaluări

- Concrete Mix Design Step by Step Full CalculationDocument11 paginiConcrete Mix Design Step by Step Full CalculationtalatzahoorÎncă nu există evaluări

- Concrete Mix Design Final 7654Document11 paginiConcrete Mix Design Final 7654talatzahoorÎncă nu există evaluări

- Pervious Concrete Mix Design (M35) 1. Data For Mix ProportioningDocument5 paginiPervious Concrete Mix Design (M35) 1. Data For Mix ProportioningRashmi PleaseÎncă nu există evaluări

- Mix Design of Concrete-IS MethodDocument26 paginiMix Design of Concrete-IS MethodashoknrÎncă nu există evaluări

- Mix Design M40 Grade Per IS 10262 & IS 456Document6 paginiMix Design M40 Grade Per IS 10262 & IS 456Sanjoy RoyÎncă nu există evaluări

- Mix Design Report M35Document6 paginiMix Design Report M35Zeeshan AbbasÎncă nu există evaluări

- Assignment - Mix DesignDocument3 paginiAssignment - Mix Designdharul khairÎncă nu există evaluări

- Mix DesignsDocument6 paginiMix DesignsJerry TomÎncă nu există evaluări

- Specific Gravity & Water Absorption Test (I S 2386 Iii/63)Document11 paginiSpecific Gravity & Water Absorption Test (I S 2386 Iii/63)End EndÎncă nu există evaluări

- Concrete Design MixDocument4 paginiConcrete Design Mixsubhashchandra chandruÎncă nu există evaluări

- Calculation For Design MixDocument2 paginiCalculation For Design MixZaeem BurnÎncă nu există evaluări

- Abstract: Problem Based LearningDocument10 paginiAbstract: Problem Based LearningHaris RiazÎncă nu există evaluări

- Stipulations For Mix Design Concrete M40Document5 paginiStipulations For Mix Design Concrete M40Md Sabbir HossainÎncă nu există evaluări

- Civil Engineering Mix Design M-50Document2 paginiCivil Engineering Mix Design M-50Lambu Sampath0% (1)

- Mix DesignDocument6 paginiMix DesignDhl KshtjÎncă nu există evaluări

- UntitledDocument7 paginiUntitledRashmi PleaseÎncă nu există evaluări

- Mix DesignDocument6 paginiMix DesignSwapnika BodapatiÎncă nu există evaluări

- Data Required For Concrete Mix DesignDocument9 paginiData Required For Concrete Mix DesignNyan Lin100% (1)

- Tabel KonversiDocument5 paginiTabel KonversiGilang PerdanaÎncă nu există evaluări

- Addis Ababa Science and Technology UniversityDocument9 paginiAddis Ababa Science and Technology UniversityLamiÎncă nu există evaluări

- Mix Design As Per IS 10262-2019Document18 paginiMix Design As Per IS 10262-2019Suchitra PandaÎncă nu există evaluări

- (A) Design StipulationDocument2 pagini(A) Design StipulationSravan Kumar AnumoluÎncă nu există evaluări

- Concrete Mix DesignDocument21 paginiConcrete Mix DesignfaheemqcÎncă nu există evaluări

- Understanding Membrane Distillation and Osmotic DistillationDe la EverandUnderstanding Membrane Distillation and Osmotic DistillationÎncă nu există evaluări

- Synthetic Natural Gas: From Coal, Dry Biomass, and Power-to-Gas ApplicationsDe la EverandSynthetic Natural Gas: From Coal, Dry Biomass, and Power-to-Gas ApplicationsTilman J. SchildhauerÎncă nu există evaluări

- Biofilms in Bioelectrochemical Systems: From Laboratory Practice to Data InterpretationDe la EverandBiofilms in Bioelectrochemical Systems: From Laboratory Practice to Data InterpretationÎncă nu există evaluări

- Overland FlowDocument74 paginiOverland Flowsatria11Încă nu există evaluări

- Domestic DirectDocument1 paginăDomestic Directvenkat_nsnÎncă nu există evaluări

- MainDocument11 paginiMainvenkat_nsnÎncă nu există evaluări

- CFD Old PapersDocument6 paginiCFD Old Papersvenkat_nsnÎncă nu există evaluări

- Q. 1 - Q. 5 Carry One Mark Each.: Fact: If It Rains, Then The Field Is WetDocument17 paginiQ. 1 - Q. 5 Carry One Mark Each.: Fact: If It Rains, Then The Field Is WetAnkita PaliwalÎncă nu există evaluări

- 8em BioDocument202 pagini8em Biovenkat_nsnÎncă nu există evaluări

- 10em EeDocument66 pagini10em Eevenkat_nsnÎncă nu există evaluări

- GATE 2016 Official CE 1 AnsKey PDFDocument2 paginiGATE 2016 Official CE 1 AnsKey PDFvenkat_nsnÎncă nu există evaluări

- 6em SocDocument194 pagini6em SocmurallliÎncă nu există evaluări

- S1 MeDocument13 paginiS1 MeAnonymous ncBe0B9bÎncă nu există evaluări

- 7em SocDocument226 pagini7em Socvenkat_nsnÎncă nu există evaluări

- 8em SocDocument282 pagini8em Socvenkat_nsn100% (1)

- 7em Gensc PDFDocument182 pagini7em Gensc PDFvenkat_nsn67% (3)

- Chap03 PDFDocument49 paginiChap03 PDFvenkat_nsnÎncă nu există evaluări

- Chap01 PDFDocument36 paginiChap01 PDFvenkat_nsnÎncă nu există evaluări

- Chap02 PDFDocument42 paginiChap02 PDFvenkat_nsnÎncă nu există evaluări

- B374Q23AdmitCard PDFDocument1 paginăB374Q23AdmitCard PDFvenkat_nsnÎncă nu există evaluări

- 6em GenscDocument190 pagini6em GenscAravind AllamÎncă nu există evaluări

- List of International & National Important Days - 2015 by AffairsCloudDocument9 paginiList of International & National Important Days - 2015 by AffairsCloudyeshuÎncă nu există evaluări

- CDS GK 2015Document48 paginiCDS GK 2015sachinsaxena1986Încă nu există evaluări

- 2013 SSC Objective Paper PDFDocument21 pagini2013 SSC Objective Paper PDFvenkat_nsnÎncă nu există evaluări

- Current Affairs Pocket PDF - November 2015 by AffairsCloudDocument20 paginiCurrent Affairs Pocket PDF - November 2015 by AffairsCloudrravat111Încă nu există evaluări

- B374Q23ApplicationForm PDFDocument1 paginăB374Q23ApplicationForm PDFvenkat_nsnÎncă nu există evaluări

- 2015 Civils Prelims Paper-IDocument40 pagini2015 Civils Prelims Paper-IతెలుగువెలుగుÎncă nu există evaluări

- Current Affairs December 2015 Final by D2GDocument62 paginiCurrent Affairs December 2015 Final by D2GHemanth KumarÎncă nu există evaluări

- Current Affairs Quiz PDF December 2015 by D2GDocument42 paginiCurrent Affairs Quiz PDF December 2015 by D2GEsakkiPonniahÎncă nu există evaluări

- Essential GS Part - 1Document7 paginiEssential GS Part - 1swapnil_6788Încă nu există evaluări

- English 100 Error Detection & Correction For All Exams by Das Sir (09038870684)Document19 paginiEnglish 100 Error Detection & Correction For All Exams by Das Sir (09038870684)Vijay Vikram Singh100% (1)

- 2015 Civils Prelims Paper-IDocument40 pagini2015 Civils Prelims Paper-IతెలుగువెలుగుÎncă nu există evaluări

- SSC Jrengg Paper1 PDFDocument32 paginiSSC Jrengg Paper1 PDFvenkat_nsnÎncă nu există evaluări

- CH PE AnInspRpt 001 20160114Document75 paginiCH PE AnInspRpt 001 20160114online reviewÎncă nu există evaluări

- NCHRP RPT 597Document152 paginiNCHRP RPT 597Kyle ForemanÎncă nu există evaluări

- LPPJFF RL - Envi - 2013 04 04Document10 paginiLPPJFF RL - Envi - 2013 04 04Petros IosifidisÎncă nu există evaluări

- Brick Field AffidavitDocument5 paginiBrick Field Affidavithell raiserÎncă nu există evaluări

- Adiabatic Temperature Rise Test of Cemented Sand ADocument12 paginiAdiabatic Temperature Rise Test of Cemented Sand Asharvan10Încă nu există evaluări

- Compressed Stabilised Earth Block: A Case Study ReportDocument2 paginiCompressed Stabilised Earth Block: A Case Study ReportShubham SrivastavaÎncă nu există evaluări

- Physical and Chemical Characterization of Ashes From Municipal Solid Waste Incinerator in ChinaDocument13 paginiPhysical and Chemical Characterization of Ashes From Municipal Solid Waste Incinerator in ChinaPasindu PramodÎncă nu există evaluări

- Intercem Product Sheet - WebDocument2 paginiIntercem Product Sheet - Webb4rfÎncă nu există evaluări

- ACC - K N RaoDocument12 paginiACC - K N RaoIshan SinghÎncă nu există evaluări

- Experimental Study On Mechanical Properties of Fly Ash and GGBS Based Geopolymer ConcreteDocument6 paginiExperimental Study On Mechanical Properties of Fly Ash and GGBS Based Geopolymer ConcreteAnonymous kw8Yrp0R5rÎncă nu există evaluări

- Ec Minutes Tiru Feb'16Document92 paginiEc Minutes Tiru Feb'16Ranjan MehrotraÎncă nu există evaluări

- Astm C618Document4 paginiAstm C618Fitria RindangÎncă nu există evaluări

- Technologies Used by Green Buildings in Haryana StateDocument9 paginiTechnologies Used by Green Buildings in Haryana Statevasheena mittalÎncă nu există evaluări

- 2008 Rakshya ShresthaDocument91 pagini2008 Rakshya ShresthaBartoFreitasÎncă nu există evaluări

- Cement Review PaperDocument24 paginiCement Review Paperleojay24100% (1)

- Annexure IVDocument38 paginiAnnexure IVSHEENA CHERIANÎncă nu există evaluări

- My Presentation On Thermal Power PlantDocument29 paginiMy Presentation On Thermal Power PlantGopal GuptaÎncă nu există evaluări

- Alccofine Tech InfoDocument14 paginiAlccofine Tech InfoKamal HamsaÎncă nu există evaluări

- A Comparative Evaluation of Various AdditivesDocument11 paginiA Comparative Evaluation of Various Additivesagus_ip3808Încă nu există evaluări

- SEE-Nagoya 2018-Accepted Abstract-Group 1-3Document11 paginiSEE-Nagoya 2018-Accepted Abstract-Group 1-3Gemilang Lara UtamaÎncă nu există evaluări

- Solid Waste TreatmentDocument29 paginiSolid Waste TreatmentAnkit Jain100% (1)

- RRL Group 11 Newton Draft 7 1Document3 paginiRRL Group 11 Newton Draft 7 1Richard Del RosarioÎncă nu există evaluări

- Black 2Document14 paginiBlack 2KashyapÎncă nu există evaluări

- Concrete: Concrete Is A Composite Material Composed of Fine and CoarseDocument36 paginiConcrete: Concrete Is A Composite Material Composed of Fine and CoarseclubmailusÎncă nu există evaluări