Documente Academic

Documente Profesional

Documente Cultură

Case: 100 Yen Sushi House

Încărcat de

sachin15kalraDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Case: 100 Yen Sushi House

Încărcat de

sachin15kalraDrepturi de autor:

Formate disponibile

CASE: 100 YEN SUSHI HOUSE6 Sang M.

Lee tells of a meeting with two Japanese businessmen in Tokyo to plan a joint U.S.-Japanese conference to explore U.S. and Japanese management systems. As lunchtime drew near, his hosts told him with much delight that they wished to show him the "most productive operation in Japan." Lee describes the occasion: "They took me to a sushi shop, the famous 100 Yen Sushi House, in the Shinzuku area of Tokyo. Sushi is the most popular snack in Japan. It is a simple dish, vinegared rice wrapped in different things, such as dried seaweed, raw tuna, raw salmon, raw red snapper, cooked shrimp, octopus, fried egg, etc, Sushi is usually prepared so that each piece will be about the right size to be put into the mouth with chop-^ sticks. Arranging the sushi in an appetizing and aes thetic way with pickled ginger is almost an art in itself. "The 100 Yen Sushi House is no ordinary sushi restaurant. It is the ultimate showcase of Japanese productivity. As we entered the shop, there was a chorus of 'Iratsai,' a welcome from everyone working in the shop-cooks, waitresses, the owner, and the owner's children. The house features an ellipsoid-shaped serving area in the middle of the room, where inside three or four cooks were busily preparing sushi. Perhaps 30 stools surrounded the serving area. We took seats at the counters and were promptly served with a cup of 'Misoshiru, which is a bean paste soup, a pair of chopsticks, a cup of green tea, a tiny plate to make our own sauce, and a small china piece to hold the chopsticks. So far, the service was average for any sushi house. Then, I noticed something special. There was a con veyor belt going around the ellipsoid service area, like a toy train track. On it I saw a train of plates of sushi. You can find any kind of sushi that you can think of from the cheapest seaweed or octopus kind to the expensive raw salmon or shrimp dishes. The price is uniform, however, 100 yen per plate. On closer examination, while my eyes were racing to keep up with the speed of the traveling plates, I found that a cheap seaweed plate had four pieces, while the more expensive raw salmon dish had only two pieces. I sat down and looked around at the other customers at the counters. They were all enjoying their sushi and slurping their soup while reading newspapers or magazines. "I saw a man with eight plates all stacked up neatly. As he got up to leave, the cashier looked over and said, '800 yen, please.' The cashier had no cash register, since she can simply count the number of plates and then multiply by 100 yen. As the customer was leaving, once again we heard a chorus of 'Arigato Go-saimas' (thank you) from all the workers." Lee continues his observations of the sushi house operations: "In the 100 Yen Sushi' House, Professor Tamura lone of his hosts] explained to me how efficient this family-owned restaurant is. The owner usually has a superordinate organizational purpose such as customer service, a contribution to society, or the well-being of the community. Furthermore, the organizational purpose

is achieved through a long-term effort by all the members of the organization, who are considered 'family.' "The owner's daily operation is based on a careful analysis of information. The owner has a complete summary of demand information about different types of sushi plates, and thus he knows exactly how many of each type of sushi plates he should prepare and when. Furthermore, the whole operation is based on the repetitive manufacturing principle with appropriate 'just-in-time' and quality control systems. For example, the store has a very limited refrigerator capacity (we could see several whole fish or octopus in the glassed chambers right in front of our counter). Thus, the store uses the 'just-in-time' inventory control system. Instead of increasing the refrigeration capacity by purchasing new refrigeration systems, the company has an agreement with the fish vendor to deliver fresh fish several times a day so that materials arrive 'just-in-time' to be used for sushi making. Therefore, the inventory cost is minimum. "... In the 100 Yen Sushi House, workers and their equipment are positioned so close that sushi making is passed on hand to hand rather than as independent operations. The absence of walls of inventory allows the owner and workers to be involved in the total operation, from greeting the customer to serving what is ordered. Their tasks are tightly interrelated and everyone rushes to a problem spot to prevent the cascading effect of the problem throughout the work process. "The 100 Yen Sushi House is a labor-intensive operation, which is based mostly on simplicity and common sense rather than high technology, contrary to American perceptions. I was very impressed. As I finished my fifth plate, I saw the same octopus sushi plate going around for about the 30th time. Perhaps I had discovered the pitfall of the system. So I asked the owner how he takes care of the sanitary problems when a sushi plate goes around all day long, until an unfortunate customer eats it and perhaps gets food poisoning. He bowed with an apologetic smile and said, 'Well, sir, we never let our sushi plates go unsold longer than about 30 minutes.' Then he scratched his head and said, 'Whenever one of our employees takes a break, he or she can take off unsold plates of sushi and either eat them or throw them away. We are very serious about our sushi quality.' " Questions 1. Prepare a service blueprint for the 100 Yen Sushi House operation. 2. What features of the 100 Yen Sushi House service delivery system differentiate it from the competition, and what competitive advantages do they offer? 3. How has the 100 Yen Sushi House incorporated the just-in-time system into its operation? 4. Suggest other services that could adopt the 100 Yen Sushi House service delivery concepts.

S-ar putea să vă placă și

- 6 Week Weight Loss ChallengeDocument6 pagini6 Week Weight Loss Challengerunrg100% (25)

- DinosaurusDocument67 paginiDinosaurusSpataru Cristina100% (2)

- Host Script 1Document5 paginiHost Script 1jerson hidalgoÎncă nu există evaluări

- Consolidated Worksheet of Reversible IrreversibleDocument15 paginiConsolidated Worksheet of Reversible IrreversibleAngkita KiranaÎncă nu există evaluări

- Using Solver TableDocument4 paginiUsing Solver TableErik Njølstad100% (1)

- Using Solver TableDocument4 paginiUsing Solver TableErik Njølstad100% (1)

- Managerial AccountingDocument18 paginiManagerial Accountingirfan103158Încă nu există evaluări

- GORA by Rabindranath TagoreDocument4 paginiGORA by Rabindranath Tagoresachin15kalra50% (2)

- Bon Appetit PLCDocument1 paginăBon Appetit PLCAbiud UrbinaÎncă nu există evaluări

- Case Studies - II (100 Yen Sushi House) - by AnantaDocument4 paginiCase Studies - II (100 Yen Sushi House) - by AnantaAnanta MallikÎncă nu există evaluări

- Yen 100 Shop QuestionDocument2 paginiYen 100 Shop QuestionTony WongÎncă nu există evaluări

- The Complete Guide to Making Authentic Sushi at HomeDocument45 paginiThe Complete Guide to Making Authentic Sushi at HomeMajo100% (4)

- 12 Lessons On Becoming An ExpertDocument49 pagini12 Lessons On Becoming An ExpertcmndrcoolÎncă nu există evaluări

- Campua BUSINESS PLAN 12 ABMDocument14 paginiCampua BUSINESS PLAN 12 ABMAngelica CampuaÎncă nu există evaluări

- Soal Tryout Bahasa Inggris Kelas Ix 19-20Document15 paginiSoal Tryout Bahasa Inggris Kelas Ix 19-20Arif Munandar100% (1)

- 7 ElevenDocument9 pagini7 ElevenArman TÎncă nu există evaluări

- MS - by Ngoc AnhDocument30 paginiMS - by Ngoc Anhmiuchu73Încă nu există evaluări

- Ibusiness Plan Draft FinalDocument28 paginiIbusiness Plan Draft FinalHifz Ur Rehman AwanÎncă nu există evaluări

- Case StudyDocument5 paginiCase StudyAjit Kumar K100% (2)

- Gloria Jean's Coffee Franchise in MalaysiaDocument7 paginiGloria Jean's Coffee Franchise in MalaysiaShayan Jan0% (1)

- The Gloria Jeans and Its Performance inDocument18 paginiThe Gloria Jeans and Its Performance insoe sanÎncă nu există evaluări

- Islamic Equity MarketsDocument40 paginiIslamic Equity Marketstrevorsum123Încă nu există evaluări

- Business Plan 4000 Chinese Tea HouseDocument18 paginiBusiness Plan 4000 Chinese Tea HouseLu XiyunÎncă nu există evaluări

- Business 4050: Tim Horton's Case Analysis Group 8Document15 paginiBusiness 4050: Tim Horton's Case Analysis Group 8Prince FahadÎncă nu există evaluări

- Group 8 - Amul & Kwality Wall'sDocument11 paginiGroup 8 - Amul & Kwality Wall'sShivaÎncă nu există evaluări

- Subway Marketing Analysis: Team MembersDocument18 paginiSubway Marketing Analysis: Team MembersmkduraÎncă nu există evaluări

- Pizza Hut PakistanDocument6 paginiPizza Hut PakistanSuleman AsgharÎncă nu există evaluări

- Group 6 - Case Study OptimizationDocument17 paginiGroup 6 - Case Study OptimizationLinh ChiÎncă nu există evaluări

- Cross Culture Psychological SegmentationDocument2 paginiCross Culture Psychological SegmentationChintan GoriÎncă nu există evaluări

- CAFÉ COFFEE DAY VS COSTA COFFEE: A COMPARATIVE REPORTDocument21 paginiCAFÉ COFFEE DAY VS COSTA COFFEE: A COMPARATIVE REPORTSarthak YadavÎncă nu există evaluări

- Arrive Find Seat Make Paste Select Plate Eat Stack Plates & Pay LeaveDocument2 paginiArrive Find Seat Make Paste Select Plate Eat Stack Plates & Pay LeaveDevendra MahajanÎncă nu există evaluări

- Marketingmidterm Draft v1Document10 paginiMarketingmidterm Draft v1marinaquashaÎncă nu există evaluări

- Accessories Februari 2018 PDFDocument2 paginiAccessories Februari 2018 PDFwenska 18Încă nu există evaluări

- Traditional Taste of Himalayas CafeDocument10 paginiTraditional Taste of Himalayas CafeRavinder DhimanÎncă nu există evaluări

- AI Refrigerator Makes Grocery Shopping Hassle-FreeDocument12 paginiAI Refrigerator Makes Grocery Shopping Hassle-FreeAnupamÎncă nu există evaluări

- M.Aslam Khaki v. Syed Mohammad Hashim Supreme Court of Pakistan Riba Interest BankingDocument5 paginiM.Aslam Khaki v. Syed Mohammad Hashim Supreme Court of Pakistan Riba Interest BankingTalha Ansari0% (1)

- Rocket Singh Sales Man of The YearDocument5 paginiRocket Singh Sales Man of The YearBhavesh Gupta0% (1)

- Part 2Document3 paginiPart 2Thuan TruongÎncă nu există evaluări

- Ghillyer EthicsNow Notes Ch07 Blowing WhistleDocument25 paginiGhillyer EthicsNow Notes Ch07 Blowing WhistleSitti Najwa100% (1)

- Today Large Shopping Centers and Supermarkets Are More Common Than Small Local ShopsDocument1 paginăToday Large Shopping Centers and Supermarkets Are More Common Than Small Local ShopsQuốc Cường ĐặngÎncă nu există evaluări

- Gloria Jean's Coffees History and ControversiesDocument4 paginiGloria Jean's Coffees History and ControversiesCarlos Alberto Lopez SanchezÎncă nu există evaluări

- SM ProjectDocument61 paginiSM Projectpreeti_bph74467% (3)

- Test 2Document6 paginiTest 2Saadat Bin SiddiqueÎncă nu există evaluări

- Movie Review - Emily in ParisDocument3 paginiMovie Review - Emily in ParisDivine Dimamay100% (1)

- Analysis of The Sales ProcessDocument12 paginiAnalysis of The Sales ProcessSameena YusufÎncă nu există evaluări

- Is Taxation an Effective Selling Tool for Life InsuranceDocument52 paginiIs Taxation an Effective Selling Tool for Life InsuranceHimanshu Mehra100% (1)

- Service ScapeDocument17 paginiService ScapeKiran Peravali100% (1)

- Ready to Eat Vegetables Project ReportDocument7 paginiReady to Eat Vegetables Project ReportMita TannaÎncă nu există evaluări

- Final Case HRMDocument6 paginiFinal Case HRMThashin OntuÎncă nu există evaluări

- DU Coffee Shop and Gift Corner Business Plan PresentationDocument23 paginiDU Coffee Shop and Gift Corner Business Plan PresentationTahminaAnnieÎncă nu există evaluări

- Pizza Hut IntroductionDocument3 paginiPizza Hut IntroductionGunjan KhutÎncă nu există evaluări

- Competitive analysis of Chuong Duong Beverages Joint Stock CompanyDocument5 paginiCompetitive analysis of Chuong Duong Beverages Joint Stock CompanyThu Võ ThịÎncă nu există evaluări

- Hummus Bar Should Expand to Berlin for its First International LocationDocument7 paginiHummus Bar Should Expand to Berlin for its First International LocationAbhishekKumarÎncă nu există evaluări

- Group6 SO Project BenihanaDocument4 paginiGroup6 SO Project BenihanaAnkit VarshneyÎncă nu există evaluări

- The Coffee House: I. General IntroductionDocument2 paginiThe Coffee House: I. General IntroductionThảo Vân Nguyễn 25Încă nu există evaluări

- Old Town White Coffee: Introducing To ThailandDocument21 paginiOld Town White Coffee: Introducing To ThailandNurul' IzatiÎncă nu există evaluări

- Agri Assignment FinalDocument10 paginiAgri Assignment Finalkanika1992Încă nu există evaluări

- Gloria Jean CoffeeDocument19 paginiGloria Jean CoffeeBhargav PadhÎncă nu există evaluări

- Coffee Industry of IndiaDocument43 paginiCoffee Industry of IndiaSiddharth GugnaniÎncă nu există evaluări

- Case StudyDocument6 paginiCase StudyaditiÎncă nu există evaluări

- Integrated Marketing Communication: Hero HondaDocument36 paginiIntegrated Marketing Communication: Hero HondaSanjay KumarÎncă nu există evaluări

- Gold Spot Brand Analysis: Name - Roll No. - Reg No. - Subject - MKT 203Document6 paginiGold Spot Brand Analysis: Name - Roll No. - Reg No. - Subject - MKT 203GitanjaliÎncă nu există evaluări

- Bench Bulletin Issue 20Document206 paginiBench Bulletin Issue 20ohmslaw_ArigiÎncă nu există evaluări

- QuestionnaireDocument3 paginiQuestionnairearzoo26Încă nu există evaluări

- 1 Subhiksha IMT Credit CrunchersDocument43 pagini1 Subhiksha IMT Credit CrunchersAshish SachdevaÎncă nu există evaluări

- 100 Yen Sushi House: Iratsai, A Welcome From Everyone Working in The Shop-Cooks, Waitresses, TheDocument2 pagini100 Yen Sushi House: Iratsai, A Welcome From Everyone Working in The Shop-Cooks, Waitresses, ThemowitÎncă nu există evaluări

- Case Study StramaDocument7 paginiCase Study Stramanguyentrongquy12hvÎncă nu există evaluări

- Unit 3 Draft 2Document7 paginiUnit 3 Draft 2api-339975023Încă nu există evaluări

- USDA FANTA HFIAS HDDS HHS CSI WFP IFAD GHI WFS MDGs GFSIDocument1 paginăUSDA FANTA HFIAS HDDS HHS CSI WFP IFAD GHI WFS MDGs GFSIsachin15kalraÎncă nu există evaluări

- A Successful ERP Implementation Plan: Issues and ChallengesDocument53 paginiA Successful ERP Implementation Plan: Issues and Challengessachin15kalraÎncă nu există evaluări

- Marketing of ServicesDocument32 paginiMarketing of Servicessachin15kalraÎncă nu există evaluări

- Case: 100 Yen Sushi HouseDocument2 paginiCase: 100 Yen Sushi Housesachin15kalra100% (1)

- A Successful ERP Implementation Plan: Issues and ChallengesDocument53 paginiA Successful ERP Implementation Plan: Issues and Challengessachin15kalraÎncă nu există evaluări

- The Key Features AreDocument4 paginiThe Key Features Aresachin15kalraÎncă nu există evaluări

- Fab IndiaDocument3 paginiFab Indiasachin15kalraÎncă nu există evaluări

- A Successful ERP Implementation Plan: Issues and ChallengesDocument53 paginiA Successful ERP Implementation Plan: Issues and Challengessachin15kalraÎncă nu există evaluări

- Marketing of ServicesDocument32 paginiMarketing of Servicessachin15kalraÎncă nu există evaluări

- Complaint Letter - HemantDocument18 paginiComplaint Letter - HemantHemant SachanÎncă nu există evaluări

- Bank BibliographyDocument3 paginiBank Bibliographysachin15kalraÎncă nu există evaluări

- Complaint Letter - HemantDocument18 paginiComplaint Letter - HemantHemant SachanÎncă nu există evaluări

- Complaint Letter - HemantDocument18 paginiComplaint Letter - HemantHemant SachanÎncă nu există evaluări

- Presented By: Rakesh Panda Diptakshya Banerjee Swaroop Ranjan Padhay Guided By: Prof. Raj DashDocument16 paginiPresented By: Rakesh Panda Diptakshya Banerjee Swaroop Ranjan Padhay Guided By: Prof. Raj Dashsachin15kalraÎncă nu există evaluări

- Complaint Letter - HemantDocument18 paginiComplaint Letter - HemantHemant SachanÎncă nu există evaluări

- Ten IT Challenges For The 21st CenturyDocument2 paginiTen IT Challenges For The 21st Centurysachin15kalraÎncă nu există evaluări

- Marketingresearch 100403065019 Phpapp02Document6 paginiMarketingresearch 100403065019 Phpapp02Ipsita PadhiÎncă nu există evaluări

- PrEN 15593 Igiene Imballaggi PrimariDocument16 paginiPrEN 15593 Igiene Imballaggi PrimariaomartinmartinÎncă nu există evaluări

- Gulliver PDFDocument3 paginiGulliver PDFChristopherBustosÎncă nu există evaluări

- Tugas EnglishDocument7 paginiTugas EnglishRifki KenÎncă nu există evaluări

- Product Report CMCDocument8 paginiProduct Report CMCrocky7982100% (1)

- Analysis of Market Scenario (Hot Tea Stall) of Ispahani TEA and Competitors in Dhaka CityDocument55 paginiAnalysis of Market Scenario (Hot Tea Stall) of Ispahani TEA and Competitors in Dhaka CityTurjo VlogsÎncă nu există evaluări

- Grammar ModuleDocument124 paginiGrammar ModuleMeera Rania100% (1)

- Agricultural Robot Market ForecastDocument6 paginiAgricultural Robot Market Forecastnakul_069Încă nu există evaluări

- Food and Nutrition Gcse CourseworkDocument4 paginiFood and Nutrition Gcse Courseworkvyp0wosyb1m3100% (2)

- Osn Gya Inggris 2021Document12 paginiOsn Gya Inggris 2021Dhea Annisaa FebriannaÎncă nu există evaluări

- Christmas Modals of Deduction PDFDocument4 paginiChristmas Modals of Deduction PDFlizevanjaarsveld9235Încă nu există evaluări

- Top RamenDocument34 paginiTop RamenRohan Bhowmik0% (1)

- Biotic ComponentsDocument2 paginiBiotic ComponentsSarthak GoelÎncă nu există evaluări

- Pandu Class NoteDocument4 paginiPandu Class NotedrmoossÎncă nu există evaluări

- EGF3023 Chapter 1Document38 paginiEGF3023 Chapter 1hanis izzatiÎncă nu există evaluări

- Mama and Papa College EssayDocument2 paginiMama and Papa College Essayapi-581697717Încă nu există evaluări

- Final Roject of ST - Marketing DoneDocument33 paginiFinal Roject of ST - Marketing DoneSalman ArshadÎncă nu există evaluări

- VSS Project Site Visit Highlights Work Supporting Sahariya CommunityDocument2 paginiVSS Project Site Visit Highlights Work Supporting Sahariya CommunitykHUSHBOOÎncă nu există evaluări

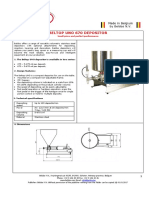

- The Beltop UNO Depositor Is Available in Two SeriesDocument5 paginiThe Beltop UNO Depositor Is Available in Two SeriesJonathan FajardoÎncă nu există evaluări

- Jeddah Restaurant MenuDocument8 paginiJeddah Restaurant Menuusama zedanÎncă nu există evaluări

- Memorable Paskong Piyu at FEUDocument1 paginăMemorable Paskong Piyu at FEUAlyssa BasilioÎncă nu există evaluări

- Family Menu ProjectDocument20 paginiFamily Menu ProjectRavenÎncă nu există evaluări

- Changing The Way The World Does Business: April 2013Document8 paginiChanging The Way The World Does Business: April 2013Lori FlemingÎncă nu există evaluări

- Growing and Varieties of Chickpeas in IndiaDocument11 paginiGrowing and Varieties of Chickpeas in IndiaManjeet ParasharÎncă nu există evaluări

- Quick Level Placement TestDocument11 paginiQuick Level Placement TestPhạm MyÎncă nu există evaluări

- Devil Fruit Powers and Haki AbilitiesDocument1 paginăDevil Fruit Powers and Haki AbilitiesNico RobinÎncă nu există evaluări