Documente Academic

Documente Profesional

Documente Cultură

Oil Mill

Încărcat de

manish.eer2394Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Oil Mill

Încărcat de

manish.eer2394Drepturi de autor:

Formate disponibile

MINI OIL MILL

1.0 INTRODUCTION Consumption of edible oils is increasing year after year and India imports large quantities every year. Different types of oilseeds are grown in the country like groundnuts, cotton seeds, mustard, rapeseed, sunflower, soyabean etc. Oilseed crop occupies important position in the agricultural and industrial economy of the country and accounts for about 13% of the cropped area. Mustard seed is one of the five major oil seeds from which edible oil is produced. Edible oil is an integral part of the Indian palate since long and different varieties are popular in different parts of the country. 2.0 PRODUCT Edible oils are a medium of cooking. Mustard oil is the medium of cooking in almost all the states of eastern India like Bihar, West Bengal, the North-East states etc. It is also used for massage in a big way. Mustard oil-cake (a by-product) is common cattle and poultry feed and used as manure in view of its high nutritional value. 2.1 3.0 Compliance with PFA Act is mandatory. Adherence to AGMARK is advisable.

MARKET POTENTIAL Oil milling is an age-old activity which has gone through many phases of development. Mini oil mill is a concept meant to cater to the local market unlike large oil mills with huge capacities and catering to regional markets with established brands and different varieties. Due to very peculiar food habits of the Indians, every household uses edible oil as a cooking medium almost everyday. Vegetarian as well as non-vegetarian food preparations need edible oils. Groundnut, cotton seed, rapeseed and mustard are the most popular edible oils in the

43

country but eastern-states prefer mustard oil as cooking medium. Oilseeds production in these states is growing year after year and there is a good scope for oil milling. 4.0 MANUFACTURING PROCESS The manufacturing process is well-established and simple. To begin with, dry mustard seeds are fed to oil expellers for extraction of oil wherein about 90% of the oil is extracted. Liquid oil and solid portion (oil cake) is then separated in the filter press. Oil is packed either in tins or jars or plastic pouches and oil cake is sold to cattle feed manufacturers. Recovery of oil from oilseeds depends upon quality of mustard seeds and it is in the range of 30% to 35%. 5.0 CAPITAL INPUTS 5.1 Land and Building There is no need to buy a piece of land and then undertake construction. Instead a readymade constructed shed of around 100 sq.mtrs. may be bought. Machines would occupy around 45-50 sq.mtrs. and balance space can be utilised for storage and packing. Cost of building would be around Rs.2.00 lacs. 5.2 Plant and Machinery

In view of the size of the market and keeping in mind the financial viability, it is assumed that the rated capacity would be to process 25 tonnes of mustard seeds per month based on working of 10-12 hours everyday. Mustard seeds will be available for not more than 8 months and thus per season processing capacity would be 200 tonnes. This would necessitate installation of following machines. Item Oil Expellers Filter Press Other support equipments like electric motors, diesel engine, conveyor belt, weighing scales, testing laboratory, etc. Qty. 2 1 -Total 5.3 Miscellaneous Assets Price (Rs.) 70,000 50,000 60,000 1,80,000

Assets like furniture and fixtures, storage tanks, packing tables, storage racks etc. are likely to cost Rs.50, 000/-. 5.4 Utilities

Power requirement will be 20 HP whereas about 50 ltrs. of diesel will be required every month. Per day water requirement will be 350-400 ltrs. 5.5 Raw and Packing Materials

The all-important raw material shall be mustard seeds. Districts like Gaya, Siwan, Bhojpur etc. produce substantial quantity of mustard seeds. Requirement of mill even at 100%

44

utilisation will not be more than 200 tonnes and therefore no difficulty is envisaged in procurement. Packing sizes and types shall have to be finalised beforehand and necessary prior arrangements shall have to be made. 6.0 MANPOWER REQUIREMENTS

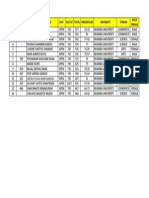

Particulars Skilled Workers Helpers Salesman

Nos. 2 3 1

Monthly Salary (Rs.) 2,000 1,250 2,000 Total

Total Monthly Salary (Rs.) 4,000 3,750 2,000 9,750

7.0

TENTATIVE IMPLEMENTATION SCHEDULE Activity Application and sanction of loan Site selection and commencement of civil work Completion of civil work and placement of orders for machinery Erection, installation and trial runs Period (in months) 2 1 4 1

8.0

DETAILS OF THE PROPOSED PROJECT 8.1 Building As discussed earlier, a readymade constructed area of 100 sq.mtrs. is adequate. It may cost Rs. 2.00 lacs. 8.2 Machinery

Total cost of machinery is expected to be Rs.1.80 lacs as explained earlier. 8.3 Miscellaneous Assets

A provision of Rs.50, 000/- is adequate as mentioned earlier. 8.4 Preliminary & Pre-operative Expenses

A provision of Rs.50,000/- is made towards certain pre-production expenses like registration, establishment and administrative expenses, interest during implementation and trial run expenses.

45

8.5

Working Capital Requirements

At 60% capacity utilisation in the first year, working capital needs shall be as under: (Rs. in lacs) Particulars Stock of Raw Materials Stock of Finished Goods Receivables Working Expenses Period Month Month 1 Month 1 Month Margin 30% 25% 25% 100% Total Total 0.80 1.00 2.00 0.20 4.00 Bank 0.55 0.75 1.50 -2.80 Promoters 0.25 0.25 0.50 0.20 1.20

8.6

Cost of the Project & Means of Financing Item Building Machinery Miscellaneous Assets P&P Expenses Contingencies @ 10% on Land and Building & Machinery Working Capital Margin Total Means of Finance Promoters' Contribution Term Loan from Bank/FI Total Debt Equity Ratio Promoters' Contribution

(Rs. in lacs) Amount 2.00 1.80 0.50 0.50 0.38 1.20 6.38

1.85 4.53 6.38 2.45 : 1 29%

Financial assistance in the form of grant is available from the Ministry of Food Processing Industries, Govt. of India, towards expenditure on technical civil works and plant and machinery for eligible projects subject to certain terms and conditions. 9.0 PROFITABILITY CALCULATIONS 9.1 Production Capacity & Build-up As against the processing capacity of 200 tonnes during 8 months, actual utilisation is expected to be 60% in the 1st year and thereafter 75%.

46

9.2

Sales Revenue at 100% (Rs. in lacs)

Product Mustard Oil Deoiled Cake

Qty. (Tonnes) 70 65

Selling Price/Ton (Rs.) 55,000 5,000 Total

Sales Value 38.50 3.25 41.75

9.3

Raw & Packing Materials Required at 100% (Rs. in lacs)

Product Mustard Seeds Others -Packing Materials

Qty. (Tonnes) 200 ---

Price/Ton (Rs.) 14,000 2.00 -Total

Value 28.00

1.50 31.50

9.4

Utilities

The annual expenditure at 100% utilisation will be Rs.60,000. 9.5 Interest

Interest on term loan of Rs. 4.53 lacs is calculated @ 12% per annum assuming repayment in 4 years including a moratorium period of 1 year whereas on bank loan for working capital, it is assumed to be 14%. 9.6 assets. Depreciation

It is computed on WDV basis @ 10% on building and 20% on machinery and miscellaneous

47

10.0

PROJECTED PROFITABILITY (Rs. in lacs) No. A Particulars Installed Capacity Capacity Utilisation Sales Realisation B Cost of Production Raw and Packing Materials Utilities Salaries Stores and Spares Repairs & Maintenance Selling Expenses @ 15% Administrative Expenses Total C Profit before Interest & Depreciation Interest on Term Loan Interest on Working Capital Depreciation Profit before Tax Income-tax @ 20% Profit after Tax Cash Accruals Repayment of Term Loan 18.90 0.36 0.78 0.15 0.18 1.25 0.42 22.04 3.01 0.48 0.40 0.66 1.47 0.27 1.20 1.86 -23.62 0.45 0.90 0.24 0.30 1.57 0.54 27.62 3.68 0.37 0.50 0.54 2.27 0.47 1.80 2.34 1.35 1st Year 60% 25.05 2nd Year 75% 31.30 --- 200 Tonnes ---

11.0

BREAK EVEN ANALYSIS No [A] [B] Particulars Sales Variable Costs Raw & Packing Material Utilities (70%) Salaries (65%) Stores & Spares Selling Expenses (75%) Admn Expenses (50%) Interest on WC [C] [D] [E] Contribution [A] - [B] Fixed Cost Break-Even Point [D] [C] 18.90 0.51 0.51 0.15 0.94 0.21 0.40

(Rs. in lacs) Amount 25.05

21.36 3.69 2.22 60%

48

12.0

[A]

LEVERAGES

Financial Leverage = EBIT/EBT = 2.35 1.47 = 1.60

Operating Leverage = Contribution/EBT = 3.69 1.47 = 2.51

Degree of Total Leverage = FL/OL = 1.60 2.51 = 0.64

[B]

Debt Service Coverage Ratio (DSCR) (Rs. in lacs)

Particulars Cash Accruals Interest on TL Total [A] Interest on TL Repayment of TL Total [B] DSCR [A] [B] Average DSCR

1st Yr 1.86 0.48 2.34 0.48 -0.48 4.88

2nd Yr 2.34 0.37 2.71 0.37 1.50 1.87 1.45

3rd Yr 2.59 0.21 2.80 0.21 1.50 1.71 1.63

4th Yr 2.86 0.12 2.98 0.12 1.53 1.65 1.81

------------------------------- 2.44 ---------------------------

49

[C]

Internal Rate of Return (IRR)

Cost of the project is Rs. 6.38 lacs. (Rs. in lacs) Year 1 2 3 4 Cash Accruals 1.86 2.34 2.59 2.86 9.65 16% 1.60 1.74 1.66 1.58 6.58 18% 1.58 1.68 1.58 1.48 6.32 20% 1.55 1.62 1.50 1.38 6.05

The IRR is around 18%.

Some of the machinery suppliers are 1. 2. 3. AMS Engg, Station Road, Patna Prabhat Agency, Siwan Chempro Engg. And consultants, 43, Sukhshine, Sunrise Park, Drive in Rd., Ahmedabad380054. Tel No. 26851135/9010 4. Lakhanpal Food Processing Machinery, 36/6, Balkashwer Rd., Agra-282004. Tel No. 2540726, Fax : 2540789

50

S-ar putea să vă placă și

- Fats & Oils Refining & Blending World Summary: Market Values & Financials by CountryDe la EverandFats & Oils Refining & Blending World Summary: Market Values & Financials by CountryÎncă nu există evaluări

- Mustard Oil Project ReportDocument8 paginiMustard Oil Project ReportAkhilesh KumarÎncă nu există evaluări

- Mustard Oil KanpurDocument10 paginiMustard Oil KanpurVinay YadavÎncă nu există evaluări

- Coconut Products: 1.0 Product and Its ApplicationsDocument6 paginiCoconut Products: 1.0 Product and Its ApplicationsAgri NetÎncă nu există evaluări

- 09 Peanut Processing PDFDocument8 pagini09 Peanut Processing PDFkalaamolÎncă nu există evaluări

- Sample Project of Mini Oil MillDocument6 paginiSample Project of Mini Oil MillLajpat Lala0% (3)

- Mustard Oil ExpellerDocument4 paginiMustard Oil Expellerpradip_kumarÎncă nu există evaluări

- Paper Bags and PouchesDocument9 paginiPaper Bags and Pouchessam krÎncă nu există evaluări

- A Project ReportDocument24 paginiA Project ReportshariquesayeedÎncă nu există evaluări

- Project Profile On Groundnut Oil and Oil Cake ManuafcuringDocument2 paginiProject Profile On Groundnut Oil and Oil Cake ManuafcuringprtmÎncă nu există evaluări

- Coir Pith Block Making UnitDocument3 paginiCoir Pith Block Making UnitMohan RajÎncă nu există evaluări

- Surgical Bandage-Ok-35-R PDFDocument2 paginiSurgical Bandage-Ok-35-R PDFSuresh KaushikÎncă nu există evaluări

- Project Report On Mustard Oil ProductionDocument6 paginiProject Report On Mustard Oil ProductionEIRI Board of Consultants and PublishersÎncă nu există evaluări

- Detailed Project Report On Rice Milling Unit at GelephuDocument19 paginiDetailed Project Report On Rice Milling Unit at GelephuHarpy happyÎncă nu există evaluări

- Plywood Project Report by Yogesh AgrawalDocument22 paginiPlywood Project Report by Yogesh AgrawalYOGESH AGRAWALÎncă nu există evaluări

- Project On National Horticulture BoardDocument9 paginiProject On National Horticulture Boardrupeshmore145Încă nu există evaluări

- Milk Dairy Management System: Submitted ToDocument29 paginiMilk Dairy Management System: Submitted ToDipali KantaleÎncă nu există evaluări

- Pulses MillDocument2 paginiPulses Millram100% (1)

- Groundnutdpr 04.08.23Document17 paginiGroundnutdpr 04.08.23TNRTP SALEMÎncă nu există evaluări

- Plastic Carry BagsDocument8 paginiPlastic Carry BagsRavi PrakashÎncă nu există evaluări

- Bio Mass Briquette PDFDocument17 paginiBio Mass Briquette PDFJigna PatelÎncă nu există evaluări

- Project Report ON Ladies Garments (Tailoring-Unit)Document4 paginiProject Report ON Ladies Garments (Tailoring-Unit)Global Law FirmÎncă nu există evaluări

- Besan Mill ProjectDocument14 paginiBesan Mill Projectshreyans01100% (1)

- Project Report For Proposed Retail Outlet Ofindian Oil Corporation LTDDocument3 paginiProject Report For Proposed Retail Outlet Ofindian Oil Corporation LTDsarada_sahu0% (1)

- Onion Dehydration: Project ProfileDocument4 paginiOnion Dehydration: Project ProfileMallikarjunReddyObbineniÎncă nu există evaluări

- Operational Guidelines Milling SchemeDocument45 paginiOperational Guidelines Milling SchemeDeep SarmahÎncă nu există evaluări

- Tent House UnitDocument18 paginiTent House UnitSrinivasa NÎncă nu există evaluări

- PROF. NO.23 Project Profile On Fly Ash Bricks Manufacturing UnitDocument8 paginiPROF. NO.23 Project Profile On Fly Ash Bricks Manufacturing UnitKroya HunÎncă nu există evaluări

- Pet Bottles Manufacturing UnitDocument20 paginiPet Bottles Manufacturing UnitYasir HabibÎncă nu există evaluări

- EdibleDocument23 paginiEdibleAjay ChoudharyÎncă nu există evaluări

- FAO Report On GROUNDNUT OIL PDFDocument16 paginiFAO Report On GROUNDNUT OIL PDFVIRTU 8 HR & IT LLPÎncă nu există evaluări

- Project Profile On Fly Ash Bricks Srs EnterprisesDocument17 paginiProject Profile On Fly Ash Bricks Srs EnterprisesRAHUL SHARMAÎncă nu există evaluări

- Project Report On Vermi Compost PDFDocument2 paginiProject Report On Vermi Compost PDFsrisairamcomputersÎncă nu există evaluări

- Tiger Grass Farming and Broom Making (Compatibility Mode) PDFDocument22 paginiTiger Grass Farming and Broom Making (Compatibility Mode) PDFMunicipalityCarranglan100% (1)

- Jute BagDocument9 paginiJute Bagafham84Încă nu există evaluări

- 4 AAC BLOCKS Other Sample Project Report Laxmi Tpe2jwDocument28 pagini4 AAC BLOCKS Other Sample Project Report Laxmi Tpe2jwDhruVikas & AssociatesÎncă nu există evaluări

- CLC Project ReportDocument10 paginiCLC Project ReportVaibhav KhodakeÎncă nu există evaluări

- Project Report On Coal BriquettesDocument10 paginiProject Report On Coal BriquettesSachin SharmaÎncă nu există evaluări

- Manufacturing of ArecaDocument32 paginiManufacturing of ArecaRocks Kiran67% (3)

- Biodiesel Business PlanDocument6 paginiBiodiesel Business Planarihant jainÎncă nu există evaluări

- Priya Rice MillDocument33 paginiPriya Rice MillKonark PoddarÎncă nu există evaluări

- Agro Seed Processing Plant PDFDocument9 paginiAgro Seed Processing Plant PDFNagendra Patel100% (1)

- Shri Ganesh Dal Mill Is A Prominent Name in The Dal IndustryDocument9 paginiShri Ganesh Dal Mill Is A Prominent Name in The Dal IndustryNeerajSinghÎncă nu există evaluări

- Bankable Project Report & Quotation For GreenhouseDocument40 paginiBankable Project Report & Quotation For Greenhousetiyasee25Încă nu există evaluări

- Project Profile On Manufacturing of Palm PlateDocument9 paginiProject Profile On Manufacturing of Palm PlateGangaraboina Praveen MudirajÎncă nu există evaluări

- Two Wheeler Repair and Service UnitDocument8 paginiTwo Wheeler Repair and Service UnitSurendra SharmaÎncă nu există evaluări

- Bankable Project MangoDocument5 paginiBankable Project MangoAmit PandhareÎncă nu există evaluări

- How To Start Mustard Oil Mill. Profitable Business Idea. Business With Huge Profit in India-339280Document68 paginiHow To Start Mustard Oil Mill. Profitable Business Idea. Business With Huge Profit in India-339280Jotirmoy AichÎncă nu există evaluări

- Paper Carry Bags PDFDocument2 paginiPaper Carry Bags PDFSuresh KaushikÎncă nu există evaluări

- Rice Bran Refined Oil - RevisedDocument14 paginiRice Bran Refined Oil - ReviseddeeptiachpalyaÎncă nu există evaluări

- Eastern SilkDocument47 paginiEastern SilkVish Nu VichuÎncă nu există evaluări

- Model Proj On Sheep Breeding FarmDocument4 paginiModel Proj On Sheep Breeding FarmSreenbabu0% (1)

- Offset Printing Press (Job Work) : NtroductionDocument4 paginiOffset Printing Press (Job Work) : NtroductionMMjagpreetÎncă nu există evaluări

- Kirti Dal MillDocument83 paginiKirti Dal MillRuishabh RunwalÎncă nu există evaluări

- Dairy Project Report BankableDocument4 paginiDairy Project Report Bankableanon_119311609Încă nu există evaluări

- Project Profile of Edible OilDocument47 paginiProject Profile of Edible OilManish Bhoyar100% (2)

- Milled Maize ProductDocument7 paginiMilled Maize ProductFarhat DurraniÎncă nu există evaluări

- Papad MFGDocument8 paginiPapad MFGFarhat DurraniÎncă nu există evaluări

- 10 Pigeon Pea ProcessingDocument8 pagini10 Pigeon Pea ProcessingPaneendra KumarÎncă nu există evaluări

- Desiccated CoconutDocument8 paginiDesiccated CoconutYohanes Slamet WidodoÎncă nu există evaluări

- L. Chandran Vs Venkatalakshmi and Anr. On 5 September, 1980 PDFDocument2 paginiL. Chandran Vs Venkatalakshmi and Anr. On 5 September, 1980 PDFmanish.eer2394Încă nu există evaluări

- Kerala Court Judgement 2 Child CustodyDocument5 paginiKerala Court Judgement 2 Child Custodymanish.eer2394Încă nu există evaluări

- 2 PDFDocument2 pagini2 PDFmanish.eer2394Încă nu există evaluări

- Kerala HC Judgement CustodyDocument7 paginiKerala HC Judgement Custodymanish.eer2394Încă nu există evaluări

- Kerala Court Judgement 3 Child CustodyDocument1 paginăKerala Court Judgement 3 Child Custodymanish.eer2394Încă nu există evaluări

- Gaurav Nagpal Vs Sumedha Nagpal On 19 November, 2008 PDFDocument10 paginiGaurav Nagpal Vs Sumedha Nagpal On 19 November, 2008 PDFmanish.eer2394Încă nu există evaluări

- rightsOfVictims PDFDocument14 paginirightsOfVictims PDFArkClicksÎncă nu există evaluări

- Abusive and Violent Women in RelationshipsDocument2 paginiAbusive and Violent Women in Relationshipshardikm007Încă nu există evaluări

- Maruti WagonR Owners Manual - Petrol PDFDocument108 paginiMaruti WagonR Owners Manual - Petrol PDFAjinkyaSalgaonkarÎncă nu există evaluări

- Facts and Figure of Death PenaltyDocument4 paginiFacts and Figure of Death Penaltymanish.eer2394Încă nu există evaluări

- Warning Signs of Future 498aDocument2 paginiWarning Signs of Future 498apradipkpÎncă nu există evaluări

- VolupDocument2 paginiVolupmanish.eer2394Încă nu există evaluări

- WiMAX Presentation PDFDocument22 paginiWiMAX Presentation PDFjcy1978Încă nu există evaluări

- Catalog Sun Acrylam PVT LTDDocument9 paginiCatalog Sun Acrylam PVT LTDmanish.eer2394Încă nu există evaluări

- Sharmila Manohar Sawant: SR - No Form No Name of Students Cast Out of Total Percentage University Stream Male FemaleDocument1 paginăSharmila Manohar Sawant: SR - No Form No Name of Students Cast Out of Total Percentage University Stream Male Femalemanish.eer2394Încă nu există evaluări

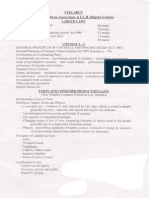

- Syllabus 3 Year LLB All SemesterDocument44 paginiSyllabus 3 Year LLB All SemesterRadharaman DasÎncă nu există evaluări

- Putting Therapeutic Jurisprudence Into PracticeDocument3 paginiPutting Therapeutic Jurisprudence Into Practicemanish.eer2394Încă nu există evaluări

- DIR 600 B 2 Manual EN UK PDFDocument97 paginiDIR 600 B 2 Manual EN UK PDFRafael GarciaÎncă nu există evaluări

- 4059EE ProductDescription Ed02 PDFDocument13 pagini4059EE ProductDescription Ed02 PDFmanish.eer2394Încă nu există evaluări

- Historical School of JurisprudenceDocument2 paginiHistorical School of Jurisprudencemanish.eer23940% (1)

- Netscaler Data SheetDocument9 paginiNetscaler Data Sheetmanish.eer2394Încă nu există evaluări

- 9 Series Phone Brochure PDFDocument6 pagini9 Series Phone Brochure PDFmanish.eer2394Încă nu există evaluări

- Datasheet OmniPCXOffice-hotel EN July09 EPG3310090609 PDFDocument4 paginiDatasheet OmniPCXOffice-hotel EN July09 EPG3310090609 PDFmanish.eer2394Încă nu există evaluări

- MIC Mobile For OpenTouch Users EN Datasheet PDFDocument4 paginiMIC Mobile For OpenTouch Users EN Datasheet PDFmanish.eer2394Încă nu există evaluări

- Brochure 8 Series PhonesDocument6 paginiBrochure 8 Series Phonesmanish.eer2394Încă nu există evaluări

- Contents Foundations of Service Level ManagementDocument2 paginiContents Foundations of Service Level Managementmanish.eer2394Încă nu există evaluări

- An Analysis: by Somya JainDocument8 paginiAn Analysis: by Somya JainKaran SahooÎncă nu există evaluări

- Classification of EntrepreneursDocument6 paginiClassification of EntrepreneursAnn Mary John0% (1)

- Krugman - A Country Is Not A Company PDFDocument9 paginiKrugman - A Country Is Not A Company PDFdavidÎncă nu există evaluări

- Accenture Thinking Strategically About The Interactive Advertising IndustryDocument13 paginiAccenture Thinking Strategically About The Interactive Advertising IndustrymscallonÎncă nu există evaluări

- Worksheet For Cost Accounting11Document3 paginiWorksheet For Cost Accounting11Abdii Dhufeera100% (1)

- AnamikaDocument23 paginiAnamikaAnamika VermaÎncă nu există evaluări

- Assumptions by Kundan PDFDocument67 paginiAssumptions by Kundan PDFSusmitha KollaÎncă nu există evaluări

- Tutorial 5Document2 paginiTutorial 5ivyling29Încă nu există evaluări

- 2012 CB Vendor FlyerDocument1 pagină2012 CB Vendor FlyerKristina AquiloneÎncă nu există evaluări

- Introduction To Business TaxesDocument3 paginiIntroduction To Business Taxesyatot carbonelÎncă nu există evaluări

- Buiser V Leogardo DigestDocument2 paginiBuiser V Leogardo DigestYodh Jamin OngÎncă nu există evaluări

- Yohann Douglas 259-59 149th Road Rosedale, NY 11422 (Phone) 917-693-9008Document2 paginiYohann Douglas 259-59 149th Road Rosedale, NY 11422 (Phone) 917-693-9008Anonymous z8k62UÎncă nu există evaluări

- Rural Marketing: Module-3Document72 paginiRural Marketing: Module-3Prithvish ShettyÎncă nu există evaluări

- S.M Case (Revlon)Document24 paginiS.M Case (Revlon)Mohid SharifÎncă nu există evaluări

- Chapter 1 Marketing Principles and StrategiesDocument32 paginiChapter 1 Marketing Principles and StrategiesAnaliza Peregrino MojaresÎncă nu există evaluări

- ConsumerDocument36 paginiConsumergagandeepÎncă nu există evaluări

- Case Study 1 Ethics and The ManagerDocument2 paginiCase Study 1 Ethics and The ManagerTino AlappatÎncă nu există evaluări

- 5.1 Questions: Chapter 5 Relevant Information For Decision Making With A Focus On Pricing DecisionsDocument37 pagini5.1 Questions: Chapter 5 Relevant Information For Decision Making With A Focus On Pricing DecisionsLiyana ChuaÎncă nu există evaluări

- Chapter 2Document2 paginiChapter 2Gaurav ChaudharyÎncă nu există evaluări

- Tax Invoice/Bill of Supply/Cash Memo: (Original For Recipient)Document1 paginăTax Invoice/Bill of Supply/Cash Memo: (Original For Recipient)AMAN BANSALÎncă nu există evaluări

- GE Honeywell.Document20 paginiGE Honeywell.Sripal ShahÎncă nu există evaluări

- Methods To Initiate VenturesDocument16 paginiMethods To Initiate VenturesRaquel GonzalesÎncă nu există evaluări

- Tutorial Partnership LawDocument7 paginiTutorial Partnership LawLoveLyzaÎncă nu există evaluări

- QUIZ AdvanceDocument1 paginăQUIZ AdvanceFenny MarietzaÎncă nu există evaluări

- Arun Ice Cream Situation StatementDocument6 paginiArun Ice Cream Situation StatementDisha TulsaniÎncă nu există evaluări

- Proposal Engineer BasicsDocument3 paginiProposal Engineer BasicsAnonymous E2oSW7Încă nu există evaluări

- P8 Syl2012 InterDocument23 paginiP8 Syl2012 Internivedita_h42404Încă nu există evaluări

- Detectprevent Final ProjectDocument18 paginiDetectprevent Final Projectapi-282483815100% (2)

- Ona Vs Commissioner On Internal RevenieDocument2 paginiOna Vs Commissioner On Internal RevenieJustin LoredoÎncă nu există evaluări

- Arrow ElectronicsDocument9 paginiArrow ElectronicsAnkit SeniarayÎncă nu există evaluări