Documente Academic

Documente Profesional

Documente Cultură

Design Control

Încărcat de

JOHNKDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Design Control

Încărcat de

JOHNKDrepturi de autor:

Formate disponibile

AL JABER PRECISION ENGINEERING PROCEDURE: DESIGN CONTROL NUMBER: 04

Page 1 of 8 QUALITY MANUAL ISSUE LEVEL - Rev. 0 DATE:

QUALITY MANUAL CONTRACT NO.20705 BITUMEN STORAGE FACILITY AT PORT KHALID SHARJAH

DESIGN CONTROL PROCEDURE : 04

INDEX: 4.01 Responsibility 4.02 Scope 4.03 Purpose 4.04 Organizational and Technical Interface 4.05 Design and Development Planning 4.06 Design Review 4.07 Design Verification and Validation 4.08 Control of Design Changes 4.09 Records

18-12-2006 Date

0 Revision

M.D Prepared by

D.L Reviewed By

W.D Approved By

AL JABER PRECISION ENGINEERING PROCEDURE: DESIGN CONTROL NUMBER: 04

Page 2 of 8 QUALITY MANUAL ISSUE LEVEL - Rev. 0 DATE:

4.1

RESPONSIBILITY: 4.1.1 The TECHNICAL COORDINATOR, being the head of the Engineering Department is responsible for the technical aspect of projects assigned to the department requiring product design and or development of shop drawings.

4.2

SCOPE: 4.2.1 Assigned projects involving structural design activities. 4.2.2 Assigned projects involving shop drawing development activities. 4.2.3 Coordination for changes, and modifications from design input to output. 4.2.4 Approval of design and development output.

4.3

PURPOSE: 4.3.1 To provide a product designed to meet customers approval as well as satisfying applicable statutory and regulatory codes and standards. 4.3.2 To design a product that would guarantee safety and proper function during production, installation and service.

4.4

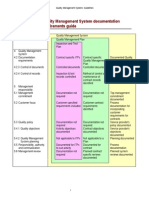

ORGANIZATIONAL AND TECHNICAL INTERFACE: 4.4.1 Coordination with the GENERAL MANAGER for review of tender packages and technical specifications. Provide preliminary designs if required. 4.4.2 Approval and or submittal of technical documents to the customer may be coordinated by the SITE ENGINEER or with the PROJECT COORDINATOR which ever may apply. 4.4.3 Provide the Project Coordinator with updated status of the project design plan and master drawing list upon request or as agreed in the project opening meetings. 4.4.4 Coordination with the FACTORY MANAGER for revised shop drawings under production. 4.4.5 Table of Organization

AL JABER PRECISION ENGINEERING PROCEDURE: DESIGN CONTROL NUMBER: 04

Page 3 of 8 QUALITY MANUAL ISSUE LEVEL - Rev. 0 DATE:

ENGINEERING DEPARTMENT

Table Of Organization

4.4.6

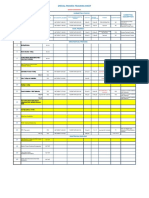

Document Control Flow Chart

Technical Coordinator Senior Designer Senior Detailer

Detailer 1

Detailer 2

Detailer 3

Detailer 4

AL JABER PRECISION ENGINEERING PROCEDURE: DESIGN CONTROL NUMBER: 04

Customer Tender, Specs

Page 4 of 8 QUALITY MANUAL ISSUE LEVEL - Rev. 0 DATE:

Techincal Co-ordinat or Review tender and associat ed specifications. Est ablish Feasibilit y for Design (Sec. 4.1) Inform ambiguous or conflict ing design requirements t o Operat ions Manager. Operat ions Manager To resolve ambiguous / conflicting design requirements wit h the Client. Quot at ion Ref. P rocedure 03 "Cont ract R eview"

R eview Tender Requirement s

No

Cont ract Awarded? Yes

Prepare Schem atic

Drawings

Technical Co-ordinat or Review Client drawings and cont ract specificat ion/requirement s Raise P roject Design P lan (Ref. Sec. 4.2) Prepare Design Drawings Technical Co-ordinat or Verify and approve Design drawings Verify and approve struct ural calculat ions (reference Sec. 4.5) Design R eview (Sec. 4.4) Project Co-ordinat or Arrange for client validat ion of design drawing and calculat ions (where specified wit hin contract )

Project Design P lan Design Drawings Struct ural Calculat ions

Approved Design Drawings and Calculations

Prepare Shop Drawings

St ruct ural E ngineer Prepare Mast er P acking List , Det ail and Erect ion Det ail Drawings drawings based upon approved Design drawings and calculations. Submit t o Technical Co-ordinat or for verification and approval. Technical Co-ordinat or Verify and approve Mast er P acking List , Det ail and Erection drawings. (Reference Sec. 4.5) Conduct Design R eview (Sec. 4.4) if necessary Project Co-ordinat or Arrange for client validat ion of det ail and erect ion drawings. (where required)

Hold

Approved Det ail drawings

Developm ent of Fabrication

Drawings

Design Det ailer Prepare Fabricat ion drawings, based on approved Master P acking List , Design Det ail and Erection drawings. Submit to T echnical Co-ordinator for verification and approval, prior t o issue to Project Co-ordinat or. Technical Co-ordinat or Verify and approve Fabricat ion drawings (R eference Sec. 4.5) Conduct Final Design Review (Sec. 4.4) Project Co-ordinat or Obt ain Client validat ion where required Technical Co-ordinat or Endorse Fabricat ion drawings t o P roject Co-ordinat or (R eference P rocedure 05 "Document and Data Cont rol") Project Co-ordinat or Issue fabrication drawing to concern (R eference P rocedure 05 "Document and Data Cont rol")

Fabricat ion Drawings

Hold

Endorsem ent of Fabrication

Drawings

Issue for Fabricat ion

4.5

DESIGN AND DEVELOPMENT PLANNING:

AL JABER PRECISION ENGINEERING PROCEDURE: DESIGN CONTROL NUMBER: 04

Page 5 of 8 QUALITY MANUAL ISSUE LEVEL - Rev. 0 DATE:

4.5.1 For any assignment to the Engineering Department where structural or mechanical design is a major requirement in the project, The Technical Coordinator shall oversee that a documented Project Design Plan is provided in the project file. He shall: a) Ensure that the following details are properly addressed in the plan: Job reference Design Activity Review of design Verification of design Validation of design Development of Shop Drawings Activity Verification of shop drawings Validation of shop drawing Time duration for each activity if applicable b) Assign designers responsible for design activities if applicable. c) Assign Detailers responsible for development of drawings if applicable. d) Task assignment may be identified individually however in multitask environment, designers and detailers must sign his initials on every completed document. e) Update the project design plan as the design and or development progresses. 4.5.2 Projects requiring direct application of customers design data, specification and standards to the development of shop drawings, Special format for reporting purposes may also be generated when the above forms do not apply to the project. 4.5.3 Design calculations where applicable.

AL JABER PRECISION ENGINEERING PROCEDURE: DESIGN CONTROL NUMBER: 04 4.6 DESIGN REVIEW:

Page 6 of 8 QUALITY MANUAL ISSUE LEVEL - Rev. 0 DATE:

4.6.1 In as much as majority of projects comprises mainly of standard structural steel mills and buildings, vertical and horizontal cylindrical steel storage tanks, design formats generated are also following internationally accepted codes and standards and customer specifications derived from the same standard. Design verification therefore takes more weight than reviews. However, when a certain project calls for non-standard designs, reviews must be conducted. 4.6.2 At appropriate stages of the design, an assigned member of the design team or the Technical Coordinator may conduct design reviews. 4.6.3 Reviews conducted internally by the Engineering Department design team shall be identified. 4.6.4 Reviews conducted involving customer representative and design team shall be documented in black and white as minutes of reviews or meetings and shall be maintained in the project design file. 4.6.5 Reviews resulting in document change or modification shall be registered.

4.7

DESIGN VERIFICATION AND VALIDATION: 4.7.1 For every completion of design and development of shop drawings, verification and validation must be performed to ensure that the design input meets the desired output. 4.7.2 Completion of verification activity shall be identified by signing on the completed document i.e. drawings and calculations. 4.7.3 Verified documents shall also bear the stamp and initials indicating verification was conducted and approved by the Technical Coordinator 4.7.4 When validation of design or shop drawings is performed by the customer or his representative, validation results shall be registered (Validations Log). In the event that customer validation is not required, design calculations shall be maintained in the project file and shop drawings to be stamped with approval and signed by the Technical Coordinator.

AL JABER PRECISION ENGINEERING PROCEDURE: DESIGN CONTROL NUMBER: 04

Page 7 of 8 QUALITY MANUAL ISSUE LEVEL - Rev. 0 DATE:

4.7.5 Verifications conducted involving customer representative and design team shall be documented in black and white as minutes of or meetings and shall be maintain project design file. 4.7.6 Verifications resulting in document change or modification. 4.8 CONTROL OF DESIGN CHANGES: 4.8.1 For every change or modification in the design or drawing, the Technical Coordinator shall assess the implications of the proposed change. If deemed necessary, customer approval shall be sought for every changes or modification prior to implementation. Assessment shall take into account the following : a) Function / Performance requirements b) Safety c) Statutory or Regulatory requirements d) Cost 4.8.2 Request for changes to the design or shop drawings which is of inter-disciplinary origin but not from the design team, shall be agreed by the coordinating party and the Technical Coordinator. This shall be accomplished by (Design Change Request) and approved by the Technical Coordinator. 4.8.3 Changes and modifications to the design or drawings which is a result of a customer review, verification and or validation shall be accomplished (Design Change Notice). 4.8.4 The Technical Co-ordinator shall assign personnel to incorporate the desired change in the document. 4.8.5 Review and approve all subsequent amendments to the affected design calculations and drawings to ensure proper implementation of change requirements.

AL JABER PRECISION ENGINEERING PROCEDURE: DESIGN CONTROL NUMBER: 04 4.9 RECORDS:

Page 8 of 8 QUALITY MANUAL ISSUE LEVEL - Rev. 0 DATE:

4.9.1 The Technical Coordinator shall establish and maintain a Project Design File, for each assigned project. This shall include the following: a) Customer Contract / Specifications b) Project Design Plan c) Master Drawing List and Status d) Design Review Meeting/Verification Minutes e) Validations f) Deviations g) Incoming and outgoing correspondences h) Original Calculations and Shop Drawings 4.9.2 Collect and Index the above document where applicable to ensure ease of retrieval. 4.9.3 Control the issuance of drawings/specifications to affected personnel. 4.9.4 Retain all records associated with this procedure for a period of two (2) years.

S-ar putea să vă placă și

- Value Of Work Done A Complete Guide - 2020 EditionDe la EverandValue Of Work Done A Complete Guide - 2020 EditionÎncă nu există evaluări

- M160-6 Design Control ProcedureDocument20 paginiM160-6 Design Control ProcedureBrewer HouseÎncă nu există evaluări

- 204-05 - Design ControlDocument18 pagini204-05 - Design ControlYusufÎncă nu există evaluări

- Documents Distributing Matrix For Management TrainingDocument1 paginăDocuments Distributing Matrix For Management TrainingMasoud MirshekarÎncă nu există evaluări

- 2082-PM-CQP-7011 Rev.0 - Constructin Quality PlanDocument22 pagini2082-PM-CQP-7011 Rev.0 - Constructin Quality PlanAmarKumarÎncă nu există evaluări

- Ed0016 Design Change Management DCN and VerianceDocument8 paginiEd0016 Design Change Management DCN and Verianceshiviitd02100% (1)

- CM-MA-119 Procedure For Document ControlDocument8 paginiCM-MA-119 Procedure For Document ControlIgnacio Luis Reig MataixÎncă nu există evaluări

- Qms Guidelines Appendix A 0Document3 paginiQms Guidelines Appendix A 0BranErikÎncă nu există evaluări

- E-M00006-00-Q-QCP-100 Rev.0 - IFU Project Quality PlanDocument26 paginiE-M00006-00-Q-QCP-100 Rev.0 - IFU Project Quality Planmahesh100% (1)

- VECO-QM-PRO-0001 Project Quality Audit Procedure, Rev. 0Document10 paginiVECO-QM-PRO-0001 Project Quality Audit Procedure, Rev. 0hymerchmidtÎncă nu există evaluări

- 6 1 Engineering Quality PlanDocument35 pagini6 1 Engineering Quality PlanRangga Adi PutraÎncă nu există evaluări

- 216-05 - Control of Quality RecordsDocument8 pagini216-05 - Control of Quality RecordsYusufÎncă nu există evaluări

- Design ControlDocument16 paginiDesign ControlYusufÎncă nu există evaluări

- PR-1159 - Commissioning and Start-UpDocument116 paginiPR-1159 - Commissioning and Start-Upvegasl001Încă nu există evaluări

- Og&C Standard Work Process Procedure Welding ProgramDocument15 paginiOg&C Standard Work Process Procedure Welding ProgramGordon LongforganÎncă nu există evaluări

- Supplier Audits and SurveysDocument13 paginiSupplier Audits and SurveysBighneswar PatraÎncă nu există evaluări

- Vendor Qualification ProcDocument3 paginiVendor Qualification ProcSa Ra100% (1)

- 15need of SOP in Building Construction Managemenmanagementt PDFDocument4 pagini15need of SOP in Building Construction Managemenmanagementt PDFJannatul FirdousÎncă nu există evaluări

- SC Project Closeout Report v6Document27 paginiSC Project Closeout Report v6SateeshIngoleÎncă nu există evaluări

- PEP Equinox PDFDocument66 paginiPEP Equinox PDFnizardsouissiÎncă nu există evaluări

- S-000-5138-302 - B Design Change Procedure PDFDocument6 paginiS-000-5138-302 - B Design Change Procedure PDFMahadevan MahalingamÎncă nu există evaluări

- Project Deliverables TrackingDocument5 paginiProject Deliverables Trackingmoytabura96Încă nu există evaluări

- QMS-03 Rev 1 Procedure For Design ControlDocument22 paginiQMS-03 Rev 1 Procedure For Design ControlbanglvhÎncă nu există evaluări

- Qatar Petrolum Qsp-Qac-09Document40 paginiQatar Petrolum Qsp-Qac-09Victor SimionÎncă nu există evaluări

- K101-QC-PL.001 - Quality Plan - Rev 0 PDFDocument85 paginiK101-QC-PL.001 - Quality Plan - Rev 0 PDFberthitasÎncă nu există evaluări

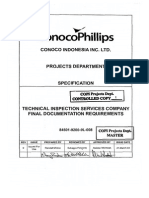

- 84501-9200-9L-008 Rev-0 Technical Inspection Services Company Final Documentation RequirementsDocument7 pagini84501-9200-9L-008 Rev-0 Technical Inspection Services Company Final Documentation RequirementsPeni M. SaptoargoÎncă nu există evaluări

- Quality Audit Plan EniDocument16 paginiQuality Audit Plan EniNaveed Ahmed Get-InfoÎncă nu există evaluări

- Project Standard and Specifications Project Control Procedure Rev01 WebDocument5 paginiProject Standard and Specifications Project Control Procedure Rev01 WebVũ Giang100% (1)

- Design Control Procedure 2014.02.12Document20 paginiDesign Control Procedure 2014.02.12Lai HuynhÎncă nu există evaluări

- Quality Management Plan Jan12 RevisionDocument11 paginiQuality Management Plan Jan12 RevisionLau Meng YongÎncă nu există evaluări

- MOS Commisioning AreaDocument6 paginiMOS Commisioning Areaharun yucelÎncă nu există evaluări

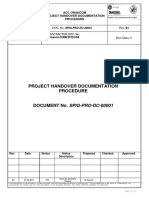

- Acc Orascom Project Handover DocumentatiDocument28 paginiAcc Orascom Project Handover Documentatimsb_75100% (1)

- QA Programme Rev.3, TERFDocument46 paginiQA Programme Rev.3, TERFUmesh Mishra100% (1)

- Project Quality Plan FormatDocument6 paginiProject Quality Plan FormatNABEEL ABDUL GAFFARÎncă nu există evaluări

- Engineering Document Control ProcedureDocument10 paginiEngineering Document Control ProceduretulaskarÎncă nu există evaluări

- Sample MRB Index For ENIDocument1 paginăSample MRB Index For ENIAnanthu Krishnan100% (1)

- Section 5 GposDocument21 paginiSection 5 GposDangolÎncă nu există evaluări

- MOC2145672 FormDocument7 paginiMOC2145672 FormPersonal GmailÎncă nu există evaluări

- CCFM U 00 TP430 010 R5 Field QC ProcedureDocument258 paginiCCFM U 00 TP430 010 R5 Field QC ProcedureCARLOS OLIVEROSÎncă nu există evaluări

- TMS - Specialties Div.: Document Master ListDocument43 paginiTMS - Specialties Div.: Document Master Listnice guyÎncă nu există evaluări

- QC Inspection and Test PlanDocument9 paginiQC Inspection and Test PlanAjaz MalikÎncă nu există evaluări

- Saudi Aramco Test ReportDocument5 paginiSaudi Aramco Test ReportzhangÎncă nu există evaluări

- Document Control PlanDocument6 paginiDocument Control PlanBatmanÎncă nu există evaluări

- Qualtiy Plan 1. Quality Objectives & Policies 1.1 Quality ObjectivesDocument7 paginiQualtiy Plan 1. Quality Objectives & Policies 1.1 Quality ObjectivesRHOWELLE TIBAYÎncă nu există evaluări

- MAI 07 - Control of Insp Measuring and Testing Equipment - DJ - v1Document9 paginiMAI 07 - Control of Insp Measuring and Testing Equipment - DJ - v1IT Support - FernanÎncă nu există evaluări

- NCT-SCN-000-E06-00002 - A01 - Site Query Deviation Concession RequestDocument1 paginăNCT-SCN-000-E06-00002 - A01 - Site Query Deviation Concession RequestCharles KingÎncă nu există evaluări

- Project Design Manual As Per Jan 06 2010Document39 paginiProject Design Manual As Per Jan 06 2010Abi PascuaÎncă nu există evaluări

- SOP-RD-7.1-001 Advanced Product Quality PlanningDocument13 paginiSOP-RD-7.1-001 Advanced Product Quality PlanningXionÎncă nu există evaluări

- Quality Record Procedure Rev-JDocument4 paginiQuality Record Procedure Rev-JherminÎncă nu există evaluări

- Sibp Gep Design PlanningDocument8 paginiSibp Gep Design PlanningEnrique PomalesÎncă nu există evaluări

- 001-Pro Document and Data ControlDocument25 pagini001-Pro Document and Data ControlKöksal PatanÎncă nu există evaluări

- SS-000-15200-0101 - 03 Quality Control Requirements To VendorDocument35 paginiSS-000-15200-0101 - 03 Quality Control Requirements To VendorNima SharifiÎncă nu există evaluări

- Engineering Process Change Order FormDocument12 paginiEngineering Process Change Order FormBernathTurnip100% (1)

- Bagging and Tagging ProcedureDocument21 paginiBagging and Tagging ProcedureKingsley EtimÎncă nu există evaluări

- Project Management Project MatrixDocument2 paginiProject Management Project MatrixBruno CannasÎncă nu există evaluări

- Document Numbering Procedure 20-10-14Document7 paginiDocument Numbering Procedure 20-10-14MohamedÎncă nu există evaluări

- Contrat Jesa 4582K/12: Annex N Quality RequirementsDocument33 paginiContrat Jesa 4582K/12: Annex N Quality RequirementsoundilahmedÎncă nu există evaluări

- QAP 19 - Design ControlDocument5 paginiQAP 19 - Design Controlrajatchib1296Încă nu există evaluări

- Procedure For Design andDocument4 paginiProcedure For Design andSharif KhanÎncă nu există evaluări

- Procedure For Certification of Design PersonnelDocument6 paginiProcedure For Certification of Design PersonnelSantosh LatakeÎncă nu există evaluări

- Complete Manufacturing PlaybookDocument38 paginiComplete Manufacturing PlaybookJOHNKÎncă nu există evaluări

- TBSMStatus ReportDocument7 paginiTBSMStatus ReportJOHNKÎncă nu există evaluări

- TBSMStakeholder RegisterDocument3 paginiTBSMStakeholder RegisterJOHNKÎncă nu există evaluări

- TBSMScope StatementDocument10 paginiTBSMScope StatementJOHNKÎncă nu există evaluări

- ORK Reakdown Tructure: (Agency Name) (Project Name)Document13 paginiORK Reakdown Tructure: (Agency Name) (Project Name)Jack 123Încă nu există evaluări

- TBSMStatementof WorkDocument10 paginiTBSMStatementof WorkJOHNKÎncă nu există evaluări

- 2015.08.20 ESWET Answer Circular Economy ConsultationDocument6 pagini2015.08.20 ESWET Answer Circular Economy ConsultationJOHNKÎncă nu există evaluări

- Serenergy Introduction Methanol Institute - July 15th 1 1Document14 paginiSerenergy Introduction Methanol Institute - July 15th 1 1JOHNKÎncă nu există evaluări

- Complete Transportation PlaybookDocument31 paginiComplete Transportation PlaybookJOHNKÎncă nu există evaluări

- Filborna - Helsingborg - SwedenDocument2 paginiFilborna - Helsingborg - SwedenJOHNKÎncă nu există evaluări

- Techno Economic Assessment of Municipal Solid Waste Incineration Plant Case Study of Tehran Iran 1Document5 paginiTechno Economic Assessment of Municipal Solid Waste Incineration Plant Case Study of Tehran Iran 1JOHNKÎncă nu există evaluări

- Design Calculations PDFDocument43 paginiDesign Calculations PDFJOHNKÎncă nu există evaluări

- Methanol To H2 Fuel Cell MobilityDocument26 paginiMethanol To H2 Fuel Cell MobilityJOHNKÎncă nu există evaluări

- AffaldPlus - Naestved - DenmarkDocument4 paginiAffaldPlus - Naestved - DenmarkJOHNKÎncă nu există evaluări

- A Step-By-step Process To Build Valued BrandsDocument12 paginiA Step-By-step Process To Build Valued BrandsSyed AndrabiÎncă nu există evaluări

- 2015.08.20 ESWET Answer Circular Economy ConsultationDocument2 pagini2015.08.20 ESWET Answer Circular Economy ConsultationJOHNKÎncă nu există evaluări

- CN-NL Bioenergy WS 8 May 2013 (Waste Incineration Amsterdam Peter Simoes AEB)Document22 paginiCN-NL Bioenergy WS 8 May 2013 (Waste Incineration Amsterdam Peter Simoes AEB)JOHNKÎncă nu există evaluări

- Energy Performance Contacts and GuaranteesDocument20 paginiEnergy Performance Contacts and GuaranteesR. Mega MahmudiaÎncă nu există evaluări

- Enviroemntal Oil and Gas Project Management PDFDocument76 paginiEnviroemntal Oil and Gas Project Management PDFOrtiz CatalinaÎncă nu există evaluări

- 2015.08.20 ESWET Answer Circular Economy ConsultationDocument2 pagini2015.08.20 ESWET Answer Circular Economy ConsultationJOHNKÎncă nu există evaluări

- Guide To Creating A BrandDocument7 paginiGuide To Creating A BrandJOHNKÎncă nu există evaluări

- PIpe LIneDocument18 paginiPIpe LIneDxtr MedinaÎncă nu există evaluări

- Business Letter of RecommendationDocument2 paginiBusiness Letter of RecommendationJOHNKÎncă nu există evaluări

- CN-NL Bioenergy WS 8 May 2013 (Waste Incineration Amsterdam Peter Simoes AEB)Document22 paginiCN-NL Bioenergy WS 8 May 2013 (Waste Incineration Amsterdam Peter Simoes AEB)JOHNKÎncă nu există evaluări

- 2006tf Rubin, Group Against Smog & Poll (C)Document29 pagini2006tf Rubin, Group Against Smog & Poll (C)Max Yee Min JueyÎncă nu există evaluări

- Weight - Xls 0Document8 paginiWeight - Xls 0JOHNKÎncă nu există evaluări

- Production ProcessDocument2 paginiProduction ProcessJOHNKÎncă nu există evaluări

- Machines Details: S.No. Make M/C # Function CapacityDocument2 paginiMachines Details: S.No. Make M/C # Function CapacityJOHNKÎncă nu există evaluări

- Schedule 9141Document1 paginăSchedule 9141JOHNKÎncă nu există evaluări

- Silo ProcedureDocument1 paginăSilo ProcedureJOHNKÎncă nu există evaluări

- CE162P MODULE 2 LECTURE 4 Analysis & Design of Mat FoundationDocument32 paginiCE162P MODULE 2 LECTURE 4 Analysis & Design of Mat FoundationPROSPEROUS LUCKILYÎncă nu există evaluări

- Logistic RegressionDocument7 paginiLogistic RegressionShashank JainÎncă nu există evaluări

- 5.0008786 Aluminum GrapheneDocument11 pagini5.0008786 Aluminum GrapheneBensinghdhasÎncă nu există evaluări

- IJRHAL - Exploring The Journey of Steel Authority of India (SAIL) As A Maharatna CompanyDocument12 paginiIJRHAL - Exploring The Journey of Steel Authority of India (SAIL) As A Maharatna CompanyImpact JournalsÎncă nu există evaluări

- Applications of Wireless Sensor Networks: An Up-to-Date SurveyDocument24 paginiApplications of Wireless Sensor Networks: An Up-to-Date SurveyFranco Di NataleÎncă nu există evaluări

- 12 Step Worksheet With QuestionsDocument26 pagini12 Step Worksheet With QuestionsKristinDaigleÎncă nu există evaluări

- Community Profile and Baseline DataDocument7 paginiCommunity Profile and Baseline DataEJ RaveloÎncă nu există evaluări

- Strategic Management SlidesDocument150 paginiStrategic Management SlidesIqra BilalÎncă nu există evaluări

- Data SheetDocument56 paginiData SheetfaycelÎncă nu există evaluări

- Peter Szekeres-Solutions To Problems of A Course in Modern Mathematical Physics - Groups, Hilbert Space and Differential Geometry PDFDocument382 paginiPeter Szekeres-Solutions To Problems of A Course in Modern Mathematical Physics - Groups, Hilbert Space and Differential Geometry PDFMed Chouaybi0% (1)

- TTDM - JithinDocument24 paginiTTDM - JithinAditya jainÎncă nu există evaluări

- Electronic Diversity Visa ProgrambDocument1 paginăElectronic Diversity Visa Programbsamkimari5Încă nu există evaluări

- Spanish Greeting Card Lesson PlanDocument5 paginiSpanish Greeting Card Lesson Planrobert_gentil4528Încă nu există evaluări

- How To Install Metal LathDocument2 paginiHow To Install Metal LathKfir BenishtiÎncă nu există evaluări

- Department of Education: Consolidated Data On Learners' Grade Per QuarterDocument4 paginiDepartment of Education: Consolidated Data On Learners' Grade Per QuarterUsagi HamadaÎncă nu există evaluări

- Structural Design Basis ReportDocument31 paginiStructural Design Basis ReportRajaram100% (1)

- 28 TerminalsDocument42 pagini28 TerminalsAlin FazacasÎncă nu există evaluări

- 7 - Monte-Carlo-Simulation With XL STAT - English GuidelineDocument8 pagini7 - Monte-Carlo-Simulation With XL STAT - English GuidelineGauravShelkeÎncă nu există evaluări

- Documentation Report On School's Direction SettingDocument24 paginiDocumentation Report On School's Direction SettingSheila May FielÎncă nu există evaluări

- Moral GPS: A Positive Ethic For Our Multicultural WorldDocument279 paginiMoral GPS: A Positive Ethic For Our Multicultural WorldLeonard Bowman75% (4)

- SDS ERSA Rev 0Document156 paginiSDS ERSA Rev 0EdgarVelosoCastroÎncă nu există evaluări

- بتول ماجد سعيد (تقرير السيطرة على تلوث الهواء)Document5 paginiبتول ماجد سعيد (تقرير السيطرة على تلوث الهواء)Batool MagedÎncă nu există evaluări

- Audi A4-7Document532 paginiAudi A4-7Anonymous QRVqOsa5Încă nu există evaluări

- A Project Report ON Strategic Purchasing Procedure, Systems and Policies (Hospital Industry)Document20 paginiA Project Report ON Strategic Purchasing Procedure, Systems and Policies (Hospital Industry)amitwin1983Încă nu există evaluări

- A Short Survey On Memory Based RLDocument18 paginiA Short Survey On Memory Based RLcnt dvsÎncă nu există evaluări

- Philo Q2 Lesson 5Document4 paginiPhilo Q2 Lesson 5Julliana Patrice Angeles STEM 11 RUBYÎncă nu există evaluări

- MPI Unit 4Document155 paginiMPI Unit 4Dishant RathiÎncă nu există evaluări

- Atomberg Gorilla FanDocument12 paginiAtomberg Gorilla FanjothamÎncă nu există evaluări

- TM Mic Opmaint EngDocument186 paginiTM Mic Opmaint Engkisedi2001100% (2)

- AYUMJADocument1 paginăAYUMJASoumet Das SoumetÎncă nu există evaluări