Documente Academic

Documente Profesional

Documente Cultură

Marine Piping System

Încărcat de

safutra90%(10)90% au considerat acest document util (10 voturi)

2K vizualizări130 paginiDrepturi de autor

© Attribution Non-Commercial (BY-NC)

Formate disponibile

PDF sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Attribution Non-Commercial (BY-NC)

Formate disponibile

Descărcați ca PDF sau citiți online pe Scribd

90%(10)90% au considerat acest document util (10 voturi)

2K vizualizări130 paginiMarine Piping System

Încărcat de

safutraDrepturi de autor:

Attribution Non-Commercial (BY-NC)

Formate disponibile

Descărcați ca PDF sau citiți online pe Scribd

Sunteți pe pagina 1din 130

Training Manual

Mechanical Division

School of Engineering

NGEE ANN POLYTECHNIC

conrents

1 toon

TL Consetaon Engine room Layout

12 Gasitean Socks Stator dies and Cove for Piping

12.1 Clasieaton cece

122 Stat bdr

123 Coe

1. The Role of Chasteaon Soin, Stitory Boies and Ces Msi sad

Manufacture o Piping Syste

2.Pipeand Symbols 6

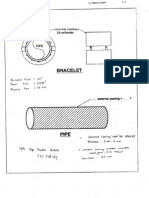

21 Pipe 5

22 Symbols B

23 Antevinions

5. Pipe Materials 6

4 angs is

Flanges @

42 ellos 2

453 Reduces 2

ates B

453 Unione a

1 Bxpesione »

407 Poneration eos 6

43 Omer Figs »

49 Suppors 3

1 Gate Vales

52.Glabe Vale

53 Check Vale

54 Butery Valve

53 Ball Vahe

SP Valve

57 Diapieagn Valve

SiPresure Rei Vane

59 Suction Valve

510 Foot Valve

5:11 Operators nd Actors of Valve

512 Staines

‘St Mad box

5122 Bask stinee

5123 Autclen ssiner

5.124 Magnet ier

S13 Vale alton

6.Baupment

“61 Pumps and Pring Stems

"3 led fo pars

612 Respcting pny

613 Rotary pumps

614 Rotor dame pps

6.15 Chnractesies of eign! pump

Introduction

Piping systems cary Muids from one point to another. The fuds may be corrosive,

erosive, amiable o¢ benign. Pressoe and temperstre-may be high or low

ecanse of the varying notre of the Function, the requirements from the ship

construction, the ature and arrangement of the machinery and ropulations of

cetilying autores, piping systems may bucome complex and may require

‘arc offitings & materials.

An efficient piping system is esenil tothe safety and comtect operation of ships

and offshore srvetores,

[Compared to the total weight of all teclwork, the weight of piping syst is

‘smal. But fabication & installation of piping system involves sobstantil amount

fof job. Because of the complicated routes & interference with other installations,

‘improper fabrication and installation of piping system cin lead 10 high cost of

production and delay in delivery. Hence the people involved in fabrication and

Installation of piping sysioms need to have proper understanding ofthe various

aspects of piping systems, No doutt, for development of thorough understanding

ofthe proctical aspects, nothing can beat capesienue: Bute gual knee ane

Sart can take a long way towards achieving the objective of thorough

lundrstanding ofthe various aspects of piping system.

‘This manual atemprs to introduce varios aspects of piping systems in an “easy to

vnderstand” wy,

LL Considerations of Engine Room layout

‘When we arrange pipes in engine rom or other places, the followings should be

considered,

1) Optimize the available space

+= Could increase eargo carrying capacity

‘osu: Increase eargo payload

2) Grouping related components together

+ Minrnze pipes and cable runs

= Reduce operating power loss

Reauce operators movement

Result: Reduce construction and operating costs

3) Maintenance

Provide sutficent clearances for earying out msintenance

- Provide clear wansfer passages

+ Provide access fr lifting by hang wolley beams and overad eranes

Result: Reduce maintenance downtime and cost

S-ar putea să vă placă și

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Demolition Work-V1Document39 paginiDemolition Work-V1safutraÎncă nu există evaluări

- Demolition E2004 (HK)Document180 paginiDemolition E2004 (HK)Daniel YongÎncă nu există evaluări

- Assetintegrityassessmentfpsopresadsapacomae0716rev0 160719030741Document37 paginiAssetintegrityassessmentfpsopresadsapacomae0716rev0 160719030741safutraÎncă nu există evaluări

- Demolition Method Statement PDFDocument33 paginiDemolition Method Statement PDFsafutra100% (1)

- Pipelineintegritydocumentation 151210183202Document75 paginiPipelineintegritydocumentation 151210183202safutraÎncă nu există evaluări

- Cathodic ProtectionDocument1 paginăCathodic ProtectionsafutraÎncă nu există evaluări

- Orca FlexDocument402 paginiOrca FlexThangiPandian1985Încă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)