Documente Academic

Documente Profesional

Documente Cultură

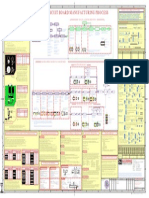

INF 2887378 PCB Fab Wallchart

Încărcat de

noman888Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

INF 2887378 PCB Fab Wallchart

Încărcat de

noman888Drepturi de autor:

Formate disponibile

1

10

11

12

DESIGN INFORMATION

LAND SIZE

PRINTED CIRCUIT BOARD MANUFACTURING PROCESS

CUSTOMER

DESIGN AND FABRICATION TABLE

MANUFACTURING DRAWINGS SHOULD INCLUDE A DESIGN AND FABRICATION TABLE AS SHOWN BELOW. THE DRAWING SHALL CONTAIN DIMENSIONS REFERENCING NPTH AND PTH HOLES TO AN ORIGIN OR DATUM. FOR FULL DETAILS ON DIMENSIONING AND TOLERANCING OF PRINTED BOARDS REFER IPC-D-300G.

Copies of this table are available from Morris Productions in a DXF file or Protel formats.

TRACK TO PAD

HOLE SIZE

MULTI- LAYER BOARDS ONLY

ELECTRICAL TEST

ACCOUNTS SUPPLIERS STORE MATERIAL ISSUE - EG. BURIED VIAS

TRACK WIDTH

PAD TO PAD

PREFERRED INPUTS NEEDED

NPTH

DESIGN INFORMATION

BOARD TECHNOLOGY : BOARD SIZE : X

LAY-UP

- GERBER FILES

TRACK TO TRACK

- PROTEL PCB FILE

TRACK TO BOARD EDGE TRACK TO NPTH

(mm)

- 1:1 PHOTOPLOTS

IMAGE

ETCH INNER LAYER(S)

- REMOVE UNWANTED COPPER - INSPECT ( Q.C)

STRIP DRY FILM INNER LAYER(S)

- REMOVE PHOTO RESIST - VISUAL INSPECTION

PRESSING PREPARATION

- BLACK OXIDE (IMPROVES ADHESION AT BONDING STAGE) - CONDITION ( REMOVE MOISTURE)

EXTERNAL SIGNAL LAYERS FEATURE

* PTH - LAND SIZE * NPTH - LAND SIZE TRACK WIDTH TRK/PAD TO PAD/TRK TRK TO EDGE (min) ** TRK TO NPTH (min) **

INTERNAL SIGNAL LAYERS

STANDARD

+0.50mm +0.70mm 0.20mm 0.20mm 0.53mm 0.53mm

SPECIAL

ON APPLICATION 0.125mm 0.125mm 0.53mm 0.53mm

FEATURE

* PTH - LAND SIZE

STANDARD

+0.50mm 0.20mm 0.20mm 0.50mm 0.50mm

SPECIAL

ON APPLICATION 0.125mm 0.125mm 0.50mm 0.50mm

- MANUFACTURING DRAWINGS SHOWING ALL DIMENSIONS & SPECIFICATIONS - DIMENSIONED OUTLINE DRAWING

ORDER ACCEPTANCE

MATERIALS PURCHASING

MATERIAL CUT

- SPECIFIED MATERIAL CUT TO REQUIRED FORMAT SIZE

INNER LAYER(S)

- LAMINATE DRY FILM (PHOTO SENSITIVE RESIST) - PUNCH REGISTRATION HOLES - IMAGE (EXPOSE WITH NEGATIVE PHOTOTOOL) - DEVELOP

(MIN. TRACKS/PADS/CLEARANCE IN 0.025mm (0.001")

- HIGH PRESSURE/ TEMPERATURE VACUUM CURING CYCLE - CONTROLLED COOLING CYCLE

(REFER ALSO PROFILING INFORMATION)

TRACK WIDTH TRK/PAD TO PAD/TRK TRK TO EDGE (min) ** TRK TO NPTH (min) **

PCB DESIGN

- NC DRILL AND ROUT FILES - TECHNICAL STANDARDS (DESIGN RULES USED)

ENGINEERING PLANNING

PRODUCTION TOOLING

- ALL LAYERS LAID TOGETHER, INTERLEAVED WITH PREPREG, MOULD RELEASE FILM AND PRESS PLATES.

(MINIMUM ANNULAR RING 0.05mm (0.002")

CIRCUIT TYPE :

SS

DS

PTH

ML

No. OFF _____ AS SHOWN

NORMALISE

FINGER CONNECTOR DIM PER :

No. OFF TOTAL

4 LAYER BOARD AS EXAMPLE 18um Foil

ONE SIDE TENTED MIXED

TWO SIDES

* Land-to-hole relationship is established by the following equation: Refer to IPC-2221 Section 9.0 - Holes/Interconnections. This standard is also endorsed as Military Standard. Land size, minimum = a + 2b +c where: a = Maximum diameter of the finished hole b = Minimum annular ring requirements ( see 9.1.2) ** Min. distance between conductive area and the edge of a board is calculated by adding 0.4mm to the minimum electrical clearance as determined in IPC-2221, IPC-2222. Table 6-1. For 0-100 Volts a spacing of 0.13mm is required for a PCB with external conductors. (Thus 0.4mm + 0.13mm = 0.53mm). For 0-100 Volts a spacing of 0.10mm is required for a PCB with internal conductors. (Thus 0.4mm + 0.1mm= 0.5mm). Lands for surface mounting are covered extensively in this Standard and IPC - SM - 782A, as well as the various recommendations laid down by component manufacturers.

- CHECK CUSTOMER DOCUMENTATION, DATA, GERBER FILES / ARTWORK SPECIFICATIONS - PERFORM DESIGN RULE CHECKS - STEP UP ARTWORK TO DESIRED FORMAT SIZE - PRODUCE DRILL AND ROUT FILES - PRODUCE ELECTRICAL TEST JIG FILES - PREPARE WORK INSTRUCTIONS

- CHECK REGISTRATION - ENSURE DRILL PATTERN ON TEST BOARD MATCHES ARTWORK - ADD VENTING, LOGOS CODING ETC. - PREPARE FINAL NC TOOLING FILES - ENSURE ARTWORK MEETS MANUFACTURING REQUIREMENTS - GENERATE PRODUCTION

- PROVIDES STRESS RELIEF AND AIDS DIMENSIONAL STABILITY

VIAS :

NONE

FEED THROUGH UNIQUE DRILL

BURIED LAYER SEQ ____________ BLIND LAYER SEQ ____________ AS SHOWN

PREPREG (0.35mm) PHOTO RESIST REMOVE UNWANTED COPPER FR4 SUBSTRATE (TYP. 0.71mm) PREPREG (0.35mm)

LAYER CONSTRUCTION PER :

LAMINATION SEQUENCE

PHOTO RESIST

BASE COPPER TYP. 18/35um

18um Foil FR4 SUBSTRATE (TYP. 0.71mm)

ARTWORK :

MANUAL

CAD

TYPE

TRACK

PAD

TRACK

PAD

TRACK

PAD

REFER TO MORRIS' STANDARD MULTI-LAYER COMBINATIONS FOR DETAILS ON TYPICAL LAYUPS USING MATERIALS COMMONLY HELD IN STOCK.

ARTWORK/PATTERN MASTER LIST

DESCRIPTION DRAWING No./CAD FILE REF. ISS ARTWORK/FILM REF GERBER FILE REF ISS

INTERNAL POWER AND GROUND LAYERS

GND AND PWR CLEARANCE PAD LAND SIZE

FEATURE

LAND SIZE * D<=3.0mm (Fin Hole D+) D>=3.0mm CLEAR. PAD *D<=3.0mm (Fin Hole D+) D>=3.0mm WEB (CONDUCTOR) * AIR GAP PWR/GND TO BRD EDGE ** PWR/GND TO NPTH **

STANDARD

+0.50mm +0.55mm +0.90mm +1.00mm 0.25mm 0.25mm 1.27mm 0.50mm

SPECIAL

ON APPLICATION " " " " " 0.50mm

AFTER PRESSING AND TRIMMING OF THE BOARD, THE MANUFACTURING PROCESS IS THE SAME AS FOR DOUBLE SIDED BOARDS.

AIR GAP

DOUBLE SIDED AND MULTI-LAYER BOARDS

REFLOW SOLDER PROCESS

NI/GOLD PLATE EDGE CONTACTS - LAB TEST

MATERIAL :

GLASS FIBRE EPOXY RESIN NEMA GRADE FR4 (IPC - 4101) OTHER THICKNESS : TOLERANCE : BOW AND TWIST : COPPER (FINISHED) : OUTER : INNER SIG :

CLEAN REFLOW SOLDER INSPECT SOLDER MASK

FIN HOLE SIZE (D)

WEB FIN HOLE SIZE (D)

C

2.4mm OTHER + / AS SHOWN 3.2mm

NPTH

LAND SIZE

AIR GAP

* For further details on land size calculations refer IPC -2221 IPC-2222. This standard is also endorsed as Military Standard. Typically, web size is determined by dividing 60% of the minimum land size by the number of webs required. If a larger land size is used, the web size is reduced to allow adequate soldering dwell time. (Ensure that the web size is not thinner than the minimum ** Min. distance between conductive area and the edge of a board is calculated by adding 0.4mm to the minimum electrical clearance as determined in IPC-2221, IPC-2222. Table 6-1. For 0-100 Volts a spacing of 0.1mm is required for a PCB with internal conductors. (Thus 0.4mm + 0.1mm = 0.5mm). However, for PWR/GND to board edge a clearance of 1.27mm is preferred. It is not necessary to have a land around a pin which does not make connection to anything on that plane. If a land is placed around a component lead, it increases the chance of a short occuring if a small slither of copper bridges the land and a plane

0.8mm

1.2mm

1.6mm

IN A/W IPC - D - 300G CLASS IN A/W IPC - D - 300G CLASS

PWR AND GND TO NPTH

STRIP SOLDER EDGE CONTACTS

18um 18um 18um

35um 35um 35um

70um 70um 70um

PWR/GND TO BOARD EDGE

INNER PWR :

STRUCTURE :

STANDARD 'MORRIS PRODUCTIONS' LAYUP AS PER DRAWING AS SHOWN

DRILLING :

PAD TO RESIST

VIEWED FROM :

COMPONENT SIDE AS SHOWN

WIRING SIDE PATTERN MASTER LIST 20um PADS REMOVED BOTH NC_DRILL FILES OTHER REMOVE PADS AS SHOWN REFER PATTERN MASTER LIST COMP. YELLOW

SOLD.

SOLDER RESIST

FEATURE

PAD TO RESIST:(LIQUID PHOTOIMAGEABLE) (EPOXY SCREEN PRINT) MASK TO MASK BLOCKOUT MASK TO MASK BLOCKOUT

ELECTRICAL TEST

ELECTROLESS NICKEL / IMMERSION GOLD PROCESS

STANDARD

0.05mm (min) 0.25mm 0.15mm DRILLING HOLE PREPARATION FIRST COPPER PLATE IMAGE SECOND PLATE STRIP DRY FILM ETCH SOLDER REMOVED

REFERENCE :

PTH MINIMUM COPPER THICKNESS : NPTH :

STRIP SOLDER INSPECT CLEAN SOLDER MASK ELECTROLESS NICKEL / IMMERSION GOLD NICKEL / GOLD SCREEN PRINT LEGEND PROFILING

TENTED 2nd DRILL

FINAL ACCEPTANCE TESTING

DESPATCH

BOARD FINISH :

LEGEND / SCREEN PRINT : COLOUR :

ETCHING NONE WHITE

VIA (TENTED) VIA (MASKED)

Vias which are to be tented &/or filled with resist must be specified in your documentation. Note also, vias which are to be tented (covered) with solder resist, must have a maximum finished hole size no greater than 0.6mm. A unique hole size should be used for these vias so that they can be identified during manufacture. Morris Productions uses solder resist that complies with MIL-I-46058 and meets the requirements of IPC-SM-840. Available in both liquid imageable and screen print, typical thickness is 15-20um and 20-25 um respectively. Photoimageable solder resists are preferred for surface mount applications. UL approved resists are also available. Typical colours available are green, green / yellow, and blue : other

- HIGH PRESSURE WATER RINSE - VISUAL CHECK - DESMEAR/ ETCHBACK

- CHEMICAL DEPOSITION OF COPPER TO ALL DRILLED HOLES - 1ST COPPER PLATE - LAB TEST

- LAMINATE DRY FILM (PHOTO SENSITIVE RESIST) - IMAGE (EXPOSE WITH POSITIVE PHOTOTOOL) - DEVELOP - INSPECT (Q.C)

- 2ND COPPER PLATE (BUILD UP COPPER TO FINAL THICKNESS) - TIN/LEAD PLATE - LAB TEST

- REMOVE PHOTO RESIST - VISUAL INSPECTION

- REMOVE UNWANTED COPPER (TIN/LEAD PROTECTS COPPER PATTERN)

- PHOTOIMAGEABLE SOLDER MASK

- Q.C

OTHER

SCREEN PRINT

- LAB TEST

SOLDER RESIST : COLOUR :

SOLDER RESIST

LIQUID PHOTOIMAGEABLE GREEN MATTE BLUE GLOSS YLW/GRN

OTHER

HOT AIR LEVEL (SMOBC) PROCESS

PHOTO RESIST AND UNWANTED COPPER REMOVED

TRACK FINISH :

SELECTIVE SOLDER

REFLOW TIN/LEAD

THICKNESS LINES AND TEXT

LEGEND

NPTH (LANDLESS OTHERWISE 2ND DRILLING)

DEPOSITION OF ELECTROLESS COPPER NOM. THK 2.0 um

PHOTO RESIST

ELECTROLESS Ni/Au - 0.1 / 0.2um GOLD OVER 3.0um NICKEL REFER PATTERN MASTER LIST

SCREEN PRINT LEGEND NI/GOLD PLATE EDGE CONTACTS - LAB TEST STRIP SOLDER EDGE CONTACTS LEGEND

OTHER

R1

TEXT HEIGHT

FEATURE

LINE THICKNESS TEXT THICKNESS TEXT HEIGHT LEGEND TO PAD LEGEND TO EDGE

MINIMUM

0.15mm 0.15mm 1.00mm 0.25mm 0.25mm STRIP SOLDER INSPECT CLEAN SOLDER MASK HOT AIR LEVEL

EDGE BOARD CONTACTS :

COPPER

1.3um HARD GOLD OVER 5.0um NICKEL HARD FINISH GOLD PLATE AS SHOWN OTHER REFER

LEGEND TO PAD

COMPONENT HOLE 0R VIA

DRY FILM TENTS(COVER) NPTH

TIN/LEAD OVER COPPER

- PHOTOIMAGEABLE SOLDER MASK

- SOLDER APPLIED TO BARE COPPER (PADS, VIAS ETC) - Q.C

PROFILING :

TIN/LEAD ELECTROLESS NICKEL / GOLD SELECTIVE SOLDER SOLDER RESIST PHOTO RESIST

AS DIMENSIONED , MEASURED AND CUT FROM SPECIFIED DATUM. REFER PCB BLANK DWG No.

Typical colours available are white, yellow and black ; and made

LEGEND TO BOARD EDGE

USE PROFILE/ROUT TAPE SUPPLIED REFER PATTERN MASTER LIST SQUARE CUT N.C. ROUT V- GROOVE BLANK

ARTWORK ALLOWANCES

CONDUCTOR WIDTH : - To obtain minimum design conductor width refer tables such as those in IPC - 2221, IPC-2222 for the relevant current ratings. To allow for processing effects such as pits, nicks, undercut etc, artwork track width should be drawn 0.05mm (0.002") wider for 35um (1oz) foil. CONDUCTOR SPACING : - Refer electrical conductor spacing table as published in IPC -2221, IPC-2222 . To ensure minimum spacing allow 0.05mm (0.002") on artworks with 35um (1oz) copper.

NOTES. 1: LAB TEST INCLUDES ALL TESTS THAT ARE REQUIRED TO PROVE PROCESS CAPABILITIES, BUT ALSO THOSE TESTS (SUCH AS MICROSECTIONS), AND DOCUMENTATION NEEDED TO MEET CUSTOMER REQUIREMENTS INCLUDING IPC CERTIFICATION LEVELS AND MILITARY SPECIFICATIONS. 2 : THE PROCESSES SHOWN IN THIS DIAGRAM ARE TYPICAL OF MOST PCB MANUFACTURERS. PLEASE CHECK WITH YOUR MANUFACTURER WITH REGARD TO SPECIAL REQUIREMENTS.

SOLDER REMOVED

- LAB TEST

ACCEPTABILITY :

MATERIALS AND WORKMANSHIP FOR ALL PRINTED WIRING BOARDS MUST MEET OR EXCEED THE REQUIREMENTS OF : IPC - 6011, IPC - 6012 CLASS

SOLDER RESIST

U.L CERTIFICATION MIL -P- 55110D ADDITIONAL REQUIREMENTS : OTHER __________________

F mm

RECOMMENDED MULTILAYER LAYUP COMBINATIONS

Morris Productions produce PCB'S to 24 layers . Unless there is a need to specify certain dielectric separations(eg. Controlled Impedence), the thickness of core material or quantity of prepreg used between each successive conductive layer is best left to the manufacturer. Most boards should have a minimum of 0.09mm separation between conductive layers. The layup should be kept balanced i.e. the distribution of layers, copper thickness, and layer separations shou ld be symmetrical to prevent warping, however some designs require large copper areas on the outside layers. Ensure these areas are cross- hatched to reduce the possibility of blistering or warping in the soldering process. Listed below are Morris' most common multilayer layups using materials generally kept in stock. Other layups are available on request. These layups are for 1.6mm nominal thickness. For thicker or thinner PCB's, please contact our Sales Engineer or PCB Designer. Foil lamination uses a 0.05mm maximum thickness resin backed foil.

ARTWORK REQUIREMENTS

Artwork Design Rules To aid our Pre-production Engineers the designer should ensure that the following is adhered to : - separate file per artwork and layer sequence is specified.. - Gerber files, aperture file & drill file formats eg.2,4 inch format or 3,3 metric - Gerber 274X (Embedded Apertures) preferred - Gerber files are registered to one another ( has the same offset). - files should be viewed from the "component side " (primary side). - use design standards (such as IPC-2221, IPC-2222) and adequate allowances for processing. - each corner should have corner delineation marks. - NPTH less than 6.5mm dia should have pads removed to allow tenting of the hole during processing. - ensure that legend markings are 0.25mm (0.010") from lands and/or holes. - if you require gold edge connectors add a plating bar 5mm away from the fingers and extend the length of the connector. The thickness of the bar and connections to the fingers to be 0.5mm (0.020"). - to aid in routing, at least two(2) diagonally opposite NPTH holes should be provided at the board extremities, the diameter of which should be between 2.5 - 6.0mm. Preferred size is 3.175mm (1/8").

DRILLING, ROUTING & V-GROOVE

Drill Design Rules - finished hole size should be specified rather than drill size - via hole size typically fall in the range of 0.3 to 0.7mm( via holes < 0.2mm should be avoided to ensure hole integrity) - if via hole size is < 0.2mm then land size should equal 0.5mm - aspect ratio should not exceed 1:8 ie. finished hole size divided by board thickness (Refer IPC - 2221, IPC - 2222) - preferred format for drill files is ASCII 2,4 inch leading zero's but will accept other formats (please specify) - separate drill fil es for Plated and Non-plated holes - number of different drill sizes should be minimised, but there are no limits on the number of drill changes Tenting (NPTH) It is common for PCB's to have a mix of Plated(PTH) and Non-plated holes(NPTH). To aid in the positional tolerance of PTH to NPTH, drilling can be done in one operation. It is then necessary to tent (cover) the NPTH with photosensitive film during processing. There must be sufficient surface area around the NPTH for the tent to hold so it is important to have no land around the hole nor should there be any copper pattern within 2 x the diameter of the hole. Maximum hole size for tenti ng NPTH is 4.5mm. If these design rules are not met, 2nd drilling will be necessary . Rout Design Rules Certifications

QUALITY ASSURANCE

Morris Productions has a committment to Quality. As a means of continuous improvement in our manufacturing and technical capibilities Morris has gained the following certifications: Quality Management Systems - AS/NZS ISO9001: 1994 (Certified by LRQA) Scope - "Design and Manufacture of single, double sided and multilayer printed circuit boards". Certification Number : 926131 Laboratory (N.A.T.A certified) Registration Number : 365 Underwriters Laboratories UL approval to MP194V-0 and MP-2

DESIGN SERVICE

Morris Productions offer our customers a PCB design service. The service provides a number of facilities dependent on your requirements : ** Schematic Capture and laser plots ** Bill of Materials ** Board Layout (From Schematic or Netlist) - Photoplots - Checkplots - Photoplot Files - Drill Files - Shape Based Routing ** Manufacturing Drawings ** Arrangement of Production ** Design advice ** Up to date information on current trends in manufacturing and specifications ** Extract gerber files from Protel generated PCB files and amend

MICROSECTION : CERTIFICATION : NONE

NONE

SAMPLE PLAN IPC CLASS

MIL - P - 55110D

MIL - P - 55110D

QUALITY RELEASE REPORT ELEC. TEST : NONE REQUIRED FOIL

OTHER __________________ PER ORDER LEGEND AS/NZS ISO 9001 REFER ______

MANUFACTURER'S LOGO : MANUFACTURER'S CERTIFICATION : PACKAGING AND HANDLING :

OTHER __________ NONE

PER ORDER

REFER ______

HOLE DATA

SYMBOL SIZE (FIN) TYPE QUANTITY HOLE SIZE NPTH HOLES

+ / - 0.03 + / - 0.05 + / - 0.08

4 LAYER BOARD Foil Lamination (Preferred)

* SHEETS PREPREG CORE THK(mm)

Cu (um) PER SIDE

8 LAYER BOARD Conventional Build

* SHEETS PREPREG CORE THK(mm)

Cu (um) PER SIDE

Foil Lamination (Preferred)

* SHEETS PREPREG CORE THK(mm) Cu (um) PER SIDE

Conventional Build

SHEETS PREPREG CORE THK(mm) Cu (um) PER SIDE

Conformance Testing Morris can provide customers with a range of Quality Assurance Certifications dependent on need. Certificates of Conformance can be attained to customer's own specification, IPC-6011, IPC -6012 or Military Standards such as MIL-P-55110D. Microsectioning is the means by which Quality Assurance can be tested but requires the destruction of a good board. Rather than destroying a good board, Test Coupons (refer IPC-2221, IPC -2222 Section 12.4.3.1) positioned alongside and/or between pairs ( or as a "popout" within the board outline) will exhibit all the basic qualities of the production board. Tests and Inspections that can be carried out are as follows:VISUAL General Appearance Cleanliness Plating Appearance Etched line widths and Spacings. MICROSECTION Plating Thickness Plating Quality Interconnection hole/inner layer Hole Quality Annular Ring (internal) Layer Registration Copper thickness (inner) Dielectric Separations Pre-production Integrity Checks Board Integrity following We recommend customers approve production tooling generated from their own information. This may reveal errors in design, manufacturability or potential design improvements. For large production runs, we also recommend that pre-production samples be obtained. Both Morris and our customers are then assured of the boards suitability for manufacture, and can see at first hand the quality expected. If either option is not requested the customer must accept responsibility for errors due to incorrect data supplied. Handling & Storage of PCB's Aging and storage of your PCB's impacts upon solderability and flatness therefore the following general guidelines should be applied: - clean, tidy environment, - avoid allowing the board to come into contact with silicones (hand creams, etc), sulphur -containing material which may degrade solderability. - avoid abrasive materials,moisture and handling edge contacts. - boards should be left in sealed and dessicated bags - should be stoved flat for a min. 6 hrs at 115 - 120 deg C in an air circulating oven immediately prior to assembly to remove moisture wicking (ingress of moisture absorbed by epoxy glass at board edge). Failure to perform this function and applying rapid heating (eg. hand soldering) can result in localised separation of the inner layer surfaces(delamination).. Specific inspection, acceptability, packaging and handling methods are detailed in IPC-2221, PHYSICAL Plating adhesion Conductor Peel Strength Solderability Thermal Stress (solder float test) ELECTRICAL Continuity Current Carrying Capacity Co-Planer and layer to layer insulation. Dielectric withstanding voltage test to IPC -6011, IPC-6012 class 3 (1 KV DC for 30

Foil Foil

2xB

18/00 .25 35/35 35/35

18/00 2xA

.25

18/00

2xA

.18

2xA

.25 35/35

G

2xB

.71

35/35 2xA

.50

35/35

1xB .18 35/35 2xA

Foil

18/00

.25

18/00 1xB

.18 35/35 18/00

.25

35/35

Note - phototools and their condition are vital to PCB manufacture. For example, the maximum layer to layer misregistration of pattern features should not exceed 0.003" (0.075mm) at full size. In this way Morris Pre-production engineers can perform a comprehensive design rule check, step and repeat artwork to a standard format size, add venting (to aid in the flow of prepreg for multilayer boards, and to give mechanical strength and stability) and most importantly, ensure the accuracy and stability of the diazo's (phototools) used in manufacture.

- the smallest rout bit diameter should be equal to or greater than the board thickness - rout bit tolerance(+/-0.1mm) should be taken into consideration when determining finished board size especially panelised boards - if panelised then breakout point positioning and number must taken into consideration to aid in the mechanical strength of the PCB. Typically the distance between breakouts is 50 - 80 mm. Refer to drawing below. - preferred router bit size is 2.0mm Morris stocks a full range of both drill and router bits. Stock drill bit sizes range from : 0.35 to 3.20mm in 0.05 increments and 3.30 to 6.5mm in 0.10 increments. Stock rout bit sizes range from : 0.8, 1.0, 1.2, 1.5, 1.6, 1.8, 2.0, 2.4, 3.0 & 3.175mm.Other sizes available on request. Holes greater than 6.50mm are either stitched drilled, hand machined or routed, and preferably nonplated. Typical routing breakout methods 2.4mm +/- 0.1mm TYP ROUTER DIA

2.5 +/- 0.2mm 0.5 +/- 0.1mm 5.0 +/- 0.2mm

PTH HOLES

+ / - 0.05 + / - 0.05 + / - 0.10

SOLDER PASTE STENCILS

Quality, service and fast turn around have made us leaders in the Australian Market for Chemically milled Solder Paste and Glue Stencils. These are available with a shim thickness range of 0.010", .008" , .006", .005" and .004". . It is strongly recommended that you contact your printed circuit board assembler to determine the desired aperture size opening, fiducial marks, mounting position and the thickness of the stencil. Morris prefers to work from Gerber Files and aperture table. The ap erture size should be the same as for the lands used on your track artwork. There is no need to reduce the size of the lands on the solder paste artwork, as Morris must reduce your artwork to allow for etch factors. If the assembler requires a smaller aperture opening than the land size used, then Morris will allow for this as well. For Gerber files, it is preferred if you create your pads as flashes ( rather than as shape fills). Morris can provide you with the stencil only, the stencil mounted in your frame, or, the stencil mounted in a frame by us. The frame will be custom designed to your

TOLERANCE ON HOLE SIZE

0 TO 0.8 0.81 TO 1.6 1.61 TO 5.0

2xA

.25 35/35

2xA 6 LAYER BOARD Foil Lamination (Preferred)

* SHEETS PREPREG CORE THK(mm) Cu (um) PER SIDE

Foil

BARE BOARD TESTING

Morris Productions employs advanced, flexible and fully integrated Bare Board testing systems. Viking Digital Bed of Nails Testing Probot - Flying Probe Testing Capabilities - netlist testing - analyse and create netlist for PCB's upto 24 layers - high complexity designs - Fine Pitch SMD to 0.25mm pitch and below - low volume work - high speed discharge test - Ball Grid Array - Fault Finding capability for Netlist Testing Test Parameters Test Method - Analogue Voltage Test - 0.5 to 500 VDC (programmable) Resistance Tests - 1Ohm to 500MOhms (programmable) Card Size (Maximum) - 863 x 609mm

10 LAYER BOARD Conventional Build

* SHEETS PREPREG CORE THK(mm) Cu (um) PER SIDE

Foil Lamination (Preferred)

* SHEETS PREPREG CORE THK(mm) Cu (um) PER SIDE

Conventional Build

SHEETS PREPREG CORE THK(mm) Cu (um) PER SIDE

2.4mm +/- 0.1mm TYP ROUTER DIA

Foil

2xA .38 1xB .38

18/00 2xA 35/35 4xA 35/35 2xA 18/00

.15

18/00

Foil 2xA

.15

18/00 .15 35/35 35/35

2xA

.15 35/35

.25

35/35 1xB .15 35/35

.25 .15

2xA .15 35/35

35/35 18/00

Capabilities - testing to known good board or netlist - analyse and create netlist for PCB's upto 24 layers - high complexity designs - Fine Pitch SMD to 0.5mm pitch and below - high volume work - Fault Finding capability for Netlist Testing - Simultaneous Double sided Testing

Head Office : 2-12 Harp Street, P.O. Box 196, Campsie, N.S.W., Australia 2194 Telephone: (02) 97896200 Facsimile: (02) 97872529 Modem: (02) 97188671 Email : Sales@morris.com.au Web Site: www.morris.com.au

2.0 +/- 0.2mm

4 NPTH HOLES 0.6 to 0.8 DIA EQUALLY SPACED

0.8 +/- 0.1mm

1xB

.15 35/35

STANDARD BRIDGE METHOD V - Groove Detail

INTERNAL BREAKOUT METHOD

This publication is copyright and all rights are reserved. Other than as permitted under the Copyright Act, no part may be reproduced by any process without the written permission of Morris Productions Pty Limited. The information contained in this publication is based upon IPC standards. The information is advisory only and its use or adaption is entirely voluntary. Morris Productions Pty Limited and its servants or agents shall not be responsible for continued currency of the information or fo r any errors, omissions or inaccuracies in this publication arising from negligence or otherwise howsoever or for any consequense arising therefrom.

AMENDMENTS EXAM APPD DATE ISS

2xA

Foil

2xA

.15 35/35

H

DO NOT SCALE DIMENSIONS IN MILLIMETRES

0.8mm = 0.4 +/-0.1

1.6mm = 0.5 +/-0.1

.15

35/35 18/00

2xA

.15 35/35

2xA Foil

The fibreglass core thickness does not include the foil (copper thickness). The required board thickness should be stated as the finished size (after plating and addition of solder resist), however, in critical areas, such as edge connectors, the thickness tolerance may be more stringent . Overall board thickness tolerances in general, (including double and single boards) should be in as per IPC - D - 300G, and typically + / - 0.2mm.

Board Dimensions 0.8mm = 0.16mm * Min Size = 80 x 80mm 1.6mm = 0.50mm 2.4mm = 0.80mm Max Size = 400 x 400mm * - not applicable to panelised boards Tolerances V-Groove depth = +/- 0.1mm V-Groove to V-Groove = +/- 0.2mm V-Groove to Board Edge = +/- 0.2mm

0.5 mm Min Track or Pad 45 +/- 5

2.4mm = 0.6 +/-0.1

* Overall thickness of the board can be altered by varying the quantity & type of prepreg. Morris standard prepreg types are as follows: A = 1 piece of 1080 prepreg with an approximate finished thickness of 0.07mm B = 1 piece of 7628 prepreg with an approximate finished thickness of 0.175mm. Note - approximate finished thickness can vary with the amount of copper area.

Test Parameters Test Method - 12 volt digital Voltage Test - 12 volt Resistance Test - breakpoint 70 kOhms Card Size (Maximum) Single Sided Test - 488 mm x 406mm Double Sided Simultaneous Test - 325mm x 244mm (Top)

1xB

Board Thickness

V -Groove Width

MORRIS CIRCUITS & MORRIS GRAPHICS CERTIFIED BY : -

ORDER

DRAWN

CHKD

MORRIS PRODUCTIONS

MORRIS CIRCUITS

PL GR GR

PL PL PL

JF REDRAWN REDRAWN JF JF

GE GE GE

25.5.92 6.3.95 10.7.98

1 2 3

PRINTED CIRCUIT BOARD DESIGNERS GUIDE

BLOCK DIAGRAM

3.5 mm Min

0.1 max deviation

AS/NZS ISO 9001 : 1994

MD1001

10 11

C

SHEET 1 OF 1

1

PCBPRO7A

12

Copyright Morris Productions Pty. Limited 1998 A1

S-ar putea să vă placă și

- CATIA - Generative Dynamic Response Analysis 2 (GDY)Document4 paginiCATIA - Generative Dynamic Response Analysis 2 (GDY)liapomiÎncă nu există evaluări

- CATIA - Elfini Structural Analysis (EST)Document5 paginiCATIA - Elfini Structural Analysis (EST)liapomiÎncă nu există evaluări

- Thermoforming Design Guide (GE Plastics) PDFDocument57 paginiThermoforming Design Guide (GE Plastics) PDFAlexis Andrés Durán OyanederÎncă nu există evaluări

- CATIA - Generative Part Structural Analysis 2 (GPS)Document5 paginiCATIA - Generative Part Structural Analysis 2 (GPS)liapomi0% (1)

- DAC Converter FamiliarizationDocument5 paginiDAC Converter FamiliarizationShuvro Sankar SenÎncă nu există evaluări

- Plastic Notes ShortsDocument4 paginiPlastic Notes ShortsTejas MahadikÎncă nu există evaluări

- GD&T Geometric Dimensioning and TolerancesDocument19 paginiGD&T Geometric Dimensioning and TolerancesAlejandro LeeÎncă nu există evaluări

- Machine tools circular tests for bore machiningDocument15 paginiMachine tools circular tests for bore machiningsimioncristescuÎncă nu există evaluări

- 03 Circuit Schematics An4988Document3 pagini03 Circuit Schematics An4988Adam Mamani100% (1)

- CATIA V5 Foundation Course - Part Design WorkbenchDocument90 paginiCATIA V5 Foundation Course - Part Design WorkbenchRaghavendraÎncă nu există evaluări

- Optimize a circuit diagram for search enginesDocument1 paginăOptimize a circuit diagram for search enginespdt590100% (1)

- Catia - Fem Surface 2 (FMS)Document4 paginiCatia - Fem Surface 2 (FMS)liapomiÎncă nu există evaluări

- GasSpring 157-160 enDocument4 paginiGasSpring 157-160 enRavi KodwaniÎncă nu există evaluări

- Mil DTL 83538C PDFDocument72 paginiMil DTL 83538C PDFJoe HicksÎncă nu există evaluări

- Integral Shaft Support ManualDocument80 paginiIntegral Shaft Support ManualBill NevisÎncă nu există evaluări

- SOLIDWORKS Inspection CMM Calypso PDFDocument5 paginiSOLIDWORKS Inspection CMM Calypso PDFJosephRomeraloÎncă nu există evaluări

- XR5 Data SheetDocument7 paginiXR5 Data SheetReeta DuttaÎncă nu există evaluări

- Development Kit For The CANBus Exercise BookDocument60 paginiDevelopment Kit For The CANBus Exercise Booksribodduna100% (3)

- Automatic Poor QualityDocument5 paginiAutomatic Poor Qualityqwerty187190Încă nu există evaluări

- Tutorials: Making A PCB Using An Etch TankDocument4 paginiTutorials: Making A PCB Using An Etch Tankmrtiger888Încă nu există evaluări

- CH 8Document6 paginiCH 8Mustafa JumaÎncă nu există evaluări

- Creo Simulate 3.0 SAXSIM7Document36 paginiCreo Simulate 3.0 SAXSIM7Jean AbelaÎncă nu există evaluări

- 12v To 18v ConverterDocument7 pagini12v To 18v ConverterLuis Paulo100% (1)

- Standard Drawing ConventionsDocument18 paginiStandard Drawing Conventionshendrasaputralingga8Încă nu există evaluări

- Unigraphics Nx7 5 Mold Wizard PDFDocument23 paginiUnigraphics Nx7 5 Mold Wizard PDFyuwrajc100% (1)

- PW-3 Part Design For Ultrasonic Welding (Single PGS) HRDocument8 paginiPW-3 Part Design For Ultrasonic Welding (Single PGS) HRAlba R.Încă nu există evaluări

- Using FEA to Replace ASME Code RulesDocument5 paginiUsing FEA to Replace ASME Code RulesAmit SharmaÎncă nu există evaluări

- Airbus Catia V5 Wireframe and Surface PDFDocument17 paginiAirbus Catia V5 Wireframe and Surface PDFCentipedeWormÎncă nu există evaluări

- PING) ) ) ™ Ultrasonic Distance Sensor (#28015) : Features Key SpecificationsDocument12 paginiPING) ) ) ™ Ultrasonic Distance Sensor (#28015) : Features Key SpecificationsAn Vesh100% (1)

- GTU Microcontroller Embedded Systems CourseDocument2 paginiGTU Microcontroller Embedded Systems CourseAshok ShahÎncă nu există evaluări

- Course ContentsDocument147 paginiCourse ContentsPralhad Thorat100% (1)

- Parametric Modeling and Drafting of Knuckle Joint by APIDocument6 paginiParametric Modeling and Drafting of Knuckle Joint by APIabc defÎncă nu există evaluări

- Lab LCDDocument6 paginiLab LCDJesus Cotrina100% (1)

- CPU Instruction SummaryDocument9 paginiCPU Instruction SummaryDereck AntonyDengo DomboÎncă nu există evaluări

- UNIT 3 Power PointDocument87 paginiUNIT 3 Power PointJithan KumarÎncă nu există evaluări

- Welding Electrode Classifications Wallchart PDFDocument1 paginăWelding Electrode Classifications Wallchart PDFask101Încă nu există evaluări

- Assembly of Flexible Circuits With Lead - Free Solder AlloyDocument16 paginiAssembly of Flexible Circuits With Lead - Free Solder AlloyBorad AlpeshÎncă nu există evaluări

- Knuckle Joint: Design Procedure, Problems and QuestionsDocument11 paginiKnuckle Joint: Design Procedure, Problems and QuestionscaveshgmailcomÎncă nu există evaluări

- Open Source Frequency Counter DIY Kit 10Hz-250MHzDocument10 paginiOpen Source Frequency Counter DIY Kit 10Hz-250MHzBruno Santos de Miranda100% (1)

- M XrutytDocument12 paginiM XrutytDistribuidorIBoolPedregalDeSantoDomingo100% (1)

- Design Considerations For System-Level ESD Circuit ProtectionDocument6 paginiDesign Considerations For System-Level ESD Circuit Protectionmincingthought6612Încă nu există evaluări

- CETOL by SigmetrixDocument6 paginiCETOL by SigmetrixnmjboseÎncă nu există evaluări

- Color Code Chart Qfm-qc-03 Rev. 17Document1 paginăColor Code Chart Qfm-qc-03 Rev. 17Balram Ji100% (1)

- Modbus Embedded Controller: Ndustrial Omputer Roducts Ata Cquisition YstemDocument34 paginiModbus Embedded Controller: Ndustrial Omputer Roducts Ata Cquisition Ystemramesh_br85100% (1)

- Stpper MotorDocument18 paginiStpper Motors.jyotshna100% (1)

- Iso 485 Pi9Document1 paginăIso 485 Pi9Oscar Felipe C.100% (1)

- PCB Designing Guide for BeginnersDocument16 paginiPCB Designing Guide for BeginnersPraveen Kumar Chitluri100% (1)

- pc3sd21 eDocument17 paginipc3sd21 eeduardogallegos100% (1)

- WWW Tec Ease Com GDT Terms PHPDocument14 paginiWWW Tec Ease Com GDT Terms PHPlaboratorioÎncă nu există evaluări

- 5703Document51 pagini5703Brandy WilsonÎncă nu există evaluări

- Membrane BendingDocument12 paginiMembrane BendingAnonymous tGFxtqNÎncă nu există evaluări

- GCI Storage Tank Data SheetDocument4 paginiGCI Storage Tank Data SheetAlvin Smith60% (5)

- Data Sheets PDFDocument7 paginiData Sheets PDFshareyhouÎncă nu există evaluări

- TCE Consulting Engineers Process Data Sheet for Ammonia Storage and Compression VesselsDocument59 paginiTCE Consulting Engineers Process Data Sheet for Ammonia Storage and Compression Vesselsrotatic_engineerÎncă nu există evaluări

- IC Data SheetDocument14 paginiIC Data SheetAnugrah AjyÎncă nu există evaluări

- PE D Vi10 422.023 ME CAL 001 01 E - Calculation Sheet Acc. en 14015 - VAR - 3Document33 paginiPE D Vi10 422.023 ME CAL 001 01 E - Calculation Sheet Acc. en 14015 - VAR - 3Virginia Elena Iordache67% (3)

- RPG Cables Manufacturing Process GuideDocument77 paginiRPG Cables Manufacturing Process GuideVarun ShahÎncă nu există evaluări

- REF NIST Spectral InterpDocument10 paginiREF NIST Spectral Interpnoman888Încă nu există evaluări

- DI-MGMNT-81808 Risk Management Plan PDFDocument2 paginiDI-MGMNT-81808 Risk Management Plan PDFnoman888Încă nu există evaluări

- MIL SF-30 Contract Change OrderDocument2 paginiMIL SF-30 Contract Change Ordernoman888Încă nu există evaluări

- Army Regulation 700–18 Provisioning GuideDocument29 paginiArmy Regulation 700–18 Provisioning Guidenoman888Încă nu există evaluări

- MIL-E-12397A Eraser PDFDocument4 paginiMIL-E-12397A Eraser PDFnoman888Încă nu există evaluări

- DI-MGMNT-81808 Risk Management Plan PDFDocument2 paginiDI-MGMNT-81808 Risk Management Plan PDFnoman888Încă nu există evaluări

- MIL DFARS Provisioning PGI217 - 76 PDFDocument4 paginiMIL DFARS Provisioning PGI217 - 76 PDFnoman888Încă nu există evaluări

- INF 2887378 PCB Fab WallchartDocument1 paginăINF 2887378 PCB Fab Wallchartnoman888100% (1)

- FED-STD-228 Cable Wire Testing (Flex) PDFDocument222 paginiFED-STD-228 Cable Wire Testing (Flex) PDFnoman888Încă nu există evaluări

- MIL-A-3920B Thermosetting Optical AdhesiveDocument13 paginiMIL-A-3920B Thermosetting Optical Adhesivenoman888Încă nu există evaluări

- Air Force TR-1994-0111 ANVIS Goggle Adjust GuideDocument22 paginiAir Force TR-1994-0111 ANVIS Goggle Adjust Guidenoman888Încă nu există evaluări

- Mil Ar 700 - 127 IlsDocument46 paginiMil Ar 700 - 127 Ilsnoman888Încă nu există evaluări

- FEDERAL STANDARD COLORS USED IN GOVERNMENT PROCUREMENTDocument59 paginiFEDERAL STANDARD COLORS USED IN GOVERNMENT PROCUREMENTnoman888Încă nu există evaluări

- MIL DI-RELI-80251 Reliability Test SheetsDocument11 paginiMIL DI-RELI-80251 Reliability Test Sheetsnoman888Încă nu există evaluări

- MIL-T-7928F Terminal Conductor CrimpDocument28 paginiMIL-T-7928F Terminal Conductor Crimpnoman888Încă nu există evaluări

- Anodized Coatings Spec for Aluminum AlloysDocument20 paginiAnodized Coatings Spec for Aluminum Alloysnoman888Încă nu există evaluări

- Mil Dd-1692 Ecp Form ExampleDocument10 paginiMil Dd-1692 Ecp Form Examplenoman888Încă nu există evaluări

- Checklist for Teaching Strategies for Learners with Special NeedsDocument2 paginiChecklist for Teaching Strategies for Learners with Special NeedsJasmin Aldueza100% (6)

- 1 - Chapter Ii - Lesson 1 - Understanding The Value of Philippine LiteratureDocument14 pagini1 - Chapter Ii - Lesson 1 - Understanding The Value of Philippine LiteratureJuliaÎncă nu există evaluări

- Moon SignsDocument2 paginiMoon SignsAdvotiya RaskolnikovaÎncă nu există evaluări

- Abis For GSM TelecommunicationsDocument2 paginiAbis For GSM TelecommunicationsUmar Abbas BabarÎncă nu există evaluări

- SS 100-Writing and CommunicationDocument10 paginiSS 100-Writing and CommunicationCool MomÎncă nu există evaluări

- Plato's Philosophy of Arithmetic PEDE CASINGDocument75 paginiPlato's Philosophy of Arithmetic PEDE CASINGPede CasingÎncă nu există evaluări

- Manual de Feeder Gravimetrico PDFDocument0 paginiManual de Feeder Gravimetrico PDFEfrain SaldañaÎncă nu există evaluări

- Environmental Engineering ExplainedDocument3 paginiEnvironmental Engineering ExplainedElaine Mae ButalonÎncă nu există evaluări

- Asco Series 314 Exida Sil Certificate 2016Document2 paginiAsco Series 314 Exida Sil Certificate 2016AkoKhalediÎncă nu există evaluări

- Affidavit of Carol Jean CoscoDocument54 paginiAffidavit of Carol Jean CoscochchiangÎncă nu există evaluări

- Moschino Hermes Comparative PositioningDocument21 paginiMoschino Hermes Comparative PositioningTONGSHU JIANGÎncă nu există evaluări

- PVC Water Pumps PDFDocument26 paginiPVC Water Pumps PDFYulidar Wahyu RachmawanÎncă nu există evaluări

- List of books and standards on vibratory machine foundationsDocument5 paginiList of books and standards on vibratory machine foundationsMiminoRusÎncă nu există evaluări

- EMT3-C10186 Manual (Rev. 1) W E-Stop and Throttle Pot (71610)Document17 paginiEMT3-C10186 Manual (Rev. 1) W E-Stop and Throttle Pot (71610)Matias Contreras Köbrich100% (2)

- Psyc1001 Lecture 1 Summary NotesDocument3 paginiPsyc1001 Lecture 1 Summary NotesDeadly ChillerÎncă nu există evaluări

- International Perspectives on Dyslexia, Dyscalculia and Maths Learning DifficultiesDocument29 paginiInternational Perspectives on Dyslexia, Dyscalculia and Maths Learning DifficultiesJose Luis Mendieta VilaÎncă nu există evaluări

- Lesson 2: Problem Solving Through Flowcharts 1Document14 paginiLesson 2: Problem Solving Through Flowcharts 1catherine carreonÎncă nu există evaluări

- Rating: Interpretive Guides For Behavioural Interview SDocument8 paginiRating: Interpretive Guides For Behavioural Interview SMaestro MertzÎncă nu există evaluări

- English For Ethiopia: Grade 6Document3 paginiEnglish For Ethiopia: Grade 6Esrom Abebe100% (2)

- Microprocessors and MicrocontrollerDocument2 paginiMicroprocessors and MicrocontrollerKumar MukeshÎncă nu există evaluări

- Logic NotesDocument19 paginiLogic NotesCielo PulmaÎncă nu există evaluări

- The Alphabet of Technical WritingDocument3 paginiThe Alphabet of Technical WritingAdeel RazaÎncă nu există evaluări

- MentahanDocument2 paginiMentahanNoviyanti 008Încă nu există evaluări

- Self Driving Cars PresentationDocument42 paginiSelf Driving Cars PresentationGeorgia CastoroÎncă nu există evaluări

- Early 2011 Macbook Pro SpecsDocument4 paginiEarly 2011 Macbook Pro SpecsMatthew Timothy PuaÎncă nu există evaluări

- May I... ?: Activity TypeDocument2 paginiMay I... ?: Activity Typebebyfebri14Încă nu există evaluări

- Turban Dss9e Ch04Document50 paginiTurban Dss9e Ch04Agha Agha FaisalÎncă nu există evaluări

- Midlands State University Library Department Course: Information Literacy Skills (Hcs135)Document7 paginiMidlands State University Library Department Course: Information Literacy Skills (Hcs135)Loveniah Yemurai MbakataÎncă nu există evaluări

- TrinaPro SP160 Single Axis Tracker - SingleRow - 2019ADocument2 paginiTrinaPro SP160 Single Axis Tracker - SingleRow - 2019AsuÎncă nu există evaluări

- Alan Maley Poster 2Document1 paginăAlan Maley Poster 2Cory KobyÎncă nu există evaluări