Documente Academic

Documente Profesional

Documente Cultură

Sub 131

Încărcat de

kjfenTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Sub 131

Încărcat de

kjfenDrepturi de autor:

Formate disponibile

116

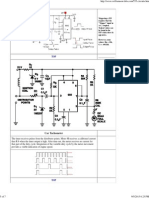

8 Cable Systems

0.20 0.18 0.16 3

1 x 1 (W km )

6 8

0.14 4 0.12 0.10 0.08 0.06 10 2

1 15 25 35 50 70 95120 185 q (mm2) 500

Figure 8.3 Inductive reactances (positivesequence component) of three-phase cables. 1, 0.6/1 kV, four-core cable, NKBA; 2, 0.6/1 kV, four-core cable, NA2XY; 3 three-core cable with armoring 10 kV; 4, PVC-insulated cable 6/10 kV, NYFGbY; 5, VPE-insulated cable

6/10 kV, NA2XSEY; 6, single-core oil-lled cable 110 kV, triangle formation; 7, singlecore oil-lled cable 110 kV, at formation; 8, XLPE-insulated 110 kV triangle formation; 9, XLPE-insulated cable 110 kV at formation, distance 15 cm.

of the cable concerned. For this reason, measurements of the impedances in the zero-sequence component should be carried out during commissioning and in high-voltage systems should be repeated at intervals of at most some years.

8.4 Losses and Permissible Current 8.4.1 General

The permissible current of cables is determined by maximal permissible temperature of the cable insulation, which should not be exceeded at any time so as to protect the insulation against deterioration. Table 8.4 indicates the maximal permissible temperatures of insulating materials. Cable losses originate from current-dependent losses in conductor, metallic sheath, coatings, screens and armoring and possibly in outer metal tubes as well as from current-independent losses in the dielectricum of the cable insulation. These losses heat the individual parts of the cable construction and must be trans-

8.4 Losses and Permissible Current

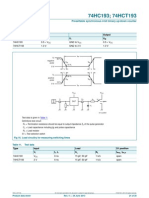

Table 8.4 Maximal permissible temperature of cable insulation.

117

Cable type

Maximal permissible temperature (C) Operating temperature Copper conductor 90 70 70 80 80 70 65 60 65 Aluminum conductor 90 70 70 80 80 70 65 60 65 At end of short-circuit

Cable with soft-soldered joints VPE and XLPE insulation PVC insulation 300 mm2 >300 mm2 Oil-impregnated insulation 0.6/1 kV 3.6/6 kV 6/10 kV 12/20 kV 18/30 kV Electric eld-limited insulation 12/20 kV VPE and XLPE insulation PVC insulation 300 mm2 >300 mm2 Oil-impregnated insulation 0.6/1 kV 3.6/6 kV 6/10 kV 12/20 kV 18/30 kV Electric eld-limited insulation 12/20 kV

160 250 160 140 250 170 170 170 150 170 250 160 140 250 170 170 170 150 170

ferred through the different layers to the surrounding soil, or to the surrounding air if laid in air. Generally one starts from the thermal equivalent diagram as shown in Figure 8.4. The maximal permissible current is calculated by Equation 8.1. = T Ptot with = temperature difference T = thermal resistance Ptot = losses. The different types of losses are to be determined in detail. Based on the knowledge of the thermal resistances of the cable construction and the surrounding soil

(8.1)

118

8 Cable Systems

Ohmic conductor losses PVL Dielectric losses PVD Thermal resistance of insulation TIs Sheet losses PVM Thermal resistance of inner sheath TSi Armor losses PVB Thermal resistance of outer sheath TSa

Ji

M

Surface area of cable Thermal resistance of surroundingTU

Ja

Unaffected surrounding

U

= a + i

Figure 8.4 Thermal equivalent diagram for cables.

or air, either the temperatures at individuals layers in the cable for given load current or the maximal permissible current for given temperatures can be calculated.

8.4.2 Calculation of Losses

Cable losses consist of two parts, current-dependent and current-independent losses. Losses of the conductor are given by Equation 8.2. PVL = I 2 R20 [1 + ( L 20 C)]FS FP with R20 = DC resistance per unit length at 20 C I = conductor current = temperature coefcient L = conductor temperature in C FS = factor of skin effect (to be considered with cross-sections above 185 mm2) FP = factor of proximity effect (to be considered with cross-sections above 185 mm2). Methods for calculation of the factors of skin effect and proximity effect are outlined in [23, 24], denoted there by yS and yP. Losses in a steel pipe considered as outside casing are taken into account by adjusted factors for skin effect and

(8.2)

8.4 Losses and Permissible Current

119

proximity effect. Depending upon the arrangement of the cable cores in the pipe and the presence of armoring, the losses in the steel pipe can amount up 70% of the losses by skin and proximity effects [23]. The calculation of the resistance per unit length considering the skin and proximity effect is valid up to cable cross-sections of 1500 mm2 (copper conductors) and up to 2000 mm2 (aluminum conductors). For larger cross-sections and for large hollow conductors, additional considerations are needed [23]. Losses occur also in screens, sheaths and armoring due to eddy-current and longitudinal currents and are likewise current-dependent. In the case of magnetic materials, as used in pressure bandages and in metallic casings and pipes, magnetization losses arise. The losses in sheaths and screens depend strongly on the kind of earthing of sheaths and screens. With earthing at one end, no longitudinal current can ow and the losses are accordingly small; with earthing at both ends, the losses in sheaths and screens can be up to 40% of the total losses of the cable depending on the conductor cross-section [23]. If sheaths are cross-bonded, that is, the sheath is grounded at the beginning, at the end and with one-third and two-thirds of the length with cyclic exchange of the sheath sections, the sheath losses are reduced to an insignicant part of the total losses. In practice, an exact cross-bonding of the sheaths (at each third of the cable length) usually cannot be realized; the sheath currents of the three length sections do not compensate themselves completely and the sheath losses are higher in this case. The sheath losses by longitudinal currents are taken into and the eddy-current losses by a factor 1 as multiples of account by a factor 1 the conductor losses according to Equation 8.3a. PVM = PVL (1 + 1 )

(8.3a)

The detailed procedure for the calculation of losses by Equation 8.3a is outlined in [23, 24]. If the cross-bonding locations of the cable system are not exactly known should be assumed to in the planning and design stage, the respective factor 1 = 0.05 for cables be 1 = 0.03 for cables buried directly in the ground and 1 buried in pipes and ducts. Longitudinal current losses and eddy-current losses in armoring and steel for the losses by tubes are considered in a similar way by the factors 2 longitudinal current and 2 for the eddy-current losses according to Equation 8.3b. PVB = PVL ( 2 + 2 )

(8.3b)

The detailed procedure for the calculation of losses by Equation 8.3b can be found in [23, 24]. The current-independent dielectric losses depend on the dissipation factor tan and on the capacitance of the cable C1 (positive-sequence component) and can be calculated with Equations 8.4 and 8.5.

120

8 Cable Systems

PVD = C1 C1 =

Un tan 3

(8.4)

2 0 r d ln I dL

(8.5)

with 0 = permittivity (0 = 8.8 542 1012 A s V1m1) r = relative permittivity (see Table 8.3) dI = outer diameter of insulation dL = conductor diameter. For detailed analysis, the thermal dependence of the dissipation factor tan has also to be considered.

8.4.3 Soil Characteristics

The determination of the heat dissipation to the surrounding soil requires knowledge of the thermal characteristics (temperature and thermal conductivity) of the soil. The temperature of the soil changes with laying depth, yearly seasonal changes, the mean air temperature and the type of surface (grass, bitumen, concrete). The mean monthly soil temperature for Central European conditions is outlined in Figure 8.5. The temperature of a grass-covered earth surface corresponds approximately to the ambient air in the respective period. If the surface is sealed with bitumen, the temperature of the earth surface varies in a wide range, summer season having far higher and winter season lower temperatures. As can be seen in Figure. 8.6, the soil temperature at depths larger than 34 m is nearly constant at 10 C; typically no cables are laid in this depth. Figure 8.6 indicates the seasonal variation of soil temperature under grasscovered surfaces in Central Europe in different depths [25]. It can be observed that the soil temperature follows a sine function similar to that of the solar radiation with a time delay of several weeks depending on the depths. At larger depth the maximum soil temperature is lower and at 10 m depth is roughly constant at 8.510 C. The thermal conductivity of the soil depends on the water content of the soil, expressed by the humidity content m, and on the porosity G (the ratio of cavity volume to the total volume). For conditions surrounding cables those types of soil are desirable which consist of consolidated sand and sandgravel mixtures with at grain distributions, as the ne sand portions ll up the cavities between the coarser constituents. A loam proportion of 10% leads to a lower drainage of the soil, improves the compressibility of the soil and increases the heat conductivity. Figure 8.7 indicates the thermal conductivity of sandy soil as function of the temperature and of the humidity content m. It is assumed that the humidity content

8.4 Losses and Permissible Current

Soil temperature (C)

-2 0 0.25 0.50 January 0.75 November August 0 2 4 6 8 10 12 14 16 18 20 22

121

Depth (m)

1.00 March 1.25 1.50 1.75 2.00 2.25

May September

Soil temperature (C)

-2 0 0.25 0.50 0.75 January March November 1.25 1.50 1.75 2.00 2.25 May June September 0 2 4 6 8 10 12 14 16 18 20 22 24 26

Depth (m)

1.00

Figure 8.5 Mean soil temperature in Central Europe as a function of the soil depth [22]. (a) Grass covered; (b) sealed with bitumen.

m of sandy soils at depth greater 1 m remains above 25% even after long periods of suppressed rehumidication, for example, when the surface has been sealed. The thermal conductivity of different soils as function of the saturation factor h is outlined in Figure 8.8.

122

8 Cable Systems

20

15

Surface

1m

Soil temperature (C)

2m 10 4m 10 m

0 1 3 5 7 9 11 13 15 17 19 21 23 25 27 29 31 33 35 37 39 41 43 45 47 49 51 53

-5

Week of the year

Figure 8.6 Seasonal changes of the soil temperature under grass-covered surfaces in Central Europe at different laying depths.

2.2 2.0 1.8

l (W K1 m1)

1.6 1.4

0.24 0.08 0.04 m 0.03 0.02

1.2

1.0 0.8 0.6

10

20

30

Temperature (C)

40

50

60

Figure 8.7 Thermal conductivity of sandy soil as a function of temperature and humidity content m [26].

The thermal conductivity remains constant within the range up to h < 0.25 for thermally stabilized sandy soils and h < 0.5 for loam soils. These gures characterize the range of the dried soil. Soil drying is to be attributed to the temperature eld in the ground with a dened temperature gradient, which is related to the humidity gradient depending on the type of soil. Each isotherm corresponds to a

8.4 Losses and Permissible Current

2.5

123

2.0

Thermally stabilized soil

l (W K1 m1)

1.5

Sandy soil

1.0

Clay soil

0.5

0 0

0.1

0.2

0.3

0.4 0.5 0.6 Saturation factor h

0.7

0.8

0.9

1.0

Figure 8.8 Thermal conductivity of different soils as a function of the saturation factor h [27].

dened humidity content. If the temperature exceeds a limit value, characteristic for each type of ground, the rehumidication of the soil is insufcient to compensate for the drying by evaporation, drainage and water transportation; consequently the soil dries out completely. A critical temperature for soil drying can be assigned to this humidity content, which is dependent on the soil type, the soil temperature, the humidity content of the unimpaired soil and the load and/or the load cycles of the buried cable. The thermal conductivity of the soil remains constant below the critical humidity content. Based on Figures 8.7 and 8.8, thermal conductances of the ground can be assumed as outlined below:

Thermally stabilized sandy soil: during soil drying: Sandy soil: during soil drying: Loamy soil: during soil drying:

8.4.4 Thermal Resistances of Cables

= 1.82.2 W K1m1 = 1.1 W K1m1 = 1.01.5 W K1m1 = 0.5 W K1m1 = 0.91.1 W K1m1 = 0.25 W K1m1.

For the calculation of the maximal permissible loading (current), the thermal resistances of the cable and/or the individual layers of the cable such as conductor, insulation, screens, sheaths, coating and so on need to be known. Reliable data can only be given by the manufacturer and should be required in detail in each specication. Values for typical materials used in the cable construction and of given laying conditions are shown in Table 8.5.

124

8 Cable Systems

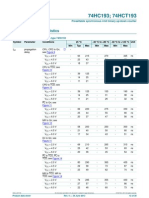

Table 8.5 Typical thermal parameters of materials used in cable construction and laying material [23].

Material

Thermal resistance (Km W1)

Thermal capacity 106 W s K1m3 2.0 2.4 1.7 2.0 2.0 2.0 2.0 1.7 2.0 2.4 2.0 2.2 2.0 1.7 2.4

Paper insulation VPE, XLPE and PE insulation PVC insulation (depending on voltage) Butyl-rubber and rubber insulation Fiber and textile coatings Rubber protective layers Polychloroprene layers and coatings PVC protective layers PVC/bitumen on Al-coatings PE protective coatings Concrete Glass ber Stone materials PVC covers PE covers

5.06.5 3.5 5.06.0 5.0 6.0 6.0 5.5 5.06.0 6.0 3.5 1.0 4.8 1.2 7.0 3.5

8.4.5 Calculation according to VDE 0276-1000

Calculation of maximal permissible loading is described in VDE 0276-1000 for cables with rated voltages up to 30 kV. One proceeds from standardized laying arrangement, soil surrounding conditions and operating cycles that are typical in power systems of public utilities and in industry. The application of VDE 02761000 is subject to the following conditions: Cables of the same type are assumed in one trench. Cables of same rated voltage are assumed in the trench. Cables of the same loading conditions and load cycles are assumed. Only standardized cable types are included. Only standard laying arrangements are considered. Electrically parallel operated cable systems are not considered. Sheaths are assumed to be earthed on both sides. No external heat sources are assumed. Temporary overloading of the cables is not considered.

Operating and laying conditions deviating from standard conditions as in Table 8.6 are considered in VDE 0276-1000 with factors f1 and f2. The maximal permissible current is found from Equation 8.6. Izul = I r f 1 f 2 f

(8.6)

8.4 Losses and Permissible Current

Table 8.6 Standard conditions for the determination of the

125

maximal permissible loading of cables in earth according to VDE 0276-1000. Standard operating and trench conditions for the calculation of rated current Operation mode (Section 5.3.1.1 of VDE 0276-1000) load factor m = 0.7; peak load for laying in earth Laying conditions (Section 5.3.1.2 of VDE 02761000) Laying depth 0.7 m Formation 1 multiple-core cable 1 single-core cable (DC system) 3 single-core cables (AC system), triangle formation 3 single-core cables (AC system) at formation, distance between cables 7 cm Bedding in sand or relled soil Protective covering from concrete tiles or at plastic plates Deviation in operating conditions

Reduction factors according to Tables 4 to 9 of VDE 0276-1000 See Section 5.3.1.2.1 of VDE 0276-1000

Reduction factors Multiple cable trench as per Tables 4, 5, 9 and 13 of VDE 0276-1000 Multiple cable trench as per Tables 4 to 7 of VDE 0276-1000 Multiple cable trench as per Tables 4, 5 and 8 of VDE 0276-1000 Reduction factors For protective covering with air inclusions see Section 5.3.1.2.3 of VDE 0276-1000 For protective pipes see Section 5.3.1.2.4 of VDE 0276-1000 Reduction factors As per Tables 4 to 9 of VDE 0276-1000 As per Tables 4 to 9 of VDE 0276-1000 See Section 5.2 of VDE 0276-1000

Trench surrounding (Section 5.3.1.3 of VDE 0276-1000) Soil temperature in laying depth: 20 C Specic thermal resistivity of soil Wet areas: 1.0 Km W1 Dry areas: 2.5 Km W1

Earthing of sheaths, screens and armoring at both ends

with Ir = permissible current for standard conditions f = Product of other conversion factors, for example, for laying in pipes and ducts. The calculation method according to VDE 0276-1000 is based on the characteristic diameter, which depends on the energy loss factor as per Equation 8.7, see also Section 4.2.

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (894)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Manual de Referencia PlanmecaDocument288 paginiManual de Referencia PlanmecaJorge Escalona Hernandez100% (2)

- Journalize The Following Transactions in The Journal Page Below. Add Explanations For The Transactions and Leave A Space Between EachDocument3 paginiJournalize The Following Transactions in The Journal Page Below. Add Explanations For The Transactions and Leave A Space Between EachTurkan Amirova100% (1)

- Life Sciences Part 1 CSIR JRF NET GATE DBT PDFDocument132 paginiLife Sciences Part 1 CSIR JRF NET GATE DBT PDFPavani Reddy68% (22)

- Black Girl Magic: Over 200+ AffirmationsDocument229 paginiBlack Girl Magic: Over 200+ AffirmationsDestiny S. Harris100% (2)

- Load Forecasting and Standardized Load CurvesDocument10 paginiLoad Forecasting and Standardized Load CurveskjfenÎncă nu există evaluări

- Water Treatments: Steam Water Cycle TreatmentDocument2 paginiWater Treatments: Steam Water Cycle TreatmentkjfenÎncă nu există evaluări

- Selo 1Document26 paginiSelo 1kjfenÎncă nu există evaluări

- 7SA522 CatalogueDocument53 pagini7SA522 CataloguePhilip D'cruzÎncă nu există evaluări

- Temperature Monitoring: FaizanDocument5 paginiTemperature Monitoring: FaizankjfenÎncă nu există evaluări

- Timer Tutorials 555Document1 paginăTimer Tutorials 555kjfenÎncă nu există evaluări

- 7 Ways Signal Noise Can Impact Your Electrical EquipmentDocument5 pagini7 Ways Signal Noise Can Impact Your Electrical EquipmentkjfenÎncă nu există evaluări

- REG670Document88 paginiREG670Rafael Hoffmann PaludoÎncă nu există evaluări

- 555 Timer Tutorial - How to Build CircuitsDocument1 pagină555 Timer Tutorial - How to Build CircuitskjfenÎncă nu există evaluări

- 74HC193 74HCT193: NXP SemiconductorsDocument2 pagini74HC193 74HCT193: NXP SemiconductorskjfenÎncă nu există evaluări

- Timer Tutorials 555Document1 paginăTimer Tutorials 555kjfenÎncă nu există evaluări

- Timer Tutorials 555Document1 paginăTimer Tutorials 555kjfenÎncă nu există evaluări

- Timer Tutorials 555Document1 paginăTimer Tutorials 555kjfenÎncă nu există evaluări

- Timer Tutorials 555Document1 paginăTimer Tutorials 555kjfenÎncă nu există evaluări

- 74HC193 74HCT193: 17. Contact InformationDocument2 pagini74HC193 74HCT193: 17. Contact InformationkjfenÎncă nu există evaluări

- Timer Tutorials 555Document1 paginăTimer Tutorials 555kjfenÎncă nu există evaluări

- 74HC193 74HCT193: 14. AbbreviationsDocument2 pagini74HC193 74HCT193: 14. AbbreviationskjfenÎncă nu există evaluări

- 74HC193 74HCT193: NXP SemiconductorsDocument2 pagini74HC193 74HCT193: NXP SemiconductorskjfenÎncă nu există evaluări

- 74HC193 74HCT193: 13. Package OutlineDocument2 pagini74HC193 74HCT193: 13. Package OutlinekjfenÎncă nu există evaluări

- 74HC193 74HCT193: NXP SemiconductorsDocument2 pagini74HC193 74HCT193: NXP SemiconductorskjfenÎncă nu există evaluări

- 74HC193 74HCT193: NXP SemiconductorsDocument2 pagini74HC193 74HCT193: NXP SemiconductorskjfenÎncă nu există evaluări

- 74HC193 74HCT193: NXP SemiconductorsDocument2 pagini74HC193 74HCT193: NXP SemiconductorskjfenÎncă nu există evaluări

- 74HC193 74HCT193: 10. Dynamic CharacteristicsDocument2 pagini74HC193 74HCT193: 10. Dynamic CharacteristicskjfenÎncă nu există evaluări

- 74HC HCT193Document2 pagini74HC HCT193kjfenÎncă nu există evaluări

- 74HC193 74HCT193: 9. Static CharacteristicsDocument2 pagini74HC193 74HCT193: 9. Static CharacteristicskjfenÎncă nu există evaluări

- 74HC193 74HCT193: 10. Dynamic CharacteristicsDocument2 pagini74HC193 74HCT193: 10. Dynamic CharacteristicskjfenÎncă nu există evaluări

- 74HC193 74HCT193: NXP SemiconductorsDocument2 pagini74HC193 74HCT193: NXP SemiconductorskjfenÎncă nu există evaluări

- 74HC193 74HCT193: 5. Pinning InformationDocument2 pagini74HC193 74HCT193: 5. Pinning InformationkjfenÎncă nu există evaluări

- 74HC193 74HCT193: NXP SemiconductorsDocument2 pagini74HC193 74HCT193: NXP SemiconductorskjfenÎncă nu există evaluări

- LAST CARGOES AND CLEANINGDocument1 paginăLAST CARGOES AND CLEANINGAung Htet KyawÎncă nu există evaluări

- Cap 716 PDFDocument150 paginiCap 716 PDFjanhaviÎncă nu există evaluări

- Disinfecting Water Wells Shock ChlorinationDocument3 paginiDisinfecting Water Wells Shock ChlorinationmayaÎncă nu există evaluări

- Merit of RatingDocument1 paginăMerit of RatingRaidasÎncă nu există evaluări

- Cfm56-3 Engine Regulation by CFMDocument43 paginiCfm56-3 Engine Regulation by CFMnono92100% (5)

- Auramo Oy spare parts listsDocument12 paginiAuramo Oy spare parts listsYavuz ErcanliÎncă nu există evaluări

- Ethamem-G1: Turn-Key Distillery Plant Enhancement With High Efficiency and Low Opex Ethamem TechonologyDocument25 paginiEthamem-G1: Turn-Key Distillery Plant Enhancement With High Efficiency and Low Opex Ethamem TechonologyNikhilÎncă nu există evaluări

- SM RSJ 420 800Document77 paginiSM RSJ 420 800elshan_asgarovÎncă nu există evaluări

- DPW Series Profile Wrapping Application HeadDocument2 paginiDPW Series Profile Wrapping Application HeadNordson Adhesive Dispensing SystemsÎncă nu există evaluări

- GSIS vs. de LeonDocument9 paginiGSIS vs. de Leonalwayskeepthefaith8Încă nu există evaluări

- Daudo PH-396PVP PDFDocument54 paginiDaudo PH-396PVP PDFVanBang TNÎncă nu există evaluări

- Cement ReportDocument86 paginiCement ReportSohaibÎncă nu există evaluări

- Solcon Catalog WebDocument12 paginiSolcon Catalog Webquocviet612Încă nu există evaluări

- How To Practice Self Care - WikiHowDocument7 paginiHow To Practice Self Care - WikiHowВасе АнѓелескиÎncă nu există evaluări

- Construction and Operation 1. Air Conditioning Control PanelDocument18 paginiConstruction and Operation 1. Air Conditioning Control PanelRoma KuzmychÎncă nu există evaluări

- Nursing Plan of Care Concept Map - Immobility - Hip FractureDocument2 paginiNursing Plan of Care Concept Map - Immobility - Hip Fracturedarhuynh67% (6)

- Pack Alimentacion Clin in Perin 14Document194 paginiPack Alimentacion Clin in Perin 14Paz BustosÎncă nu există evaluări

- Book 1Document94 paginiBook 1JOHNÎncă nu există evaluări

- Chemical and Physical Properties of Refined Petroleum ProductsDocument36 paginiChemical and Physical Properties of Refined Petroleum Productskanakarao1Încă nu există evaluări

- Alternate Dialysis Platforms:: Sorbents SorbentsDocument17 paginiAlternate Dialysis Platforms:: Sorbents SorbentsJoe Single100% (2)

- Block 1 Board Review - Lecture NotesDocument127 paginiBlock 1 Board Review - Lecture NotesCece RereÎncă nu există evaluări

- HTM 2025 2 (New) Ventilation in HospitalsDocument123 paginiHTM 2025 2 (New) Ventilation in HospitalsArvish RamseebaluckÎncă nu există evaluări

- Lesson 1 CA 3Document13 paginiLesson 1 CA 3myndleÎncă nu există evaluări

- Operating Instructions: Katflow 100Document52 paginiOperating Instructions: Katflow 100Nithin KannanÎncă nu există evaluări

- Interface GSKTMTRLBRCHR A4 Int 4webDocument7 paginiInterface GSKTMTRLBRCHR A4 Int 4webROGERIO GUILHERME DE OLIVEIRA MARQUESÎncă nu există evaluări

- Supply Chain Management of VodafoneDocument8 paginiSupply Chain Management of VodafoneAnamika MisraÎncă nu există evaluări