Documente Academic

Documente Profesional

Documente Cultură

Puetpaiboon U PDF

Încărcat de

mehrdad_k_rTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Puetpaiboon U PDF

Încărcat de

mehrdad_k_rDrepturi de autor:

Formate disponibile

ANAEROBIC TREATMENT OF PALM OIL MILL WASTEWATER UNDER MESOPHILIC CONDITION

U. Puetpaiboon1 and J. Chotwattanasak2

1

Civil Engineering Department, Faculty of Engineering, Prince of Songkla University, Thailand (E-mail: pudompho@ratree.psu.ac.th) 2 The Joint Graduate School of Energy and Environment, Kings Mongkut University of Technology Thonburi, Thailand (E-mail:j_chotwattana@hotmail.com)

Abstract This paper reports the investigation of performance of the full scale anaerobic digester of wastewater from production of palm oil at the Asian Palm Oil Co., Ltd. Krabi, Southern Thailand which has been started operation since December 2001. The dimension of an anaerobic digester is 13.5 m in diameter and 15.3 m in height with average volume of 2,100 m3. Wastewater generation rate was found to be about 0.5 m3 per ton of fresh fruit bunch. Wastewater from palm oil production was pretreated by oil recovery process and primary ponds before feeding to the digester using centrifugal pump with average flow rate of 300 m3/d. Average volumetric organic loading and HRT were found to be about 4.53 kgCOD/m3.day and 7 days, respectively. The digester reduces water pollutants and odor from wastewater and produces energy in form of biogas. The biogas produced from anaerobic digester is a cheap source of energy which can be used as a gas engine fuel to produce electricity and can be sold out as very small power producer in Thailand.

Keywords: Anaerobic treatment process; anaerobic digester; wastewater from palm oil; biogas

Introduction Palm oil mill is one of the most important agro-industry in the South of Thailand. The oil palm processing plant releases large amount of organic pollutant wastewater. Discharge of palm oil mill wastewater without proper treatment will damage environment both in receiving water quality and foul smell in the neighborhood of factory. The proper wastewater treatment methods should take advantage. Usually anaerobic stabilization ponds are widely used for treatment of wastewater from palm oil production because of their low capital and operating cost. However, foul smell generated from anaerobic ponds is disturbed the neighborhood community. Another efficient treatment system is the closed anaerobic digester tank that becomes more popular at present. Furthermore, biogas from the closed treatment system can be further utilized as fuel. Due to energy and environment are the interested issues for nowadays. The Royal Thai Government creates a policy to promote and subsidize the projects concerning with the energy from biomass such as a production of biogas from anaerobic digestion in agro-industry section especially

anaerobic digestion of high concentration of organic matter in wastewater. The full-scale anaerobic digester for treatment of wastewater from production of palm oil at the Asian Palm Oil Co., Ltd. Krabi, Southern Thailand is one example of these subsidized projects. The digester has been started in operation since December 2001. The system reduces pollutants and also produces biogas that today the mill utilizes as fuel to produce electricity using the internal combustion engine. The modified diesel engine with induction motor is used to produce electricity and supply to the factory office, labor houses and biogas plant itself.

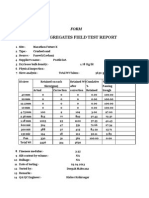

Methods The anaerobic digester with a diameter of 13.5 m and 15.3 m in height and effective volume of 2,100 m3 was constructed at the Asian Palm Oil Co., Ltd. Krabi, Southern Thailand. The reactor comprises of gear motor, torque tube, scrapper set and draft tube as shown in Figure 1. Palm oil mill wastewater from the production process was pre-treated by oil recovery tank and primary ponds before feeding to the anaerobic digester by centrifugal pump at feeding rate 300 m3/day from the tank bottom as up flow. The hydraulic retention time of the system was about 7 days with the average organic loading rate of about 4.53 kgCOD/m3.day. The flow diagram of anaerobic digestion system was shown in Figure 2.

Figure 1 Anaerobic digester at Asian palm oil mill, Krabi, Thailand.

Figure 2 Flow diagram of anaerobic digestion system at Asian Palm Oil Mill, Krabi, Thailand.

Influent and effluent from anaerobic digester were analyzed for BOD5, COD, pH, temperature, VFA and alkalinity every 3-4 days. The analytical methods used were in accordance with that specified in the standard methods for the examination of water and wastewater (APHA, AWWA and WEF, 1998). Gas volume was monitored by EPI gas flow meter Model: Series 8200 MPNH insertion style with remote display. Gas composition was determined by gas chromatography.

Results and Discussion The results of treatment of wastewater from palm oil mill production after pre-treated by oil recovery and primary ponds before feeding to the anaerobic digester without pH adjustment is shown in Table 1. It can be seen that pH of influent was in a range of 4.69 - 4.85, 4.75 in average, whereas pH of effluent from the anaerobic digester was in a range of 7.29 - 7.47, 7.36 in average. Alkalinity of influent to the anaerobic digester was in a range of 1,150 - 1,598 mg/L as CaCO3. Alkalinity of effluent from digester was in a range of 2,578 - 3,050 mg/L as CaCO3. Since alkalinity in the anaerobic digester was maintained within a range of 2,500-5,000 mg/L as CaCO3, a good buffering capacity was obtained in the anaerobic digester (Polprasert, 1996). This indicated that the alkalinity of the influent allowed the neutralization of the volatile fatty acids, preventing the reduction of pH from the optimal value (Borja et al., 1996). Temperatures before and after feeding to anaerobic digester were in a range of 40-45 and 36-40 oC, or 42 and 38 oC in average, respectively. The warm temperature of wastewater from palm oil mill production after pretreatment was appropriate to the biochemical reaction in the anaerobic digester which converted organic matter to biogas under mesophilic temperature range, between 30 and 38 oC (Metcalf & Eddy, 2003).

COD in influent and effluent were found to be in a range of 21,560 - 39,200 mg/L and 5,880 17,640 mg/L, respectively. Average COD in influent and effluent of the anaerobic digester were about 31,687 and 11,270 mg/L, respectively. BOD5 in influent and effluent were in range of 16,950 - 24,600 mg/L and 1,100 - 2,115 mg/L, respectively, and were in average of 20,830 mg/L and 1,564 mg/L, respectively. VFA in influent and effluent was found to be between 6,600-7,200 mg/L as CaCO3 and 643-1,425 mg/L as CaCO3, respectively. Average VFA in influent and effluent were about 6,902 mg/L and 1,220 mg/L as CaCO3, respectively. The average performance of full-scale of anaerobic digester is shown in Figure 3.

Table 1 Performance of full-scale anaerobic digester treating palm oil mill effluent at Asian Palm Oil Mill, Krabi, Thailand.

Influent Parameter Range 1. pH 2. Temperature ( oC) 3. COD (mg/L) 4. BOD5 (mg/L) 4. Alkalinity (mg/L as CaCO3) 5. VFA (mg/L) 4.69-4.85 40-45 21,560-39,200 16,950-24,600 1,150-1,598 6,600-7,200 Average 4.750.05 421 31,6876,371 20,8302,861 1,308165 6,902339 Range 7.29-7.47 36-40 5,880-17,640 1,100-2,115 2,578-3,050 643-1,425 Average 7.360.06 381 11,2704,100 1,564365 2,845156 1,220288 Effluent Removal Efficiency (%) 64 92 -

35,000 30,000 25,000

Concentration (mg/L)

20,000 15,000 10,000 5,000 0 Alkalinity Volatile Fatty Acid COD

BOD BOD5 5

Influent

Effluent

Figure 3 Performance of full-scale anaerobic digester treating wastewater from palm oil production at Asian Palm Oil Mill, Krabi, Thailand.

From the operation of the anaerobic digester to treat wastewater from palm oil mill production at hydraulic retention time of 7 days with the average organic loading rate of about 4.53 kgCOD/m3.day, the average removal efficiencies of COD and BOD5 were found to be about 64% and 92%. Average biogas production rate was found to be 6,000 m3/day. The results of biogas composition analysis in Table 2 showed that methane (CH4) concentration was found to be maximum at about 66 67%, whereas carbon dioxide (CO2) and nitrogen (N2) was found to be about 29% and 2%, respectively. Oxygen (O2) was found to be less than 1%.

Table 2 Results of biogas composition analysis.

Gas CO2 O2 N2 CH4 Unit % % % % Results Sample II 29.37 0.96 2.97 66.70

Sample I 29.69 0.91 2.83 66.57

Sample III 29.81 0.72 2.23 67.24

At present, biogas produced from anaerobic digester is used in modified diesel engine with induction motor, which has a capacity of 90 kW as shown in Figure 4. This system produces electricity and supplies to the office, labor houses and anaerobic digester plant in the factory. Because it is essential to prevent corrosion to the gas engine, biogas from the anaerobic reactor is first scrubbed by lime to reduce H2S. Then removal of water by cyclone is performed to eliminate water vapor.

Figure 4 Two modified diesel engines with induction motor at Asian Palm Oil Mill, Krabi, Thailand. Conclusions The anaerobic digester at the Asian Palm Oil Mill can reduce water pollutants and foul smell from the wastewater and produces energy in form of biogas. At average organic loading rate of 4.53 kgCOD /m3.day and hydraulic retention time of 7 days, BOD5 and COD removal efficiency of up to 92% and 64% was achieved. It was found from biogas production rate that 20 m3 of biogas can be obtained from 1 m3 of wastewater from palm oil production or at about 0.51 m3 CH4/kgCOD.day. Biogas was used as fuel in modified diesel engines with induction motor to produce electricity and supply to the factory office, labor houses and biogas plant itself. Furthermore, the factory plans to invest in a project called very small power producer (VSPP) in accordance with a renewable energy policy of the Royal Thai Government.

References APHA, AWWA and WEF, (1998), Standard Methods for the Examination of Water and Wastewater, 20th Edition, Washington D.C., USA. Biomass One-stop Clearing House (2003). Introduction to conversion of Biomass to Electricity and Thermal Energy. Available online: http://www.efe.or.th/indexs.htm Borja, R., et al. (1996), Anaerobic treatment of palm oil mill effluent in a two-stage up-flow anaerobic sludge blanket system, Biotechnology, 45, pp. 125-135. Food and Agriculture Organization of the United Nations, FAO. (1995), Rural Energy Medium and Large Scale Biogas System: In the Asia-Pacific Region. 10th Anniversary issue, Bangkok. Malasian Palm Oil Board (2000). Oil Palm and the Environment. Available online: http://mpob.gov.my/oilpalm_env/mill_waste1.html Metcalf & Eddy (2003), Wastewater Engineering: Treatment, Disposal, and Reuse, 4th ed., McGraw-Hill, Singapore. Polprasert C., (1996), Organic waste recycling, 2nd ed., John Wiley & Sons Ltd, England. Rao, Peram M. (1999), Wastewater Management in a Palm Oil Mill: a case study, M.Eng. Thesis, Asian Institute of Technology, Thailand.

S-ar putea să vă placă și

- Untitled1 PDFDocument1 paginăUntitled1 PDFmehrdad_k_rÎncă nu există evaluări

- Excel Solutions To The Chemical Engineering Problem SetDocument54 paginiExcel Solutions To The Chemical Engineering Problem SetAna Isabel Roldán ToroÎncă nu există evaluări

- Ammonia B PDFDocument9 paginiAmmonia B PDFmehrdad_k_rÎncă nu există evaluări

- Dimethyl EtherDocument7 paginiDimethyl EtherAna Laura Sanchez100% (1)

- BeyondWaste EnergyAndFertilizerFromMSW PDFDocument1 paginăBeyondWaste EnergyAndFertilizerFromMSW PDFmehrdad_k_rÎncă nu există evaluări

- Syllabusprocess PDFDocument8 paginiSyllabusprocess PDFmehrdad_k_rÎncă nu există evaluări

- SunnySide Case Study PDFDocument5 paginiSunnySide Case Study PDFmehrdad_k_rÎncă nu există evaluări

- Color Vision and Occupational Toluene Exposure PDFDocument8 paginiColor Vision and Occupational Toluene Exposure PDFmehrdad_k_rÎncă nu există evaluări

- Paper Glycerol For Distribution PDFDocument4 paginiPaper Glycerol For Distribution PDFmehrdad_k_rÎncă nu există evaluări

- Flow Chart Nyongara Slaughter House PDFDocument1 paginăFlow Chart Nyongara Slaughter House PDFmehrdad_k_r100% (1)

- Bioprocess PDFDocument11 paginiBioprocess PDFmehrdad_k_rÎncă nu există evaluări

- Basic Biogas DigesterDocument7 paginiBasic Biogas DigesterOpen Knowledge and Education Book ProgramsÎncă nu există evaluări

- Biogas SystemsDocument8 paginiBiogas SystemsvedpathakÎncă nu există evaluări

- Full Scale Anaerobic Digester For Treating Palm Oil Mill Wastewater PDFDocument4 paginiFull Scale Anaerobic Digester For Treating Palm Oil Mill Wastewater PDFmehrdad_k_rÎncă nu există evaluări

- Maintaining The System Chemical Engineering Magazine PDFDocument4 paginiMaintaining The System Chemical Engineering Magazine PDFmehrdad_k_rÎncă nu există evaluări

- SustainChem2011 Posters PDFDocument8 paginiSustainChem2011 Posters PDFmehrdad_k_rÎncă nu există evaluări

- 823 Aerobic Digestion Design PDFDocument6 pagini823 Aerobic Digestion Design PDFmehrdad_k_rÎncă nu există evaluări

- Bio 4 PDFDocument8 paginiBio 4 PDFmehrdad_k_rÎncă nu există evaluări

- YR07.12.04 Event GLFVF Expo PDFDocument7 paginiYR07.12.04 Event GLFVF Expo PDFmehrdad_k_rÎncă nu există evaluări

- AmmoniaDocument2 paginiAmmonia4liinnÎncă nu există evaluări

- nrcs143 026500 PDFDocument2 pagininrcs143 026500 PDFmehrdad_k_rÎncă nu există evaluări

- Bioremediation of Oil-Contaminated Soil - Microbiological Methods For Feasibility Assessment and Field Evaluation PDFDocument10 paginiBioremediation of Oil-Contaminated Soil - Microbiological Methods For Feasibility Assessment and Field Evaluation PDFmehrdad_k_rÎncă nu există evaluări

- NRCS Digester Standard 366 PDFDocument6 paginiNRCS Digester Standard 366 PDFmehrdad_k_rÎncă nu există evaluări

- Biogas PDFDocument9 paginiBiogas PDFmehrdad_k_rÎncă nu există evaluări

- Ammonia and Urea ProductionDocument10 paginiAmmonia and Urea Productionwaheed_bhattiÎncă nu există evaluări

- Stable Links Sciencedirect PDFDocument2 paginiStable Links Sciencedirect PDFmehrdad_k_rÎncă nu există evaluări

- Appendix C UKWIN AD Briefing December 2009 PDFDocument2 paginiAppendix C UKWIN AD Briefing December 2009 PDFmehrdad_k_rÎncă nu există evaluări

- Design of An Anaerobic Waste Digester PDFDocument1 paginăDesign of An Anaerobic Waste Digester PDFmehrdad_k_rÎncă nu există evaluări

- Ammonia and Urea ProductionDocument10 paginiAmmonia and Urea Productionwaheed_bhattiÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Roject Report Honours in Accounting& Finance Under The University of Calcutta)Document36 paginiRoject Report Honours in Accounting& Finance Under The University of Calcutta)sourav jana100% (1)

- Desalination ManualDocument20 paginiDesalination ManualSenthil KumarÎncă nu există evaluări

- Philippine Environment CodeDocument2 paginiPhilippine Environment CodeGreta Andrea TalipÎncă nu există evaluări

- SlogansDocument1 paginăSlogansNeena DhawanÎncă nu există evaluări

- Assessment of Water Quality Parameters PDFDocument7 paginiAssessment of Water Quality Parameters PDFMuhammad Faroq Abu Wildan100% (1)

- Topic 5 Resource Management ConceptsDocument26 paginiTopic 5 Resource Management ConceptsyahyaÎncă nu există evaluări

- Electric Buses in DelhiDocument8 paginiElectric Buses in DelhiThe United IndianÎncă nu există evaluări

- South West Museums Libraries and Archives Council Signposts To Collections Care Factsheet 4 Preventive Conservation March 2006Document5 paginiSouth West Museums Libraries and Archives Council Signposts To Collections Care Factsheet 4 Preventive Conservation March 2006Willi De Barros GonçalvesÎncă nu există evaluări

- Environmental Condoc ENG Chapter1Document6 paginiEnvironmental Condoc ENG Chapter1Omer AkramÎncă nu există evaluări

- Combined GradingDocument12 paginiCombined Gradingkishor1506880% (1)

- Demolition Works Presentation 07052017 HCE COMMENT 1Document104 paginiDemolition Works Presentation 07052017 HCE COMMENT 1Yam BalaoingÎncă nu există evaluări

- Phase One Environmental Assessment DQ University 33250 County Road 31 Davis, CA 95616Document41 paginiPhase One Environmental Assessment DQ University 33250 County Road 31 Davis, CA 95616api-68563297Încă nu există evaluări

- Sewage Discharge StandardsDocument5 paginiSewage Discharge StandardskokkulanÎncă nu există evaluări

- AnnotatedbibDocument5 paginiAnnotatedbibapi-272557921Încă nu există evaluări

- 140 - Training & Troubleshooting Guide For NGV ConversionDocument7 pagini140 - Training & Troubleshooting Guide For NGV ConversionAndres Fernando Sokol UrzagasteÎncă nu există evaluări

- Revelstoke Liquid Waste Management Plan - Stage 1Document272 paginiRevelstoke Liquid Waste Management Plan - Stage 1AlexCooperRTRÎncă nu există evaluări

- EPA Pamphlet 27 - Lead-Based PaintDocument17 paginiEPA Pamphlet 27 - Lead-Based PainthafuchieÎncă nu există evaluări

- PolymerAdditives - Rianlon Chemical - Thanox 168 - MSDS - 2011-AugustDocument5 paginiPolymerAdditives - Rianlon Chemical - Thanox 168 - MSDS - 2011-AugustVictor CastrejonÎncă nu există evaluări

- Environm Ental Im Pact Assessm Ent ReportDocument118 paginiEnvironm Ental Im Pact Assessm Ent ReportRidhima4Încă nu există evaluări

- Jisa1460 2015Document12 paginiJisa1460 2015LongÎncă nu există evaluări

- PollutionDocument12 paginiPollutionsamy naikÎncă nu există evaluări

- Water Quality Modelling Qual 2KW For River Tungabhadra (India) .Document4 paginiWater Quality Modelling Qual 2KW For River Tungabhadra (India) .Ranjith ShepurÎncă nu există evaluări

- Republic of The Philippines City of Taguig Taguig City University Gen. Santos Avenue, Central Bicutan, Taguig CityDocument2 paginiRepublic of The Philippines City of Taguig Taguig City University Gen. Santos Avenue, Central Bicutan, Taguig CityAldrich ColladoÎncă nu există evaluări

- Student Exploration: Water PollutionDocument5 paginiStudent Exploration: Water PollutionMartinaXu50% (2)

- Energy Efficiency Best PracticeDocument35 paginiEnergy Efficiency Best PracticewatiÎncă nu există evaluări

- Air Pollution Market - FinalDocument310 paginiAir Pollution Market - FinalS V RAJAGOPALAN100% (1)

- NT2 L3 G GC - GN 69 00001 - BDocument34 paginiNT2 L3 G GC - GN 69 00001 - BHuynh Thanh TamÎncă nu există evaluări

- Sustainable DevelopmentDocument34 paginiSustainable DevelopmentNayan Rathore100% (1)

- Unit4. Legal Bases Related To Environmental Protection and Conservation in The PhilippinesDocument32 paginiUnit4. Legal Bases Related To Environmental Protection and Conservation in The PhilippinesNa ToyÎncă nu există evaluări

- Cv. Bintang Sembilan: General Contractor & SupplierDocument2 paginiCv. Bintang Sembilan: General Contractor & SupplierdrakorÎncă nu există evaluări