Documente Academic

Documente Profesional

Documente Cultură

Fujitsu FerVID HF + UHF Brochure

Încărcat de

rgovindramDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Fujitsu FerVID HF + UHF Brochure

Încărcat de

rgovindramDrepturi de autor:

Formate disponibile

FUJITSU SEMICONDUCTOR LIMITED

Nomura Fudosan Shin--yokohama Bldg. 10-23, Shin--yokohama 2-Chome, Kohoku--ku Yokohama Kanagawa 222-0033, Japan Tel: +81-45-415-5858 http://jp.fujitsu.com/fsl/en/ For further information please contact: North and South America FUJITSU SEMICONDUCTOR AMERICA, INC. 1250 E. Arques Avenue, M/S 333 Sunnyvale, CA 94085-5401, U.S.A. Tel: +1-408-737-5600 Fax: +1-408-737-5999 http://us.fujitsu.com/micro/ Europe FUJITSU SEMICONDUCTOR EUROPE GmbH Pittlerstrasse 47, 63225 Langen, Germany Tel: +49-6103-690-0 Fax: +49-6103-690-122 http://emea.fujitsu.com/semiconductor/ Korea FUJITSU SEMICONDUCTOR KOREA LTD. 902 Kosmo Tower Building, 1002 Daechi-Dong, Gangnam-Gu, Seoul 135-280, Republic of Korea Tel: +82-2-3484-7100 Fax: +82-2-3484-7111 http://kr.fujitsu.com/fsk/ Asia Pacific FUJITSU SEMICONDUCTOR ASIA PTE. LTD. 151 Lorong Chuan, #05-08 New Tech Park 556741 Singapore Tel : +65-6281-0770 Fax : +65-6281-0220 http://sg.fujitsu.com/semiconductor/ FUJITSU SEMICONDUCTOR SHANGHAI CO., LTD. 30F, Kerry Parkside, 1155 Fang Dian Road, Pudong District, Shanghai 201204, China Tel : +86-21-6146-3688 Fax : +86-21-6146-3660 http://cn.fujitsu.com/fss/ FUJITSU SEMICONDUCTOR PACIFIC ASIA LTD. 10/F., World Commerce Centre, 11 Canton Road, Tsimshatsui, Kowloon, Hong Kong Tel : +852-2377-0226 Fax : +852-2376-3269 http://cn.fujitsu.com/fsp/

FerVID family

FRAM RFID LSI

Specifications are subject to change without notice. For further information please contact each office. All Rights Reserved. The contents of this document are subject to change without notice. Customers are advised to consult with sales representatives before ordering. The information, such as descriptions of function and application circuit examples, in this document are presented solely for the purpose of reference to show examples of operations and uses of FUJITSU SEMICONDUCTOR devices; FUJITSU SEMICONDUCTOR does not warrant proper operation of the device with respect to use based on such information. When you develop equipment incorporating any device based on such information, you must assume any responsibility arising out of such use of the information. FUJITSU SEMICONDUCTOR assumes no liability for any damages whatsoever arising out of the use of the information. Any information in this document, including descriptions of function and schematic diagrams, shall not be construed as license for the use or exercise of any intellectual property right, such as patent right or copyright, or any other right of FUJITSU SEMICONDUCTOR or any third party, nor does FUJITSU SEMICONDUCTOR warrant non-infringement of any third-party's intellectual property right or other right by using such information. FUJITSU SEMICONDUCTOR assumes no liability for any infringement of the intellectual property rights or other rights of third parties which would result from the use of information contained herein. The products described in this document are designed, developed and manufactured as contemplated for general use, including without limitation, ordinary industrial use, general office use, personal use, and household use, but are not designed, developed and manufactured as contemplated (1) for use accompanying fatal risks or dangers that, unless extremely high safety is secured, could have a serious effect to the public, and could lead directly to death, personal injury, severe physical damage or other loss (i.e., nuclear reaction control in nuclear facility, aircraft flight control, air traffic control, mass transport control, medical life support system, missile launch control in weapon system), or (2) for use requiring extremely high reliability (i.e., submersible repeater and artificial satellite). Please note that FUJITSU SEMICONDUCTOR will not be liable against you and/or any third party for any claims or damages arising in connection with above-mentioned uses of the products. Any semiconductor device has an inherent chance of failure. You must protect against injury, damage or loss from such failures by incorporating safety design measures into your facility and equipment such as redundancy, fire protection, and prevention of overcurrent levels and other abnormal operating conditions. Exportation/release of any products described in this document may require necessary procedures in accordance with the regulations of the Foreign Exchange and Foreign Trade Control Law of Japan and/or US export control laws. The company names and brand names herein are the trademarks or registered trademarks of their respective owners.

2003-2012 FUJITSU SEMICONDUCTOR LIMITED Printed in Japan AD05-00028-9E April 2012 Edited: Sales Promotion Department

FUJITSU SEMICONDUCTOR LIMITED

Expand the Possibilities of Your RFID Tags with FRAM

Introducing Fujitsu Semiconductor's FRAM RFID LSI;

FA, Maintenance

Complete Visibility of Production and Real Time Operations

Large density memory and fast writing will improve the operational efficiency and quality of production in the factory

FRAM (Ferroelectric RAM) is the non-volatile memory that outperforms the conventional non-volatile memories E2PROM and Flash. Unlike E2PROM and Flash, FRAM does not require a higher internal voltage for writing operation, and this feature provides you with virtually unlimited read/write endurance, and fast writing speed. This advantage realizes large density of storage memory and stable communication distance for read and write operation. And unlike E2PROM and Flash, FRAM is resistant to sterilization by gamma-ray. Thus more and more RFID tag manufacturers around the world are selecting Fujitsu's of FRAM RFID LSI as the best RFID for data carriers. Because of large density memory and fast writing speed, FRAM RFID is the best solution for factory automation applications requiring frequent production data logging and efficiency of operation, and for maintenance applications requiring real time operation and on-site confirmation of maintenance history and parts information. Production Management (Factory Automation) The benefit of FRAM RFID tags as large density data carriers lies in their ability to store large amounts of information and to be written fast and frequentlywhich makes them ideal for use in production management in factories like automobile plants. The tags can record such information as production and inspection histories, customized parts and operation information, manuals, and so on. Off-line data management improves the flexibility of the production line, and shortens production lead times.

Aircraft Maintenance Management Fujitsus 64kByte FRAM RFID has been selected for use in the maintenance of Boeings aircraft. In order to manage the many kinds of parts in an aircraft, the RFID tags have been standardized as data carriers to keep track of maintenance history, maintenance manuals, parts information, and more. This RFID solution is expected to enhance the accuracy of all Boeing aircraft maintenance, cut turnaround time, and result in much safer and more efficient aircraft management. Great Promise as Data Carrier Tags Because of the large density memory of FRAM RFID tags and their fast and frequent writing capability, the maintenance application fields are not just the FA and aviation industries, but other industries as wella partial listing of which would include: the electricity industry, the construction industry, the infrastructure, transportation (vehicle, track, road), and rental machinery industries, and the facilities management industries (gas, water, chemicals, and oil).

FRAM RFID Can Realize a Wider Range of RFID Applications than Ever Before Fujitsu's consists of large density FRAM which are available

Large Density Memory

Fast Writing Speed High Read/Write Endurance Gamma-ray Hardness Embedded RF

for HF (13.56MHz) and UHF (860MHz960MHz) applications. The feature of large density memory is perfect for RFID use in factory automation, maintenance, asset management, and logistic tracking. And the feature of gamma-ray sterilization hardness is perfect for RFID use in the medical, pharmaceutical, biomedical, foods, and cosmetic industries. Moreover, the serial interface feature enables RFID to connect a microcontroller, and expands the possibilities of RFID into the realm of embedded applications.

FerVID family is a trademark of Fujitsu Semiconductor Limited.

Medical / Pharmaceutical / Biomedical

Gamma-ray Sterilization Hardness Enables Total Traceability

Due to its resistance to gamma-ray sterilization, FRAM RFID makes possible total traceability of medical instruments and packages from production to waste management.

Embedded RF

Serial Interface for Creating New Value

New applications can be created by connecting FRAM RFID to microcontrollers and sensors

The remarkable feature of FRAM RFID for healthcare applications is strong radiation hardness, which permits RFID to be attached to products to be sterilized by gamma-ray. Unlike conventional memory used for RFID, the data stored in FRAM survives gamma-ray sterilization. This feature is of great importance to the medical, pharmaceutical, and biomedical industries, which are continuously seeking to improve the safety and reliability of traceability management through the entire cycle from production and sterilization to logistics, warehousing, use in hospital, and waste. Traceability of Products Unlike conventional RFID tags, FRAM RFID tags can be placed on a medical or pharmaceutical product at the production stage before gamma-ray sterilization takes place from outside the package. After shipment, RFID tags can record the history of the logistic process as well. Thus, FRAM RFID enables complete visibility during all stages of the process, and thereby prevents counterfeiting. Also, when connected with sensors, FRAM RFID will be able to improve the reliability of the logistic process by recording the environmental history, such as temperature and physical stress.

The serial interface feature of RFID LSI makes it possible to add value not only for simple RFID applications but also for embedded microcontroller applications. Because the FRAM is commonly accessed from both interfaces, it can be used as the storage memory for environmental monitoring data taken by sensors through a microcontroller. And FRAM can also be used for storage of microcontroller parameters, which can be changed wirelessly. Environment Monitoring By connecting sensors and a microcontroller to RFID through a serial interface, you can monitor the environment of the logistic process, establishing better traceability management for quality control and product safety. For example, RFID can be used to record the temperature environment during the transportation of foods and wines, or to monitor the oscillation of delicate equipment during transportation. It can also be used to monitor the status of industrial equipment and facilities like railroads, in order to detect signs of fault or need for maintenance.

SALE

Traceability in Hospitals FRAM RFID is also expected to improve safety management and operational efficiency in hospitals. For example, the right quantity of medicines must be kept in stock at all times, and any expired medicines must be detected. The number of surgical tools must be checked before and after operations. Patient medication must be executed with flawless accuracy. These are some of the areas where FRAM RFID can help. Also, the penetration of NFC smart phones and tablet terminals into the medical scene may increase potential applications of FRAM RFID.

Management

Stock and Expiration Sterilization Count Reuse Count

Operating Parameter Setting The key feature of RFID is that data can be read and written by RF, even if RFID is embedded in products and packaging. This feature creates new value for the microcontroller with which RFID is connected. In product distribution, for example, the parameter data for individual customers can be written in FRAM even after the product is packed, and in the same way important traceability information and keys can be added during the logistic process or after arrival at the retail site. Then when the product is used for the first time, the microcontroller can load the data stored in FRAM to activate the product, or if the data is missing, the product may not be activated. Also if FRAM is used for parameter memory, the operational condition of the microcontroller can be changed by RF. A Tool for the Realization of New RFID Possibilities Fujitsu Semiconductor has developed an evaluation board for embedded use on which FRAM RFID is connected to a microcontroller, several sensors, and an LCD. Customers can use this board as a tool to explore new ideas and possibilities for RFID.

FRAM

Identification, Optimization

Surgical Tools (number detection) Medication to Patient Fluid System (connection matching)

Traceability

Waste Management Logistics and Warehousing

Radiation Hard

Gamma-ray/E-Beam Sterilization Radiation to Blood Products

for UHF Passive RFID MB97R803A/B, MB97R804A/B, MB97R7051

ISO/IEC18000-6C, EPC C1G2 Ver.1.2.0 compliant Worldwide UHF frequency (860960MHz) Large memory density and fast writing performance Stable communication distance between writing and reading (the same distance) Write Lock and Read Lock feature with password Anti-collision feature Serial interface for Embedded RF solutions (Evaluation board with FM3 family microcontroller and sensors)

MB97R803A Memory size User memory size Operating frequency Modulation Data coding Baudrate (Reader to RFID) Baudrate (RFID to Reader) Read/write sensitivity Command (RF) Serial interface Serial input frequency Serial input voltage Command (serial) Data retention Read/Write endurance Evaluation kit Shipping Form Wafer Package TSSOP-16 Wafer 1010 times Yes Package TSSOP-16 Wafer, Package Thin type QFN-40 MB97R803B MB97R804A

32K bits 4K Bytes

RFID Development Kit for Embedded Use MB9BF506RA-EVB-RF-01

The microcontroller board, equipped with the FM3 Microcontroller MB9BF506R, and the antenna board, equipped with the MB97R804B, are joined through an SPI interface. The microcontroller board has temperature, humidity and illuminant sensors, a 3-axis accelerometer, a clock function and an LCD, which are connected to it through a I2C interface. Sensor data collected periodically can be LCD displayed, and applications which can read by a reader/writer can be run. The main frequency of the antenna board is about 920MHz. When the board is connected to a PC through a USB connector on it, microcontroller firmware can be written on the board. Demos and programs can be created and executed for evaluation. And the board can be

MB97R804B

MB97R7051 72K Bytes 64K Bytes

used through an ICE interface as firmware for a microcontroller development kit.

Evaluation

1

3,434 Bytes 860 960MHz DSB-ASK, SSB-ASK, PR-ASK

M=2,4,8 FM0, Miller Subcarrier

PC Applications and Deliverables

PC software (for PC: Execution file) Evaluation application (for FM3: binary data) Read/write access to FRAM Access interval setting Attribute and area setting Repeat access setting PC software operation manual

2 3 4

40kbps 160kbps (0 data transmission) 40kbps 640kbps -6 dBm EPC C1G2Ver.1.2.0 commands Block Permalock, Read Lock (custom) SPI 2MHz (Max) 2.3 3.6V Read, Write 10 years (+55) -

Microcontroller Board

USB

Antenna Board

RFID Reader Writer Atid AT870

ICE

MB97R804B

LCD

Development

FM3 Microcontroller MB9BF506R

Demonstration

Deliverables

Operation manual Command manual

Sample source

FM3 initialization source code SPI driver for accessing RFID I2C driver for accessing sensors Driver for accessing external interfaces Source code manual

Temperature and Humidity Sensor

3-axis Accelerometer

Board hardware manual Demonstration application

Illuminant Sensor

(for FM3: binary data)

Demonstration application

(for AT870: binary data)

for HF Passive RFID MB89R118C, MB89R119B

ISO/IEC15693, 18000-3/Mode1 compliant Large memory density and fast writing performance Fast reading performance with custom commands Outstanding gamma-ray radiation hardness (more than 25kGy sterilization for medical usage) Anti-collision feature High-input capacitance for antenna downsizing requirements Serial interface for embedded RF solutions (in development) Ucode tag certification by Ubiquitous ID Center

MB89R118C MB89R119B

2,048 bits 256Bytes

In development MB89Rxxx

Production Roadmap

Distance

Next Production Development

UHF 860960MHz

72K bits 9K Bytes

Memory size User memory size Block structure Operating frequency Modulation Data coding Sub-carrier Baudrate Commands Input capacitance Serial interface Data retention Read/Write endurance Shipping Form Fail Die detection

16K bits 2K

3m

2,000Bytes 8Bytes, 256Blocks

232Bytes 4Bytes, 64Blocks 13.56MHz 7kHz ASK10/100% 1 out of 4(1out of 256 is not supported) One sub-carrier (Two sub-carrier is not supported) 26.48, 52.97kbps (Response to Fast command)

8192Bytes 32Bytes,256Blocks

FA, Maintenance Medical/Biomedical/ Pharmaceutical Embedded RF

MB97R803A/B MB97R804A/B

FRAM 4KB SPI I/F

MB97R7051

FRAM 64KB

Energy Harvesting Sensor I/F Small Density UHF (for Pharmaceutical Sterilization Use)

Contactless Authentification

ISO15693 commands, Custom commandsFast Read/Write SPI

ISO15693 commands, ISO15693 commands, Fast Read/Write,EAS Custom commands Kill,Fast Read/Write,EAS Custom commands 24pF/96pF 10 years (+85) 1012 times Diced Wafer (Plating bump, Backwrapped up to 150um) MAP (.xml format), Bad Mark (option)

50cm

MB89R119B

FRAM 256B

MB89R118C

FRAM 2KB

MB89Rxxx(In development)

FRAM 9KB SPI I/F

Security Feature EPC Feature NFC Type6 Feature

HF 13.56MHz

Diced Wafer (Plating bump, Backwrapped up to 150um) Pakage QFN-24

Density

256B

2KB4KB

8KB

S-ar putea să vă placă și

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- A Study of Saturn Friend Guide by D.P. Saxena PDFDocument179 paginiA Study of Saturn Friend Guide by D.P. Saxena PDFиван скворцов75% (4)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Antenna PrimerDocument14 paginiAntenna PrimerStephen Dunifer100% (3)

- Instructor ManualDocument184 paginiInstructor Manualrobsous100% (1)

- WEG HGF Low and High Voltage High Performance Electric Motor Range Broa017 Brochure EnglishDocument40 paginiWEG HGF Low and High Voltage High Performance Electric Motor Range Broa017 Brochure EnglishHatem AbdelrahmanÎncă nu există evaluări

- 05 GSM BSS Network KPI (TCH Congestion Rate) Optimization ManualDocument35 pagini05 GSM BSS Network KPI (TCH Congestion Rate) Optimization ManualPaul Claver AllouÎncă nu există evaluări

- Cen-Tech Multimeter Manual PDFDocument12 paginiCen-Tech Multimeter Manual PDFmike davisÎncă nu există evaluări

- Maquinas Electronicas CaterpillarDocument46 paginiMaquinas Electronicas CaterpillarJuan AmanquiÎncă nu există evaluări

- Signal Integrity PDFDocument23 paginiSignal Integrity PDFKhadar Basha100% (1)

- RMP200-8 HW Mod Description - 300992BDocument28 paginiRMP200-8 HW Mod Description - 300992BTEUKU50% (8)

- Design & Control Smart Automatic Water Monitoring SystemDocument3 paginiDesign & Control Smart Automatic Water Monitoring SystemRahul SharmaÎncă nu există evaluări

- Emerson DCSDocument27 paginiEmerson DCSSrikar Reddy GummadiÎncă nu există evaluări

- Test 1.57MM ML04 Tg135 35 MDocument1 paginăTest 1.57MM ML04 Tg135 35 MrgovindramÎncă nu există evaluări

- IEEE 802.3bj: 100GBASE-CR4 Specifications Minneapolis, MN May 2012Document24 paginiIEEE 802.3bj: 100GBASE-CR4 Specifications Minneapolis, MN May 2012rgovindramÎncă nu există evaluări

- DDR4 Memory Interface Solving PCB Design ChallengesDocument7 paginiDDR4 Memory Interface Solving PCB Design ChallengesrgovindramÎncă nu există evaluări

- DDRX AN2010Document7 paginiDDRX AN2010rgovindramÎncă nu există evaluări

- Web Evaluation Form: I. General InformationDocument4 paginiWeb Evaluation Form: I. General InformationrgovindramÎncă nu există evaluări

- Si8000 Si9000 Process WindowDocument6 paginiSi8000 Si9000 Process WindowrgovindramÎncă nu există evaluări

- BESt Impedance Matching TechniqueDocument4 paginiBESt Impedance Matching TechniquergovindramÎncă nu există evaluări

- Agilent 8712E Network AnalyserDocument32 paginiAgilent 8712E Network AnalyserrgovindramÎncă nu există evaluări

- Woodtag: Wurth-EmbidsDocument4 paginiWoodtag: Wurth-EmbidsrgovindramÎncă nu există evaluări

- m209 Emc-Filter v11 RBTDocument12 paginim209 Emc-Filter v11 RBTrgovindramÎncă nu există evaluări

- Ip Nucleus BrochureDocument5 paginiIp Nucleus BrochurergovindramÎncă nu există evaluări

- R IntroDocument103 paginiR Introtajjj9Încă nu există evaluări

- Metal Tag: Folded Dipole Tag Designed For The Use On Metal, Under Specific ConditionsDocument5 paginiMetal Tag: Folded Dipole Tag Designed For The Use On Metal, Under Specific ConditionsrgovindramÎncă nu există evaluări

- Kanakadhara StotramDocument3 paginiKanakadhara StotramPadmanabhan100% (5)

- 2010 Compact Yagi Antenna For Handheld UHF RFID ReaderDocument4 pagini2010 Compact Yagi Antenna For Handheld UHF RFID ReaderrgovindramÎncă nu există evaluări

- Wideband Metal Mount UHF RFID Tag: 978-1-4244-2042-1/08/$25.00 ©2008 IEEEDocument4 paginiWideband Metal Mount UHF RFID Tag: 978-1-4244-2042-1/08/$25.00 ©2008 IEEErgovindramÎncă nu există evaluări

- VijayDocument3 paginiVijayrgovindramÎncă nu există evaluări

- Patch Antenna Design MAnualDocument36 paginiPatch Antenna Design MAnualkarthikvel_852246Încă nu există evaluări

- New Meritta E - BrochureDocument16 paginiNew Meritta E - BrochurergovindramÎncă nu există evaluări

- Introduction To Antenna and Near-Field Simulation in CSTDocument23 paginiIntroduction To Antenna and Near-Field Simulation in CSTtavoosiÎncă nu există evaluări

- Advt2 2013Document5 paginiAdvt2 2013rgovindramÎncă nu există evaluări

- HFAntenna Design NotesDocument47 paginiHFAntenna Design NotesMathieu BastideÎncă nu există evaluări

- Implementation of A Wideband Micro Strip Phased Array Antenna ForDocument97 paginiImplementation of A Wideband Micro Strip Phased Array Antenna ForrgovindramÎncă nu există evaluări

- J 12034$1$2012 MGNREGA SL - No.3Document2 paginiJ 12034$1$2012 MGNREGA SL - No.3rgovindramÎncă nu există evaluări

- 8 EM SimulationDocument28 pagini8 EM SimulationrgovindramÎncă nu există evaluări

- Auxiliary Relay (7PJ11) and Trip Relay (7PJ12) : Answers For Infrastructure and CitiesDocument8 paginiAuxiliary Relay (7PJ11) and Trip Relay (7PJ12) : Answers For Infrastructure and CitiesAbhishek RajputÎncă nu există evaluări

- Comparative Analysis of HV Cables Electrical CharacteristicsDocument4 paginiComparative Analysis of HV Cables Electrical CharacteristicsmaisalailaÎncă nu există evaluări

- 19-8011 Lineman Slang Diccionary HUBBELLDocument24 pagini19-8011 Lineman Slang Diccionary HUBBELLAlberto Alber100% (1)

- HVMotorCtrl PFCKit - HowToRunGuideDocument15 paginiHVMotorCtrl PFCKit - HowToRunGuideRintuMathunniÎncă nu există evaluări

- Legislation and Codes of PracticeDocument1 paginăLegislation and Codes of Practicebuddhika MadusankaÎncă nu există evaluări

- Homework IDocument4 paginiHomework Ikjmd092399Încă nu există evaluări

- Simulation Study of Qzsi Z-Source Inverter For Resistive and Inductive LoadDocument13 paginiSimulation Study of Qzsi Z-Source Inverter For Resistive and Inductive LoadIJIERT-International Journal of Innovations in Engineering Research and TechnologyÎncă nu există evaluări

- Hamamatsu Opto-Semiconductor ModulesDocument28 paginiHamamatsu Opto-Semiconductor ModulesnorbertscribdÎncă nu există evaluări

- ApcDocument20 paginiApcShaw ShaokÎncă nu există evaluări

- Variable Range Led VoltmeterDocument1 paginăVariable Range Led VoltmeterweberpermetersquareÎncă nu există evaluări

- Banner Compact Photo EyesDocument21 paginiBanner Compact Photo EyesMemik TylnÎncă nu există evaluări

- KiloVault HLX PLUS UL Datasheet 110321Document2 paginiKiloVault HLX PLUS UL Datasheet 110321xkn6brv8p8Încă nu există evaluări

- Led TV : Owner'S ManualDocument56 paginiLed TV : Owner'S ManualAndres EscobarÎncă nu există evaluări

- Samsung Le32a65 Le37a65 Le40a65 Le46a65 Le52a65 Le37a616a 40a616a Chassis N46aDocument425 paginiSamsung Le32a65 Le37a65 Le40a65 Le46a65 Le52a65 Le37a616a 40a616a Chassis N46aenerjay80% (5)

- Fig.1 Block Diagram of TransmitterDocument5 paginiFig.1 Block Diagram of TransmitterKranthi KumarÎncă nu există evaluări

- Takshila VLSI BrochureDocument8 paginiTakshila VLSI Brochuretariq786Încă nu există evaluări

- DTC P2759: Torque Converter Clutch Pressure Control Solenoid Control Circuit Electrical (Shift Solenoid Valve Slu)Document3 paginiDTC P2759: Torque Converter Clutch Pressure Control Solenoid Control Circuit Electrical (Shift Solenoid Valve Slu)luisÎncă nu există evaluări

- Targa Instruction ManualDocument18 paginiTarga Instruction ManualPedro Elias SantanaÎncă nu există evaluări

- f00Document83 paginif00Rajeev Ranjan KumarÎncă nu există evaluări

- Donnees Mosfet NTMYS014N06CL - D-2319325Document8 paginiDonnees Mosfet NTMYS014N06CL - D-2319325Philippe GuillemetÎncă nu există evaluări

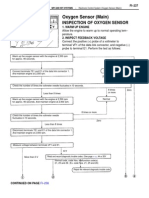

- 4afe O2sensor TestDocument3 pagini4afe O2sensor Testkkg4782Încă nu există evaluări

- Indian Standard: Application Guide For Voltage TransformersDocument16 paginiIndian Standard: Application Guide For Voltage TransformersGnanavel GÎncă nu există evaluări