Documente Academic

Documente Profesional

Documente Cultură

LCD Programming PDF

Încărcat de

Fadli Fatur RahmatDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

LCD Programming PDF

Încărcat de

Fadli Fatur RahmatDrepturi de autor:

Formate disponibile

Interfacing to Liquid Crystal Display (LCD) module.

Reading Notes For microcontroller applications, it may be required to interact with a human being. Examples include displaying messages using a LCD module (known as output device) and entering information using the keypad (known as input device). One of the most commonly used LCD module is the 16x2 displays that can display 2 lines of 16 characters each. Fortunately, a very popular standard from Hitachi exists that allows the users to communicate with the vast majority of LCDs regardless of their manufacturer. The standard requires 3 control lines as well as either 4 or 8 data lines. The user may select whether the LCD module is to operate with a 4-bit data bus or an 8-bit data bus. If a 4-bit data bus is used, the LCD module will require a total of 7-lines (3 control lines plus the 4 data lines). If an 8-bit data bus is used, the LCD module will require a total of 11-lines (3 control lines plus the 8 data lines). The three control lines are referred to as RS, E and R/~W. The RS line is the Register Select line. When RS is low (Logic 0), the data on the data bus is to be treated as a control word (such as clear display, position cursor, etc.). When RS is high (Logic 1), the data on the data bus is text data that should be displayed on the LCD. The E line is the Enable line. To send data to the LCD module, your program should first set E high (Logic 1) and set the other two control lines and put the data on the data bus. When everything is completed or ready, bring E low (Logic 0). The 1-0 transition will latch the data on the data bus into the LCD. The R/~W line is the Read/Write line. When R/~W is low (Logic 0), the data on the data bus is being written to the LCD. When R/~W is high (Logic 1), the program is effectively reading the LCD. Writing a control word to LCD module In order to write a control word to LCD we must follow the following timing diagram. RS signal must be low and the pulse width for the E signal must be at least 230nsecs.

AY 2006/2007MCT Property of TP, Copyright Page 2 of 9

RS (low) E 230nsecs

control word

Writing text data to LCD module for displaying In order to write text data to LCD we must follow the following timing diagram. RS signal must be high and the pulse width for the E signal must be at least 230nSecs.

RS (high) E 230nsecs

Text data

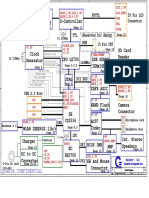

For the target board in the laboratory, a 16 characters by 2 lines LCD module is used and each character is made up of a 5 by 7 dots matrix (5 dots in horizontal and 7 dots in vertical). The LCD module interfaces to the PIC18F4520 microcontroller through a 8-bit data bus and the R/~W line is tied to ground so as to enable LCD for Write Operation only (R/~W = logic 1). Appendix A shows the schematic diagram of the target board. To display messages on the LCD, you must follow the steps mentioned below:

1. Configure the ports for the microcontroller that interface to the LCD module. 2. Initialise the LCD module by writing the control word. 3. Output text data to the LCD module for display.

Configure the ports Before you can output data to the LCD module you must first set the respective ports of the microcontroller that are used for the data lines and the control lines, as outputs. Initialise the LCD For the LCD used in the laboratory, we need to set the Function Set control word to 8-bit interfacing, 2 lines and 5 by 7 dots matrix for each character so that the LCD can display

AY 2006/2007MCT Property of TP, Copyright Page 3 of 9

messages. The next control word is the Display On/Off Control which turns the display for the LCD module ON followed by the Entry Mode Set control word to increase the position of the cursor after each character is displayed. The last two control words are the Home and Clear which set the cursor to the home position and clear the display of the LCD. Refer to the Table and Flowchart below. Control word Function Set D7 0 D6 0 D5 1 D4 D L D3 N D2 F D1 0 D0 0 Description DL = 1(8-bit data length) DL = 0(4-bit data length) N = 1(2 lines) N = 0(1 line) F = 1(5 by 10 dots) F = 0(5 by 7 dots) Display On/Off Control 0 0 0 0 1 D C B D = 1(Display ON) D = 0(Display OFF) C = 1(Cursor Display ON) C = 0(Cursor Display OFF) B = 1(Blink) B = 0(Dont Blink) Entry Mode Set 0 0 0 0 0 1 I/D S I/D= 1(Increment position) I/D= 0(Decrement position) S = 1(Shift) S = 0(Dont Shift) Cursor at Home 0 0 0 0 0 0 1 0 Return Cursor to home position (Address 0) Clear Display Set DD RAM Address Table: Control words for the LCD module. 0 1 0 A6 0 A5 0 A4 0 A3 0 A2 0 A1 1 Clear all display

A0 Setting the cursor position

AY 2006/2007MCT

Property of TP, Copyright

Page 4 of 9

Flowchart : For initialising the LCD module.

AY 2006/2007MCT

Property of TP, Copyright

Page 5 of 9

Display Data RAM Address (DD RAM Address) The LCD module contains a certain amount of memory that is assigned for display. All the text data written to the LCD module are stored in this memory before displaying on the LCD screen. This memory can be represented by the following memory map. Display 01 Line 1 Line 2 00 40 02 01 41 03 02 42 04 03 43 05 04 44 06 05 45 07 06 46 08 07 47 09 08 48 10 09 49 11 12 13 0C 4C 14 15 16 0F 4F

0A 0B 4A 4B

0D 0E 4D 4E

Memory map for 16x2 LCD module. In the above memory map, the numbers in each box is the DD RAM Address that corresponds to the LCD screen positions (cursor position). Thus, the first character on the upper left-hand corner of the LCD screen is at address H00. The next character position (character #2 on the first line) is at address H01, etc. This continues until we reach the 16th character of the first line which is at address H0F. However, the first character of line 2, as shown in the memory map above, is at address H40. Thus, we need to send a control word to the LCD module to position the cursor on the second line. Hence, the value for the Set DD RAM Address control word is B11000000, where the MSB bit is always high (refer to the table for control word).

AY 2006/2007MCT

Property of TP, Copyright

Page 6 of 9

S-ar putea să vă placă și

- 8051 Interfacing LCD 16x2Document14 pagini8051 Interfacing LCD 16x2Imran Shaukat100% (3)

- LCD PPTDocument41 paginiLCD PPTSneh Srijan100% (1)

- LCDDocument11 paginiLCDNikhith Reddy100% (1)

- LCD 2x16 SpecDocument13 paginiLCD 2x16 SpecArnoldA100% (1)

- Digital Temperature Meter Using PIC16F688Document3 paginiDigital Temperature Meter Using PIC16F688Bhuvaneswaran VutwobwnÎncă nu există evaluări

- Control IC For Single-Ended and Push-Pull Switched-Mode Power Supplies (SMPS) TDA 4718 ADocument17 paginiControl IC For Single-Ended and Push-Pull Switched-Mode Power Supplies (SMPS) TDA 4718 ASledge HammerÎncă nu există evaluări

- Eb355 80 4Document44 paginiEb355 80 4David CochlinÎncă nu există evaluări

- LC4 6eDocument93 paginiLC4 6eecureuil67Încă nu există evaluări

- Pure Sine Invereter InfoDocument107 paginiPure Sine Invereter Infoolawale gbadeboÎncă nu există evaluări

- Voltmeter Using 8051.: Circuit DiagramDocument16 paginiVoltmeter Using 8051.: Circuit DiagramVikas Ps100% (1)

- Philips 28pfl2908h-12 Chassis Vem1.1ela 17mb82sDocument43 paginiPhilips 28pfl2908h-12 Chassis Vem1.1ela 17mb82svios08Încă nu există evaluări

- SPIPGM LPT Port WriterDocument1 paginăSPIPGM LPT Port WriterabnomaloÎncă nu există evaluări

- The Drive Design of The STM32-based Brushless DC Motor: Song Wang, Wang Guo, Wenqiang DunDocument9 paginiThe Drive Design of The STM32-based Brushless DC Motor: Song Wang, Wang Guo, Wenqiang DunMarco LisiÎncă nu există evaluări

- Railway GateDocument46 paginiRailway GateRocky SinghÎncă nu există evaluări

- Renesas Flash Programmer Sample Circuit For Programming PC Serial PDFDocument5 paginiRenesas Flash Programmer Sample Circuit For Programming PC Serial PDFAjay J VermaÎncă nu există evaluări

- Intelligent Street Light Control While Obstacle PassingDocument32 paginiIntelligent Street Light Control While Obstacle Passingprashanthi_komatireddyÎncă nu există evaluări

- XO-1 Schematics PDFDocument25 paginiXO-1 Schematics PDFshibilvÎncă nu există evaluări

- Rda5876 RdaDocument22 paginiRda5876 RdaTolikÎncă nu există evaluări

- Confu HDMI To LVDS RGB TTL Driver - Specification V1802Document2 paginiConfu HDMI To LVDS RGB TTL Driver - Specification V1802ROBERTO LUOÎncă nu există evaluări

- Data Communication and Computer NetworksDocument105 paginiData Communication and Computer NetworksTalha HashmiÎncă nu există evaluări

- LG 42 Inch Plasma TV Training ManualDocument79 paginiLG 42 Inch Plasma TV Training ManualMelvin Augustus50% (2)

- PIC PWM ControllerDocument10 paginiPIC PWM Controllerkeitabando100% (2)

- Manual Pluto DataDocument8 paginiManual Pluto DataDouglas RodriguesÎncă nu există evaluări

- Dkg-109 Automatic Mains Failure UnitDocument46 paginiDkg-109 Automatic Mains Failure UnitmohsenÎncă nu există evaluări

- Panel LG Display Lc216exn-Sfa1 0Document36 paginiPanel LG Display Lc216exn-Sfa1 0Rinaldy100% (1)

- FA Mainboard CV512H-B42Document53 paginiFA Mainboard CV512H-B42Salomon ChiquilloÎncă nu există evaluări

- PHILIPS Chassis QM14.3E LA PDFDocument98 paginiPHILIPS Chassis QM14.3E LA PDFboroda2410Încă nu există evaluări

- Philips L04Document94 paginiPhilips L04Marco Antonio100% (20)

- LCD 16 X 2Document9 paginiLCD 16 X 2Pradeev Balakrishnan100% (1)

- 2080-LC10-12DWD: M810 8di 4ai Config 4do Source 12V DC Catalogue NoDocument3 pagini2080-LC10-12DWD: M810 8di 4ai Config 4do Source 12V DC Catalogue NojkhkbkbjbjhÎncă nu există evaluări

- Optocoupler Solutions Guide PDFDocument24 paginiOptocoupler Solutions Guide PDFBen Salah IssamÎncă nu există evaluări

- CPU921-922 6ES5998-0UL22 (E) OCRDocument548 paginiCPU921-922 6ES5998-0UL22 (E) OCRnasir_khan_24Încă nu există evaluări

- Adc Lab Pic18Document23 paginiAdc Lab Pic18Bolarinwa Joseph100% (1)

- PMBT2222 PMBT2222A: 1. Product ProfileDocument12 paginiPMBT2222 PMBT2222A: 1. Product ProfileLuis Figueroa100% (1)

- Universal Asynchronous Receiver Transmitter (UART)Document38 paginiUniversal Asynchronous Receiver Transmitter (UART)Chandresh Trivedi100% (1)

- User Manual For ConnectingDocument5 paginiUser Manual For ConnectingMassimo BalvisÎncă nu există evaluări

- Panel LG Display LC470EUN-PEF1 0 (DS) PDFDocument39 paginiPanel LG Display LC470EUN-PEF1 0 (DS) PDFaldo_suvi100% (2)

- Fire Bird Software ManualDocument62 paginiFire Bird Software ManualEyantra_resourcesÎncă nu există evaluări

- 5W USB Flyback Design ReviewApplication ReportDocument21 pagini5W USB Flyback Design ReviewApplication ReportleechulmiuÎncă nu există evaluări

- Bd9423efv e 1223519 PDFDocument61 paginiBd9423efv e 1223519 PDFVươngÎncă nu există evaluări

- 8051 Project LCD InterfacingDocument7 pagini8051 Project LCD InterfacingShailesh Sankdasariya100% (5)

- Mikromeia Board For PIC18FJDocument2 paginiMikromeia Board For PIC18FJmorghabiÎncă nu există evaluări

- LVDSDocument2 paginiLVDSmarco giustiÎncă nu există evaluări

- Group Project: Members: Parth Patel (08IT071) Sunil Patel (09IT256)Document24 paginiGroup Project: Members: Parth Patel (08IT071) Sunil Patel (09IT256)Prakash KumarÎncă nu există evaluări

- Mstar - Firmware Download - enDocument16 paginiMstar - Firmware Download - enrabas_Încă nu există evaluări

- Design and Implementation of Space Vector PWM Inverter Based On A Low Cost MicrocontrollerDocument12 paginiDesign and Implementation of Space Vector PWM Inverter Based On A Low Cost MicrocontrollerHaider NeamaÎncă nu există evaluări

- Service Manual 21GIII-08 SLIMDocument33 paginiService Manual 21GIII-08 SLIMAlexandra BarzaianuÎncă nu există evaluări

- Adc Pic18f452Document8 paginiAdc Pic18f452Muhammad Ummair100% (1)

- The Seven Segment DisplayDocument5 paginiThe Seven Segment DisplayTewodros Kassahun100% (2)

- Design: IdeasDocument6 paginiDesign: IdeasSamantha EwingÎncă nu există evaluări

- LCD TV: Service ManualDocument43 paginiLCD TV: Service Manualmariana acostaÎncă nu există evaluări

- Analysis 3v5v Sony MBX223 M960 ICDocument3 paginiAnalysis 3v5v Sony MBX223 M960 ICmadumadawa rajapakshaÎncă nu există evaluări

- CNC Milling (Arabic Book)Document146 paginiCNC Milling (Arabic Book)Mohamed WahidÎncă nu există evaluări

- USB To RS232 Using Atmel ATtiny2313 or ATmega8Document4 paginiUSB To RS232 Using Atmel ATtiny2313 or ATmega8Nugraha Indrawan100% (2)

- LCD InterfacingDocument16 paginiLCD InterfacingKarthik DmÎncă nu există evaluări

- Interfacing 8051 (LCD and Matrix Keyboard)Document20 paginiInterfacing 8051 (LCD and Matrix Keyboard)Sayantan Mukherjee100% (2)

- Interfacing LCD Module To 8086Document7 paginiInterfacing LCD Module To 8086sreepadaravikumar100% (2)

- Unit - Iii MPMC-1Document79 paginiUnit - Iii MPMC-1gunda manasa100% (1)

- Programming Pic Microcontrollers in Picbasic Pro - LCD Lesson 1 Cornerstone Electronics Technology and Robotics IiDocument15 paginiProgramming Pic Microcontrollers in Picbasic Pro - LCD Lesson 1 Cornerstone Electronics Technology and Robotics IiDomDoretoÎncă nu există evaluări

- Demo 3 - : LCD Interface With 8-Bit BusDocument14 paginiDemo 3 - : LCD Interface With 8-Bit BusNguyễn Tuấn CươngÎncă nu există evaluări

- Connection Diagramm C30-C30sDocument1 paginăConnection Diagramm C30-C30sFadli Fatur RahmatÎncă nu există evaluări

- NTE3078 & NTE3079 0.56" Single Digit Numeric Display Seven Segment, RHDPDocument2 paginiNTE3078 & NTE3079 0.56" Single Digit Numeric Display Seven Segment, RHDPFadli Fatur RahmatÎncă nu există evaluări

- 2N3906 PDFDocument10 pagini2N3906 PDFFadli Fatur RahmatÎncă nu există evaluări

- Pc817 DatasheetDocument5 paginiPc817 DatasheetprincebahariÎncă nu există evaluări

- ThemeDocument26 paginiThemeFadli Fatur RahmatÎncă nu există evaluări

- Kontes Robot Indonesia 2013Document44 paginiKontes Robot Indonesia 2013Fadli Fatur RahmatÎncă nu există evaluări

- Transistorred Code Lock With TorchDocument1 paginăTransistorred Code Lock With TorchFadli Fatur RahmatÎncă nu există evaluări

- Simplicity Feature List Ver1.0 RevADocument25 paginiSimplicity Feature List Ver1.0 RevAbuk ipahÎncă nu există evaluări

- Third Periodic TestDocument4 paginiThird Periodic TestCrizelda AmarentoÎncă nu există evaluări

- Design of Adaptive Headlights For AutomobilesDocument5 paginiDesign of Adaptive Headlights For AutomobilesEditor IJRITCCÎncă nu există evaluări

- Lesson 5 Appraising Diagnostic Research StudiesDocument23 paginiLesson 5 Appraising Diagnostic Research StudiesProject MedbooksÎncă nu există evaluări

- UNIX Intro and Basic C Shell Scripting: Khaldoun Makhoul Khaldoun@nmr - Mgh.harvard - EduDocument36 paginiUNIX Intro and Basic C Shell Scripting: Khaldoun Makhoul Khaldoun@nmr - Mgh.harvard - Edudaitoan402Încă nu există evaluări

- Basics, Maintenance, and Diagnostics 19Document1 paginăBasics, Maintenance, and Diagnostics 19imcoolmailme2Încă nu există evaluări

- TP3000WC ProWeatherStation User GuideDocument40 paginiTP3000WC ProWeatherStation User GuideRANDY SANTIAGOÎncă nu există evaluări

- BasCal (1st Long Exam Reviewer)Document23 paginiBasCal (1st Long Exam Reviewer)Ethan Erika BionaÎncă nu există evaluări

- Pick and Place Robotic Arm Controlled by Computer - TJ211.42.M52 2007 - Mohamed Naufal B. OmarDocument26 paginiPick and Place Robotic Arm Controlled by Computer - TJ211.42.M52 2007 - Mohamed Naufal B. OmarSAMÎncă nu există evaluări

- Mechanical Vibrations ME-307: Instructor: Luqman Ahmad Nizam Assistant Professor, HITEC University TaxilaDocument14 paginiMechanical Vibrations ME-307: Instructor: Luqman Ahmad Nizam Assistant Professor, HITEC University TaxilaAbdullahJavedÎncă nu există evaluări

- Paper I & 11 Answer All Questions: (E) Explain The Use of Correlation and Regression Studies in Busainess?Document5 paginiPaper I & 11 Answer All Questions: (E) Explain The Use of Correlation and Regression Studies in Busainess?Suthaharan PerampalamÎncă nu există evaluări

- MATLAB Modeling of SPT and Grain Size Data in Producing Soil-ProfileDocument5 paginiMATLAB Modeling of SPT and Grain Size Data in Producing Soil-Profileicv.xaviÎncă nu există evaluări

- Boxer EngineDocument84 paginiBoxer EngineTOONGA100% (7)

- Phase Diagrams: By: Cherides P. MarianoDocument25 paginiPhase Diagrams: By: Cherides P. MarianoWild RiftÎncă nu există evaluări

- Reading A Film - Problem of Denotation in Fiction FilmDocument0 paginiReading A Film - Problem of Denotation in Fiction FilmragatasuryaÎncă nu există evaluări

- Class and ObjectsDocument15 paginiClass and ObjectsIwan SaputraÎncă nu există evaluări

- Experiment 1Document6 paginiExperiment 1srinathlalÎncă nu există evaluări

- Grade 11 SEM: Markscheme Examiners ReportDocument29 paginiGrade 11 SEM: Markscheme Examiners ReportDr. Love TrivediÎncă nu există evaluări

- Flanges: SI SMEDocument16 paginiFlanges: SI SMEbalaÎncă nu există evaluări

- Al-Farabi The Theory of Emanation and THDocument14 paginiAl-Farabi The Theory of Emanation and THManuel Ricardo Fernandes SoaresÎncă nu există evaluări

- Applied Dynamics PDFDocument862 paginiApplied Dynamics PDFLeonardo Mereles100% (1)

- Math Academy AppDocument4 paginiMath Academy Appkisame1357Încă nu există evaluări

- Fabry PerotDocument11 paginiFabry PerotG. P HrishikeshÎncă nu există evaluări

- Hook Height With Drawwork SensorDocument3 paginiHook Height With Drawwork SensorJose PalumboÎncă nu există evaluări

- Given Values: Pressure Temperature Compressor Inlet 1.0325 Bar 300K Turbine Outlet 1.0325 Bar 815K Pressure Ratio 18.6Document3 paginiGiven Values: Pressure Temperature Compressor Inlet 1.0325 Bar 300K Turbine Outlet 1.0325 Bar 815K Pressure Ratio 18.6Walter BircherÎncă nu există evaluări

- Fatty Acid SynthesisDocument28 paginiFatty Acid Synthesishassanainshahi13Încă nu există evaluări

- Comba ODV-065R15E18J-GDocument1 paginăComba ODV-065R15E18J-GGaga ChubinidzeÎncă nu există evaluări

- Anchor Lliberty Mpa ManDocument8 paginiAnchor Lliberty Mpa ManIgnacio Barriga NúñezÎncă nu există evaluări

- SSP-NR 550 The Passat GTE PDFDocument72 paginiSSP-NR 550 The Passat GTE PDFan89% (9)

- Chapter 5 - Electric FieldDocument5 paginiChapter 5 - Electric FieldTHIÊN LÊ TRẦN THUẬNÎncă nu există evaluări