Documente Academic

Documente Profesional

Documente Cultură

Effect of Temperature On Mechanical Behavior of AZ31 Magnesium Alloy

Încărcat de

azizieh5701Descriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Effect of Temperature On Mechanical Behavior of AZ31 Magnesium Alloy

Încărcat de

azizieh5701Drepturi de autor:

Formate disponibile

Effect of temperature on mechanical behavior of AZ31 magnesium alloy

TAN Cheng-wen()1, 2, XU Shan-na()2, WANG Lu( )2, CHEN Zhi-yong()2, 3, WANG Fu-chi()2, CAI Hong-nian()1, 2 1. School of Materials Science and Engineering, Beijing University of Aeronautics and Astronautics, Beijing 100083, China; 2. School of Materials Science and Engineering, Beijing Institute of Technology, Beijing 100081, China; 3. School of Materials Science and Engineering, Central South University, Changsha 410083, China Received 30 September 2006; accepted 29 December 2006

Abstract: Strain rate sensitivity and tension/compression asymmetry of AZ31 magnesium alloy at different temperatures and strain rates were investigated. Both of mechanical behaviors are temperature dependent. Strain rate sensitivity increases with increasing temperature. Thermally activated slip is the source of strain rate sensitivity. At the temperature below or near 373 K, strain rate sensitivity is very little. Tension/compression asymmetry in yielding decreases with increasing temperature. Twinning is the reason of tension/compression asymmetry. At the temperature above or near 573 K, the material shows little tension/compression asymmetry of the flow stress. Key words: AZ31 magnesium alloy; strain rate sensitivity; tension/compression asymmetry; temperature effect

1 Introduction

Magnesium and its alloys have some advantageous properties that make them an excellent choice for a number of applications. Magnesium has a high specific strength with a density that is only 2/3 that of aluminum and 1/4 that of iron. Magnesium also has high thermal conductivity, high dimensional stability, good electromagnetic shielding characteristics, high damping characteristics, good machinability and is easily recycled. These properties make magnesium and its alloys valuable in a number of applications including automobile, aerospace components and so on[14]. Under some conditions, the mechanical behaviors are determinant whether they can be used effectively[56]. AZ31 is one of the most frequently used commercial alloys[7]. There is few investigation on the strain rate sensitivity and tension/compression asymmetry at different temperatures. But under impact and pressure loading condition, all these properties are important. The purpose of the present paper is to make an effort to make

up the insufficiency of this aspect, so the temperature effect of mechanical behavior in AZ31 magnesium alloy is investigated systematically.

2 Experimental

The experimental alloy was a commercial AZ31 (Mg-3%Al-1%Zn, mass fraction) hot rolled plate, which was homogenized at 600 K for 0.5 h. Fig.1 shows the initial microstructure of the hot-rolled AZ31 sheet. Tensile specimens with a gauge dimension of d 5 mm14 mm were machined from the plate. The tensile direction of the samples is parallel to the rolling direction of the plate, as shown in Fig.2(a). Compressive specimens with a dimension of d 8 mm12 mm were machined from the same plate, as shown in Fig.2(b). And the axis direction of the samples is along rolling direction. Tensile tests and compressive tests were conducted on a Gleeble 1500D at temperatures of 373, 473 and 573 K, and at the strain rates of 1103, 1101 and 1101 s1 under constant cross-head speed control.

Corresponding author: TAN Cheng-wen; Tel: +86-10-68912712; E-mail: tanchengwen@126.com

42

TAN Cheng-wen, et al/Trans. Nonferrous Met. Soc. China 17(2007)

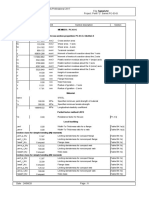

calculated m values are listed in Table 1. The results indicate that, the strain rate sensitivity of AZ31 alloy is temperature dependent, for both tensile and compressive tests, and the strain rate sensitivity increases with increasing temperature, suggesting a transition of different controlling deformation mechanisms. On the other hand, at the same temperature, the tensile m value is less than the compressive one, that is, there are different deformation mechanisms also.

Table 1 Strain rate sensitivity (m) of AZ31 alloy corresponding to different temperatures (=0.2, strain rate 101101 s1) Test Tensile Compressive Temperature/K 373 0.058 0.074 473 0.233 0.332 573 0.648 0.750

Fig.1 Initial microstructure of hot-rolled AZ31 sheet

Fig.2 Specimen for tensile test (a) and for compression test (b)

3 Results and discussion

3.1 Strain rate sensitivity The index of strain rate sensitivity (m) is used to evaluate strain rate effect of AZ31 magnesium alloy. Based on the equation[89], it yields

&m = K

Basal slip is the dominant deformation mechanism in magnesium alloys, and it is athermal in the interested temperature range[1011]. So the basal slip mechanism is not the reason for the strain rate sensitivity change. The non-basal slips increase with increasing temperature because they are strongly thermally activated. So the strain rate sensitivity is controlled by non-basal slips. When the temperature is less than 373 K, only the basal slip system (0001) <11 2 0> is operated, and the m value is almost equal to zero. When the temperature is less than 473 K but more than 373 K, prism slip {10 1 0} <11 2 0> is operated also, and the m value increases. At the temperature above 473 K, pyramidal slip {10 1 1} <11 2 0> and {11 2 2} <11 2 3> are operated, the number of slip systems increase from 4 to 10 or 15, so the m value increases from 0.233 (0.332) to 0.648 (0.750). Thermally activated slip is the source of strain rate sensitivity. 3.2 Tension/compression asymmetry in yielding Tension/compression asymmetry in yielding for wrought magnesium alloy is an important property, which has been considered only at the room temperature [1213]; while there is few investigation on the asymmetry at different temperatures. Fig.4 shows the tensile/compressive yield asymmetry evolution with temperature. Tension/compression asymmetry in yielding can be estimated by the factor stc, defined as follows: stc=yt/yc (4)

(1)

m can be calculated as

m= ln & ln

(2)

where is the tensile or compressive flow stress and & is the strain rate. By different strain rate tests, m can be calculated by

m=

ln( 1 / 2 ) &1 / &2 ) ln(

(3)

Fig.3 shows the true stress strain curves at different temperatures and strain rates. The strain rate sensitivity can be obtained from the tensile and compressive curves. For contrast expediently, all the values are obtained when the values equal to 0.2. The

where yt and yc are the tensile and compressive yield stresses, respectively. For wrought magnesium alloy, tensile yield stress is bigger than compressive yield stress. So stc is more than or equal to 1, and when stc equals 1, there is not tension/compression asymmetry.

TAN Cheng-wen, et al/Trans. Nonferrous Met. Soc. China 17(2007)

43

Fig.3 True stressstrain curves of AZ31 alloy at different temperatures: (a) 373 K, tensile; (b) 473 K, tensile; (c) 573 K, tensile; (d) 373 K, compressive; (e) 473 K, compressive; (f) 573 K, compressive

The stc values are listed in Table 2. The results indicate that, the tension/compression asymmetry in yielding is temperature dependent, and decreases with increasing temperature.

Table 2 stc values corresponding to different temperatures and strain rates Strain rate/s1 0.001 0.1 373 2.26 2.27 Temperature/K 473 1.39 1.91 573 1.22 1.15

According to Von-Mises theory, only five independent active systems are necessary in order to accomplish an arbitrary shape change when polycrystalline materials are deformed. But there are only two independent slip systems for basal slip in Mg alloys deformed at room temperature or high a little, and others depend on twinning[1415]. Generally, the yield strength for tension is asymmetric to that for compression in the case that both slip and twinning take place or only twinning happens. With the temperature increasing, non-basal slip systems are operated easily.

44

TAN Cheng-wen, et al/Trans. Nonferrous Met. Soc. China 17(2007)

Fig.4 True stressstrain curves of AZ31 Mg alloy at different temperatures and strain rates: (a) 373 K, =0.001 s1; (b) 373 K, =0.1 s1; (c) 473 K, =0.001 s1; (d) 473 K, =0.1 s1; (e) 573 K, =0.001 s1; (f) 573 K, =0.1 s1

The tendency for twinning would be reduced, with a consequent decrease in the tension/compression anisotropy. It can be explained by the symmetry of slip and twinning yield surfaces in stress space. The slip yield surface is symmetric about the origin since the slip direction can be positive and negative; while the twinning yield surface is asymmetric about the origin since the twinning direction is unidirectional. Therefore, the material shows obvious tension/compression asymmetry at 373 K due to the large number of twinning. At the temperature above or near 573 K, the critical resolved shear stress (CRSS) for basal and non-basal slip

is almost in the same order. The material shows little tension/compression asymmetry of the flow stress as a result of decreased twinning.

4 Conclusions

1) Hot-rolled commercial AZ31 magnesium alloy is one of strain rate sensitivity materials. The index of strain rate sensitivity (m) increases with increasing temperature. Strain rate sensitivity of 0.058, 0.233 and 0.648 are obtained at 373, 473 and 573 K, respectively. Thermally activated slip is the reason of strain rate

TAN Cheng-wen, et al/Trans. Nonferrous Met. Soc. China 17(2007)

45

sensitivity. 2) In hot-rolled commercial AZ31 magnesium alloy, tension/compression asymmetry in yielding is temperature dependent and decreases with increasing temperature. The value stc, which estimates tension/ compression asymmetry, of 2.26, 1.39 and 1.22 are obtained at 373, 473 and 573 K, respectively. Twinning is the reason of tension/compression asymmetry in yielding.

[7] [8]

[9]

[10]

References

[1] MORDIKE B L, EBERT T. Magnesium propertiesapplications-potential [J]. Materials Science and Engineering A, 2001, A302: 3745. LUO A A. Magnesium: current and potential automotive applications [J]. Journal of the Minerals and Materials Society, 2002, 54(2): 4248. LIU Y. Transient Plasticity and Micro-structural Evolution of a Commercial AZ31 Magnesium Alloy at Elevated Temperatures [D]. Detroit: Wayne State University, 2003: 124. GARCES G, PEREZ P, ADEVA P. Thermal stability of metastable Mg-30%Ti-2%Al-0.9%-Mn (wt.%) alloy synthesized by PVD [J]. Journal of Alloys and Compounds, 2005, 387(1/2): 115120. HIRAI K, SOMEKAWA H, TAKIGAWA Y, YORINOBU T, KENJI H. Effects of Ca and Sr addition on mechanical properties of a cast AZ91 magnesium alloy at room and elevated temperature [J]. Materials Science and Engineering A, 2005, A403(1/2): 276280. MA C J, LIU M, WU G H, DING W J, ZHU Y P. Microstructure and mechanical properties of extruded ZK60 magnesium alloy containing rare earth [J]. Materials Science and Technology, 2004, 20(12):

[11]

[2]

[12]

[3]

[13]

[4]

[14]

[5]

[15]

[6]

16611665. MATUCHA H. Structure and Properties of Nonferrous Alloys [M]. New York: VCH, 1996: 117206. TAKUDA H, MORISHITA T, KINOSHITA T, SHIRAKAWAB N. Modeling of formula for flow stress of a magnesium alloy AZ31 sheet at elevated temperatures [J]. Journal of Materials Processing Technology, 2005, 164(15): 12581262. WANG Cong, XU Yong-bo, HAN En-hou. Serrated flow and abnormal strain rate sensitivity of a magnesium-lithium alloy [J]. Materials Letters, 2006, 60(24): 29412944. AGNEW S R, DUYGULU O. A mechanistic understanding of the formability of magnesium: examining the role of temperature on the deformation mechanisms [J]. Materials Science Forum, 2003, 419/422: 177188. AGNEW S R, YOO M H, TOME C N. Application of texture simulation to understanding mechanical behavior of Mg and solid solution alloys containing Li or Y [J]. Acta Materialia, 2001, 49(20): 42774289. MANN G, GRIFFITHS J R, CCERES C H. Hall-Petch parameters in tension and compression in cast Mg-2Zn alloys [J]. Journal of Alloys and Compounds, 2004, 378(1/2): 188191. CAZACU O, PLUNKETT B, BARLAT F. Orthotropic yield criterion for hexagonal closed packed metals [J]. International Journal of Plasticity, 2006, 22(7): 11711194. STAROSELSKY A, ANAND L. A constitutive model for HCP materials deforming by slip and twinning: application to magnesium alloy AZ31B [J]. International Journal of Plasticity, 2003, 19(10): 18431864. KOIKE J, OHYAMA R, KOBAYASHI T, SUZUKI M, MARUYAMA K. Grain-boundary sliding in AZ31 magnesium alloys at room temperature to 523 K [J]. Materials Transactions, 2003, 44(4): 445451. (Edited by YANG Bing)

S-ar putea să vă placă și

- Testing of The Plastic Deformation of MetalsDocument385 paginiTesting of The Plastic Deformation of MetalsAlexander Jose Chacin NavarroÎncă nu există evaluări

- DoubleAngleCapacityDocument2 paginiDoubleAngleCapacityIsprotec IngenieriaÎncă nu există evaluări

- AWS Cwi Exercise Questions Part 2Document90 paginiAWS Cwi Exercise Questions Part 2Einsteinw2100% (17)

- Materials Data for Cyclic Loading: Aluminium and Titanium AlloysDe la EverandMaterials Data for Cyclic Loading: Aluminium and Titanium AlloysEvaluare: 1 din 5 stele1/5 (1)

- Lecture 4 - Cam ClayDocument43 paginiLecture 4 - Cam Clayalexjos1Încă nu există evaluări

- LS SrinathDocument409 paginiLS SrinathAnshul TiwariÎncă nu există evaluări

- API 1104 Defects Acceptance Criteria FinalDocument9 paginiAPI 1104 Defects Acceptance Criteria Finalazizieh5701Încă nu există evaluări

- Mechatronics MujDocument45 paginiMechatronics MujRocker byÎncă nu există evaluări

- Member Design Reinforced Concrete Corbel bs8110 v2015 01Document10 paginiMember Design Reinforced Concrete Corbel bs8110 v2015 01Aboalmaali100% (1)

- Connections in Steel Structures II - Behavior Strength and DesignDocument471 paginiConnections in Steel Structures II - Behavior Strength and DesignCarlo Dizon100% (3)

- Friction Stir Welding of High Strength 7XXX Aluminum AlloysDe la EverandFriction Stir Welding of High Strength 7XXX Aluminum AlloysÎncă nu există evaluări

- AWS - CWI Model Question Foundamental - Part 2Document17 paginiAWS - CWI Model Question Foundamental - Part 2dhasdj100% (6)

- Simple Stresses & StrainsDocument31 paginiSimple Stresses & Strainsrahul_patil85100% (1)

- Study On Welding Temperature Distribution in Thin Welded Plates Through Experimental Measurements and Finite Element SimulationDocument7 paginiStudy On Welding Temperature Distribution in Thin Welded Plates Through Experimental Measurements and Finite Element SimulationAr PanÎncă nu există evaluări

- Study of Transient Temperature Distribution in A Friction Welding Process and Its Effects On Its JointsDocument12 paginiStudy of Transient Temperature Distribution in A Friction Welding Process and Its Effects On Its JointsMuhammad Fatka FirmansyahÎncă nu există evaluări

- 1989 - Hecker - Effects of Strain StateDocument8 pagini1989 - Hecker - Effects of Strain StateOctvo Lzd FlÎncă nu există evaluări

- Welding Research: Development of A New Hot-Cracking Test-The SigmajigDocument6 paginiWelding Research: Development of A New Hot-Cracking Test-The SigmajigElaine JohnsonÎncă nu există evaluări

- Investigation On Zener-Hollomon Parameter of A Medium Carbon Low Alloy of 1Cr-1Mn-1.5Ni-1Si-0.1V Under Hot Compression TestDocument7 paginiInvestigation On Zener-Hollomon Parameter of A Medium Carbon Low Alloy of 1Cr-1Mn-1.5Ni-1Si-0.1V Under Hot Compression TestEidelsayedÎncă nu există evaluări

- Formability of Stamping Magnesium-Alloy AZ31 SheetsDocument5 paginiFormability of Stamping Magnesium-Alloy AZ31 SheetsVarthini RajaÎncă nu există evaluări

- Pierer R CreepDocument12 paginiPierer R CreepFahrgerusteÎncă nu există evaluări

- On The Hot Tensile Deformation Behaviour of AISI 316LN Stainless SteelDocument8 paginiOn The Hot Tensile Deformation Behaviour of AISI 316LN Stainless SteelMallikarjunrao PanabakaÎncă nu există evaluări

- A060822 PDFDocument8 paginiA060822 PDFEidelsayedÎncă nu există evaluări

- 1-Fundamentals of Creep in MaterialsDocument6 pagini1-Fundamentals of Creep in MaterialsLucianoBorasiÎncă nu există evaluări

- Plastic Deformation of The Intermetallic: Compound MGZNDocument11 paginiPlastic Deformation of The Intermetallic: Compound MGZNFaris FadliÎncă nu există evaluări

- A Finite Element Analysis For The Least Temperature Rise in A Hot Torsion Test SpecimenDocument14 paginiA Finite Element Analysis For The Least Temperature Rise in A Hot Torsion Test SpecimenkotakamalsÎncă nu există evaluări

- Temperature Effect On The Mechanical Behavior of Acrylic Polymers Under Quasi-Static and Dynamic LoadingDocument6 paginiTemperature Effect On The Mechanical Behavior of Acrylic Polymers Under Quasi-Static and Dynamic LoadingXimena RuizÎncă nu există evaluări

- Numerical Simulation On Residual Stress Distribution of Hard-Face-Welded Steel Specimens With Martensite TransformationDocument5 paginiNumerical Simulation On Residual Stress Distribution of Hard-Face-Welded Steel Specimens With Martensite TransformationJR ZookÎncă nu există evaluări

- Annales de Chimie: Science Des Materiaux: Received: 13 January 2019 Accepted: 2 April 2019Document4 paginiAnnales de Chimie: Science Des Materiaux: Received: 13 January 2019 Accepted: 2 April 2019purnashisÎncă nu există evaluări

- High-Cycle Fatigue Behavior of Type 316L Stainless SteelDocument9 paginiHigh-Cycle Fatigue Behavior of Type 316L Stainless SteelDeva RajÎncă nu există evaluări

- Obect:-Apparatus Required:: Practical No.1Document5 paginiObect:-Apparatus Required:: Practical No.1mohammad_nizamaniÎncă nu există evaluări

- Effect of Strain Rate Upon Plastic Flow of SteelDocument12 paginiEffect of Strain Rate Upon Plastic Flow of SteelLily MaÎncă nu există evaluări

- The Creep Parameters of SAC305 Unleaded SoldersDocument10 paginiThe Creep Parameters of SAC305 Unleaded SoldersMartin BánfalviÎncă nu există evaluări

- Yield Strength Estimation For Stainless Steel Using Plane Strain Compression TestDocument10 paginiYield Strength Estimation For Stainless Steel Using Plane Strain Compression TestGeraldy Faiq PutraÎncă nu există evaluări

- 2018 Grabowski Et Al. - Anisotropy of Thermal Expansion of 3Y-TZP, α-Al2O3 and Composites From 3Y-TZP - α-Al 2 O 3 SystemDocument10 pagini2018 Grabowski Et Al. - Anisotropy of Thermal Expansion of 3Y-TZP, α-Al2O3 and Composites From 3Y-TZP - α-Al 2 O 3 Systemnorthpole_plÎncă nu există evaluări

- Form Ability Od A8011 Aluminium Alloy SheetDocument6 paginiForm Ability Od A8011 Aluminium Alloy SheetwojciechsciezorÎncă nu există evaluări

- Nani Babu-High-Temperature Fatigue Crack Growth Behaviour of SS 316LN PDFDocument10 paginiNani Babu-High-Temperature Fatigue Crack Growth Behaviour of SS 316LN PDFAvinash ChittellaÎncă nu există evaluări

- Ceramics 03 00033Document12 paginiCeramics 03 00033Kristanto WahyudiÎncă nu există evaluări

- The Effect of The Initial Rolling Temperature On The Microstructure Evolution During and After Hot Rolling of AA6082Document4 paginiThe Effect of The Initial Rolling Temperature On The Microstructure Evolution During and After Hot Rolling of AA6082Mahendra DhadweÎncă nu există evaluări

- Reducing The Distortion in Thin-Sheet Structures MDocument6 paginiReducing The Distortion in Thin-Sheet Structures MJose Marie Rmgrocks BatoÎncă nu există evaluări

- MG Tech Manuscript Final RevisedDocument11 paginiMG Tech Manuscript Final RevisedSEENUVASAPERUMAL PÎncă nu există evaluări

- Identification of Constitutive Material Model Parameters For High-Strain Rate Metal Cutting Conditions Using Evolutionary Computational AlgorithmsDocument18 paginiIdentification of Constitutive Material Model Parameters For High-Strain Rate Metal Cutting Conditions Using Evolutionary Computational AlgorithmskeepingbusyÎncă nu există evaluări

- 58 4 NieDocument12 pagini58 4 Nieestag.engÎncă nu există evaluări

- Tensile Properties and Strain Rate SENSITIVITY OF Ti-47Al-2Cr-0.2Si Sheet Material With Different MicrostructuresDocument6 paginiTensile Properties and Strain Rate SENSITIVITY OF Ti-47Al-2Cr-0.2Si Sheet Material With Different MicrostructuresTommy NoviantoÎncă nu există evaluări

- Paper PublishedDocument7 paginiPaper PublishedNavlesh JamdarÎncă nu există evaluări

- Dwell Time Effects On Fatigue Life and Damage Mechanisms: ArticleDocument10 paginiDwell Time Effects On Fatigue Life and Damage Mechanisms: Articleabraham silva hernandezÎncă nu există evaluări

- Magneto-Elastic Effect For 316LN-IG Stainless Steel at Low TemperatureDocument6 paginiMagneto-Elastic Effect For 316LN-IG Stainless Steel at Low Temperature82865200Încă nu există evaluări

- Hot Deformation Behaviour Studies On 58Ni-39Cr Nickel Super Alloy by Thermo-Mechanical Simulation and Finite Element MethodDocument10 paginiHot Deformation Behaviour Studies On 58Ni-39Cr Nickel Super Alloy by Thermo-Mechanical Simulation and Finite Element MethodTJPRC PublicationsÎncă nu există evaluări

- Effect of Tool Temperature On The Reduction of The Springback of Aluminum SheetsDocument4 paginiEffect of Tool Temperature On The Reduction of The Springback of Aluminum SheetsJabbar AljanabyÎncă nu există evaluări

- IJME - Low and High Temperature Micromechanical Behavior of BN3003 Aluminum Alloy NanocompositesDocument8 paginiIJME - Low and High Temperature Micromechanical Behavior of BN3003 Aluminum Alloy Nanocompositesiaset123Încă nu există evaluări

- Temper Bead Welding 36036664Document9 paginiTemper Bead Welding 36036664sv1xv100% (1)

- Finite Element Analysis On The Temperature - DependDocument11 paginiFinite Element Analysis On The Temperature - DependSharat ChandraÎncă nu există evaluări

- Filip Vanden AbeeleDocument8 paginiFilip Vanden Abeelewcjjang06078959Încă nu există evaluări

- Numerical Study of Residual Thermal Stresses in MMCDocument12 paginiNumerical Study of Residual Thermal Stresses in MMCKamel FedaouiÎncă nu există evaluări

- Transient Temperature Distribution in A Steel Rod Subjected To Friction WeldingDocument11 paginiTransient Temperature Distribution in A Steel Rod Subjected To Friction WeldingMuhammad Fatka FirmansyahÎncă nu există evaluări

- B Y S. TimoshenkoDocument23 paginiB Y S. TimoshenkovpcÎncă nu există evaluări

- Creep ExperimentalDocument8 paginiCreep ExperimentalPanji Haryono AzisÎncă nu există evaluări

- Mechanical Behavior of 316L Stainless Steel AfterDocument6 paginiMechanical Behavior of 316L Stainless Steel AfterRicardo Andrés García LeónÎncă nu există evaluări

- 7206 9292 1 PB PDFDocument11 pagini7206 9292 1 PB PDFMichael SerraÎncă nu există evaluări

- Compression Properties of Lead-Bismuth: Y. Dai, F. Barbagallo, F. GroeschelDocument4 paginiCompression Properties of Lead-Bismuth: Y. Dai, F. Barbagallo, F. GroeschelRadu CristianÎncă nu există evaluări

- JMPS 2004 Zhang DunnDocument26 paginiJMPS 2004 Zhang Dunnp1muellerÎncă nu există evaluări

- Creep Behavior of Type 310 Stainless Steel. Part 1: Parameters From The Norton, Arrhenius and Monkman-Grant RelationsDocument13 paginiCreep Behavior of Type 310 Stainless Steel. Part 1: Parameters From The Norton, Arrhenius and Monkman-Grant Relationssezgin bayramÎncă nu există evaluări

- 1997 CST Creep of Al MMCs With SiC, Al2O3 and TiB2 ParticlesDocument6 pagini1997 CST Creep of Al MMCs With SiC, Al2O3 and TiB2 Particlesyaswanth1992Încă nu există evaluări

- Tensile, Creep, and ABI Tests On Sn5%Sb Solder PDFDocument8 paginiTensile, Creep, and ABI Tests On Sn5%Sb Solder PDFeid elsayedÎncă nu există evaluări

- Aleaciones 7000 AlDocument20 paginiAleaciones 7000 AlDavid FellinÎncă nu există evaluări

- Dislocation Mechanics1 PDFDocument9 paginiDislocation Mechanics1 PDFkakarlasantosh22Încă nu există evaluări

- Fractography Analysis and Constitutive Modeling For Dynamic Plasticity of Austenite Stainless Steel (ASS 304) at Hot-Working TemperaturesDocument33 paginiFractography Analysis and Constitutive Modeling For Dynamic Plasticity of Austenite Stainless Steel (ASS 304) at Hot-Working TemperaturesNuno FerreiraÎncă nu există evaluări

- PhysicsDocument5 paginiPhysicsAditya Budi FauziÎncă nu există evaluări

- Creep Mechanism and Creep Constitutive Model of Aluminum Silicate Short-Fiber-Reinforced Magnesium Matrix CompositeDocument9 paginiCreep Mechanism and Creep Constitutive Model of Aluminum Silicate Short-Fiber-Reinforced Magnesium Matrix CompositeSharan AnnapuraÎncă nu există evaluări

- Dylatometria Ferryt DeltaDocument9 paginiDylatometria Ferryt DeltaGrzegorz CiosÎncă nu există evaluări

- English Grammar Fast (WWW - Patoghu.com)Document40 paginiEnglish Grammar Fast (WWW - Patoghu.com)azizieh5701Încă nu există evaluări

- Measurements Errors KimDocument2 paginiMeasurements Errors Kimazizieh5701Încă nu există evaluări

- AWS CWI Reexam Application PackageDocument3 paginiAWS CWI Reexam Application Packageazizieh5701Încă nu există evaluări

- 1 Duties and Responsibilities Section 1Document22 pagini1 Duties and Responsibilities Section 1azizieh5701Încă nu există evaluări

- Certified Welding Inspector Program Package: 2009 AWS CWI Seminar and Exam Schedule/Price ListDocument9 paginiCertified Welding Inspector Program Package: 2009 AWS CWI Seminar and Exam Schedule/Price Listazizieh5701Încă nu există evaluări

- 6 Material InspectionDocument8 pagini6 Material Inspectionazizieh5701Încă nu există evaluări

- 20 Arc Welding SafetyDocument2 pagini20 Arc Welding Safetyazizieh5701Încă nu există evaluări

- Welding Inspector: Codes & Standards Section 7Document3 paginiWelding Inspector: Codes & Standards Section 7azizieh5701Încă nu există evaluări

- Experimental Investigation of The Stress-Stretch Behavior of EPDM Rubber With Loading Rate EffectsDocument20 paginiExperimental Investigation of The Stress-Stretch Behavior of EPDM Rubber With Loading Rate EffectsPaulo Venicio Alves VieiraÎncă nu există evaluări

- 10 1002@suco 201200060Document25 pagini10 1002@suco 201200060PCPCÎncă nu există evaluări

- BME 332 - StressDocument16 paginiBME 332 - Stressselva_raj215414Încă nu există evaluări

- Design of Machine Elements Practical FileDocument14 paginiDesign of Machine Elements Practical FileAshish K. Yadav100% (1)

- MCQ m8Document3 paginiMCQ m8Karan BansalÎncă nu există evaluări

- Modeling of Squat Structural Walls Controlled by Shear: ArticleDocument11 paginiModeling of Squat Structural Walls Controlled by Shear: ArticleRory Cristian Cordero RojoÎncă nu există evaluări

- Mendecki Et Al1999 Guide To Seismic Monitoring in MinesDocument36 paginiMendecki Et Al1999 Guide To Seismic Monitoring in MinesAriberto SaccoÎncă nu există evaluări

- Application of User Defined Subroutine U PDFDocument58 paginiApplication of User Defined Subroutine U PDFmatmean100% (2)

- Concrete Model in AdinaDocument28 paginiConcrete Model in AdinaAdolfo Gálvez VillacortaÎncă nu există evaluări

- Rubber-Deterioration by Heating in Air (Test Tube Enclosure) 'Document4 paginiRubber-Deterioration by Heating in Air (Test Tube Enclosure) 'pankaj100% (1)

- Mechanical Properties of Recycled Aggregate Concrete Under Uniaxial LoadingDocument8 paginiMechanical Properties of Recycled Aggregate Concrete Under Uniaxial LoadingCristián JiménezÎncă nu există evaluări

- Esa Lecture Notes PDFDocument205 paginiEsa Lecture Notes PDFSwaroop MunavalliÎncă nu există evaluări

- Dr. Raghuwar D Singh Associate Professor: Prosthodontic Department King George's Medical University UP, LucknowDocument28 paginiDr. Raghuwar D Singh Associate Professor: Prosthodontic Department King George's Medical University UP, LucknowAnsa CervicalisÎncă nu există evaluări

- What Is Difference Between Bending and BucklingDocument7 paginiWhat Is Difference Between Bending and BucklingPacha Khan KhogyaniÎncă nu există evaluări

- S195 Philippe J Couturier PHD ThesisDocument202 paginiS195 Philippe J Couturier PHD ThesisAnonymous hprsT3WlPÎncă nu există evaluări

- Memoria Samet SimpleDocument2 paginiMemoria Samet SimpleJuan Emanuel VenturelliÎncă nu există evaluări

- L3 - Design Against Static Load-2Document13 paginiL3 - Design Against Static Load-2Dhyan PatelÎncă nu există evaluări

- Mechanical Testing (Tension)Document33 paginiMechanical Testing (Tension)ZANTHERÎncă nu există evaluări

- Lecture 07 Mechanical Properties 2Document20 paginiLecture 07 Mechanical Properties 2antoine demeireÎncă nu există evaluări

- Unity Check Examples (ASD Vs LFRD) PDFDocument3 paginiUnity Check Examples (ASD Vs LFRD) PDFLaurence Arcon BanalÎncă nu există evaluări

- MOM Module 1Document26 paginiMOM Module 1Ramesh Reddy B TÎncă nu există evaluări