Documente Academic

Documente Profesional

Documente Cultură

Oxygen USP

Încărcat de

Martha Lucia Roa FonsecaDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Oxygen USP

Încărcat de

Martha Lucia Roa FonsecaDrepturi de autor:

Formate disponibile

Accessed from 190.216.198.

50 by JNJconsumer on Mon May 06 11:48:03 EDT 2013

USP 36

glacial acetic acid, and 1.0 mL of triethylamine. Pass through a filter of 0.5-m or finer pore size. Solution B: 2.2 g of sodium 1-octanesulfonate in 500 mL of water. Add 500 mL of methanol, 20 mL of glacial acetic acid, and 1.0 mL of triethylamine. Pass through a filter of 0.5-m or finer pore size. Mobile phase: See Table 1.

Table 1 Time (min) 0 30 50 55 Solution A (%) 90 80 0 0 Solution B (%) 10 20 100 100

Official Monographs / Oxygen 4649

Acceptance criteria Individual impurities: NMT 1.0% Total impurities: NMT 2.0% SPECIFIC TESTS CONTENT OF TEREPHTHALIC ACID Sample solution: Transfer 1 g into a 50-mL beaker. Add 25 mL of 0.2 N hydrochloric acid, and heat to boiling with continuous stirring. Cover the beaker with a watch glass, and allow to cool to room temperature. Pass the suspension through a tared, medium-porosity filtering crucible. Transfer any material remaining in the beaker to the crucible with the aid of small portions of cold 0.2 N hydrochloric acid. Wash the material in the crucible with several portions of cold 0.2 N hydrochloric acid. [NOTEReserve the combined filtrates for use in Identification test A.] Analysis: Dry the material in the crucible at 105 for 1 h, allow to cool, and reweigh. The material in the crucible is terephthalic acid. Determine the weight of terephthalic acid, and calculate the percentage of terephthalic acid. Acceptance criteria: Between 20.2% and 21.5% of terephthalic acid (C8H6O4) in Oxycodone Terephthalate on the dried basis LOSS ON DRYING 731: Dry a sample at 105 for 4 h: it loses NMT 1.5% of its weight. ADDITIONAL REQUIREMENTS PACKAGING AND STORAGE: Preserve in tight containers. USP REFERENCE STANDARDS 11 USP Oxycodone RS

Diluent: 0.1 N hydrochloric acid Standard stock solution: 0.9 mg/mL of USP Oxycodone RS in Diluent Standard solution: 0.09 mg/mL of USP Oxycodone RS from the Standard stock solution, prepared by adding to 20% of the flask volume of methanol, and diluting with Diluent to volume System suitability stock solution: 0.05 mg/mL of 4-hydroxybenzoic acid isopropyl ester in methanol System suitability solution: 0.01 mg/mL of 4-hydroxybenzoic acid isopropyl ester and 0.09 mg/mL of USP Oxycodone RS in Diluent from the System suitability stock solution and Standard stock solution, respectively Sample solution: 11 mg/mL of Oxycodone Terephthalate in methanol prepared as follows. Transfer the required amount of sample to a suitable volumetric flask. Add 80% of the flask volume of methanol, and shake by mechanical means for about 20 min to dissolve. Dilute with methanol to volume. Chromatographic system (See Chromatography 621, System Suitability.) Mode: LC Detector: UV 280 nm Column: 3.9-mm 15-cm; packing L1 Column temperature: 45 1 Flow rate: 1.5 mL/min Injection size: 25 L System suitability Samples: Standard solution and System suitability solution Suitability requirements Resolution: NLT 8 between the oxycodone and 4-hydroxybenzoic acid isopropyl ester peaks, System suitability solution Relative standard deviation: NMT 5.0%, Standard solution Analysis Samples: Standard solution and Sample solution Calculate the percentage of each impurity in the portion of the sample taken: Result = (rU/rS) (CS/CU) (Mr1/Mr2) 100 rU = peak area of an individual impurity from the Sample solution rS = peak area of oxycodone from the Standard solution CS = concentration of USP Oxycodone RS in the Standard solution (mg/mL) CU = concentration of Oxycodone Terephthalate in the Sample solution (mg/mL) Mr1 = one-half of the molecular weight of oxycodone terephthalate, 398.43 Mr2 = molecular weight of oxycodone, 315.37 [NOTEIf any impurity is found having a retention time of about 2 in relation to that of the oxycodone peak, divide its apparent percentage by 4.8.]

Oxygen

.

O2 32.00 Oxygen. Oxygen [7782-44-7].

Oxygen contains not less than 99.0 percent, by volume, of O2. [NOTEOxygen that is produced by the air-liquefaction process is exempt from the requirements of the tests for Carbon dioxide and Carbon monoxide.]

Packaging and storagePreserve in cylinders or in a pressurized storage tank. Containers used for Oxygen must not be treated with any toxic, sleep-inducing, or narcosisproducing compounds, and must not be treated with any compound that will be irritating to the respiratory tract when the Oxygen is used. NOTEReduce the container pressure by means of a regulator. Measure the gases with a gas volume meter downstream from the detector tube in order to minimize contamination or change of the specimens. LabelingLabel it to indicate whether or not it has been produced by the air-liquefaction process. Where it is piped directly from the cylinder or storage tank to the point of use, label each outlet Oxygen. [NOTEThe various detector tubes called for in the respective tests are listed under Reagents in the section Reagents, Indicators, and Solutions.] Identification A: When tested as directed in the Assay, not more than 1.0 mL of gas remains. B: Pass 100 5 mL released from the vapor phase of the contents of the Oxygen container through a carbon dioxide detector tube at the rate specified for the tube: no color change is observed (distinction from carbon dioxide).

Official from May 1, 2013 Copyright (c) 2013 The United States Pharmacopeial Convention. All rights reserved.

Accessed from 190.216.198.50 by JNJconsumer on Mon May 06 11:48:03 EDT 2013

4650 Oxygen / Official Monographs

OdorCarefully open the container valve to produce a moderate flow of gas. Do not direct the gas stream toward the face, but deflect a portion of the stream toward the nose: no appreciable odor is discernible. Carbon dioxidePass 1000 50 mL through a carbon dioxide detector tube at the rate specified for the tube: the indicator change corresponds to not more than 0.03%. Carbon monoxidePass 1000 50 mL through a carbon monoxide detector tube at the rate specified for the tube: the indicator change corresponds to not more than 0.001%. AssayPlace a sufficient quantity of ammonium chlorideammonium hydroxide solution, prepared by mixing equal volumes of water and ammonium hydroxide and saturating with ammonium chloride at room temperature, in a test apparatus composed of a calibrated 100-mL buret, provided with a two-way stopcock, a gas absorption pipet, and a leveling bulb, both of suitable capacity and all suitably interconnected. Fill the gas absorption pipet with metallic copper in the form of wire coils, wire mesh, or other suitable configuration. Eliminate all gas bubbles from the liquid in the test apparatus. Activate the test solution by performing two or three tests that are not for record purposes. Fill the calibrated buret, all interconnecting tubing, both stopcock openings, and the intake tube with liquid. Draw 100.0 mL of Oxygen into the buret by lowering the leveling bulb. Open the stopcock to the absorption pipet, and force the Oxygen into the absorption pipet by raising the leveling bulb. Agitate the pipet to provide frequent and intimate contact of the liquid, gas, and copper. Continue agitation until no further diminution in volume occurs. Draw the residual gas back into the calibrated buret, and measure its volume: not more than 1.0 mL of gas remains.

USP 36

Carbon dioxidePass 1000 50 mL through a carbon dioxide detector tube at the rate specified for the tube: the indicator change corresponds to not more than 0.03%. Carbon monoxidePass 1000 50 mL through a carbon monoxide detector tube at the rate specified for the tube: the indicator change corresponds to not more than 0.001%. AssayPlace a sufficient quantity of ammonium chlorideammonium hydroxide solution, prepared by mixing equal volumes of water and ammonium hydroxide and saturating with ammonium chloride at room temperature, in a test apparatus composed of a calibrated 100-mL buret, provided with a two-way stopcock, a gas absorption pipet, and a leveling bulb, both of suitable capacity and all suitably interconnected. Fill the gas absorption pipet with metallic copper in the form of wire coils, wire mesh, or other suitable configuration. Eliminate all gas bubbles from the liquid in the test apparatus. Activate the test solution by performing two or three tests that are not for record purposes. Fill the calibrated buret, all interconnecting tubing, both stopcock openings, and the intake tube with liquid. Draw 100.0 mL of Oxygen 93 Percent into the buret by lowering the leveling bulb. Open the stopcock to the absorption pipet, and force the Oxygen 93 Percent into the absorption pipet by raising the leveling bulb. Agitate the pipet to provide frequent and intimate contact of the liquid, gas, and copper. Continue agitation until no further diminution in volume occurs. Draw the residual gas back into the calibrated buret, and measure its volume: not more than 10.0 mL and not less than 4.0 mL of gas remains.

Water O 15 Injection*

.

Oxygen 93 Percent

.

Oxygen 93 Percent is Oxygen produced from air by the molecular sieve process. It contains not less than 90.0 percent and not more than 96.0 percent, by volume, of O2, the remainder consisting mostly of argon and nitrogen.

Packaging and storagePreserve in cylinders or in a low pressure collecting tank. Containers used for Oxygen 93 Percent must not be treated with any toxic, sleep-inducing, or narcosis-producing compounds, and must not be treated with any compound that will be irritating to the respiratory tract when the Oxygen 93 Percent is used. LabelingWhere it is piped directly from the collecting tank to the point of use, label each outlet Oxygen 93 Percent. NOTEThe various detector tubes called for in the respective tests are listed under Reagents in the section Reagents, Indicators, and Solutions. Where it is preserved in cylinders, reduce the pressure by means of a regulator. Measure the gases with a gas volume meter downstream from the detector tube in order to minimize contamination or change of the specimens. Identification A: When tested as directed in the Assay, not more than 10.0 mL and not less than 4.0 mL of gas remains. B: Pass 100 5 mL released from the vapor phase of the contents of the Oxygen 93 Percent container or from the outlet at the point of use through a carbon dioxide detector tube at the rate specified for the tube: no color change is observed (distinction from carbon dioxide). OdorCarefully open the container valve or system outlet to produce a moderate flow of gas. Do not direct the gas stream toward the face, but deflect a portion of the stream toward the nose: no appreciable odor is discernible.

Water O 15 Injection is a sterile solution of H215O in Sodium Chloride Injection suitable for intravenous injection, in which a portion of the molecules are labeled with radioactive 15O (see Positron Emission Tomography Drugs for Compounding, Investigational, and Research Uses 823). It contains not less than 90.0 percent and not more than 110.0 percent of the labeled amount of 15O expressed in MBq (or mCi) per mL at the time indicated in the labeling.

Packaging and storagePreserve in a single-dose container that is adequately shielded. LabelingLabel it to include the following, in addition to the information specified for Labeling under Injections 1: the time and date of calibration; the amount of 15O as water expressed as MBq (mCi) per mL, at time of calibration; total activity at time of calibration; the expiration time and date; and the statement CautionRadioactive Material. The labeling indicates that in making dosage calculations, correction is to be made for radioactive decay and also indicates that the radioactive half-life of 15O is 2.03 minutes. The label also includes the statement, Do not use if cloudy or if it contains particulate matter. USP Reference standards 11 USP Endotoxin RS Identification A: Radionuclidic identityIts half-life, determined using a suitable detector system (see Radioactivity 821), is between 1.83 and 2.08 minutes. B: Radiochemical identityThe retention time of the major peak in the chromatogram of the Test solution corresponds to that of the water contained within the product formulation, as obtained in the test for Radiochemical purity.

* Assignment of an official United States Adopted Name (USAN) is pending.

Official from May 1, 2013 Copyright (c) 2013 The United States Pharmacopeial Convention. All rights reserved.

S-ar putea să vă placă și

- Electrical Design CriteriaDocument533 paginiElectrical Design CriteriaHimdad Bahri100% (3)

- Pyriproxyfen Papaya Draft ProtocolDocument16 paginiPyriproxyfen Papaya Draft ProtocolprecauteÎncă nu există evaluări

- Or RQ 101Document9 paginiOr RQ 101Rosa Maria OrtegaÎncă nu există evaluări

- Aka GMP Audit FormDocument8 paginiAka GMP Audit FormAlpian BosixÎncă nu există evaluări

- Sample FAT ProtocolDocument6 paginiSample FAT ProtocolMatej Petric0% (1)

- Gardner Denver: Operating and Service ManualDocument41 paginiGardner Denver: Operating and Service ManualCESAR MORAÎncă nu există evaluări

- EIGA (2008) - Comparison of EP, USP & JP For Medicinal GasDocument21 paginiEIGA (2008) - Comparison of EP, USP & JP For Medicinal GashuynhhaichauchauÎncă nu există evaluări

- Salom Pharmacy LTD: Quality Control Laboratory SPL-SOP-QC-DISS-001 Operation of Dissolution Rate ApparatusDocument2 paginiSalom Pharmacy LTD: Quality Control Laboratory SPL-SOP-QC-DISS-001 Operation of Dissolution Rate ApparatusPaolo Peps100% (1)

- FCC TBA JL 2013 - 23 Sep 2013Document4 paginiFCC TBA JL 2013 - 23 Sep 2013LailaÎncă nu există evaluări

- Sop-Standard Operating Procedure: ObjectiveDocument4 paginiSop-Standard Operating Procedure: ObjectiveDivyashree PatilÎncă nu există evaluări

- Issuance of DocumentsDocument2 paginiIssuance of DocumentsAshok KumarÎncă nu există evaluări

- Sop For High Performance Liquid ChromatographyDocument3 paginiSop For High Performance Liquid ChromatographyRainMan75100% (1)

- Sop Fume HoodDocument2 paginiSop Fume HoodKoko AshourÎncă nu există evaluări

- Op QD 015Document5 paginiOp QD 015ujangketul62100% (1)

- Stability Data - ConcordDocument127 paginiStability Data - Concordтатьяна васильковаÎncă nu există evaluări

- Astm F1089-02 - Standard Test Method For Corrosion of Surgical InstrumentsDocument3 paginiAstm F1089-02 - Standard Test Method For Corrosion of Surgical InstrumentsmurleyjÎncă nu există evaluări

- Cream & Ointment Process ValidationDocument3 paginiCream & Ointment Process Validationtajmir haqueÎncă nu există evaluări

- Vodka CertificateDocument1 paginăVodka CertificateJevgeni BeliaikinÎncă nu există evaluări

- Sample 03.62 Water System Validation - SOPDocument44 paginiSample 03.62 Water System Validation - SOPKenechukwu Igwagu100% (2)

- Parker - Compressed Air For Food GMPsDocument8 paginiParker - Compressed Air For Food GMPsXavierÎncă nu există evaluări

- Clarity and Cleanness of Paint and Ink Liquids: Standard Test Method ForDocument3 paginiClarity and Cleanness of Paint and Ink Liquids: Standard Test Method ForShaker QaidiÎncă nu există evaluări

- Quality ControlDocument78 paginiQuality ControlAhmad Yusrizal FaizinÎncă nu există evaluări

- Supplier Auditpak 2000Document52 paginiSupplier Auditpak 2000Adrian AustinÎncă nu există evaluări

- Rideal Walker CoefficientDocument3 paginiRideal Walker CoefficientManjusha KondepudiÎncă nu există evaluări

- Sop For Cleaning of Sampling Booth 038aDocument2 paginiSop For Cleaning of Sampling Booth 038aMulticaps unit100% (2)

- FSSC 22000: Foundation For Food Safety CertificationDocument14 paginiFSSC 22000: Foundation For Food Safety CertificationAhmedElSayedÎncă nu există evaluări

- 4013 Stability TestingDocument5 pagini4013 Stability TestingtghonsÎncă nu există evaluări

- Alconox Detergent Cleaning ValidationDocument12 paginiAlconox Detergent Cleaning ValidationstanlesÎncă nu există evaluări

- URS Contents: Blank TemplateDocument11 paginiURS Contents: Blank TemplateBREWSKI100% (1)

- Operation and Calibration of HPLC SystemDocument12 paginiOperation and Calibration of HPLC SystemMubarak PatelÎncă nu există evaluări

- Content: Standard Operating Procedure (SOP) Use and Maintenance of A FreezerDocument7 paginiContent: Standard Operating Procedure (SOP) Use and Maintenance of A FreezerPrincess PiaÎncă nu există evaluări

- Forced DegradationDocument8 paginiForced DegradationBiyaya San PedroÎncă nu există evaluări

- PRP 10.3 Allergen Control SystemDocument3 paginiPRP 10.3 Allergen Control SystemAnggerÎncă nu există evaluări

- Laksh Fine Chem. PVT LTD: Standard Operating Procedure Cleaning of Reactor Sop no:RC-01 Issue Number:01Document2 paginiLaksh Fine Chem. PVT LTD: Standard Operating Procedure Cleaning of Reactor Sop no:RC-01 Issue Number:01ncubepharmaÎncă nu există evaluări

- Eu Sop TP 001 v01 Test Procedure TPDocument4 paginiEu Sop TP 001 v01 Test Procedure TPAdriapratama MunardiÎncă nu există evaluări

- Documentation Required For Periodic GMP Compliance Inspection Annex 1 JPDocument5 paginiDocumentation Required For Periodic GMP Compliance Inspection Annex 1 JPspam_discardÎncă nu există evaluări

- Annual Product Review (APR) Product Quality Review (PQR)Document34 paginiAnnual Product Review (APR) Product Quality Review (PQR)Sundar GanesanÎncă nu există evaluări

- Specific Gravity UspDocument1 paginăSpecific Gravity UspSarah TahirÎncă nu există evaluări

- 80-00012-Whitepaper Pharma Int DisplayDocument16 pagini80-00012-Whitepaper Pharma Int DisplayNgân NgânÎncă nu există evaluări

- What Is BMR (Batch Manufacturing Record) ?Document2 paginiWhat Is BMR (Batch Manufacturing Record) ?YousifÎncă nu există evaluări

- Validation of Coating Equipment Ketik UlangDocument6 paginiValidation of Coating Equipment Ketik UlangSatish Hiremath100% (2)

- Stability Studies Assessment ExperienceDocument61 paginiStability Studies Assessment ExperienceDANIBATAÎncă nu există evaluări

- Miconazole Nitrate PreparationsDocument3 paginiMiconazole Nitrate Preparationsasit_mÎncă nu există evaluări

- SGF-GMP Self Assessment Questionnaire enDocument22 paginiSGF-GMP Self Assessment Questionnaire enOzlem Mep100% (1)

- Meclizine HCLDocument10 paginiMeclizine HCLChEng_Încă nu există evaluări

- Sop For Personnel Monitoring in Aseptic AreaDocument2 paginiSop For Personnel Monitoring in Aseptic AreaDolly BijaniÎncă nu există evaluări

- Handling of Oot ResultsDocument5 paginiHandling of Oot ResultstghonsÎncă nu există evaluări

- USP Monographs - Zinc Sulfate Usp29-Nf24Document1 paginăUSP Monographs - Zinc Sulfate Usp29-Nf24CharltondialÎncă nu există evaluări

- Water Treatment System (Sistem Pengolahan Air Spa)Document38 paginiWater Treatment System (Sistem Pengolahan Air Spa)Tjen MolynaÎncă nu există evaluări

- SMF - Schedule M (20-22 Pages) PDFDocument61 paginiSMF - Schedule M (20-22 Pages) PDFSrinivasÎncă nu există evaluări

- 2019 - GMP - CLASS A - GROUP 11 - TASK 4 - Validasi Pembersihan AlatDocument34 pagini2019 - GMP - CLASS A - GROUP 11 - TASK 4 - Validasi Pembersihan Alatega aaÎncă nu există evaluări

- PQ Sample Protocol - Water SyatemDocument45 paginiPQ Sample Protocol - Water SyatemProcesos Industriales De Transformacion FarmaceuticaÎncă nu există evaluări

- Form 18 NABL 163Document2 paginiForm 18 NABL 163asr labÎncă nu există evaluări

- GLP or Good Laboratory PracticesDocument35 paginiGLP or Good Laboratory Practicesningsih rezekiÎncă nu există evaluări

- Good Manufacturing Practices in Postharvest and Minimal Processing of Fruits and VegetablesDocument40 paginiGood Manufacturing Practices in Postharvest and Minimal Processing of Fruits and Vegetablesmaya janiÎncă nu există evaluări

- E Tag Form For DHA Resident F EDocument2 paginiE Tag Form For DHA Resident F EHaris NaeemÎncă nu există evaluări

- THAI COATER Spec PDFDocument4 paginiTHAI COATER Spec PDFConfundo Paa DuroÎncă nu există evaluări

- Cleaning and disinfection of food factories: a practical guideDe la EverandCleaning and disinfection of food factories: a practical guideÎncă nu există evaluări

- Good Distribution Practices A Complete Guide - 2021 EditionDe la EverandGood Distribution Practices A Complete Guide - 2021 EditionÎncă nu există evaluări

- Corrective And Preventative Action A Complete Guide - 2020 EditionDe la EverandCorrective And Preventative Action A Complete Guide - 2020 EditionÎncă nu există evaluări

- Quality Management Systems A Complete Guide - 2021 EditionDe la EverandQuality Management Systems A Complete Guide - 2021 EditionÎncă nu există evaluări

- Manual 924HDocument811 paginiManual 924HJuliana Magalhães100% (1)

- Casing ScrapersDocument2 paginiCasing ScrapersthetrevanianÎncă nu există evaluări

- Laws of Corrresponding States - Nelson and ObertDocument4 paginiLaws of Corrresponding States - Nelson and ObertIvan RodrigoÎncă nu există evaluări

- AlphaESS M48112-SDocument2 paginiAlphaESS M48112-SEben TeyeÎncă nu există evaluări

- CF750Document9 paginiCF750Shilpi VirmaniÎncă nu există evaluări

- 01 VRF 011 01 PDFDocument60 pagini01 VRF 011 01 PDFMechanical PowerÎncă nu există evaluări

- Gastron BDM Sarawak Summary 16.05.2023Document5 paginiGastron BDM Sarawak Summary 16.05.2023yusuf mohd sallehÎncă nu există evaluări

- EN13480-3 Chap12 ModificationsDocument37 paginiEN13480-3 Chap12 ModificationsPrashant ChauhanÎncă nu există evaluări

- Radial Turbine Design ProcessDocument15 paginiRadial Turbine Design ProcessKamaldeep GuptaÎncă nu există evaluări

- 07 Protection of HV TransformersDocument36 pagini07 Protection of HV TransformersSuresh KumarÎncă nu există evaluări

- Special Electrical MachinesDocument5 paginiSpecial Electrical MachinesEswaran0% (1)

- Alpha, Beta and Gamma RadiationDocument8 paginiAlpha, Beta and Gamma RadiationFarhan SadiqueÎncă nu există evaluări

- Max Seal Fluid Loss Control AdditiveDocument2 paginiMax Seal Fluid Loss Control AdditiveadrianitoalaÎncă nu există evaluări

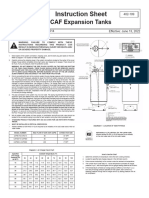

- Taco CAF Expansion Tank Install ManualDocument3 paginiTaco CAF Expansion Tank Install ManualTEMPÎncă nu există evaluări

- EGY D 22 06311 - R1 - ReviewerDocument101 paginiEGY D 22 06311 - R1 - ReviewerWEIWEI YANGÎncă nu există evaluări

- Abdul Rasheed (2019-Me-34) Thermodynamic AssignmentDocument6 paginiAbdul Rasheed (2019-Me-34) Thermodynamic AssignmentAbdul Rasheed GhaziÎncă nu există evaluări

- Wyser - Manutentore Meccanico LFDocument6 paginiWyser - Manutentore Meccanico LFMorfferroÎncă nu există evaluări

- Enclosures TechnicalDocument16 paginiEnclosures TechnicalAnonymous rYZyQQot55Încă nu există evaluări

- Project EvsDocument8 paginiProject Evsnaveenkmr04550% (2)

- Genset DataDocument12 paginiGenset DatagebreÎncă nu există evaluări

- Physics NotesDocument13 paginiPhysics Noteswaheedlakho100% (2)

- Moduł Igbt Mg25j2ys40 25a 600v Toshiba DatasheetDocument4 paginiModuł Igbt Mg25j2ys40 25a 600v Toshiba Datasheetmouelhi karimÎncă nu există evaluări

- Tech Spec of PTR 33 11 KVDocument34 paginiTech Spec of PTR 33 11 KVAnonymous sAmJfcVÎncă nu există evaluări

- Dh3 Generation Lototo Plan Phase 2 RGC 08sep2023Document8 paginiDh3 Generation Lototo Plan Phase 2 RGC 08sep2023Borislav VulicÎncă nu există evaluări

- 10 - CapacitorsDocument5 pagini10 - Capacitorschie CÎncă nu există evaluări

- Curriculum Vitae: Job ObjectiveDocument4 paginiCurriculum Vitae: Job ObjectivesambhuÎncă nu există evaluări

- CPCI Designing With Precast Concrete Structural Solutions PDFDocument44 paginiCPCI Designing With Precast Concrete Structural Solutions PDFMarie Fe Fortuno Bermido100% (1)

- SISTO-Diaphragm Valves: 1. Installation InstructionsDocument1 paginăSISTO-Diaphragm Valves: 1. Installation InstructionsEric LarrondoÎncă nu există evaluări