Documente Academic

Documente Profesional

Documente Cultură

Me472 10

Încărcat de

dreadwarriorDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Me472 10

Încărcat de

dreadwarriorDrepturi de autor:

Formate disponibile

ME 472 Engineering Metrology

and Quality Control

Dr. A. Tolga Bozdana

Assistant Professor

Mechanical Engineering

University of Gaziantep

Measurement of Gears

1

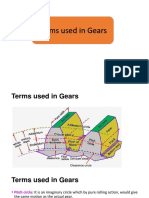

Gear Tooth Terminology

The width of the tooth Face width:

Total height of the tooth Whole Depth:

Distance a tooth projects into mating space Working Depth :

Distance between top of a tooth and bottom of

mating space

Clearance :

Thickness of a tooth along the pitch circle Tooth Thickness :

Distance on pitch circle from a point on one tooth

to corresponding point on the adjacent tooth

Circular Pitch :

Radial distance from pitch to bottom of tooth Dedendum :

Radial distance from pitch to top of tooth Addendum :

Diameter of addendum (outside) circle Outside Diameter :

Diameter of imaginary pitch circle specifying

addendum and dedendum

Pitch Diameter :

Diameter of root circle Root Diameter :

2

Gear Meshing

Line of Action

Gear catalogs are classified according to number of teeth and pressure

angle.

The pressure angle is the angle between the tangent to the pitch circles

and the line of action.

When two gear teeth are in contact, the kinematic principle of gearing is

demonstrated: angular velocity ratio of meshing gears is constant

along the line of action.

The line of action (also known as pressure line) is a line that is drawn

tangent to the base circle of pinion and gear.

Two gears having an identical module can be meshed. Meshing of two

spur gears with a center distance is shown below.

3

Tooth Thickness Measurement

Measurement

over Pins

Span

Masurement

Vernier Gear

Tooth Caliper

Span Measurement: The distance between a number of teeth is measured (AGMA 239.01)

Vernier Gear Tooth Caliper: The chordal tooth thickness and height are measured.

Measurement over Pins: Special size pins are placed between the teeth and the distance

between pins are measured (AGMA 231.52 and AGMA 239.03 for spur and helical gears).

The measurement of tooth thickness is a common feature for gears to be checked using following

methods (see the standards by American Gear Manufacturers Association www.agma.org):

4

If a large number of gears for a set (having different

values of z) are to be measured, calculations would

become laborious. Hence, constant chord thickness

(X

c

) and height (Y

c

), which are independent of z, are

calculated:

Constant chord is defined as the chord joining points

on opposite faces of tooth that make contact with the

mating teeth at the line of action. It should be noted

that formulas above are for spur gears. For helical

gears, normal module (m

n

) must be employed in

calculations.

The chordal thickness (X) and height (Y) are:

where

Measurement using Vernier Gear Tooth Caliper

( ) cos 1 sin 2 and + = =

p p

R a Y R X

z z z

R

m a

p

= = = =

90

2

2

and

2 sin

8

cos

4

and

2

m

m Y

m

X

C C

= =

a : addendum

R

p

: pitch radius

: pressure angle

m : module

z : number of teeth

5

Measurement over Pins

The tooth thickness is found as:

=

z D

D

inv e inv D t

p

g

p

cos

h

90

z

number of teeth

pin diameter

pitch diameter

tooth thickness

inv :

:

m :

H :

pressure angle D

g

:

involute of an angle z :

Module D

p

:

Distance over pins t :

( )

=

g e p

D H D

z

e

cos

arccos

( )

=

z D H D

z

e

g o p

90

cos

cos

arccos

The measurement over pins equals to:

For z is even:

For z is odd:

g e

D h H + = 2

( )

g o

D z h H + = 90 cos 2

The involute of angle e is calculated by:

( ) 180 tan = e e e inv

Even number of teeth

Odd number of teeth

Pin diameter (for internal gears):

Pin diameter (for external gears):

m D

g

58 . 13 =

m D

g

97 . 13 =

The angle e is calculated as:

For z is even:

For z is odd:

6

Span Measurement

The distance M is expressed as:

Thus, the tooth thickness can be obtained

based on base circle pitch and measured

distance of M.

+ + = s

z

inv

z

D M

p

2

cos

tooth thickness at base circle t

b

:

base circle pitch P

b

:

number of tooth spaces within M s :

number of teeth

pressure angle

pitch diameter

span distance

:

z :

D

p

:

M :

It should be noted that module in normal

plane (m

n

) and pressure angle in normal

plane (

n

) must be employed in case of

helical gears.

7

Comparison of Measurement Methods

The precision of vernier caliper directly affects the

measurements.

The measurements depend on two vernier readings,

each of which is a function of each other.

Measurement is made with an edge of the

measuring jaw (not its face), which again does not

lend itself to accurate measurement.

It is relatively easier to use

and cheaper as compared with

other methods.

Vernier Gear

Tooth Caliper

It cannot be applied when a combination of high helix

angle and narrow face width prevent the caliper from

spanning a sufficient number of teeth.

Readings are influenced by errors in base pitch and

tooth profile. Readings would be erroneous if attempted

on a portion of profile which had been modified from

true involute shape.

Measurements are not

affected by outside diameter

variations or by runout of the

outside diameter.

Span

Measurement

It is crucial that the most appropriate pins must be

selected. For gears having non-standard features, the

estimate of pin diameter may be a bottleneck.

Measurements are not

affected by outside diameter

variations or by runout of the

outside diameter.

Measurement

over Pins

DISADVANTAGES ADVANTAGES METHOD

8

Gear Tooth Profile Measurements using CMM

S-ar putea să vă placă și

- Tooth ThicknessDocument9 paginiTooth ThicknessPraveen VundrajavarapuÎncă nu există evaluări

- Gearthread 120918023938 Phpapp01Document50 paginiGearthread 120918023938 Phpapp01Bakkiya RajÎncă nu există evaluări

- New Microsoft Word DocumentDocument15 paginiNew Microsoft Word DocumentrdksjÎncă nu există evaluări

- Lecture On Gear-MeasurementDocument29 paginiLecture On Gear-MeasurementSachin100% (1)

- Gear TerminologyDocument42 paginiGear Terminologyyair Enrique Romero OspinoÎncă nu există evaluări

- 7 FCMDocument11 pagini7 FCMAbhijeetKhandagaleÎncă nu există evaluări

- Gear Tooth Thickness MeasurmentDocument7 paginiGear Tooth Thickness MeasurmentYohannes Mengistu AbebeÎncă nu există evaluări

- Gears Very BasicDocument5 paginiGears Very BasicpetsatÎncă nu există evaluări

- Metrology, Gear MeasurementDocument44 paginiMetrology, Gear MeasurementPiu Kundu100% (23)

- Gear MeasurementDocument12 paginiGear MeasurementCobra BabaÎncă nu există evaluări

- Gear Heel Pitch DiameterDocument5 paginiGear Heel Pitch DiameterMadnutsÎncă nu există evaluări

- Gears, Splines, and Serrations: Unit 24Document8 paginiGears, Splines, and Serrations: Unit 24Satish Dhandole100% (1)

- Gear TerminologyDocument11 paginiGear TerminologyGoutam AcharjeeÎncă nu există evaluări

- Gear TerminologyDocument12 paginiGear TerminologyLuis Daniel De La GarzaÎncă nu există evaluări

- Tooth Thickness Measurement With Pins or BallsDocument5 paginiTooth Thickness Measurement With Pins or Ballsemaster1Încă nu există evaluări

- Gear Measurements:-Mechanical Measurements and MetrologyDocument4 paginiGear Measurements:-Mechanical Measurements and Metrologykathir drayÎncă nu există evaluări

- Gear Drawing PDFDocument12 paginiGear Drawing PDFpradeep315Încă nu există evaluări

- Terminology SpurDocument3 paginiTerminology SpurNimish Pande100% (1)

- Gear Measurement and TestingDocument52 paginiGear Measurement and TestingHemanth Kumar MadhuÎncă nu există evaluări

- GearDocument31 paginiGearzaheer100% (2)

- Gear NomenclatureDocument41 paginiGear NomenclatureViswanathan SrkÎncă nu există evaluări

- Measurement of The Elements of Spur Gear 6Document8 paginiMeasurement of The Elements of Spur Gear 6sen_subhasis_58Încă nu există evaluări

- Pitch Diameter, DDocument2 paginiPitch Diameter, DAhmed NahrawyÎncă nu există evaluări

- Mechanical Measurements and MetrologyDocument28 paginiMechanical Measurements and MetrologySandeep OholÎncă nu există evaluări

- TheoryDocument4 paginiTheoryDavid DjÎncă nu există evaluări

- 2 - 3 Involute Spur Gear 1Document13 pagini2 - 3 Involute Spur Gear 1jiteshpaul100% (1)

- DJJ 10033-Chapter 5Document45 paginiDJJ 10033-Chapter 5Abbas SeuÎncă nu există evaluări

- Gang ADocument46 paginiGang Aganga6013Încă nu există evaluări

- Gears TerminologyDocument10 paginiGears TerminologyJawad Ullah100% (2)

- Project PPT On Effect of Parameters On Bending and Contact Stresses Developed in GearsDocument21 paginiProject PPT On Effect of Parameters On Bending and Contact Stresses Developed in GearsHrushikesh S BharadwajÎncă nu există evaluări

- Gear Tooth VernerDocument10 paginiGear Tooth Vernermanisusi10Încă nu există evaluări

- Gear Notes - SlideDocument19 paginiGear Notes - SlideNEF RIDERSÎncă nu există evaluări

- DJJ 10033-Chapter 5.GEARDocument34 paginiDJJ 10033-Chapter 5.GEARStepianus JtÎncă nu există evaluări

- Spur Gear MeasurementDocument3 paginiSpur Gear MeasurementMadan RaoÎncă nu există evaluări

- Gajra GearsDocument17 paginiGajra GearsJuhi Yadav100% (2)

- Gears & Gear TrainsDocument32 paginiGears & Gear TrainsMuhammed Ali ASÎncă nu există evaluări

- Spur and Gear Trains KOM PDFDocument18 paginiSpur and Gear Trains KOM PDFSam prabhakarÎncă nu există evaluări

- Gear Terminology: What Is Gear Module?Document5 paginiGear Terminology: What Is Gear Module?Rabia ZulqarnainÎncă nu există evaluări

- Kom Gear TerminologyDocument3 paginiKom Gear Terminologydhilip_sacetÎncă nu există evaluări

- Group 3 (Gears)Document52 paginiGroup 3 (Gears)CherrydhelÎncă nu există evaluări

- CH08 2Document52 paginiCH08 2abdallah ghannamÎncă nu există evaluări

- Experiment No (6) Spur Gear Terms and ConceptsDocument3 paginiExperiment No (6) Spur Gear Terms and ConceptsHayfa SalihÎncă nu există evaluări

- Rack and PinionDocument16 paginiRack and PinionjeronimoisraelÎncă nu există evaluări

- Spur GearsDocument13 paginiSpur GearsVignesh WaranÎncă nu există evaluări

- Gear MeasurementDocument5 paginiGear MeasurementAnand Babu100% (1)

- Inspection and Testing ProceduresDocument3 paginiInspection and Testing ProceduresChandrashekhar ReddyÎncă nu există evaluări

- Gears - General: Shigley's Mechanical Engineering DesignDocument229 paginiGears - General: Shigley's Mechanical Engineering DesignbasitÎncă nu există evaluări

- Formulas For Gear Calculation - External GearsDocument10 paginiFormulas For Gear Calculation - External GearsJag WaramÎncă nu există evaluări

- How To Measure The Pressure Angle of A Physical Spur GearDocument16 paginiHow To Measure The Pressure Angle of A Physical Spur Gearian_new100% (2)

- Gear Geometry & Profile TheoryDocument24 paginiGear Geometry & Profile Theoryansh1983100% (2)

- Machinery's Handbook Pocket Companion: Quick Access to Basic Data & More from the 31st EditionDe la EverandMachinery's Handbook Pocket Companion: Quick Access to Basic Data & More from the 31st EditionÎncă nu există evaluări

- Disston Lumberman Handbook - Containing A Treatise Of The Construction Of Saws And How To Keep Them In OrderDe la EverandDisston Lumberman Handbook - Containing A Treatise Of The Construction Of Saws And How To Keep Them In OrderÎncă nu există evaluări

- Machinery's Handbook Pocket Companion: Quick Access to Basic Data & More from the 32nd EditionDe la EverandMachinery's Handbook Pocket Companion: Quick Access to Basic Data & More from the 32nd EditionÎncă nu există evaluări

- Digitization in Dentistry: Clinical ApplicationsDe la EverandDigitization in Dentistry: Clinical ApplicationsPriyanka JainÎncă nu există evaluări

- Mid-century Woodworking: 80 projects to make by handDe la EverandMid-century Woodworking: 80 projects to make by handÎncă nu există evaluări

- Geometrical Dimensioning and Tolerancing for Design, Manufacturing and Inspection: A Handbook for Geometrical Product Specification Using ISO and ASME StandardsDe la EverandGeometrical Dimensioning and Tolerancing for Design, Manufacturing and Inspection: A Handbook for Geometrical Product Specification Using ISO and ASME StandardsEvaluare: 4.5 din 5 stele4.5/5 (3)

- The Mooring Pattern Study For Q-Flex Type LNG Carriers Scheduled For Berthing at Ege Gaz Aliaga LNG TerminalDocument6 paginiThe Mooring Pattern Study For Q-Flex Type LNG Carriers Scheduled For Berthing at Ege Gaz Aliaga LNG TerminalMahad Abdi100% (1)

- Total Physical Response (G4)Document3 paginiTotal Physical Response (G4)Aq Nadzrul LarhÎncă nu există evaluări

- Derivational and Inflectional Morpheme in English LanguageDocument11 paginiDerivational and Inflectional Morpheme in English LanguageEdificator BroÎncă nu există evaluări

- Healthy Apps Us New VarDocument9 paginiHealthy Apps Us New VarJESUS DELGADOÎncă nu există evaluări

- IM1 Calculus 2 Revised 2024 PUPSMBDocument14 paginiIM1 Calculus 2 Revised 2024 PUPSMBEunice AlonzoÎncă nu există evaluări

- ST Arduino Labs CombinedDocument80 paginiST Arduino Labs CombineddevProÎncă nu există evaluări

- Saiva Dharma ShastrasDocument379 paginiSaiva Dharma ShastrasfunnybizÎncă nu există evaluări

- RCA LCD26V6SY Service Manual 1.0 PDFDocument33 paginiRCA LCD26V6SY Service Manual 1.0 PDFPocho Pochito100% (1)

- CH-5 Further Percentages AnswersDocument5 paginiCH-5 Further Percentages AnswersMaram MohanÎncă nu există evaluări

- Breastfeeding W Success ManualDocument40 paginiBreastfeeding W Success ManualNova GaveÎncă nu există evaluări

- Pathogenic Escherichia Coli Associated With DiarrheaDocument7 paginiPathogenic Escherichia Coli Associated With DiarrheaSiti Fatimah RadÎncă nu există evaluări

- Nikos MIDI Pack - Chord Progression GuideDocument5 paginiNikos MIDI Pack - Chord Progression GuideSamuel ThompsonÎncă nu există evaluări

- PETAL Sentence StartersDocument1 paginăPETAL Sentence StartersSnip x Hunt manÎncă nu există evaluări

- Caterpillar Cat C7 Marine Engine Parts Catalogue ManualDocument21 paginiCaterpillar Cat C7 Marine Engine Parts Catalogue ManualkfsmmeÎncă nu există evaluări

- Colfax MR Series CompresorDocument2 paginiColfax MR Series CompresorinvidiuoÎncă nu există evaluări

- Engleza Referat-Pantilimonescu IonutDocument13 paginiEngleza Referat-Pantilimonescu IonutAilenei RazvanÎncă nu există evaluări

- D25KS Sanvick PDFDocument4 paginiD25KS Sanvick PDFJiménez Manuel100% (1)

- Introduction To EthicsDocument18 paginiIntroduction To EthicsMarielle Guerra04Încă nu există evaluări

- Multinational MarketingDocument11 paginiMultinational MarketingraghavelluruÎncă nu există evaluări

- J.K. Brimacombe - Design of Continuous Casting MachinesDocument13 paginiJ.K. Brimacombe - Design of Continuous Casting MachinesJavier GómezÎncă nu există evaluări

- Invisible CitiesDocument14 paginiInvisible Citiesvelveteeny0% (1)

- Virtual WorkDocument12 paginiVirtual Workdkgupta28Încă nu există evaluări

- Pathophysiology of Myocardial Infarction and Acute Management StrategiesDocument11 paginiPathophysiology of Myocardial Infarction and Acute Management StrategiesnwabukingzÎncă nu există evaluări

- Job Satisfaction VariableDocument2 paginiJob Satisfaction VariableAnagha Pawar - 34Încă nu există evaluări

- Institutional Group Agencies For EducationDocument22 paginiInstitutional Group Agencies For EducationGlory Aroma100% (1)

- Simran's ResumeDocument1 paginăSimran's ResumesimranÎncă nu există evaluări

- IR2153 Parte6Document1 paginăIR2153 Parte6FRANK NIELE DE OLIVEIRAÎncă nu există evaluări

- Arithmetic QuestionsDocument2 paginiArithmetic QuestionsAmir KhanÎncă nu există evaluări

- KPI AssignmentDocument7 paginiKPI AssignmentErfan Ahmed100% (1)

- Teaching Trigonometry Using Empirical Modelling: 2.1 Visual Over Verbal LearningDocument5 paginiTeaching Trigonometry Using Empirical Modelling: 2.1 Visual Over Verbal LearningJeffrey Cariaga Reclamado IIÎncă nu există evaluări