Documente Academic

Documente Profesional

Documente Cultură

Fluidos de Perforacion

Încărcat de

Fernanda GuerreroDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Fluidos de Perforacion

Încărcat de

Fernanda GuerreroDrepturi de autor:

Formate disponibile

Copyright 2008, AADE

This paper was prepared for presentation at the 2008 AADE Fluids Conference and Exhibition held at the Wyndam Greenspoint Hotel, Houston, Texas, April 8-9, 2008. This conference was sponsored by

the Houston Chapter of the American Association of Drilling Engineers. The information presented in this paper does not reflect any position, claim or endorsement made or implied by the American

Association of Drilling Engineers, their officers or members. Questions concerning the content of this paper should be directed to the individuals listed as authors of this work.

ABSTRACT

In conventional drilling at temperatures up to 300 F with

water-based drilling fluids carbohydrate based polymers like

starches and CMC/PAC are used for rheology stabilization

and for fluid loss control. Under HTHP conditions (300 F -

400 F) these polymers fail because of their chemical structure

which involves acetal linkages.

Fully synthetic co- and terpolymers with only carbon-

carbon bonds in the backbone based on vinysulfonate-

vinylamide type monomers provide the necessary thermal

stability for HTHP conditions. Even up to 450 F, in particular

cases even 500 F could be managed wit these polymers.

Unlike for instance CMC they also tolerate bivalent cations up

to saturation. Thus nowadays deep and hot wells can be drilled

safely with water based muds with vertical depths of 16,000

feet and more. The same class of HTHP polymers is also used

for cementing of deep and ultra deep wells.

Recently cross-linkable versions of vinylsulfonate-

vinylamide type polymers have been developed. Cross-linking

is achieved at temperatures up to 400 F with metal salts or

chelates, e.g. based on aluminum, titanium or zirconium and

yields high temperature stable gels. More viscous solutions up

to non-flowing, but deformable (ringing) gels can be

obtained by varying both polymer and cross-linker. Cross-

linking can be delayed or shifted to higher temperatures with

suitable retarders.

INTRODUCTION

The demand for oil and gas will increase and the

production from mature reservoirs will decline. The overall

production needs to grow. Therefore production methods must

be improved, more wells need to be drilled and more new

reservoirs need to be developed. This will also include more

drilling for deeper and hotter wells. Thus the demand for

systems and products with higher thermo stability will

increase.

DRILLING MUDS

Drilling muds are essential for successful drilling. They

need to be carefully designed and maintained because they

have to fulfill many complex requirements, for instance:

Adequate rheology for the removal of rock cuttings via the

annulus and for the separation in the subsurface devices.

Reduce the fluid loss into the formation by forming a thin

filter cake with low permeability.

Cool and lubricate the drill bit and drill string and reduce

friction between drill string and formation.

Stabilize the non-cased borehole by avoiding shale

swelling.

Minimize formation damage in the productive formation

(pay zone).

Ensure adequate evaluation of the formation (MWD well

logging).

Minimize the impact on the environment.

The suspension of cuttings under static conditions, their

removal from the borehole, their transport to the surface

installations and their separation requires a thixotropic - shear

thinning or pseudo plastic - fluid rheology. In water based

muds these basic rheological properties are achieved by

special clays like bentonite, predominantly a sodium

montmorillonite. The clays also reduce the fluid loss by

forming a thin filter cake with low permeability to the wall of

the borehole, thus preventing the invasion of the fluid into the

formation. To control the rheological properties of aqueous

clay suspensions, also in the presence of electrolytes, special

polymers, mostly anionic polyelectrolytes, are necessary.

Clays like montmorillonite are layered alumo silicates

which are negatively charged within the layers. The negative

charges are compensated by - exchangeable - cations between

the layers. These clays consist of plate like particles with

negative partial charges on the surfaces (faces) and positive

partial charges on the edges.

When sodium bentonite is dispersed in water it swells

significantly and finally a complex equilibrium between

aggregated, dispersed and flocculated particles is formed.

The partial flocculation of the hydrated clay results in a

"house of cards" structure. This structure impairs the basic

thixotropic rheological properties of drilling muds because of

its shear behavior:

AADE-08-DF-HO-12

Vinylsulfonate-vinylamide copolymers and cross-linkable modifications thereof

- Up-to-date chemicals for HTHP drilling, cementing and completion fluids -

Dr. Karl Heinz Heier, Dr. Christoph Kayser, Clariant Produkte (Deutschland) GmbH

2 Dr. Karl Heinz Heier, Dr. Christoph Kayser AADE-08-DF-HO-12

Partial gelation resp. flocculation under static conditions,

high viscosity at low shear rates to avoid sedimentation of

the cuttings.

Shear thinning at higher shear rates to facilitate

pumpability and circulation of the mud, providing an

adequate plastic viscosity for the transport of the cuttings.

Mud Additives

Thinners / deflocculants

In case the gelation and the viscosity profile of the mud is

too high, the flocculated particles need to be deflocculated.

Deflocculation is achieved by anionic polyelectrolytes with

short chain lengths and molecular weights below 100,000

Daltons.

Table 1: Operability limits of mud additives

- Thinners / Deflocculants

Polyphosphates 175 F

Quebracho / Tannins 250 F

Lignosulfonates 340 F

Lignites 400 F

Styrene sulfonic acid based copolymers 400 F

Polyacrylates (modified) 400 F

Ketone / aldehyde / sodium bisulfite polymer 400 F

These dispersing agents, also called thinners partly

neutralize the electrochemical charges on the clays. Thus they

deflocculate the house of card structures. Polyphosphates,

polyacrylates, tannins, lignites and lignosulfonates are the

most commonly used thinners/dispersants.

Deflocculation also aids to reduce the fluid loss by

allowing the clay particles to lay flat in the filter cake.

Protective colloids

To avoid an unstable rheology by the influx of electrolytes

from the formation, protective colloids are added to drilling

muds. These are water soluble polymers with molecular

weights in the range of 100,000 - 1,000,000 Daltons which

stabilize the "house of cards" state of the clays.

Table 2: Operability limits of mud additives

- Protective colloids / viscosifiers

Starch and Derivatives 250 F

Carboxymethylcellulose / PAC 300 F

Xanthan Gum 300 F

----------------------------------------------------------------------

Polyacrylamides / PHPA 400 F

VS / VA copolymers >400 F

Other AMPS based copolymers >400 F

Protective colloids are also mainly anionic

polyelectrolytes. The anionic groups interact with the positive

charges of the edges of the clay platelets. Depending on the

molecular weight and the adsorption behavior, these polymers

either disperse flocculated clays or stabilize the flocculated

state of the clay suspension in the presence of electrolytes.

Protective colloids are commonly called fluid loss additives

because they promote the formation of a stable, thin and

impermeable filter cake on the wall of the wellbore.

Carboxymethylcellulose - CMC - and PAC (Poly Anionic

Cellulose), a CMC with a higher degree of substitution are the

most commonly used protective colloids and fluid loss

additives in water based drilling muds.

Like starches, CMC/PAC and also xanthan gum are

carbohydrate based polymers. Their backbone of is based on

anhydro glucose units which are linked -glucosidic. The

weak points of this backbone are the repeating acetal

(-O-C-O-) linkages which are susceptible to both oxidative

and thermal cleavage at temperatures above 280 F. Whereas

the oxidative degradation can be suppressed by radical

scavengers, the thermal degradation limits the application of

carbohydrate based polymers in general.

Another limitation is the carboxymethyl substitution which

is sensitive to high concentrations of bivalent calcium and

magnesium cations in general.

In wells with vertical depth >13,000 feet, in hot spots

even already >10,000 feet, temperatures of 300 F up to 500

F are occurring. Under these conditions, carbohydrate based

polymers like CMC/PAC fail because of oxidative and

thermal degradation. The drilling muds will lose the necessary

rheological properties and also the fluid loss will increase to

unacceptably high levels.

10 60 110 160 210

Temperature [C]

5

10

15

20

25

V

i

s

c

o

s

i

t

y

[

c

P

]

Figure 1: Thermo-gelation of bentonite

Also the thermo-gelation of bentonite, occurring at

temperatures around 300 F is not suppressed by CMC. The

mud gels and it becomes difficult or even impossible to restart

the drill string after drill string reconnections or drill bit

exchanges. This could mean the loss of the well respectively

the loss of a couple of million dollars.

AADE-08-DF-HO-12 Vinylsulfonate Vinylamide copolymers and cross-linkable modifications thereof 3

Fully synthetic polymers

The stability at temperatures from 300 F to up to 450 F

and even 500 F can only be achieved with polymers with a

backbone consisting of carbon-carbon bonds only. The most

common polymers of this type are partially hydrolyzed

polyacrylamides (PHPA). Their carboxylate functions are

required for the interaction with clays but make them sensitive

to calcium ions. At elevated temperatures, the calcium

sensitivity of PHPA even increases because of the increasingly

rapid hydrolysis of the acrylamide moiety creating even more

carboxyl groups.

So PHPA is only suitable for calcium-free drilling mud

systems which are not common in practice.

Vinylsulfonate-vinylamide copolymers

Vinylsulfonate-vinylamide copolymers were expected to

be thermostable and to be highly tolerant to calcium and

magnesium because of their different hydrolytical behavior:

* *

N R1

O

R2

S O

O

-

O

Na

+

y

x

* *

N

+

R1

O

R2

S O

O

-

O

Na

+

y

x

H2O

heat

H

H

-

O

Figure 2: VS-VA hydrolysis

The vinylsulfonate group is stable to hydrolysis, whereas

the vinylamide group hydrolyses to an amine group which

helps in the interaction of the resulting polymer with the clay

lattices in the mud. The calcium sensitive carboxyl group is

split off and forms a soluble carboxylate with the alkali

present in the mud.

The first experimental product was a copolymer of sodium

vinyl sulfonate and a vinylamide which already showed the

desired properties. Because of the poor copolymerization

behavior of sodium vinylsulfonate, the necessary molecular

weights were difficult to achieve and the product was not an

economic success. But VS-VA copolymers became the

synonym of this type of polymers.

The break through was achieved when ATBS (Acrylamido

Tertiary Butyl Sulfonic Acid) became available on

commercial scale.

With the acrylamide substructure in the ATBS molecule it

is possible to achieve medium to high molecular weights up to

the 107 Dalton range if desired. The amide subgroup is

sterically shielded by the bulky branched butylsulfonate

group. This results in a much higher hydrolytic stability than

that of acrylamide itself.

Our vinylsulfonate-vinylamide type copolymers are

marketed under the brand name

Hostadrill. They are

terpolymers based on ATBS and vinylamide in the molecular

weight range of 500,000 - 1,000,000 Dalton. They have the

desired properties needed for high temperature/high pressure

(HTHP) drilling with water based muds.

Temperature stability up to 450 F, under certain

circumstances even up to 500 F.

Tolerance to calcium and magnesium cations up to

saturation.

This enables optimum rheology and fluid loss control

under these hostile conditions.

0 50 100 150 200

Temperature [C]

0

200

400

600

800

1000

1200

1400

1600

E

f

f

e

c

t

i

v

e

V

i

s

c

o

s

i

t

y

@

6

r

p

m

[

c

P

]

CMC

VS-VA

Figure 3: Rheology stabilization by VS-VA copolymers

The thermo-gelation of bentonite is effectively suppressed

by deflocculation at high temperatures.

This efficiency has been proven in many years of field

practice. No gelation of the mud occurs even after a

circulation stoppage when the mud has to withstand up to 50

hours and more at bottom hole temperatures up to 400 F and

more.

Apart from the monomer composition a special

precipitation polymerization process is the key for the

performance of the polymer. Various attempts to obtain the

same application properties by less complicated and also less

costly processes have not been successful.

Environmental aspects

Vinylsulfonate-vinylamide copolymers are non-toxic, the

LD50 to rats is above 5,000 mg/kg. Above all their favorable

aquatic toxicity profile makes them suitable for offshore

drilling with water based muds in environmental sensitive

regions. They help to avoid the use of oil based muds with

their detrimental effect of oil-wetted cuttings when disposed in

the sea.

4 Dr. Karl Heinz Heier, Dr. Christoph Kayser AADE-08-DF-HO-12

With vinylsulfonate-vinylamide type copolymers, the use

of chromium containing lignosulfonates can be avoided.

Because of their polymer structure, VS-VA copolymers

are not readily biodegradable. According to recent findings,

the biodegradability can be improved by slight modification of

the polymer composition.

CEMENTING

Vinylsulfonate-vinylamide type polymers with similar

monomer composition are also widely used as fluid loss

additives for cementing of oil and gas wells.

Hostamer grades provide efficient fluid loss control to

cement slurries over a very broad temperature range of 50 up

to 500 F. Fluid loss additives for cementing must tolerate

high electrolyte concentrations and pH values above 12. They

must be compatible with other additives like dispersants and

retarders, should not affect the setting behavior and the

compressive strength of the cement and must prevent from

micro-channeling.

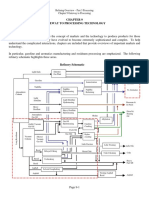

CROSS-LINKABLE VS-VA COPOLYMERS

By the addition of small amounts of a suitable comonomer,

chelating functionality can be incorporated. Thus cross-

linkability can be achieved with at least bivalent metal salts

like acetates or with metal chelates like for instance lactates

based on aluminum, chromium, titanium or zirconium.

Linearpolymer

Modified polymer backbone

Anchor groups

Chelating functionality

Linearpolymer

Modified polymer backbone

Anchor groups

Chelating functionality

Linear polymers with anchor groups and chelating

functionality.

Cross-linking is achieved with at least bivalent metal salts

or chelates, e.g. based on aluminium, chromium, titanium

or zirconium to achieve a tri-dimensional polymer

network.

More viscous solutions up to non-flowing, but deformable

(ringing) gels can be obtained by varying both polymer

and cross-linker.

Gelation can be delayed resp. shifted to higher

temperatures with retarders up to 450 F.

Figure 4: Cross-linkable VS-VA copolymers Principle

By variations of the polymers cross-linkability and the

type or amount of cross-linker more viscous solutions up to

non-flowing, but deformable (ringing) gels can be created.

Our cross-linkable polymers are anionic/nonionic

polyelectrolytes with medium to high molecular weight. They

are soluble and stable in brines and in acids, thus also suitable

for acidizing. Their high thermo stability up to 450 F allows

gelation at high temperatures as well as the formation of high

temperature stable gels.

By the addition of suitable retarders the gelation can be

delayed respectively shifted to higher temperatures.

Cross-linkable VS-VA polymers offer a broad variety of

applications at high temperatures such as:

proppants suspension and transport in fracturing fluids,

retardation by gelation of acids in acidizing,

control of fluid loss by gelation of heavy brines in

completion and workover fluids, prevention of lost

circulation in drilling and

relative permeability modification for water control and

selective or total water shut off.

CONCLUSION

Vinylsulfonate-vinylamide based polymers for drilling and

cementing have become industry standards. Because of their

relatively high price they are sometimes called "gold dust". In

the case of drilling, they are only used when the demands on

the drilling mud can no longer be met by conventional mud

additives or oil based muds are prohibited because of

environmental regulations. Cross-linkable VS-VA polymers

are providing a new interesting potential for HTHP

applications. Because of the HTHP potential for the future

exploration and production of oil and gas we see a good

perspective for the "gold dust for the black gold.

Acknowledgments

The authors would like to thank you for your attention,

the AADE and our company for allowing to present this paper,

and last but not least our group for their assistance and their

experimental works, in particular Mr. Gernold Botthof.

S-ar putea să vă placă și

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Advantages and Disadvantages of Composition and Properties of Biomass PDFDocument21 paginiAdvantages and Disadvantages of Composition and Properties of Biomass PDFNatalia Moreno MorenoÎncă nu există evaluări

- Simulation AspenDocument2 paginiSimulation AspenFernanda GuerreroÎncă nu există evaluări

- Ph.d. Thesis - Ke Qin Klar Til (Entrained Flow Gasifier)Document187 paginiPh.d. Thesis - Ke Qin Klar Til (Entrained Flow Gasifier)Fernanda GuerreroÎncă nu există evaluări

- Simulation of Biomass GasificationDocument62 paginiSimulation of Biomass GasificationFernanda Guerrero100% (2)

- Gasification Systm - SwedenDocument8 paginiGasification Systm - SwedenFernanda GuerreroÎncă nu există evaluări

- Modelling Entrained Flow ReactorDocument7 paginiModelling Entrained Flow ReactorFernanda GuerreroÎncă nu există evaluări

- JS Activated Economics Plus V84Document14 paginiJS Activated Economics Plus V84Jessica CehÎncă nu există evaluări

- Biomass To Syngas (Gasification)Document7 paginiBiomass To Syngas (Gasification)Fernanda GuerreroÎncă nu există evaluări

- Prediction of The Reid Vapor Pressure of Petroleum Fuels: M. R. Riazi, T. A. Albahri and A. H. AlqattanDocument2 paginiPrediction of The Reid Vapor Pressure of Petroleum Fuels: M. R. Riazi, T. A. Albahri and A. H. AlqattanFernanda GuerreroÎncă nu există evaluări

- The Age of Thermal RefineriesDocument11 paginiThe Age of Thermal RefineriesFernanda GuerreroÎncă nu există evaluări

- 2016Document10 pagini2016Fernanda GuerreroÎncă nu există evaluări

- Kids 2Document1 paginăKids 2Fernanda GuerreroÎncă nu există evaluări

- Petrochemical PartDocument1 paginăPetrochemical PartFernanda GuerreroÎncă nu există evaluări

- Simple & Complex RefineriesDocument6 paginiSimple & Complex RefineriesFernanda Guerrero100% (1)

- Name:: A. Complete The Following Sentences With The Past of Such Verb. B. Name Each Mean of TransportationDocument1 paginăName:: A. Complete The Following Sentences With The Past of Such Verb. B. Name Each Mean of TransportationFernanda GuerreroÎncă nu există evaluări

- The Use of Hydrogen in Refineries About This ChapterDocument7 paginiThe Use of Hydrogen in Refineries About This ChapterFernanda GuerreroÎncă nu există evaluări

- Articulo SillmanDocument25 paginiArticulo SillmanFernanda GuerreroÎncă nu există evaluări

- Simple & Complex RefineriesDocument6 paginiSimple & Complex RefineriesFernanda Guerrero100% (1)

- Vocabulary For TOEFL iBTDocument191 paginiVocabulary For TOEFL iBTquevinh94% (48)

- RefinacionDocument4 paginiRefinacionAngelSosa100% (1)

- Gasoline Manufacture OverviewDocument11 paginiGasoline Manufacture OverviewFernanda GuerreroÎncă nu există evaluări

- RefiningDocument4 paginiRefiningAngelSosaÎncă nu există evaluări

- Visual Basic TutorialDocument21 paginiVisual Basic TutorialUmesh Prasad100% (1)

- FoglerDocument105 paginiFogleryvehuangÎncă nu există evaluări

- An Another Carr and PrinceDocument10 paginiAn Another Carr and PrinceFernanda GuerreroÎncă nu există evaluări

- Elementarygrammargames SplitDocument3 paginiElementarygrammargames SplitFernanda GuerreroÎncă nu există evaluări

- Pronunciación de Los Verbos RegularesDocument2 paginiPronunciación de Los Verbos RegularesJorge Iván Albear GuevaraÎncă nu există evaluări

- Factors For Unit ConversionsDocument2 paginiFactors For Unit ConversionsChemistÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- 1Document6 pagini1Kuo Garol SarongÎncă nu există evaluări

- Assignment 2Document2 paginiAssignment 2Devashish SoniÎncă nu există evaluări

- Gale TransformDocument18 paginiGale TransformPablo Soberón BravoÎncă nu există evaluări

- Class:12 Physics Assignment 8 Topic: Electromagnetic InductionDocument3 paginiClass:12 Physics Assignment 8 Topic: Electromagnetic InductionAkshat RawatÎncă nu există evaluări

- Madhuri Question PaperDocument4 paginiMadhuri Question PaperprasadsuriÎncă nu există evaluări

- Blade Calculations For Water Turbines of The Banki Type: Citation For Published Version (APA)Document24 paginiBlade Calculations For Water Turbines of The Banki Type: Citation For Published Version (APA)Anonymous Hy5Ir9QXÎncă nu există evaluări

- LAB 5 VibrationDocument6 paginiLAB 5 Vibrationmohdiqbal930% (1)

- Catalytic Reaction Transport and Kinetics - W7Document46 paginiCatalytic Reaction Transport and Kinetics - W7Nabilahtul FullahÎncă nu există evaluări

- Dosimetry - Parotid Clinical LabDocument15 paginiDosimetry - Parotid Clinical Labapi-247574390Încă nu există evaluări

- Acids, Bases and BuffersDocument29 paginiAcids, Bases and BuffersTayba KhanÎncă nu există evaluări

- Band-to-Band Transitions: Karl W. Bo Er and Udo W. PohlDocument29 paginiBand-to-Band Transitions: Karl W. Bo Er and Udo W. PohlSakshat LakhianiÎncă nu există evaluări

- Advanced Engineering Mathematics 8Th Edition Oneil Solutions Manual Full Chapter PDFDocument36 paginiAdvanced Engineering Mathematics 8Th Edition Oneil Solutions Manual Full Chapter PDFbetty.slaton822100% (14)

- The Spin Force - A Collection of Articles & Experiments 2nd EditionDocument187 paginiThe Spin Force - A Collection of Articles & Experiments 2nd EditionJorge Casalini100% (3)

- 99 AL/Structural Question/P.1Document10 pagini99 AL/Structural Question/P.1Nawam KalpaÎncă nu există evaluări

- Solutions ManualDocument478 paginiSolutions ManualBraden Henderson100% (1)

- Space Physics NotesDocument30 paginiSpace Physics Notesfgthy100% (1)

- 4PH0 1PR Que 20140515Document32 pagini4PH0 1PR Que 20140515ramexistsÎncă nu există evaluări

- Chapter 1 Chem Kinetics Auto Saved)Document127 paginiChapter 1 Chem Kinetics Auto Saved)Mohd IzzudinÎncă nu există evaluări

- Channel Design AISCDocument9 paginiChannel Design AISCRajveer SinghÎncă nu există evaluări

- Rangkuman TRK (Deva Punya)Document4 paginiRangkuman TRK (Deva Punya)gamalielÎncă nu există evaluări

- Fluid 04Document104 paginiFluid 04Edgar HuancaÎncă nu există evaluări

- Quantum Idealism: An Idealist Consciousness Model For Collapsing The Quantum Wave FunctionDocument36 paginiQuantum Idealism: An Idealist Consciousness Model For Collapsing The Quantum Wave FunctionramponnetÎncă nu există evaluări

- Analytic Solution of Stokes Second Problem For Second-Grade FluidDocument9 paginiAnalytic Solution of Stokes Second Problem For Second-Grade FluidricljrÎncă nu există evaluări

- CMC Chapter 08Document125 paginiCMC Chapter 08MattÎncă nu există evaluări

- Boron NitrideDocument62 paginiBoron NitrideSteven SullivanÎncă nu există evaluări

- Chemistry Periodic Table PPT 1Document17 paginiChemistry Periodic Table PPT 1Hazel ValenzuelaÎncă nu există evaluări

- SAMPLEDocument3 paginiSAMPLEAlexis JaraÎncă nu există evaluări

- Physics Question BankDocument28 paginiPhysics Question BankAhmed AdhamÎncă nu există evaluări

- Khuner DaayDocument19 paginiKhuner DaayShameem AhmadÎncă nu există evaluări

- Physics Project Class 11 (Final)Document12 paginiPhysics Project Class 11 (Final)chemistry project89% (9)