Documente Academic

Documente Profesional

Documente Cultură

Lip Nozzle

Încărcat de

Sajal KulshresthaTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Lip Nozzle

Încărcat de

Sajal KulshresthaDrepturi de autor:

Formate disponibile

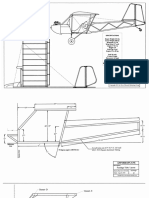

A) LIP Type Nozzle necks.

50 T1 A H2

B H1 R2 R1 C T2

Sl. No. 1 2 3 4 5 6 7 8 9 10 11 12 13

A 824 538 508 276 233 136 102 57 508 276 276 82 29

B 1344 968 928 536 453 316 252 167 908 476 526 182 129

C 1544 1168 1128 736 653 516 452 367 1108 676 726 400 329

H1 300 225 225 200 200 150 140 135 225 150 200 125 110

H2 195 179 174 106 90 74 59 39 164 76 101 34 34

T1 65 36 36 24 20 16 16 16 36 24 24 16 16

T2 520 345 330 225 210 190 180 170 300 135 200 100 150

R1 25 25 25 25 25 25 25 25 25 25 25 25 25

R2 50 50 50 50 50 50 50 50 50 50 50 50 50

QTY. 1 1 1 1 1 2 1 4 2 2 2 2 10

MOC SA 350 LF 2 SA 182 F 11 CL 2 SA 350 LF 2 SA 350 LF 2 SA 350 LF 2 SA 350 LF 2 SA 350 LF 2 SA 350 LF 2 SA 105 SA 105 SA 105 SA 105 SA 105

1) All dimensions are in mm unless otherwise noted. 2) Material shall be as per ASME Sec II Part A, 99 Addenda and shall conform to the following requirements. a) Nickel content shall be less than 1% b) Carbon content 0.23%, Ceq 0.43%. c) Hardness shall be less than 187 BHN. 3) One set of 3 Carpy V-notch impact test at 0 deg.F for SA 182 F 11 CL 2 after heat treatment. Average value for a set of 3 specimens being no less than 40 ft-lbs with not more than one value below 40 ft-lbs, but in no case less than 35 ft-lbs. Lateral expansion in mils and percent shear fracture shall be reported with impact test values.

4) Forgings shall be Ultrasonically tested as per SA 388 with acceptance standard as per AM 203.2 of ASME Sec. VIII, Div. 2. 5) All Forgings shall be in normalised and tempered condition. 6) All Forgings shall be made from Vacuum Degassed Steel. 7) All the requirement of AM 201-4 of ASME Sec. VIII, Div. 2, 1998 Edition, 99 Addenda shall be met. 8) All forgings except Sl. No. 2 shall be impact tested as per AM 204 of ASME Sec. VIII, Div. 2, 1998 Edition, 99 Addenda at 5.0 deg.C. 9) Simulated Heat Treatment for Test Coupons shall be carried out as per following cycle. Soaking temp. = 610 deg.C 10 deg.C. Soaking Time = 3 hours. Heating Rate = 70 deg.C/hour above 300 deg.C. Cooling rate = 70 deg.C/hour above 300 deg.C. 10) Tensile test shall be carried out in the direction shown in the sketch. All required testing including impact testing shall be carried out with and without simulation heat treatment and shall be reported.

B) CYLINDERS. 147 THK

2000 I.D.

1775 LONG

1) Quantity required : 4 nos. Material : SA 350 LF 2.

2) All dimensions are in mm unless otherwise noted. 3) Material shall be as per ASME Sec II Part A, 99 Addenda and shall conform to the following requirements. a) Nickel content shall be less than 1% Carbon content 0.23%, Ceq 0.43%. Hardness shall be less than 187 BHN. 4) Forgings shall be Ultrasonically tested as per SA 388 with acceptance standard as per AM 203.2 of ASME Sec. VIII, Div. 2. All Forgings shall be in normalised and tempered condition. All Forgings shall be made from Vacuum Degassed Steel. All the requirement of AM 201-4 of ASME Sec. VIII, Div. 2, 1998 Edition, 99 Addenda shall be met. All forgings shall be impact tested as per AM 204 of ASME Sec. VIII, Div. 2, 1998 Edition, 99 Addenda at 5.0 deg.C. Simulated Heat Treatment for Test Coupons shall be carried out as per following cycle. Soaking temp. = 610 deg.C 10 deg.C. Soaking Time = 3 hours. Heating Rate = 70 deg.C/hour above 300 deg.C. Cooling rate = 70 deg.C/hour above 300 deg.C. Tensile test shall be carried out. All required testing including impact testing shall be carried out with and without simulation heat treatment and shall be reported.

S-ar putea să vă placă și

- TDC PP742 F2Document3 paginiTDC PP742 F2Arjun PrajapatiÎncă nu există evaluări

- T000003407 - FileName1 - 6079A-B-590-006 Vol-2Document32 paginiT000003407 - FileName1 - 6079A-B-590-006 Vol-2kanchanabalajiÎncă nu există evaluări

- Pump Material SpecificationDocument6 paginiPump Material SpecificationshripaddixitÎncă nu există evaluări

- Sa 203Document4 paginiSa 203gst ajahÎncă nu există evaluări

- Weld Like a Pro: Beginning to Advanced TechniquesDe la EverandWeld Like a Pro: Beginning to Advanced TechniquesEvaluare: 4.5 din 5 stele4.5/5 (6)

- Case 2179-3Document2 paginiCase 2179-3Aiyappa DevrajÎncă nu există evaluări

- MQP 2Document10 paginiMQP 2prithvirajd20Încă nu există evaluări

- How to prepare Welding Procedures for Oil & Gas PipelinesDe la EverandHow to prepare Welding Procedures for Oil & Gas PipelinesEvaluare: 5 din 5 stele5/5 (1)

- Technical Specifications BAMULDocument133 paginiTechnical Specifications BAMULjaya100% (1)

- Materials Data for Cyclic Loading: Low-Alloy SteelsDe la EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsEvaluare: 5 din 5 stele5/5 (2)

- Split Tee Specifications and Drawings - 20130906 - 191217Document17 paginiSplit Tee Specifications and Drawings - 20130906 - 191217Anonymous cuOIjrLIÎncă nu există evaluări

- WN SA-105 B16 5 TT Rev0Document2 paginiWN SA-105 B16 5 TT Rev0Aço SalgueiroÎncă nu există evaluări

- Working Guide to Drilling Equipment and OperationsDe la EverandWorking Guide to Drilling Equipment and OperationsEvaluare: 5 din 5 stele5/5 (9)

- Is 2041Document8 paginiIs 2041hhr2412Încă nu există evaluări

- Is 2004Document7 paginiIs 2004raghav248Încă nu există evaluări

- Design Guidelines for Surface Mount TechnologyDe la EverandDesign Guidelines for Surface Mount TechnologyEvaluare: 5 din 5 stele5/5 (1)

- 25 App 7 To TS - MTL Requirements For PipesDocument4 pagini25 App 7 To TS - MTL Requirements For Pipesarunkl27Încă nu există evaluări

- IS 1079 Hot Rolled Carbon Steel SheetsDocument12 paginiIS 1079 Hot Rolled Carbon Steel Sheetssdmel75% (8)

- Asme Section II A Sa-395Document12 paginiAsme Section II A Sa-395Anonymous GhPzn1xÎncă nu există evaluări

- Specs - Clad PlatesDocument2 paginiSpecs - Clad PlatesKalpesh JainÎncă nu există evaluări

- Astm A 31 - 00Document4 paginiAstm A 31 - 00Oswaldo Leyva RÎncă nu există evaluări

- Is 2004Document7 paginiIs 2004shanrama100% (1)

- Quality E335Document1 paginăQuality E335Sivanaga DantuluriÎncă nu există evaluări

- ASTM A 178 Specification For ERW Carbon Steel and Carbon Manganese Steel Boiler and Superheater TubesDocument4 paginiASTM A 178 Specification For ERW Carbon Steel and Carbon Manganese Steel Boiler and Superheater TubesAnibal QuezadaÎncă nu există evaluări

- Editable 1Document16 paginiEditable 1Brayand Colonia MarquinaÎncă nu există evaluări

- Manufacture of Lead Processing KettlesDocument7 paginiManufacture of Lead Processing Kettlesdanny2kÎncă nu există evaluări

- Pressure Vessel Plates, Heat-Treated, Carbon-Manganese-Silicon Steel, For Moderate and Lower Temperature ServiceDocument3 paginiPressure Vessel Plates, Heat-Treated, Carbon-Manganese-Silicon Steel, For Moderate and Lower Temperature ServiceStanley HallÎncă nu există evaluări

- SP10277 Dot4baDocument11 paginiSP10277 Dot4baPhan VinhÎncă nu există evaluări

- Astm A269Document5 paginiAstm A269Jose M-hÎncă nu există evaluări

- All B31 Code Cases in Effect As of September 21, 2007 Will Remain Available For Use Unless Annulled by The B31 Standards CommitteeDocument39 paginiAll B31 Code Cases in Effect As of September 21, 2007 Will Remain Available For Use Unless Annulled by The B31 Standards CommitteeEl FashelÎncă nu există evaluări

- Astm A618Document4 paginiAstm A618Mohamed Farouk100% (1)

- FSH TigDocument105 paginiFSH TigChee WeiÎncă nu există evaluări

- Technical Data NRL 02301Document8 paginiTechnical Data NRL 02301Attiq Ahmad ChoudhryÎncă nu există evaluări

- Metal Specifications PDFDocument4 paginiMetal Specifications PDFJaeup YouÎncă nu există evaluări

- Astm A 178 A 178M 2002Document4 paginiAstm A 178 A 178M 2002AnamulKabir0% (1)

- Is-903 Couplings, Branch Pipe, NozzlesDocument13 paginiIs-903 Couplings, Branch Pipe, NozzlesCharls JamesÎncă nu există evaluări

- SP 13488Document15 paginiSP 13488Flavia FonsecaÎncă nu există evaluări

- API 570 - Mockup OP - Paper 2 + MDocument13 paginiAPI 570 - Mockup OP - Paper 2 + MShanawas Abdul Razak80% (5)

- Chromium-Vanadium Alloy Steel Valve Spring Quality Wire: Standard Specification ForDocument4 paginiChromium-Vanadium Alloy Steel Valve Spring Quality Wire: Standard Specification Forquiensabe0077Încă nu există evaluări

- IBR Quiz 1Document6 paginiIBR Quiz 1RAJKUMARÎncă nu există evaluări

- Astm A529 1972Document5 paginiAstm A529 1972dharlanuctcom0% (1)

- A 861 - 02 Qtg2ms1sruq - PDFDocument43 paginiA 861 - 02 Qtg2ms1sruq - PDFMung Duong XuanÎncă nu există evaluări

- Is 1079 2009Document9 paginiIs 1079 2009renjisrsÎncă nu există evaluări

- DIN 1626-84 WELDED CIRCULAR TUBES OF NON ALLOY STEELS WITH SPECIAL USt 37.0 - ST 37.0 - ST 44.0 - ST 52.0 - DIN1.0253 - 1.0254 1.0256 1.0256 1.0421 DIN1626-84Document2 paginiDIN 1626-84 WELDED CIRCULAR TUBES OF NON ALLOY STEELS WITH SPECIAL USt 37.0 - ST 37.0 - ST 44.0 - ST 52.0 - DIN1.0253 - 1.0254 1.0256 1.0256 1.0421 DIN1626-84nunosobralÎncă nu există evaluări

- Technical Notes (General Specification) FOR Flanges, Spectacle Blinds AND Drip RingsDocument11 paginiTechnical Notes (General Specification) FOR Flanges, Spectacle Blinds AND Drip RingsMunish100% (1)

- Structural Steel-Microalloyed (Medium and High Strength Qualities) - Specification (Document16 paginiStructural Steel-Microalloyed (Medium and High Strength Qualities) - Specification (Achuthan Kannankutty100% (2)

- Astm f682 1982Document7 paginiAstm f682 1982dharlanuctcomÎncă nu există evaluări

- api 510 اسئلة متنوعة لكل الكورسDocument42 paginiapi 510 اسئلة متنوعة لكل الكورسhussam ghiathÎncă nu există evaluări

- Cold Drawn Seamless For Heat Exchangers and BoilersDocument12 paginiCold Drawn Seamless For Heat Exchangers and BoilersmuhammadsaliÎncă nu există evaluări

- A 861 - 02 QTG2MS0WMG - PDFDocument28 paginiA 861 - 02 QTG2MS0WMG - PDFMung Duong XuanÎncă nu există evaluări

- Metrode Cryogenic 308lcf B-37Document5 paginiMetrode Cryogenic 308lcf B-37Claudia MmsÎncă nu există evaluări

- Asme Ccase - 2059Document2 paginiAsme Ccase - 2059ADAMJSRAOÎncă nu există evaluări

- ASME B16.5 - List of Material SpecificationDocument3 paginiASME B16.5 - List of Material Specificationjr_satish6965Încă nu există evaluări

- Grade 1Document2 paginiGrade 1Sajal KulshresthaÎncă nu există evaluări

- Ellipsoidal Head Dimensional CharacteristicsDocument2 paginiEllipsoidal Head Dimensional CharacteristicsSajal KulshresthaÎncă nu există evaluări

- Enjoy 2% Cashback: Use Your Samba Credit Card at Kalyan Jewellers andDocument1 paginăEnjoy 2% Cashback: Use Your Samba Credit Card at Kalyan Jewellers andSajal KulshresthaÎncă nu există evaluări

- Amled School Task Sheet - September Subject: Science Grade 1 (2017-2018)Document3 paginiAmled School Task Sheet - September Subject: Science Grade 1 (2017-2018)Sajal KulshresthaÎncă nu există evaluări

- Pressure VesselsDocument9 paginiPressure VesselsSajal KulshresthaÎncă nu există evaluări

- Modal Mass IDocument8 paginiModal Mass ISajal KulshresthaÎncă nu există evaluări

- Form No. 15 H: Bar Code: PanDocument2 paginiForm No. 15 H: Bar Code: PanSajal KulshresthaÎncă nu există evaluări

- Hotl ListDocument1 paginăHotl ListSajal KulshresthaÎncă nu există evaluări

- Product Specification Form Harrington Manual Trolleys/HoistsDocument1 paginăProduct Specification Form Harrington Manual Trolleys/HoistsSajal KulshresthaÎncă nu există evaluări

- The Damage Could Have Been Greater Had He Not Stopped Himself From Paying The Fourth and Final InstalmentDocument1 paginăThe Damage Could Have Been Greater Had He Not Stopped Himself From Paying The Fourth and Final InstalmentSajal KulshresthaÎncă nu există evaluări

- Seismic Design Lec 2 PDFDocument32 paginiSeismic Design Lec 2 PDFGuillermo Cordero100% (1)

- Flow Induced VibrationDocument4 paginiFlow Induced VibrationSajal KulshresthaÎncă nu există evaluări

- Common Ions Anions and CationsDocument2 paginiCommon Ions Anions and CationsSajal KulshresthaÎncă nu există evaluări

- Mixing and Reaction Technology e 23270640Document20 paginiMixing and Reaction Technology e 23270640Sajal KulshresthaÎncă nu există evaluări

- Static Mixer CatalogueDocument21 paginiStatic Mixer CatalogueSajal KulshresthaÎncă nu există evaluări

- Jis G3444Document12 paginiJis G3444yapsguanÎncă nu există evaluări

- Tesla Coil ProjectDocument8 paginiTesla Coil ProjectShivam singhÎncă nu există evaluări

- TreesDocument69 paginiTreesADITYA GEHLAWATÎncă nu există evaluări

- Study The Effect of Postharvest Heat Treatment On Infestation Rate of Fruit Date Palm (Phoenix Dactylifera L.) Cultivars Grown in AlgeriaDocument4 paginiStudy The Effect of Postharvest Heat Treatment On Infestation Rate of Fruit Date Palm (Phoenix Dactylifera L.) Cultivars Grown in AlgeriaJournal of Nutritional Science and Healthy DietÎncă nu există evaluări

- Murata High Voltage CeramicDocument38 paginiMurata High Voltage CeramictycristinaÎncă nu există evaluări

- Harmonics PatternsDocument4 paginiHarmonics PatternsIzzadAfif1990Încă nu există evaluări

- Niir Integrated Organic Farming Handbook PDFDocument13 paginiNiir Integrated Organic Farming Handbook PDFNatalieÎncă nu există evaluări

- Goldhofer FTV 850 BrochureDocument2 paginiGoldhofer FTV 850 BrochureMauroÎncă nu există evaluări

- DudjDocument4 paginiDudjsyaiful rinantoÎncă nu există evaluări

- Passenger Lift Alert - Health and Safety AuthorityDocument4 paginiPassenger Lift Alert - Health and Safety AuthorityReginald MaswanganyiÎncă nu există evaluări

- Sustainable Events Guide May 30 2012 FINAL PDFDocument118 paginiSustainable Events Guide May 30 2012 FINAL PDFInter 4DMÎncă nu există evaluări

- Plans PDFDocument49 paginiPlans PDFEstevam Gomes de Azevedo85% (34)

- SAT Practice TestDocument77 paginiSAT Practice TestfhfsfplÎncă nu există evaluări

- TM-8000 HD Manual PDFDocument37 paginiTM-8000 HD Manual PDFRoxana BirtumÎncă nu există evaluări

- OurCatholicFaith PowerPoint Chapter1Document21 paginiOurCatholicFaith PowerPoint Chapter1VinÎncă nu există evaluări

- Inverse of One-To-One FunctionDocument4 paginiInverse of One-To-One FunctionKathFaye EdaÎncă nu există evaluări

- Pediatric EmergenciesDocument47 paginiPediatric EmergenciesahmedÎncă nu există evaluări

- Indor Lighting DesignDocument33 paginiIndor Lighting DesignRajesh MalikÎncă nu există evaluări

- Better - Homes.and - Gardens.usa - TruePDF December.2018Document136 paginiBetter - Homes.and - Gardens.usa - TruePDF December.2018MadaMadutsaÎncă nu există evaluări

- Board Replacement CasesDocument41 paginiBoard Replacement CasesNadeeshÎncă nu există evaluări

- FYP ProposalDocument11 paginiFYP ProposalArslan SamÎncă nu există evaluări

- EN Manual Lenovo Ideapad S130-14igm S130-11igmDocument33 paginiEN Manual Lenovo Ideapad S130-14igm S130-11igmDolgoffÎncă nu există evaluări

- Course Syllabus: Course Code Course Title ECTS CreditsDocument3 paginiCourse Syllabus: Course Code Course Title ECTS CreditsHanaa HamadallahÎncă nu există evaluări

- Douluo Dalu Volume 05 - Star Dou Forest PDFDocument141 paginiDouluo Dalu Volume 05 - Star Dou Forest PDFRay Joseph LealÎncă nu există evaluări

- Highway-And-Railroad-Engineering SummaryDocument15 paginiHighway-And-Railroad-Engineering SummaryRodin James GabrilloÎncă nu există evaluări

- LG250CDocument2 paginiLG250CCarlosÎncă nu există evaluări

- Ham Radio Balu N ManualDocument7 paginiHam Radio Balu N Manualcolinbeeforth100% (1)

- Twilight PrincessDocument49 paginiTwilight PrincessHikari DiegoÎncă nu există evaluări

- Introduction To LCCDocument32 paginiIntroduction To LCCGonzalo LopezÎncă nu există evaluări

- Biology Accel Syllabus 2011-2012Document3 paginiBiology Accel Syllabus 2011-2012Mike DeleonÎncă nu există evaluări

- Clevo W940tu Service ManualDocument93 paginiClevo W940tu Service ManualBruno PaezÎncă nu există evaluări

- Summary of Supercommunicators by Charles Duhigg: How to Unlock the Secret Language of ConnectionDe la EverandSummary of Supercommunicators by Charles Duhigg: How to Unlock the Secret Language of ConnectionÎncă nu există evaluări

- TOEFL Writing: Important Tips & High Scoring Sample Answers! (Written By A TOEFL Teacher)De la EverandTOEFL Writing: Important Tips & High Scoring Sample Answers! (Written By A TOEFL Teacher)Evaluare: 4.5 din 5 stele4.5/5 (5)

- Summary of Miracle Morning Millionaires: What the Wealthy Do Before 8AM That Will Make You Rich by Hal Elrod and David OsbornDe la EverandSummary of Miracle Morning Millionaires: What the Wealthy Do Before 8AM That Will Make You Rich by Hal Elrod and David OsbornEvaluare: 5 din 5 stele5/5 (201)

- Summary of The Galveston Diet by Mary Claire Haver MD: The Doctor-Developed, Patient-Proven Plan to Burn Fat and Tame Your Hormonal SymptomsDe la EverandSummary of The Galveston Diet by Mary Claire Haver MD: The Doctor-Developed, Patient-Proven Plan to Burn Fat and Tame Your Hormonal SymptomsÎncă nu există evaluări

- Summary of When Things Fall Apart: Heart Advice for Difficult Times by Pema ChödrönDe la EverandSummary of When Things Fall Apart: Heart Advice for Difficult Times by Pema ChödrönEvaluare: 4.5 din 5 stele4.5/5 (22)

- Summary of Atomic Habits by James ClearDe la EverandSummary of Atomic Habits by James ClearEvaluare: 5 din 5 stele5/5 (169)

- Summary of Eat to Beat Disease by Dr. William LiDe la EverandSummary of Eat to Beat Disease by Dr. William LiEvaluare: 5 din 5 stele5/5 (52)

- SUMMARY: So Good They Can't Ignore You (UNOFFICIAL SUMMARY: Lesson from Cal Newport)De la EverandSUMMARY: So Good They Can't Ignore You (UNOFFICIAL SUMMARY: Lesson from Cal Newport)Evaluare: 4.5 din 5 stele4.5/5 (14)

- Summary of Some People Need Killing by Patricia Evangelista:A Memoir of Murder in My CountryDe la EverandSummary of Some People Need Killing by Patricia Evangelista:A Memoir of Murder in My CountryÎncă nu există evaluări

- Summary of Million Dollar Weekend by Noah Kagan and Tahl Raz: The Surprisingly Simple Way to Launch a 7-Figure Business in 48 HoursDe la EverandSummary of Million Dollar Weekend by Noah Kagan and Tahl Raz: The Surprisingly Simple Way to Launch a 7-Figure Business in 48 HoursÎncă nu există evaluări

- Summary of Rich AF by Vivian Tu: The Winning Money Mindset That Will Change Your LifeDe la EverandSummary of Rich AF by Vivian Tu: The Winning Money Mindset That Will Change Your LifeÎncă nu există evaluări

- Summary of The Dawn of Everything by David Graeber and David Wengrow: The Dawn of Everything Book Complete Analysis & Study GuideDe la EverandSummary of The Dawn of Everything by David Graeber and David Wengrow: The Dawn of Everything Book Complete Analysis & Study GuideEvaluare: 5 din 5 stele5/5 (1)

- Summary of Poor Charlie’s Almanack by Charles T. Munger and Peter D. Kaufman: The Essential Wit and Wisdom of Charles T. Munger: The Essential Wit and Wisdom of Charles T. MungerDe la EverandSummary of Poor Charlie’s Almanack by Charles T. Munger and Peter D. Kaufman: The Essential Wit and Wisdom of Charles T. Munger: The Essential Wit and Wisdom of Charles T. MungerÎncă nu există evaluări

- Summary of Talking to Strangers: What We Should Know About the People We Don't Know by Malcolm GladwellDe la EverandSummary of Talking to Strangers: What We Should Know About the People We Don't Know by Malcolm GladwellEvaluare: 4.5 din 5 stele4.5/5 (35)

- Summary of Atomic Habits: An Easy & Proven Way to Build Good Habits & Break Bad Ones by James ClearDe la EverandSummary of Atomic Habits: An Easy & Proven Way to Build Good Habits & Break Bad Ones by James ClearEvaluare: 4.5 din 5 stele4.5/5 (13)

- Summary of The Midnight Library by Matt Haig: Complete analysis and study guide of the book The Midnight Library by Matt Haig.De la EverandSummary of The Midnight Library by Matt Haig: Complete analysis and study guide of the book The Midnight Library by Matt Haig.Încă nu există evaluări

- Summary of Can’t Hurt Me by David Goggins: Can’t Hurt Me Book Analysis by Peter CuomoDe la EverandSummary of Can’t Hurt Me by David Goggins: Can’t Hurt Me Book Analysis by Peter CuomoEvaluare: 5 din 5 stele5/5 (1)

- Summary of The 48 Laws of Power by Robert GreeneDe la EverandSummary of The 48 Laws of Power by Robert GreeneEvaluare: 4.5 din 5 stele4.5/5 (62)

- Workbook & Summary of Becoming Supernatural How Common People Are Doing the Uncommon by Joe Dispenza: WorkbooksDe la EverandWorkbook & Summary of Becoming Supernatural How Common People Are Doing the Uncommon by Joe Dispenza: WorkbooksÎncă nu există evaluări

- Summary of How to Change Your Mind: What the New Science of Psychedelics Teaches Us About Consciousness, Dying, Addiction, Depression, and Transcendence by Michael PollanDe la EverandSummary of How to Change Your Mind: What the New Science of Psychedelics Teaches Us About Consciousness, Dying, Addiction, Depression, and Transcendence by Michael PollanEvaluare: 4.5 din 5 stele4.5/5 (34)

- Drilling Supervisor: Passbooks Study GuideDe la EverandDrilling Supervisor: Passbooks Study GuideÎncă nu există evaluări

- PMP Exam Prep: Master the Latest Techniques and Trends with this In-depth Project Management Professional Guide: Study Guide | Real-life PMP Questions and Detailed Explanation | 200+ Questions and AnswersDe la EverandPMP Exam Prep: Master the Latest Techniques and Trends with this In-depth Project Management Professional Guide: Study Guide | Real-life PMP Questions and Detailed Explanation | 200+ Questions and AnswersEvaluare: 5 din 5 stele5/5 (2)

- Summary of The 7 Habits of Highly Effective People by Stephen R. CoveyDe la EverandSummary of The 7 Habits of Highly Effective People by Stephen R. CoveyEvaluare: 5 din 5 stele5/5 (5)

- Summary and Analysis of The Psychology of Money: Timeless Lessons on Wealth, Greed, and Happiness by Morgan HouselDe la EverandSummary and Analysis of The Psychology of Money: Timeless Lessons on Wealth, Greed, and Happiness by Morgan HouselEvaluare: 5 din 5 stele5/5 (11)

- Workbook on The Body Keeps the Score: Brain, Mind, and Body in the Healing of Trauma by Bessel van der Kolk M.D. | Discussions Made EasyDe la EverandWorkbook on The Body Keeps the Score: Brain, Mind, and Body in the Healing of Trauma by Bessel van der Kolk M.D. | Discussions Made EasyÎncă nu există evaluări

- GMAT Prep 2024/2025 For Dummies with Online Practice (GMAT Focus Edition)De la EverandGMAT Prep 2024/2025 For Dummies with Online Practice (GMAT Focus Edition)Încă nu există evaluări

- Midnight's Children by Salman Rushdie (Book Analysis): Detailed Summary, Analysis and Reading GuideDe la EverandMidnight's Children by Salman Rushdie (Book Analysis): Detailed Summary, Analysis and Reading GuideEvaluare: 5 din 5 stele5/5 (1)

- Summary of The Obesity Code by Dr. Jason FungDe la EverandSummary of The Obesity Code by Dr. Jason FungEvaluare: 4.5 din 5 stele4.5/5 (206)