Documente Academic

Documente Profesional

Documente Cultură

Extractive System Overview

Încărcat de

babis1980Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Extractive System Overview

Încărcat de

babis1980Drepturi de autor:

Formate disponibile

Extraction CEMS Overview

An extraction Continuous Emissions Monitoring System is in simple terms a device for constantly measuring exhaust gases in a stack or duct, for the purposes of tracking and reporting specific constituents to the EPA.

In an extraction system, a sample is drawn (extracted) from the stack by a pump and sent to analyzers for measurement of specific gases. The information from the analyzers is sent to a Data Acquisition System (or DAS) where it is tracked and recorded. The DAS allows a user to create reports in the specific formats required by the EPA and other local and/or state regulatory agencies. The extraction system can be broken down into several main components: Probe Umbilical Sample Conditioner Analyzers Sample/Cal Gas Control System DAS

Monitoring Solutions has offices in Indiana, New Jersey and Pennsylvania Contact us at: 888-380-5266 or sales@monsol.com or visit us at www.monsol.com

Probe

Umbilical Analyzers

Sample Conditioner Stack

DAS

The Probe: The extraction probe is heated to keep the sample at temperatures between 350-350F. This eliminates any condensation and formation of acid gases in the probe.

Monitoring Solutions has offices in Indiana, New Jersey and Pennsylvania Contact us at: 888-380-5266 or sales@monsol.com or visit us at www.monsol.com

The probe has a 10 micron sintered Stainless Steel replaceable particulate filter. There are two ports in the probe one for introduction of cal gas, and one for purge. Cal gas is introduced before the filter. This allows the entire CEM System to be calibrated as the gas follows the same entire path as the stack gas. This is per EPA requirements. Purging is done with instrument air and is activated by the DAS at user selectable intervals. Air is sent up to the probe until a positive pressure is produced that blows out dirt and particulate. The dirtier the stack or application, the more frequent a user can set the purge cycle. This keeps the probe cleaner and allows for longer times between maintenance. The Umbilical: The umbilical transports the sample from the probe to the analyzer cabinet. It can be up to several hundred feet long as it runs from the top of the stack to the bottom where the analyzer cabinet is installed. The umbilical in an extraction system, like the probe, is heated to 350-400F to keep the sample from condensing. The umbilical serves many functions: 1. Carries the sample from the stack to the analyzer cabinet (heated 3/8 Teflon, often a spare tube is ncluded) 2. Carries the cal gas up to the probe (heated 3/8 poly) 3. Carries the purge air up to the probe (1/4 Teflon) 4. Carries the power wiring for the probe heater

Umbilical cross-section:

Monitoring Solutions has offices in Indiana, New Jersey and Pennsylvania Contact us at: 888-380-5266 or sales@monsol.com or visit us at www.monsol.com

The Sample Conditioner: Before the sample can be put through the various gas analyzers, it must first be filtered and cooled to remove moisture. Thermo-Electric Dryers are used for this. They typically reside in or on the floor next to the analyzer cabinet.

Thermo-Electric dryers cool the sample down through a heat exchanger and draw out the moisture in the saturated sample as it condenses, with a peristaltic pump. The sample is then dry and ready for the analyzers.

Monitoring Solutions has offices in Indiana, New Jersey and Pennsylvania Contact us at: 888-380-5266 or sales@monsol.com or visit us at www.monsol.com

The Analyzers: Different analyzers are used depending on the type of gases being monitored. This is because each gas is best measured with a unique methodology i.e. Chemiluminesence for NOx, pulsed fluorescence for SO2, zirconia for O2, etc. The different technologies insure the lowest concentration measurement for each gas can be attained. A number of analyzers are available to measure a variety of gases including: SO2, NOx, CO, CO2, THC, NH3 and O2. The analyzers are mounted in a rack and normally housed in an enclosure for protection from high or low ambient temperatures and severe weather:

NEMA 1 racks: these are used when the analyzer cabinet will reside in a control room type environment where the temperature and humidity are constantly controlled (typically 68-70F).

NEMA 12 Cabinets: these are typically used indoors, in areas where the temperature is not constantly controlled (i.e. turbine deck). They have built in HVAC units to keep the inside of the cabinet at a constant temperature.

Walk-in Enclosures/Shelters: utilized for outdoor placement of the CEMS equipment. They have their own HVAC for temperature control, and allow maintenance people to work on the units out of the weather.

Monitoring Solutions has offices in Indiana, New Jersey and Pennsylvania Contact us at: 888-380-5266 or sales@monsol.com or visit us at www.monsol.com

A calibration gas system is required to perform the daily and quarterly calibrations required by Federal EPA regulations. The system is completely automated and introduces the correct cal gas at appointed times and durations using solenoids that are part of a complete sample/cal control panel. This panel is found in the CEMS rack and is controlled by a PLC. Beside the analyzers and sample/cal control panel, the CEMS cabinet also typically holds the sample conditioner and pump, heater controllers, and the PLC controller.

Heater controller Sample/Cal control panel PLC with Operator Interface Terminal Analyzer Analyzer Sample Conditioner and Pump (behind cover)

Monitoring Solutions has offices in Indiana, New Jersey and Pennsylvania Contact us at: 888-380-5266 or sales@monsol.com or visit us at www.monsol.com

Data Acquisition System: Last but not least is the DAS. The DAS performs many functions: Controls the CEMS calibration check and purge cycles Monitors the system for trouble (sample conditioning system failure, monitor faults, etc.) Outputs alarms in the event of system faults or emission exceedances Collects and stores the data Generates reports for EPA

The DAS is made up of two parts the PLC and the PC. A PLC is used as the main controller and interface between the CEMS and the DAS computer. It is usually located in the analyzer cabinet. It is comprised of analog inputs and outputs and digital inputs and outputs. Some examples:

Analog Inputs: the analyzer signals, fuel flow signals, process signals, etc. Analog Outputs: retransmission of analyzer signals (gas values) to a plant PLC (can also be accomplished via an Ethernet connection) Digital Inputs: process signals (ID fan on/off for example), alarm contacts from sample conditioner, analyzers, etc. Digital Outputs: alarm contact to plant PLC (can also be accomplished via an Ethernet connection), calibration solenoid enabling, purge solenoid enabling, etc.

DAS Computer: The DAS computer is connected directly to the PLC and receives all the information for storage, calculations and reporting. The DAS computer can sometimes be found in a CEMS shelter next to the analyzer cabinet, but often it is located remotely in a control room.

Monitoring Solutions has offices in Indiana, New Jersey and Pennsylvania Contact us at: 888-380-5266 or sales@monsol.com or visit us at www.monsol.com

The DAS computer maintains and displays the status of the CEMS for an operator:

It alerts the user of alarm conditions:

and allows for reports to be generated (both manually and automatically) from the stored data:

Extraction CEMS are designed with high reliability, ease of use and ease of maintenance in mind. They are built for easy upgrades in the future and are the system of choice where low pollutant levels are found and accurate measurement is desired.

Monitoring Solutions has offices in Indiana, New Jersey and Pennsylvania Contact us at: 888-380-5266 or sales@monsol.com or visit us at www.monsol.com

S-ar putea să vă placă și

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentDe la EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentEvaluare: 4.5 din 5 stele4.5/5 (3)

- Advanced Temperature Measurement and Control, Second EditionDe la EverandAdvanced Temperature Measurement and Control, Second EditionÎncă nu există evaluări

- CEMS Primer: Automated Control Systems Inc. 122 Woodburn Drive - Dothan, AL 36301 334-792-0113 Fax 334-671-4298Document8 paginiCEMS Primer: Automated Control Systems Inc. 122 Woodburn Drive - Dothan, AL 36301 334-792-0113 Fax 334-671-4298ryan_keller_23Încă nu există evaluări

- Unit One This or That 1Document9 paginiUnit One This or That 1sushantÎncă nu există evaluări

- CEMS Newsletter: CEMS From A-Z: A Multi-Part SeriesDocument4 paginiCEMS Newsletter: CEMS From A-Z: A Multi-Part Seriesbabis1980Încă nu există evaluări

- The Differences Between Extractive and In-Situ Emissions MonitoringDocument7 paginiThe Differences Between Extractive and In-Situ Emissions MonitoringAniketÎncă nu există evaluări

- Steam and Water Analysis System - 1Document5 paginiSteam and Water Analysis System - 1Marcep Inc.100% (1)

- Ambient Air Quality Monitoring System: Easier. Faster. BetterDocument5 paginiAmbient Air Quality Monitoring System: Easier. Faster. BettersvkatkarÎncă nu există evaluări

- OverviewDocument20 paginiOverviewHashemAliHashem100% (1)

- SensorsDocument3 paginiSensorsAusaid AbdulRazzakÎncă nu există evaluări

- Environmental MonitoringDocument9 paginiEnvironmental MonitoringWAGUDELOÎncă nu există evaluări

- Online Dga PDFDocument8 paginiOnline Dga PDFromaoj671Încă nu există evaluări

- Clif Mock Lgs 2000 Sampling SystemDocument4 paginiClif Mock Lgs 2000 Sampling SystemPaula RiveraÎncă nu există evaluări

- Emerson CEMSDocument12 paginiEmerson CEMSquinteroudinaÎncă nu există evaluări

- Testo 350Document285 paginiTesto 350Nguyen Van SangÎncă nu există evaluări

- Keys To On-Line Monitoring in Steam Generating SystemsDocument9 paginiKeys To On-Line Monitoring in Steam Generating SystemsShameer MajeedÎncă nu există evaluări

- Sample Handling System For AnalyzerDocument7 paginiSample Handling System For Analyzeraugur886Încă nu există evaluări

- Improve Refinery Production and Efficiency With Asset MonitoringDocument11 paginiImprove Refinery Production and Efficiency With Asset MonitoringVishwarajÎncă nu există evaluări

- Life Support Test Facility LSTF100Document3 paginiLife Support Test Facility LSTF100Bojana MarinkovicÎncă nu există evaluări

- EcoZone System Manual ME 6668Document3 paginiEcoZone System Manual ME 6668Edwin HansÎncă nu există evaluări

- Digital Flow Meter For GasDocument1 paginăDigital Flow Meter For GasMASSFLOWMEASUREMENTSÎncă nu există evaluări

- ASHRAE 15 - Reducing Toxic Leaks in HVAC Mechanical Equipment RoomsDocument4 paginiASHRAE 15 - Reducing Toxic Leaks in HVAC Mechanical Equipment Roomspsn_kylmÎncă nu există evaluări

- LAND FGA 900 Series EnglishDocument6 paginiLAND FGA 900 Series EnglishRaymundo CorderoÎncă nu există evaluări

- Computer Controlled Absorption Refrigeration Unit, With SCADADocument19 paginiComputer Controlled Absorption Refrigeration Unit, With SCADAAhmed AzadÎncă nu există evaluări

- Analyser SDocument3 paginiAnalyser Sprashant_dc_inÎncă nu există evaluări

- Model 8066 Leak Hunter Plus Quantitative Leak DetectorDocument6 paginiModel 8066 Leak Hunter Plus Quantitative Leak Detectorsasizzo78Încă nu există evaluări

- Partisol-Plus 2025Document2 paginiPartisol-Plus 2025bogdanberchiÎncă nu există evaluări

- In-Situ Fermentors CatalogueDocument4 paginiIn-Situ Fermentors CatalogueVineet GuptaÎncă nu există evaluări

- CEMSDocument2 paginiCEMSNaveed RabbaniÎncă nu există evaluări

- Thermocouple Multiplexer2Document16 paginiThermocouple Multiplexer2Saamir JassimÎncă nu există evaluări

- Agilent GC MS SpecificationDocument5 paginiAgilent GC MS Specificationashif28Încă nu există evaluări

- Custom Made Automated System For Determination of Humidity and Temperature Gradients Climatic ChambersDocument4 paginiCustom Made Automated System For Determination of Humidity and Temperature Gradients Climatic Chamberscokelat_kÎncă nu există evaluări

- Thermo Cem SDocument30 paginiThermo Cem SfahshaikÎncă nu există evaluări

- Gases Nox SopmDocument17 paginiGases Nox SopmDienÎncă nu există evaluări

- Furnace Design and OperationDocument36 paginiFurnace Design and OperationkINGÎncă nu există evaluări

- Cone Calorimeter: (ISO 5660 ASTM E 1354) The Most Comprehensive Bench Scale Fire TestDocument12 paginiCone Calorimeter: (ISO 5660 ASTM E 1354) The Most Comprehensive Bench Scale Fire TestGaurav KumarÎncă nu există evaluări

- Remote Calibration PDFDocument6 paginiRemote Calibration PDFNguyen Van TruongÎncă nu există evaluări

- Static Pressure Concept 1Document8 paginiStatic Pressure Concept 1bharath477Încă nu există evaluări

- Process Analyzer Sample Systems: Home BlogDocument8 paginiProcess Analyzer Sample Systems: Home BlograhulÎncă nu există evaluări

- Turnkey Dust MonitorsDocument4 paginiTurnkey Dust MonitorsGiulliana Tiravanti BeoutisÎncă nu există evaluări

- Sampling - Analysis - Commissioning - Calibration 05-13 Rev.1 PDFDocument6 paginiSampling - Analysis - Commissioning - Calibration 05-13 Rev.1 PDFNguyen Van TruongÎncă nu există evaluări

- Iisco Training Report 2019Document20 paginiIisco Training Report 2019Aakarsh PrasadÎncă nu există evaluări

- Echometer Digital Well AnalyzerDocument5 paginiEchometer Digital Well AnalyzerEliyanto E BudiartoÎncă nu există evaluări

- Cold Chain SolutionDocument12 paginiCold Chain SolutionGonzalo ADS LogicÎncă nu există evaluări

- Class Notes - As Unit 3Document4 paginiClass Notes - As Unit 3aqsaleemÎncă nu există evaluări

- MEP Inline On Line at Line Off Line AnalysersDocument3 paginiMEP Inline On Line at Line Off Line AnalysersMostofa RubalÎncă nu există evaluări

- GC 7800 Gas Chromatograph With AutosamplerDocument5 paginiGC 7800 Gas Chromatograph With Autosamplerqualityc711Încă nu există evaluări

- Procon Overview Brochure Procon1Document4 paginiProcon Overview Brochure Procon1ViV CroneÎncă nu există evaluări

- Gas Calibration Method v2Document9 paginiGas Calibration Method v2Mazhar MahadzirÎncă nu există evaluări

- Analyser Shelter ATEC Italy - WWW - AtecsrlDocument3 paginiAnalyser Shelter ATEC Italy - WWW - AtecsrlMalyshAVÎncă nu există evaluări

- Polymetron Silca Analyzer PDFDocument4 paginiPolymetron Silca Analyzer PDFJibin JacobÎncă nu există evaluări

- Instrumentation Is Defined As The Art and Science of Measurement and Control of ProcessDocument4 paginiInstrumentation Is Defined As The Art and Science of Measurement and Control of Processriz2010Încă nu există evaluări

- TBMC12Document10 paginiTBMC12Joel E ValenciaÎncă nu există evaluări

- Bms System-Basic PDFDocument59 paginiBms System-Basic PDFWaelBou95% (21)

- Qualitative and Quantitative Analysis of Air Sample Using GCXGCDocument23 paginiQualitative and Quantitative Analysis of Air Sample Using GCXGCRaquel Tejero OlivaÎncă nu există evaluări

- Application of Measuring Gas Flow in The DowncomerDocument4 paginiApplication of Measuring Gas Flow in The DowncomerAhmad NilÎncă nu există evaluări

- Gas ChromatographyDocument57 paginiGas Chromatographysaeed.pdÎncă nu există evaluări

- Apex - Inteccon Conference Presentation 2015 FinalDocument38 paginiApex - Inteccon Conference Presentation 2015 FinalGabriel BustamanteÎncă nu există evaluări

- Steam and Water Analysis SystemDocument4 paginiSteam and Water Analysis SystemJASWANT ADILEÎncă nu există evaluări

- FRL SIF 618 CompressedAirDryingDocument36 paginiFRL SIF 618 CompressedAirDryingbabis1980Încă nu există evaluări

- 1220 Butt Fusion Electrofusion and Socket Fusion Welder February 2013Document2 pagini1220 Butt Fusion Electrofusion and Socket Fusion Welder February 2013babis1980Încă nu există evaluări

- GF Type 546 BallDocument10 paginiGF Type 546 Ballbabis1980Încă nu există evaluări

- FUSION MANUAL - Rev IllustrationsDocument36 paginiFUSION MANUAL - Rev IllustrationsMehmet SoysalÎncă nu există evaluări

- The Condensate, The Boiler Feed, and Their Auxiliary SystemsDocument70 paginiThe Condensate, The Boiler Feed, and Their Auxiliary Systemsbabis1980100% (1)

- Plastic Pipe - PE - Chapter01Document9 paginiPlastic Pipe - PE - Chapter01garisa1963Încă nu există evaluări

- PPG Minimizing The Effects of CorrosionDocument9 paginiPPG Minimizing The Effects of Corrosionbabis1980Încă nu există evaluări

- How To Select A Pump-By Majid HamedyniaDocument72 paginiHow To Select A Pump-By Majid Hamedyniamajid100% (2)

- Non-Circular Pressure Vessels SquareDocument27 paginiNon-Circular Pressure Vessels SquareAbhilash Kurian100% (1)

- P&IDDocument18 paginiP&IDhectornicolauÎncă nu există evaluări

- Orifice Plate Flow MetersDocument8 paginiOrifice Plate Flow MetersGaurav Dhiman100% (1)

- Advanced GE CCPPDocument20 paginiAdvanced GE CCPPR Krishna KumarÎncă nu există evaluări

- White Paper RBIDocument12 paginiWhite Paper RBImahesh070Încă nu există evaluări

- StainlessSteelinWatersGalvanicCorrosionandit PreventionAEBauerDocument14 paginiStainlessSteelinWatersGalvanicCorrosionandit PreventionAEBauerbabis1980Încă nu există evaluări

- Brochure ACCDocument8 paginiBrochure ACCbabis1980Încă nu există evaluări

- Ejector BrochureDocument8 paginiEjector Brochurebabis1980Încă nu există evaluări

- Galvanic CorrosionDocument2 paginiGalvanic CorrosionkeronsÎncă nu există evaluări

- Tech Manual Electrical Power Plant DesignDocument135 paginiTech Manual Electrical Power Plant Designd_kabulpuriaÎncă nu există evaluări

- Chapter IIIDocument19 paginiChapter IIIghostamirÎncă nu există evaluări

- Sa 312Document1 paginăSa 312babis1980Încă nu există evaluări

- Fundamentals of Vacuum Technology: 00.200.02 Kat.-Nr. 199 90Document199 paginiFundamentals of Vacuum Technology: 00.200.02 Kat.-Nr. 199 90Anshul JainÎncă nu există evaluări

- Veizades Gas Removal Systems Liquid Ring VPDocument3 paginiVeizades Gas Removal Systems Liquid Ring VPVenkatespatange RaoÎncă nu există evaluări

- What's New in API 610 11th EditionDocument4 paginiWhat's New in API 610 11th Editionshyam_anupÎncă nu există evaluări

- Ati 317Document13 paginiAti 317babis1980Încă nu există evaluări

- Energy Saving in Steam Systems.Document34 paginiEnergy Saving in Steam Systems.babis1980Încă nu există evaluări

- Ideal Bearing Temp LimitsDocument1 paginăIdeal Bearing Temp Limitsbabis1980Încă nu există evaluări

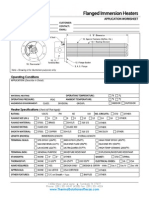

- Flanged Immersion Heaters: Operating ConditionsDocument1 paginăFlanged Immersion Heaters: Operating Conditionsbabis1980Încă nu există evaluări

- 4.24 Drains Systems Design PhilosophyDocument8 pagini4.24 Drains Systems Design Philosophybabis1980Încă nu există evaluări

- Introduction To Gas Turbines For Non-EngineersDocument9 paginiIntroduction To Gas Turbines For Non-EngineersKrishna MyakalaÎncă nu există evaluări

- ATEX Reference GuideDocument2 paginiATEX Reference Guidebabis1980Încă nu există evaluări