Documente Academic

Documente Profesional

Documente Cultură

Presentation On Tennis Balls Manufacturing

Încărcat de

adiall4uTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Presentation On Tennis Balls Manufacturing

Încărcat de

adiall4uDrepturi de autor:

Formate disponibile

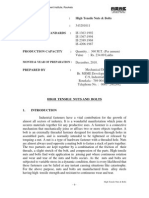

PROJECT PROFILE ON TENNIS BALL

PRODUCT CODE QUALITY STANDARD PRODUCTION CAPACITY (PA) QUANTITY VALUE YEAR OF PREPARATION PREPARED BY : : : : : : : Tennis Ball Rs. 90,00,000/- PA 2010-11 6,00,000 Balls PA

IS: 2216-19885 Or International Standards

Leather Division MSME Development Institute 34, Industrial Estate, Nunhai, Agra-282006 Ph: 2280879, Fax (0562) 2280882 E-MAIL dcdi-agra@dcmsme.gov.in *********************************************************************************** (I) INTRODUCTION Tennis is a four-point game played on a court and which is divided in the middle by a net. For playing this game, a ball is hit by players (two or four) on both sides in such a way that it goes to others side without touching the net and falls in the specified marked area of the court. This ball is known as Tennis Ball. These balls are made of vulcunised rubber and covered with Melton cloth, which has high wool content or Needle cloth, which is cheaper to produce and can have a greater content of synthetic fibres. It is available in white or optic yellow. MARKET POTENTIAL Tennis is an internationally popular game. It is played in many countries of world. It is becoming in very popular in India also as amount of Award is huge in most of the events. India is also holding international events for this game which ha popularised this game and many international stars have come up from India also. This has increased the demand of tennis balls in domestic market. In international also, Indian balls have very good demand. SCOPE This industry is a non polluting and labour intensive industry. Therefore, it has tremendous scope and this type of units can be started anywhere in rural or urban area. ( IV ) BASIS & PRESUMPTION 1. The capacity is based upon monthly production 50,000 Tennis Balls on Single Shift of 8-hrs. a day and 25-working days in a month. 2. It is presumed that Ist year, the capacity utilization will be 70% followed by 85% in the next year and 100% in the subsequent year. 3. The rates quoted in respect of salaries and wages for skilled worker and others are on the basis of minimum rate in the state of U.P. 4. Interest rate for the fixed and working capital has been taken @ 14% on an average whether financed by the Bankers or Financial Institutional. 5. The margin money required is minimum (25% of the total capital investment).

1

(II)

(III)

6. Pay Back period may be five year after the initial gestation period. 7. The gestation period in implementation of the project may be to the tune of 6 to 9 months which includes making all arrangements completion of all formalities, market surveys and tie-ups etc. 8. The Break even point of the scheme has been calculated on full capacity utilization basis. considering 3 months working capital. 9. Capacity may be achieved at the end of three years. IMPLEMENTATION SCHEDULE: The implementation of the project includes various jobs/ exercised such as procurement of technical know how transfer of technology market survey and tie ups preparation of project report selection of sitter, registration financing of project procurement of machinery and raw materials etc. recruitment of staff creation/commissioning of machines trial production and commercial production etc. PRODUCTION DETAIL AND PROCESS OF MANUFACTURE:The manufacturing of Tennis Balls involves various processes. First of all a solution is prepared by thoroughly masticating (kneading) rubber with variety of powders to give the required properties, e.g. strength, colour, and to enable it to cure and to make it softer to work and to ensure that subsequently the solution will flow correctly. The solution of this rubber compound is prepared with petroleum solvent. Then a formulation of rubber compound is prepared which contains Natural rubber, General purpose furnace' (GPF) black (a reinforcing filler), Clay, Zinc oxide, Sulphur, Diphenylguanidine (DPG) (an accelerator for the curative system), Cyclohexyl benthiazyl sulphenamide (HBS) (also an accelerator). This compound is then extruded to produce pallets. The pellets are loaded into a hydraulic press which forms them into hemispherical 'half-shells' and partially cures them, typically for 2 min at 150. The half-shells are removed from the press, joined together in a sheet by the 'flash', which has spread out of the moulds during the forming. The flash is removed by a hydraulic press fitted with cutting knives, which remove the half-shells from the sheet. The edge of the half shell is roughened (or buffed) with a grinding wheel to provide a key for the adhesive which is next applied. A vulcanising rubber solution is applied to the edge of the buffed half shell. For inflation of the ball, inflation chemicals like sodium nitrate and ammonium chloride are used which produce nitrogen during the moulding process. These cores are then cured in moulds. The core is then buffed to provide a rough surface to act as a key for the solution which is applied next. The cores are then coated with uniform layer of rubber solution. These coated cores are then covered with Melton cloth or Needle cloth. The balls are then placed in a moulding press and heated, curing together the rubber solution on the core and that on the back of the cloth. Finally, Tumbling the balls slowly through a steam laden atmosphere causes the cloth to fluff, giving a raised and softer surface and the ridge around the ball also disappears. The balls are then tested and graded brand name is marked. ( VII ) QUALITY CONTROL AND STANDARD: The balls can be produced as per international standards or Indian Standards IS: 221619885. However, following parameters are very important for a Tennis Ball Dimensions- The balls shall be of diameter 63.5 to 66.7 mm. Mass- The mass of the balls shall be between 56.7 and 58.5 g. Requirements- The ball shall have a uniform outer surface and shall be white or yellow in colour. If there are any seams, they shall be stitchless. (VI) (V).

Bounce- The ball shall have a bounce of not less than 135 cm and not more than 147 cm when dropped from a height of 254 cm upon a 1 : 3 : 6 concrete base of 76 mm thickness. Deformation- The ball shall have a forward deformation of more than 5.6 mm and less than 7.4 mm and return deformation of more than 8.9 mm and less than 10.8 mm at 8.165 kg load. The two deformation figures shall be the averages of three individual readings along three axis of the ball and no two individual readings shall differ by more than 0.8 mm in each case. (VIII) PRODUCTION CAPACITY (PER ANNUM) ITEM Tennis Ball QUANTITY 6,00,000 Balls ( @2000 balls per day, 25 days a month) VALUE 90,00,000 (@ Rs. 15/- each ball)

(IX)

POWER REQUIREMENT: Electricity Load Required 15 KW

( X ) FINANCIAL ASPECTS: 1. (A) Fixed Capital LAND & BUILDING: Rented Premises 2000 Sq ft MACHINS & EQUIPMENTS: Nos. 1 1 2 2 2 1 1 1 Rs. 10,000/- PM

(B)

S.No. Description 1. 2. 3. 4. 5. 6. 7. 8. 6. 7. 8. 9. Two Roll Mixing Mill 10X24 Hydraullic Compression Moulding Press (Two daylight) 18X18 Motor & Starter Half Cup moulding Die (16 cups) Full Ball Curing Die (16 Balls) Felt Dumbbell Cutting Press Bare Ball Abrading Drum with motor Cup Edges abrading Stone with motor Tools and Equipments Furniture and office equipments Generator Installation and electrification charges

Ind/Imp (Rs.) Ind Ind Ind Ind Ind Ind Ind Ind

Total Value 350000.00 250000.00 25,000.00 20000.00 30000.00 5000.00 10000.00 7500.00 10,000.00 50,000.00 20,000.00 20,000.00 7,97,500.00

1 TOTAL

Ind

(C)

PRE OPERATIVE EXPENSES: Pre operative Expenses Total Fixed Capital (A+B+C) : Rs.

20,000.00 8,17,500.00

3

2. (i)

Working Capital Staff and Labor (per month):No. 1 1 1 2 2 4 1 2 Salary @ 10,000 6,000 5,000 5,000 3,500 2,500 1,000 3,000 Total Total Total Value (Rs.) 10,000.00 6,000.00 5000.00 10,000.00 7,000.00 10,000.00 1,000.00 6,000.00 55,000.00 10,000.00 65,000.00

S.No. Description i) Director/Properitor ii) Supervisor iii) Clerk cum Cashier iv) Skilled Workers v) Semi skilled worker vi) Helpers vii) Sweeper (Part Time) ix) Watchman Add 20 % Per quarters

(ii) S.No. i). ii). iii) iv) v) vi) (iii)

Raw Material (per month):Description Natural Rubber CaCO3 Pigment Sulfur Accelerators Other Additives UTILITIES (p.m.) i) Power ii) Fuel iii) Water Tota OTHER EXPENSES (P.M.) i) Postage and Telephones ii) Transport iii) Consumable store iv) Sales Expenses v) Entertainment vi) Insurance vi) Other Contingencies Total Qty. 2500 kg 2500kg 10 kg 75kg 25kg Rate(Rs.) 200 10 350 15 350 Total Value (Rs.) 5,00,000.00 25000.00 3500.00 1125.00 8750.00 5000.00 Rs. 5,43,375.00 10,000.00 1,000.00 500.00 Rs. 11,500.00 1,000.00 2,000.00 500.00 2,000.00 1,000.00 1,000.00 2,500.00 Rs. 10,000.00

(iv)

(IX) WORKING CAPITAL (PER MONTH) i) Salaries and wages ii) Raw Material and chemicals iii) Utilities iv) Rent iv) Other Expenses Total

65,000.00 5,43,375.00 11,500.00 10,000.00 10,000.00 Rs 6,39,875.00

4

(XI)

WORKING CAPITAL ( FOR THREE MONTHS ) :Rs. 6,39,875X3 =

19,19,625.00

(XII) TOTAL CAPITAL INVESTMENT:Fixed capital: Working capital for 3 months: Total Say (XIII) COST OF PRODUCTION (PER ANNUM):(a) Total Recurring expenditure (b) Depreciation on Machinery @ 10% (c) Depreciation on Tools and Equipments @20% (d) Depreciation on office euip. and Furniture etc. @ 20% (e) Interest on Total Capital Investment @ 14% Total: Say: (XIV) TOTAL SALES ( PER ANNUM):Sl. No. Item 1. 6,00,000 Tennis Balls (XV) PROFITABILITY( Per Annum):Sales - Cost of Production 90,00,000 81,47,000= (XVI) NET PROFIT RATIO:Profit x 100 Sales per Annum 8,52,570X 100 90,00,000 = 9.47 % (XVII) RATE OF RETURN:Profit x 100 Total investment 8,59,000X 100 27,37,000 = 31.14% (XVIII)BREAK EVEN POINT: Fixed Cost (per annum) (a) 40 % of Salaries (b) 40 % of Utilities (c) 40 % of other expenses (c) Depreciation (d) Rent (d) Interest on total capital Investment Total Rate per pc. 15/-

8,17,500.00 19,19,625.00 Rs 27,37,125.00 Rs 27,37,000.00

76,78,500.00 73,750.00 2,000.00 10,000.00 3,83,180.00 81,47,430.00 Rs 81,47,000.00

Value (Rs.) 90,00,000.00

Rs 8,52,570

3,12,000.00 55,200.00 48,000.00 85,750.00 1,20,000.00 3,83,180.00 Rs 10,04,130.00

5

Break Even Point

= Fixed Cost x 100 Fixed cost + profit per year. = 10,04,130 X 100 10,04,130 + 8,52,570 54.08%

(XIX) LIST OF MACHINERYAND RAW MATERIAL SUPPLIERS 1. Bharaj Machineries Pvt. Ltd. Plot No. 12 & 13, Survey No 66, Hissa No. 1/1, Naik Pada, Village-Waliv, Taluka: Vasai (East) 2. Premier Engineers Post Box No. 11, Opp. Rly. Microwave Tower, Sirhind - 140406, Punjab, India 3. JRD Rubber & Plastic Technology Pvt. Ltd. K-49, Model Town II, Delhi - 110009, India 4. Santec Group Plot No. 92/6, Road No. 4, Mundka Udyog Nagar, Mundka Extension, Delhi - 110041, India 5. Uttam Rubber Machinery (P) Ltd. B-61/3, Maya Puri Indl. Area, Phase II New Delhi - 110064, (INDIA)

PROJECT PROFILE

ON

TENNIS BALL

2010-2011

Prepared by

MSME DEVELOPMENT INSTITUTE,

Ministry Of MSME 34, Industrial Estate, Nunhai Agra-282006 (U. P )

Govt. of India

Phone : 91-562-2280879 Telefax : 91-562-2280882

7

E-mail dcdi-agra@dcmsme.gov.in Website: www.msmediagra.gov.in

S-ar putea să vă placă și

- Diesel Engines For Vehicles D2066 D2676Document6 paginiDiesel Engines For Vehicles D2066 D2676Branislava Savic63% (16)

- Method Statement FINALDocument61 paginiMethod Statement FINALshareyhou67% (3)

- Besan Mill ProjectDocument14 paginiBesan Mill Projectshreyans01100% (1)

- Project Profile On Tissue Paper: ISISO 12625-1:2019 (En) 12625-1 Tissue Paper and Tissue Paper ProductsDocument9 paginiProject Profile On Tissue Paper: ISISO 12625-1:2019 (En) 12625-1 Tissue Paper and Tissue Paper ProductsAniket Jadhav100% (1)

- Dpr-Meghana Roofing Industries-From Page5Document20 paginiDpr-Meghana Roofing Industries-From Page5technopreneurvizagÎncă nu există evaluări

- Project Report On GraniteDocument6 paginiProject Report On GraniteRajneesh RawatÎncă nu există evaluări

- Project Profile On Leather ShoesDocument5 paginiProject Profile On Leather ShoesSadrul Jamil100% (1)

- OB and Attendance PolicyDocument2 paginiOB and Attendance PolicyAshna MeiÎncă nu există evaluări

- Mini Flour Mill KarnalDocument9 paginiMini Flour Mill KarnalAnand Kishore100% (2)

- Ms High Tensile Nuts and BoltsDocument11 paginiMs High Tensile Nuts and Boltsmax_ashi100% (1)

- Gents T-Shirts: NtroductionDocument8 paginiGents T-Shirts: Ntroductionharish_kavetiÎncă nu există evaluări

- Bolt Nuts MFG ProcessDocument5 paginiBolt Nuts MFG ProcessscribddaduÎncă nu există evaluări

- Mustard Oil ExpellerDocument4 paginiMustard Oil Expellerpradip_kumarÎncă nu există evaluări

- Steel Rebar Industry ProfileDocument34 paginiSteel Rebar Industry ProfileOvidiu TomaÎncă nu există evaluări

- Project Report PDFDocument11 paginiProject Report PDFamit22505Încă nu există evaluări

- High Tensile Nuts BoltsDocument10 paginiHigh Tensile Nuts BoltssagarhalappaÎncă nu există evaluări

- Plywood Project Report by Yogesh AgrawalDocument22 paginiPlywood Project Report by Yogesh AgrawalYOGESH AGRAWALÎncă nu există evaluări

- Pulses MillDocument2 paginiPulses Millram100% (1)

- A Project ReportDocument24 paginiA Project ReportshariquesayeedÎncă nu există evaluări

- Automatic Pen Manufacturing ProjectDocument6 paginiAutomatic Pen Manufacturing ProjectKamalÎncă nu există evaluări

- Fasteners - Steel: Profile No.: 121 NIC CodeDocument10 paginiFasteners - Steel: Profile No.: 121 NIC CodeSabhaya ChiragÎncă nu există evaluări

- Project Report Tent PDFDocument10 paginiProject Report Tent PDFBasant KumarÎncă nu există evaluări

- Profile On The Production of Weighing ScaleDocument26 paginiProfile On The Production of Weighing ScaleDagim GBZÎncă nu există evaluări

- Project Profile On Metal CastingDocument11 paginiProject Profile On Metal Castingchaggan AggarwalÎncă nu există evaluări

- Summer Training At: Swot Analysis OnDocument99 paginiSummer Training At: Swot Analysis OnVivek KumarÎncă nu există evaluări

- Details About Our Besan PlantDocument4 paginiDetails About Our Besan Plantpratikgarg03Încă nu există evaluări

- Project Profile For A Boutique - Based On Assumption - Nagaveni - MA FMDocument10 paginiProject Profile For A Boutique - Based On Assumption - Nagaveni - MA FMvstyleinÎncă nu există evaluări

- SHREE DURGA PLASTICS (Prop. Akhilesh Kumar) : Cost of The ProjectDocument8 paginiSHREE DURGA PLASTICS (Prop. Akhilesh Kumar) : Cost of The ProjectRamesh GuptaÎncă nu există evaluări

- Jute BagDocument9 paginiJute Bagafham84Încă nu există evaluări

- Milk Dairy Management System: Submitted ToDocument29 paginiMilk Dairy Management System: Submitted ToDipali KantaleÎncă nu există evaluări

- Stone CrusherDocument14 paginiStone Crushergsn reddyÎncă nu există evaluări

- Two Wheeler Repair and Service UnitDocument8 paginiTwo Wheeler Repair and Service UnitSurendra SharmaÎncă nu există evaluări

- Alloy Steel Heat ResistantDocument11 paginiAlloy Steel Heat ResistantRavi KiranÎncă nu există evaluări

- General Engineering WorkshopDocument3 paginiGeneral Engineering WorkshopSudhir Kushwaha0% (1)

- Project Profile On Fly Ash Bricks Srs EnterprisesDocument17 paginiProject Profile On Fly Ash Bricks Srs EnterprisesRAHUL SHARMAÎncă nu există evaluări

- GPH Proc Asst 00bop02 Ele 0001Document103 paginiGPH Proc Asst 00bop02 Ele 0001Shuhan Mohammad Ariful HoqueÎncă nu există evaluări

- Preliminary Project ReportDocument4 paginiPreliminary Project ReportChristopher SchofieldÎncă nu există evaluări

- Building Description-Rice MillDocument4 paginiBuilding Description-Rice MillKawser Hossain100% (1)

- Pmegp Project Report Cement ProductDocument8 paginiPmegp Project Report Cement ProductMangesh Alhat100% (1)

- Operational Guidelines Milling SchemeDocument45 paginiOperational Guidelines Milling SchemeDeep SarmahÎncă nu există evaluări

- Surgical Bandage-Ok-35-R PDFDocument2 paginiSurgical Bandage-Ok-35-R PDFSuresh KaushikÎncă nu există evaluări

- Paper Bags and PouchesDocument9 paginiPaper Bags and Pouchessam krÎncă nu există evaluări

- CLC Project ReportDocument10 paginiCLC Project ReportVaibhav KhodakeÎncă nu există evaluări

- Project Report For Fly Ash Bricks and It'S Allied Products: Plant & MachineryDocument3 paginiProject Report For Fly Ash Bricks and It'S Allied Products: Plant & Machinerydeepam1987Încă nu există evaluări

- Drawing Machine SpecificationDocument10 paginiDrawing Machine Specificationalopezalegria216Încă nu există evaluări

- Laminated Object ManufacturingDocument6 paginiLaminated Object Manufacturingpapajohn1383Încă nu există evaluări

- 3.2. BIC Catalyser Toolkit Annex - Business Plan EdiedDocument43 pagini3.2. BIC Catalyser Toolkit Annex - Business Plan EdiedBantamkak FikaduÎncă nu există evaluări

- Ceramic Raw Materials SpecsDocument9 paginiCeramic Raw Materials SpecsNazanin Sabet100% (1)

- Karnataka Regulation of Stone Crushers Act, 2011Document17 paginiKarnataka Regulation of Stone Crushers Act, 2011Latest Laws TeamÎncă nu există evaluări

- Project Report On Courier Bags and Air Bubble PackagingDocument9 paginiProject Report On Courier Bags and Air Bubble PackagingSachin SharmaÎncă nu există evaluări

- Best Aluminium Pro Le Manufacturers in IndiaDocument4 paginiBest Aluminium Pro Le Manufacturers in IndiaDigitalprajapatiÎncă nu există evaluări

- Bricks Project Report 10 LakhDocument9 paginiBricks Project Report 10 LakhManju Mysore100% (1)

- Project Report On Vermi Compost PDFDocument2 paginiProject Report On Vermi Compost PDFsrisairamcomputersÎncă nu există evaluări

- Wheel Balancing & Alignment UnitDocument9 paginiWheel Balancing & Alignment UnitKARTIKEYA TIWARI100% (1)

- Cotton Ginning Male-2Document32 paginiCotton Ginning Male-2Tesfaye DegefaÎncă nu există evaluări

- CH 22Document5 paginiCH 22ProfNDAcharyaÎncă nu există evaluări

- Hockey SticksDocument5 paginiHockey Stickspradip_kumarÎncă nu există evaluări

- Ice Cream Churner: Released By: The Development Commissioner (SSI), Ministry of SSI, New DelhiDocument9 paginiIce Cream Churner: Released By: The Development Commissioner (SSI), Ministry of SSI, New DelhiBunty RathoreÎncă nu există evaluări

- CH 21Document5 paginiCH 21Kader Kunju RizwanÎncă nu există evaluări

- A Project Profile On Saddlery & Harness: Dcdi-Agra@dcmsme - Gov.inDocument8 paginiA Project Profile On Saddlery & Harness: Dcdi-Agra@dcmsme - Gov.inroufzargarÎncă nu există evaluări

- Shuttle CockDocument5 paginiShuttle Cockpradip_kumarÎncă nu există evaluări

- Project Feasibility Studies ch8Document5 paginiProject Feasibility Studies ch8Pradeep KrishnanÎncă nu există evaluări

- Design Handbook MAchine DesignDocument5 paginiDesign Handbook MAchine DesignsouravÎncă nu există evaluări

- CDC UP Requirements Traceability Matrix TemplateDocument4 paginiCDC UP Requirements Traceability Matrix TemplateKrishna SaiÎncă nu există evaluări

- Appium Tutorials Can Be Found On: Java - HomeDocument11 paginiAppium Tutorials Can Be Found On: Java - Homeadiall4uÎncă nu există evaluări

- Tutorial Database Testing Using SQLDocument0 paginiTutorial Database Testing Using SQLmanu2020Încă nu există evaluări

- Appium Tutorials Can Be Found On: Java - HomeDocument11 paginiAppium Tutorials Can Be Found On: Java - Homeadiall4uÎncă nu există evaluări

- A Project Report On Online Banking SolutionDocument75 paginiA Project Report On Online Banking Solutionadiall4u0% (2)

- Iiim-Current-08 MCA IV Sem Pro Eva 13.Project-Core Banking SystemDocument29 paginiIiim-Current-08 MCA IV Sem Pro Eva 13.Project-Core Banking SystemDhiraj KasliwalÎncă nu există evaluări

- LP Week 8Document4 paginiLP Week 8WIBER ChapterLampungÎncă nu există evaluări

- Tenses English Grammar PresentationDocument14 paginiTenses English Grammar PresentationMaz Gedi60% (5)

- Painters Rates PDFDocument86 paginiPainters Rates PDFmanthoexÎncă nu există evaluări

- Tec066 6700 PDFDocument2 paginiTec066 6700 PDFExclusivo VIPÎncă nu există evaluări

- Fertilisation and PregnancyDocument24 paginiFertilisation and PregnancyLopak TikeÎncă nu există evaluări

- HDO OpeationsDocument28 paginiHDO OpeationsAtif NadeemÎncă nu există evaluări

- Physiol Toric Calculator: With Abulafia-Koch Regression FormulaDocument1 paginăPhysiol Toric Calculator: With Abulafia-Koch Regression FormuladeliÎncă nu există evaluări

- DHA - Jebel Ali Emergency Centre + RevisedDocument5 paginiDHA - Jebel Ali Emergency Centre + RevisedJam EsÎncă nu există evaluări

- PRESENTACIÒN EN POWER POINT Futuro SimpleDocument5 paginiPRESENTACIÒN EN POWER POINT Futuro SimpleDiego BenítezÎncă nu există evaluări

- CHN Nutri LabDocument4 paginiCHN Nutri LabMushy_ayaÎncă nu există evaluări

- QAU TTS Form Annual AssessmentDocument6 paginiQAU TTS Form Annual AssessmentsohaibtarikÎncă nu există evaluări

- Managing Errors and ExceptionDocument12 paginiManaging Errors and ExceptionShanmuka Sreenivas100% (1)

- HR Practices in Public Sector Organisations: (A Study On APDDCF LTD.)Document28 paginiHR Practices in Public Sector Organisations: (A Study On APDDCF LTD.)praffulÎncă nu există evaluări

- Chapter1 Intro To Basic FinanceDocument28 paginiChapter1 Intro To Basic FinanceRazel GopezÎncă nu există evaluări

- Ubicomp PracticalDocument27 paginiUbicomp Practicalvikrant sharmaÎncă nu există evaluări

- Present Tenses ExercisesDocument4 paginiPresent Tenses Exercisesmonkeynotes100% (1)

- Advanced Herd Health Management, Sanitation and HygieneDocument28 paginiAdvanced Herd Health Management, Sanitation and Hygienejane entunaÎncă nu există evaluări

- Glossary of Blasting TermsDocument13 paginiGlossary of Blasting TermsNitesh JainÎncă nu există evaluări

- Sociology A Brief Introduction Canadian Canadian 5th Edition Schaefer Test Bank DownloadDocument44 paginiSociology A Brief Introduction Canadian Canadian 5th Edition Schaefer Test Bank DownloadJohn Blackburn100% (20)

- Eng Notes2Document10 paginiEng Notes2Arti KapurÎncă nu există evaluări

- Index: © Christopher Pitt 2018 C. Pitt, The Definitive Guide To AdonisjsDocument5 paginiIndex: © Christopher Pitt 2018 C. Pitt, The Definitive Guide To AdonisjsZidi BoyÎncă nu există evaluări

- Communication Skill - Time ManagementDocument18 paginiCommunication Skill - Time ManagementChấn NguyễnÎncă nu există evaluări

- Gobekli TepeDocument2 paginiGobekli TepeCarl Feagans100% (1)

- CV Ashish PDFDocument3 paginiCV Ashish PDFRoshan KejariwalÎncă nu există evaluări

- Final SEC Judgment As To Defendant Michael Brauser 3.6.20Document14 paginiFinal SEC Judgment As To Defendant Michael Brauser 3.6.20Teri BuhlÎncă nu există evaluări

- Air Blower ManualDocument16 paginiAir Blower ManualshaiknayeemabbasÎncă nu există evaluări

- Land CrabDocument8 paginiLand CrabGisela Tuk'uchÎncă nu există evaluări