Documente Academic

Documente Profesional

Documente Cultură

9.WH SOP 08 GoodsIssueProcess 20080724063856.288 X

Încărcat de

vikasbumcaTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

9.WH SOP 08 GoodsIssueProcess 20080724063856.288 X

Încărcat de

vikasbumcaDrepturi de autor:

Formate disponibile

STANDARD OPERATING PROCEDURE (SOP) MANUAL FOR WAREHOUSING OPERATIONS TITLE : GOODS ISSUE PROCESS Reference No:.

Revision No : WH/SOP/08 00 Issue No:. Effective Date: 00 01/01/2006 Page 1 of 2

1. 2. 3. 4. 5.

Subject Purpose Terminology Responsibility Flow Diagram

: : : : :

Material Issue Process. To define the issue process of material from the warehouses. As per SOP/WH/03. Warehouse Executive

Goods Issue Process

End

Loader loads the material in the vehicle.

Loader moves the material from dispatch area to the loading bay.

Security Incharge enters the document details in the Outbound register after checking the physical material & instruct the loader to load the material in the vehicle.

Warehouse Incharge will instruct the loader to move the material from dispatch area to the loading bay & takes the document to the security incharge.

DEO prepare Invoice through system and handed the same to the warehouse incharge for dispatch.

Picker pack the material as per norm and paste the sales order no. & Party Name slip on to it & move it to the dispatch area.

Warehouse

Stock not available

Process order once stock available in w/h.

Provide ESN/Serial No. file to the DEO for SAP Updation

Scan the material, if the material is specified to capture ESN/Serial No.

Receives Sales order alert through mail from finance.

Check for stock

Stock available

Takes print out of sales order from the system

Picker picks the material from the storage area.

Takes the material to the scanning area, if the material is specified to capture ESN/Serial No..

Finance

Sends alert to the warehouse through mail.

Generates Sales Order Through system.

Start

6. Procedure Step No.. 1 2 3 4 6 7 8 9

: Performed by CFH & Team Exe Sup Sup DEO Picker Sup Sup System / Manual System System / Mail System Manual System Manual Manual Manual

Description Trigger point for this process is Sales order / STO Stock point receives alert through mail from finance with sales order no. Check sales order in the system. Check stock availability. Take print out of the sales order (WH/SOP/08/FMT/01) from the system. Picker picks the material from the storage area. Pickers takes the material to the scanning area, if the material is specified to capture ESN/Serial No. WH supervisor scans the material, if the material is specified to capture ESN/Serial No.

STANDARD OPERATING PROCEDURE (SOP) MANUAL FOR WAREHOUSING OPERATIONS TITLE : GOODS ISSUE PROCESS Reference No:. Revision No : 10 11 WH/SOP/08 00 Issue No:. Effective Date: 00 01/01/2006 Sup Picker Page 2 of 2

Provide ESN/Serial No. file to the DEO for SAP Updation Picker pack the material as per norm and paste the sales order no. & Party Name slip on to it & move it to the dispatch area. DEO prepare Invoice (WH/SOP/08/FMT/02) through system and hands the same to the warehouse executive for dispatch. Excecutive will instruct the loader to move the material from dispatch area to the loading bay & takes the document to the security incharge after entry in the material outward register (WH/SOP/08/FMT/03). Security Incharge enters the document details in the Outbound register (WH/SOP/08/FMT/04) after checking the physical material & instruct the loader to load the material in the vehicle. Loader moves the material from dispatch area to the loading bay. WH Incharge calls the transp. & dispatch the material.

Excel File Manual

12

DEO

System

13

Exe

Manual

14

WH Security

Manual

15 16

Picker Sup

Manual Manual

RECORDS S. No. 1 2 3 4 Records Sales Order List (WH/SOP/08/FMT/01) Invoice Copies / STN Copies (WH/SOP/08/FMT/02) Material Outward Register (WH/SOP/07/FMT/03) Security Gate outward register (WH/SOP/08/FMT/04) Stor Location WH WH WH WH Retention Period 2 years 2 years 2 years 2 years

S-ar putea să vă placă și

- Materials Management: An Executive's Supply Chain GuideDe la EverandMaterials Management: An Executive's Supply Chain GuideÎncă nu există evaluări

- WAR-015 Warehouse Processing Issues Return and Rejects SampleDocument3 paginiWAR-015 Warehouse Processing Issues Return and Rejects Samplesetiawanaji407100% (1)

- BN-CO-107 Standard Procedure For Material Control and WarehousingDocument20 paginiBN-CO-107 Standard Procedure For Material Control and WarehousingAli HajirassoulihaÎncă nu există evaluări

- WAR-025 - Sample (Warehouse Inventory Management)Document7 paginiWAR-025 - Sample (Warehouse Inventory Management)Edmund F. AlvarezÎncă nu există evaluări

- Warehouse SOPDocument1 paginăWarehouse SOPmazharizedÎncă nu există evaluări

- WMM1Document94 paginiWMM1Reymart SangalangÎncă nu există evaluări

- Pre Inventory Preparation 05 06 11Document33 paginiPre Inventory Preparation 05 06 11alexcadenceÎncă nu există evaluări

- Flowchart of Work Flow Document For A Manufacturing CompanyDocument2 paginiFlowchart of Work Flow Document For A Manufacturing CompanyNicasio AquinoÎncă nu există evaluări

- Warehouse Management Final Project ReportDocument22 paginiWarehouse Management Final Project ReportNainesh KÎncă nu există evaluări

- Organization of Stores DepartmentDocument3 paginiOrganization of Stores DepartmentAb techÎncă nu există evaluări

- Sop DCDocument12 paginiSop DCRitabrata MukherjeeÎncă nu există evaluări

- Arjune Gupta WAREHOUSEDocument14 paginiArjune Gupta WAREHOUSEHemant SankhalaÎncă nu există evaluări

- Subject: Logistics and Retail Information Credits: 4Document135 paginiSubject: Logistics and Retail Information Credits: 4AKASH JOEL DAVIDÎncă nu există evaluări

- Sop ReceivingDocument6 paginiSop ReceivingpoetoetÎncă nu există evaluări

- CAL To-Be Order Management and Shipping Execution v.02 12-Dec-2013Document20 paginiCAL To-Be Order Management and Shipping Execution v.02 12-Dec-2013Tharmaraj MuralikrishnanÎncă nu există evaluări

- Stock VerificationDocument10 paginiStock VerificationcomplexnoÎncă nu există evaluări

- MM WM NotesDocument37 paginiMM WM NotesRakesh Kumar BeheraÎncă nu există evaluări

- Tariff and Customs Code - Cash Bond ClarificationDocument12 paginiTariff and Customs Code - Cash Bond ClarificationJustine MarieÎncă nu există evaluări

- Delivery Boy SOPDocument2 paginiDelivery Boy SOPmanishrastogiÎncă nu există evaluări

- Ware Housing and DistributionDocument32 paginiWare Housing and DistributionChintan Ramnani100% (1)

- Inward PDFDocument4 paginiInward PDFVamsee DeepakÎncă nu există evaluări

- SOP Loading A ShipmentDocument2 paginiSOP Loading A ShipmentWilliam BudiharsonoÎncă nu există evaluări

- GMP01 Process ControlDocument4 paginiGMP01 Process ControlIzham SyafikÎncă nu există evaluări

- FIN-03. Receiving ProcedureDocument5 paginiFIN-03. Receiving ProcedureVu Dinh ThietÎncă nu există evaluări

- SOM 634 Purchasing and Supply Management: DR Atul KanyalkarDocument188 paginiSOM 634 Purchasing and Supply Management: DR Atul KanyalkarAakanksha Gulabdhar MishraÎncă nu există evaluări

- SOP Renuka WarehouseDocument4 paginiSOP Renuka WarehouseSagnik ChakrabortyÎncă nu există evaluări

- Stock Keeping and Annual Stock VerificationDocument3 paginiStock Keeping and Annual Stock VerificationSharnbasappa WaleÎncă nu există evaluări

- Stocks - Physical Verification Guidance NoteDocument2 paginiStocks - Physical Verification Guidance NoteJoão Henrique Machado100% (1)

- Transportation & Warehousing: Lal Bahadur Shastri Institute of ManagementDocument38 paginiTransportation & Warehousing: Lal Bahadur Shastri Institute of ManagementAnand RajaramÎncă nu există evaluări

- Materials ManagementDocument17 paginiMaterials ManagementAkash SahaÎncă nu există evaluări

- Warehouse Audit Checklist: Define Your Inventory Audit ObjectivesDocument3 paginiWarehouse Audit Checklist: Define Your Inventory Audit Objectivesalbert rajÎncă nu există evaluări

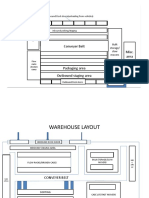

- Warehouse Layout: Misc. Area 1 Conveyer BeltDocument2 paginiWarehouse Layout: Misc. Area 1 Conveyer BeltBoppud100% (1)

- General: (A) (B) (C) (D) (E)Document3 paginiGeneral: (A) (B) (C) (D) (E)Md. Romman IslamÎncă nu există evaluări

- 19 Zfi SP 023 Handling Storage Packing DeliveryDocument3 pagini19 Zfi SP 023 Handling Storage Packing DeliverygmbyÎncă nu există evaluări

- Purchase 1Document20 paginiPurchase 1N.Usha RaoÎncă nu există evaluări

- Warehouse ManagementDocument8 paginiWarehouse ManagementPrakhar SharmaÎncă nu există evaluări

- Packaging and Shipping SpecificationDocument30 paginiPackaging and Shipping SpecificationashokclineÎncă nu există evaluări

- Dispatch SopDocument4 paginiDispatch SopPatria AMPÎncă nu există evaluări

- 250515Document2 pagini250515juanÎncă nu există evaluări

- An Introduction To Warehousing and The Underlying Facility Design IssuesDocument47 paginiAn Introduction To Warehousing and The Underlying Facility Design IssuesTrinath OjhaÎncă nu există evaluări

- Chap 06 Inventory Control ModelsDocument112 paginiChap 06 Inventory Control ModelsAiro MirandaÎncă nu există evaluări

- Team ProjectsDocument76 paginiTeam ProjectsSachin A PillaiÎncă nu există evaluări

- Procurement Processes Group 7Document14 paginiProcurement Processes Group 7انجینئر فرحانÎncă nu există evaluări

- Chapter 14 Materials Inventory ControlDocument20 paginiChapter 14 Materials Inventory ControlajaymechengineerÎncă nu există evaluări

- The Advantages and Disadvantages of FIFO MehtodDocument5 paginiThe Advantages and Disadvantages of FIFO Mehtodnaveednad2003556100% (1)

- SOP IniventoryDocument12 paginiSOP IniventorychayalocÎncă nu există evaluări

- Warehouse Processes/OperationsDocument4 paginiWarehouse Processes/OperationsNhsyyÎncă nu există evaluări

- Chapter 5 & 6 Editted StorageDocument12 paginiChapter 5 & 6 Editted StorageMOHAMMED KEDIRÎncă nu există evaluări

- Warehouse PolicyDocument2 paginiWarehouse PolicymikeljacintoÎncă nu există evaluări

- UNIT 1 LogisticsDocument10 paginiUNIT 1 Logisticsanon_124527471Încă nu există evaluări

- Daily Report-018 (Su Jinlong)Document8 paginiDaily Report-018 (Su Jinlong)sujinlongÎncă nu există evaluări

- SopsDocument40 paginiSopsPhilip PalafoxÎncă nu există evaluări

- SOP StorageDocument3 paginiSOP Storagedickson86100% (3)

- LGT - WHD - QP03-Material Handling and Storage Control ProcedureDocument7 paginiLGT - WHD - QP03-Material Handling and Storage Control ProcedureGregorÎncă nu există evaluări

- RHSP Stores Inventory Management SOPDocument36 paginiRHSP Stores Inventory Management SOPmariamisaseaÎncă nu există evaluări

- Inventory Valuation Notes 2023-24Document7 paginiInventory Valuation Notes 2023-24Siddhi JhaÎncă nu există evaluări

- Warehouse Supervisor Cum Lesson PlannerDocument56 paginiWarehouse Supervisor Cum Lesson Plannernayra khan67% (3)

- Warehouse Procedure of Project ConsumablesDocument28 paginiWarehouse Procedure of Project ConsumablesAlmario Sagun100% (4)

- AV-ST-WI-02 Tooling Receipt Inspection Storage Issue and Recovery Iss 1Document6 paginiAV-ST-WI-02 Tooling Receipt Inspection Storage Issue and Recovery Iss 1Kevin DeLimaÎncă nu există evaluări

- WH SOP 15 RetrievalProcess 20080724063701.688 XDocument2 paginiWH SOP 15 RetrievalProcess 20080724063701.688 XvikasbumcaÎncă nu există evaluări

- Up Lower Subordinate 2013Document5 paginiUp Lower Subordinate 2013Raaj SinghÎncă nu există evaluări

- Chapter 4. MDM Repository MaintenanceDocument1 paginăChapter 4. MDM Repository MaintenancevikasbumcaÎncă nu există evaluări

- Job Descriptions Rect Ad - Oct 2013 2 PDFDocument6 paginiJob Descriptions Rect Ad - Oct 2013 2 PDFaggarwalrajnishÎncă nu există evaluări

- Enterprise Structure: General LedgerDocument5 paginiEnterprise Structure: General LedgervikasbumcaÎncă nu există evaluări

- Sap Fico Configuration GuideDocument226 paginiSap Fico Configuration Guideap1983750% (2)

- October November 2007 Issue Sap Tips 495Document69 paginiOctober November 2007 Issue Sap Tips 495vikasbumcaÎncă nu există evaluări

- Assign Shipping Point To Plant: ActionsDocument1 paginăAssign Shipping Point To Plant: ActionsvikasbumcaÎncă nu există evaluări

- Advertisement 6dec13Document1 paginăAdvertisement 6dec13jahanviraghavÎncă nu există evaluări

- How To Add A Logo Into The MIME RepositoryDocument12 paginiHow To Add A Logo Into The MIME RepositoryvikasbumcaÎncă nu există evaluări

- Brain DrainDocument5 paginiBrain DrainvikasbumcaÎncă nu există evaluări

- Fci-Management Trainee 2013Document23 paginiFci-Management Trainee 2013Gokul RajeshÎncă nu există evaluări

- LSMW ManualDocument20 paginiLSMW Manualsmfatmi100% (3)

- Advertisement 6dec13Document1 paginăAdvertisement 6dec13jahanviraghavÎncă nu există evaluări

- SAP ERP - Logistics Materials Management (SAP M..Document10 paginiSAP ERP - Logistics Materials Management (SAP M..vikasbumcaÎncă nu există evaluări

- WH SOP 15 RetrievalProcess 20080724063701.688 XDocument2 paginiWH SOP 15 RetrievalProcess 20080724063701.688 XvikasbumcaÎncă nu există evaluări

- Remarriage According To The BibleDocument1 paginăRemarriage According To The BiblevikasbumcaÎncă nu există evaluări

- SAP ERP - Logistics Materials Management (SAP M..Document10 paginiSAP ERP - Logistics Materials Management (SAP M..vikasbumcaÎncă nu există evaluări

- PLNT Doc. Date Purch - Doc. Material Short Text Matl Group Vendor/Supplying Plant Net Price Quantity Oun Net ValueDocument1 paginăPLNT Doc. Date Purch - Doc. Material Short Text Matl Group Vendor/Supplying Plant Net Price Quantity Oun Net ValuevikasbumcaÎncă nu există evaluări

- 3.WH SOP 02 AmendmentRecordSheet 20080724064043.876 XDocument1 pagină3.WH SOP 02 AmendmentRecordSheet 20080724064043.876 XvikasbumcaÎncă nu există evaluări

- Enterprise Structure: General LedgerDocument5 paginiEnterprise Structure: General LedgervikasbumcaÎncă nu există evaluări

- 28.WH SOP 12 FMT 01 CycleCountSheet 20080724063151.875 XDocument1 pagină28.WH SOP 12 FMT 01 CycleCountSheet 20080724063151.875 XvikasbumcaÎncă nu există evaluări

- 40.FixedAssetRegister (TTSLAssets) 20080724062828.149 XDocument2 pagini40.FixedAssetRegister (TTSLAssets) 20080724062828.149 XvikasbumcaÎncă nu există evaluări

- 9.WH SOP 08 GoodsIssueProcess 20080724063856.288 XDocument2 pagini9.WH SOP 08 GoodsIssueProcess 20080724063856.288 Xvikasbumca0% (1)

- 123Document1 pagină123vikasbumcaÎncă nu există evaluări

- 32.BlindCountProcess 20080724063035.418 X PDFDocument1 pagină32.BlindCountProcess 20080724063035.418 X PDFvikasbumcaÎncă nu există evaluări

- 9.WH SOP 08 GoodsIssueProcess 20080724063856.288 XDocument2 pagini9.WH SOP 08 GoodsIssueProcess 20080724063856.288 Xvikasbumca0% (1)

- 11.WH SOP 10 ESNManagementProcess 20080724063826.868 X PDFDocument2 pagini11.WH SOP 10 ESNManagementProcess 20080724063826.868 X PDFvikasbumcaÎncă nu există evaluări

- 12.WH SOP 11 PhysicalInventoryProcess 20080724063811.675 XDocument2 pagini12.WH SOP 11 PhysicalInventoryProcess 20080724063811.675 XvikasbumcaÎncă nu există evaluări

- 14.WH SOP 13 PurchaseReturnProcess 20080724063732.394 XDocument2 pagini14.WH SOP 13 PurchaseReturnProcess 20080724063732.394 XvikasbumcaÎncă nu există evaluări

- .Sample&wmactchecksheet 20080724063056.435 XDocument1 pagină.Sample&wmactchecksheet 20080724063056.435 XvikasbumcaÎncă nu există evaluări

- Comparison Between Plaxis and DeepXcav - 2012 EditionDocument5 paginiComparison Between Plaxis and DeepXcav - 2012 EditionTan Yi LiangÎncă nu există evaluări

- Cheat SheetDocument163 paginiCheat Sheetfatalist3Încă nu există evaluări

- Template Method Design PatternDocument3 paginiTemplate Method Design PatternRadheshyam NayakÎncă nu există evaluări

- Power ViewDocument2 paginiPower ViewcerebroÎncă nu există evaluări

- 1.universal Journal in SAP S4HANADocument10 pagini1.universal Journal in SAP S4HANASivaram GÎncă nu există evaluări

- 10 Obscure Excel Tricks That Can Expedite Common ChoresDocument8 pagini10 Obscure Excel Tricks That Can Expedite Common ChoresHamza IslamÎncă nu există evaluări

- Vormetric Backup and Recover 5Document14 paginiVormetric Backup and Recover 5sargateÎncă nu există evaluări

- Eee 122 CH 6 CountersDocument26 paginiEee 122 CH 6 Countersjayacomp100% (1)

- Autodesk - Authorised Training Centres - India - KarnatakaDocument3 paginiAutodesk - Authorised Training Centres - India - Karnatakaचन्दनप्रसादÎncă nu există evaluări

- UltraDefrag Handbook 7.0.0 LetterDocument81 paginiUltraDefrag Handbook 7.0.0 LetterMeandme123Încă nu există evaluări

- Tornimi - Libri AaaaaDocument132 paginiTornimi - Libri AaaaaBurim FejzajÎncă nu există evaluări

- A8. Forms and DataDocument38 paginiA8. Forms and DataPradeep VermaÎncă nu există evaluări

- Queen Problem - Allegro 5Document3 paginiQueen Problem - Allegro 5Alexandru Gabriel StoicaÎncă nu există evaluări

- Ethernet: Introduction To NetworksDocument61 paginiEthernet: Introduction To Networksllekhanya-1Încă nu există evaluări

- Lient IDE Cripting Sing AVA Cript: C - S S U J SDocument49 paginiLient IDE Cripting Sing AVA Cript: C - S S U J SKiran Kumar KÎncă nu există evaluări

- Flow DWDocument200 paginiFlow DWPino Watson PisoloÎncă nu există evaluări

- Salon Management System SoftwareDocument23 paginiSalon Management System SoftwareAlexander Arya100% (1)

- Manual de Controladores y Periféricos AUTOCAD 2010 PDFDocument194 paginiManual de Controladores y Periféricos AUTOCAD 2010 PDFJulia CuellarÎncă nu există evaluări

- Creating Kali Linux Live USB With Persistence, A Simple GuideDocument6 paginiCreating Kali Linux Live USB With Persistence, A Simple GuidejuanimanuelmewoÎncă nu există evaluări

- MT6757 Android ScatterDocument10 paginiMT6757 Android Scatteramir mamiÎncă nu există evaluări

- 2006 Study With Costs of Transmission and OtherDocument171 pagini2006 Study With Costs of Transmission and OtherdougmcculloughÎncă nu există evaluări

- SQL Book-1Document57 paginiSQL Book-1Ron ParekhÎncă nu există evaluări

- MCSA - Windows Server 2008Document9 paginiMCSA - Windows Server 2008Michael RandolphÎncă nu există evaluări

- Detailed Lesson Plan in Mathematics 5 (For Ranking)Document7 paginiDetailed Lesson Plan in Mathematics 5 (For Ranking)Lerry John Acedera Giray86% (14)

- Lab7 MSCDocument11 paginiLab7 MSCaminerachedÎncă nu există evaluări

- Programming Concepts in JavaDocument12 paginiProgramming Concepts in Javarishabhindoria57Încă nu există evaluări

- Andrew Britecell Plus User Manual PDFDocument241 paginiAndrew Britecell Plus User Manual PDFAnonymous smdEgZN2IeÎncă nu există evaluări

- Doble Wan en FortinetDocument3 paginiDoble Wan en FortinetYaha TRÎncă nu există evaluări

- Advanced Arduino: Direct Use of Atmega Counter/TimersDocument5 paginiAdvanced Arduino: Direct Use of Atmega Counter/TimersSuaib DanishÎncă nu există evaluări

- Toc Question BankDocument16 paginiToc Question BankKandula UpendarreddyÎncă nu există evaluări