Documente Academic

Documente Profesional

Documente Cultură

Expansion Joints

Încărcat de

BhushanRajDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Expansion Joints

Încărcat de

BhushanRajDrepturi de autor:

Formate disponibile

R10-19-06 MODULAR EXPANSION JOINTS The Standard Specifications are revised as follows: SECTION 724, BEGIN LINE 1, DELETE

AND INSERT AS FOLLOWS:

SECTION 724 STRUCTURAL EXPANSION JOINTS 724.01 Description (a) Structural Expansion Joint This work shall consist of furnishing and placing, for new construction, structural expansion joints of the type specified, in accordance with the plans and these requirements 105.03. (b) Replacement of Existing Structural Expansion Joint This work shall consist of the removal and replacement of an existing structural expansion joint with a joint of the type shown on the plans and specified, in accordance with these requirements 105.03. (c) Replacement of Existing Structural Expansion Joint Seal This work shall consist of the replacement of the joint seal in an existing structural expansion joint of the type shown on the plans specified. MATERIALS 724.02 Materials Materials shall be in accordance with the following: Expansion Joint BS................................................................906.07(b) Concrete, Class C..................................................................702 Expansion Joint M..................................................................906.07(c) Expansion Joint SS.................................................................906.07(a) Inorganic Zinc Primer............................................................909.02(a)1 Structural Steel.......................................................................910.02 The joint manufacturer shall prepare and submit four sets of shop drawings showing details of the assembly, manufacturers specifications, and joint setting data, for approval, prior to manufacture of the joints. (a) Expansion Joint SS The sliding cover plate required over that portion of expansion joint SS located in a sidewalk shall be the same material as the extrusion and shall be galvanized in accordance with ASTM A 123. The joint assembly shall consist of one of the allowable alternates for this type of joint as shown on the plans. The strip seal shall be sized to accommodate a minimum of 4 in. (100 mm) of movement. The strip seal shall be furnished in one continuous length

724-B-046 1 of 6

R10-19-06

for the entire limits of the installed joint. Field splicing of the strip seal will not be allowed. (b) Expansion Joint M This joint shall consist of prefabricated, multiple elastomeric seals, separator beams, and support bars. The structural design of expansion joint M shall be in accordance with the current AASHTO Standard Specifications for Highway Bridges and shall be for the same design loading as the bridge structure at which it is installed, but in no case less than HS 20 44 truck loading and impact. The joint shall be designed to accommodate the movement shown on the plans. The sliding cover plate required over that portion of expansion joint M located in a sidewalk or concrete rail shall be the same material as the extrusion and shall be galvanized in accordance with ASTM A 123. The joint assembly shall be manufactured in accordance with the details shown on the shop drawings as prepared by the manufacturer of the joint assembly. The strip seals shall be furnished in one continuous length for the entire limits of the installed joint. Field splicing of the strip seals will not be allowed. CONSTRUCTION REQUIREMENTS 724.03 General Requirements The manufacturer shall prepare and submit four sets of detailed shop drawings for approval, prior to the manufacture of joint assemblies SS and M. The shop drawings shall be a minimum of 22 in. by 34 in. (560 mm by 860 mm) in overall size. Expansion joints SS and M shall not be fabricated until the shop drawings are approved. Joint installation and the replacement of existing joints shall be in accordance with the manufacturers recommendations, the plans, and the approved shop drawings. If there is a dispute between the plans and the approved shop drawings, the approved shop drawings shall govern. The Contractor shall submit, for approval, the manufacturers shall furnish a copy of the installation instructions prior to the placement of these joints. The instructions must be approved before installation begins. The fabrication and installation of the joint assembly, where changes in joint direction are required, shall be in accordance with the plans and the approved shop drawings. All welding shall be in accordance with 711.32. All splice welds shall develop full strength. All welds which come in contact with the seals shall be ground smooth. All metal surfaces in direct contact with the seal shall be cleaned and properly treated in accordance with the manufacturers recommendations. All exposed structural steel surfaces, except for polytetrafluoroethylene coated surfaces and stainless steel, shall be shop painted in accordance with 619.11. Lubricants and adhesives shall be used in accordance with the joint manufacturers recommendations. All excess lubricant and adhesive shall be removed before it has set. Final adjustment of the assembly shall be made as directed at the time of installation. All movements due to such factors as shrinkage, creep, and midslab deflection shall be accounted for prior to this final adjustment.

724-B-046 2 of 6

R10-19-06

SECTION 724, DELETE LINES 66 THROUGH 114 SECTION 724, BEGIN LINE 116, DELETE AND INSERT AS FOLLOWS:

(d) (a) Replacement of Existing Structural Expansion Joint The existing joint and adjacent concrete shall be removed to the limits shown on the plans. Additional removal, as directed, may be required to encounter sound concrete adjacent to the joint area. The replacement joint shall be in accordance with the requirements contained herein for the specified type. Concrete shall be class C in accordance with 702. (e) (b) Replacement of Existing Structural Expansion Joint Seal The existing seal shall be removed in its entirety. The new seal shall be installed in accordance with the requirements contained herein for the specified joint type. 724.04 Method of Measurement Structural expansion joints will be measured by the linear foot (meter) along and parallel to the plane of the finished joint surface. Replacement of existing structural expansion joints will be measured by the linear foot (meter) along and parallel to the plane of the finished joint surface. Concrete removal and new concrete required for the replacement of existing structural expansion joints will not be measured for payment. Sliding cover plates will not be measured for payment. Replacement of existing structural expansion joint seals will be measured by the linear foot (meter) along and parallel to the plane of the finished seal installation. 724.05 Basis of Payment Structural expansion joint will be paid for at the contract unit price per linear foot (meter) of the type specified, complete in place. Replacement of existing structural expansion joint will be paid for at the contract unit price per linear foot (meter) for structural expansion joint, of the type specified, replace, complete in place. Replacement of existing structural expansion joint seals will be paid for at the contract unit price per linear foot (meter) for structural expansion joint seal, of the joint type specified, replace. Payment will be made under: Pay Item Pay Unit Symbol

Structural Expansion Joint, ____...........................................................LFT (m) type Structural Expansion Joint, ____, Replace.............................................LFT (m) type Structural Expansion Joint Seal, ____, Replace.....................................LFT (m) type The cost of sliding cover plates shall be included in the cost of structural expansion joint or structural expansion joint, replace, as applicable. The cost of reinforcing steel, concrete removal and new class C concrete for the replacement of

724-B-046 3 of 6

R10-19-06

existing structural expansion joint shall be included in the cost of structural expansion joint, replace.

SECTION 906, BEGIN LINE 173, DELETE AND INSERT AS FOLLOWS:

906.07 Bridge Expansion Joints Joints, including anchor assemblies, shall be shop fabricated, delivered and installed as a continuous unit for lengths up to 46 ft (14 m). Joints longer than 46 ft (14 m) shall be furnished in continuous units or in appropriate shorter sections as shown on the shop drawings and approved by the Engineer. Joints used in stage construction shall be furnished in sections appropriate to accommodate the work. All joints furnished in sections shall be spliced with welds, with ends prepared for welding in the shop. All welds shall be in accordance with 711.32. The profile of the joint in the roadway area shall conform to the roadway cross section. Where changes in direction are required, such as at curbs or concrete rails, the sections shall be cut to the bevel required to produce the same cross section on each piece being joined. Slider plates shall be provided at curbs, walkways, and concrete rails as part of the completed joint assembly. The slider plate shall be the same material as the extrusion and shall be galvanized in accordance with ASTM A 123. All welds in contact with the elastomeric seals shall be ground smooth. Metal surfaces in direct contact with the elastomeric seal shall be cleaned and treated in accordance with the manufacturers recommendations to provide a high strength bond between the elastomeric seal and mating metal surfaces. The elastomeric seals shall be clean and free of foreign materials. All exposed structural steel surfaces, except stainless steel or polytetrafluoroethylene coated, shall be shop painted in accordance with 619. (a) Type SS Structural steel shall be in accordance with ASTM A 36 (A 36M), A 588 (A 588M), A 570 (A 570M), A 242 (A 242M), or Merchant Quality 1010, 1020. Sealant and grouts shall be in accordance with Federal Specifications TT-S-00230 or as recommended by the manufacturers recommendations. The elastomer shall be neoprene in accordance with ASTM D 5973 except that the physical requirements in Table 1 for low temperature recovery, high temperature recovery, and compression-deflection properties will not apply. The strip seal shall be furnished in one continuous length for the entire limits of the installed joint. Field splicing of the strip seal will not be permitted. Miter cut, vulcanized shop splices will be required in the strip seal. The shop vulcanization of the strip seal splice may be either a hot or cold process so long as the process produces a splice of equal or greater strength than the elastomer.

724-B-046 4 of 6

R10-19-06

The structural steel and polyurethane sealant shall be covered by a type C certification, and the elastomer shall be covered by a type B certification, both in accordance with 916.

SECTION 906, DELETE LINES 189 THROUGH 199 SECTION 906, BEGIN LINE 201, DELETE AND INSERT AS FOLLOWS:

(c) (b) Type M This joint shall consist of prefabricated multiple elastomeric seals, separator beams, and support bars. The structural design of the joint shall be in accordance with AASHTO Standard Specifications for Highway Bridges and shall be for the same design loading as the bridge structure at which it is to be installed, but not less than HS 20- 44 truck loading and impact. The joint shall be designed to accommodate the movement shown on the plans. The joint assembly shall be preset by the manufacturer in accordance with the approved shop drawings, joint setting data and specifications. The assembly shall be properly secured for shipping and contain provision for final field adjustment at the time of installation. The manufacturer shall furnish a copy of the installation instructions prior to the placement of these joints. Structural steel shall be in accordance with ASTM A 36 (A 36M), A 570 (A 570M), A 242 (A 242M), A 588 (A 588M), or Merchant Quality 1010, 1020 in accordance with ASTM A 576. Sealant and grout shall be in accordance with Federal Specification TT-00230 or as recommended by the joint manufacturers recommendation. Elastomer shall be neoprene in accordance with ASTM D 3542. The structural steel and sealant shall be covered by a type C certification and the elastomer by a type B certification, both in accordance with 916. Bearings above and below the support bar shall be a nylon or urethane compound with polytetrafluorethylene riding surfaces. All components of the system shall be accessible to periodic inspection and component replacement if necessary. The elastomer seals shall be in accordance with the requirements as follows: 1. be held in place by compressive forces throughout the normal limits of joint movement, 1. 2.be supplied and installed in one piece; 2. 3.have corner locked edges for a watertight fit; 3. 4.not be any part of the load bearing riding surface; 4. 5.be installed using seal lubricant-adhesive or be mechanically clamped in position to produce a watertight seal;

724-B-046 5 of 6

R10-19-06

5. 6.have a shape which promotes self removal of foreign material during normal joint operation; 6. 7.be recessed 1/2 in. (13 mm) below the riding surface throughout the normal limits of joint movement; 7. 8.be held in position by the separator beams; 8. 9.have a hollow box shape for joints utilizing urethane equilibrium control spacers or a strip seal configuration for joints using a mechanical linkage to maintain equidistant separator beam spacing. The joint shall have a maximum opening of 3 in. (75 mm) per seal. The separator beams shall be in accordance with the requirements as follows: 1. 2. 3. 4. 5. provide the riding surface across the joint; have an extruded or machined shape suitable to hold the seals; be stable against tipping, tilting, or lifting during application of traffic loads by use of a suitable shape and connection to the support bar; be supported individually on their own independent support bars; maintain equidistant spacing through use of suitable urethane equilibrium type control spacers to counter the compressive forces of the seals or through a positive horizontal mechanical linkage or proportioning bar.

The support bars shall be in accordance with the requirements as follows: 1. 2. incorporate stainless steel sliding surfaces to minimize resistance to joint movements; be supported above, below, and laterally as required to prevent lifting, to transmit bearing loads, and to maintain positioning of the bar.

All support bar boxes and joint housings shall have top, bottom, and sides made of steel plate with 1/2 in. (13 mm) minimum thickness. Anchorages shall consist of looped No. 5 reinforcing bars welded to 1/2 in. (13 mm) steel plates spaced at 9 in. (230 mm) centers. No unwelded Non-welded steel to steel contact will not be permitted.

724-B-046 6 of 6

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- 2017 Bridge ToffulDocument9 pagini2017 Bridge ToffulBhushanRajÎncă nu există evaluări

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Electrical Safety - Preventive-Maintenance Program Electrical Safety - Preventive-Maintenance ProgramDocument8 paginiElectrical Safety - Preventive-Maintenance Program Electrical Safety - Preventive-Maintenance ProgramBhushanRajÎncă nu există evaluări

- Experimental Investigation On The Out-Of-Plane Behaviour of Concrete Masonry Infilled FramesDocument180 paginiExperimental Investigation On The Out-Of-Plane Behaviour of Concrete Masonry Infilled FramesBhushanRajÎncă nu există evaluări

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Post-Tensioned Box Girder Design Manual: June 2016Document389 paginiPost-Tensioned Box Girder Design Manual: June 2016aandueza_1Încă nu există evaluări

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Wrana 2015 4 PDFDocument11 paginiWrana 2015 4 PDFarslanpasaÎncă nu există evaluări

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Creep and Shrinkage of Concrete and Their Influence On Structural Behavior - Illston and EnglandDocument10 paginiCreep and Shrinkage of Concrete and Their Influence On Structural Behavior - Illston and EnglandBhushanRajÎncă nu există evaluări

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Uls Design of Conrete StructuresDocument20 paginiUls Design of Conrete StructuresBhushanRajÎncă nu există evaluări

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Semi-Integral Abutment BridgesDocument35 paginiSemi-Integral Abutment BridgesBhushanRajÎncă nu există evaluări

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- IRC IH Mar 2018 Pages 1-72 With CoverDocument72 paginiIRC IH Mar 2018 Pages 1-72 With CoverBhushanRajÎncă nu există evaluări

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- CAMSKRA Individual Form PDFDocument2 paginiCAMSKRA Individual Form PDFKowshik ChakrabortyÎncă nu există evaluări

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Wyche Bridge 2000Document12 paginiWyche Bridge 2000BhushanRajÎncă nu există evaluări

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- How Big Is That BeamDocument2 paginiHow Big Is That BeamBhushanRajÎncă nu există evaluări

- IRC IH Jan 2018Document68 paginiIRC IH Jan 2018Akash YadavÎncă nu există evaluări

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Invesco India Growth Fund Jun 30 2017Document97 paginiInvesco India Growth Fund Jun 30 2017BhushanRajÎncă nu există evaluări

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Rule of Thumb Concrete DesignDocument54 paginiRule of Thumb Concrete DesignrunkirÎncă nu există evaluări

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- HanGil IT BrochureDocument6 paginiHanGil IT BrochureBhushanRajÎncă nu există evaluări

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- Strength Design - Plain Conc FootingDocument4 paginiStrength Design - Plain Conc Footingma100% (1)

- Earthquake Analysis ProcedureDocument4 paginiEarthquake Analysis ProcedureV.m. RajanÎncă nu există evaluări

- Study On Cover Depth For Prestressed Concrete Bridges in Airborne-Chloride EnvironmentsDocument12 paginiStudy On Cover Depth For Prestressed Concrete Bridges in Airborne-Chloride EnvironmentsBhushanRajÎncă nu există evaluări

- Creep Coefficient CalculationDocument1 paginăCreep Coefficient CalculationBhushanRajÎncă nu există evaluări

- ABC-DES703-14 Wheel Load Effects On Buried Arch Structures PDFDocument13 paginiABC-DES703-14 Wheel Load Effects On Buried Arch Structures PDFBhushanRajÎncă nu există evaluări

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- CV SamplesDocument8 paginiCV SamplesJohn Carl ValdezÎncă nu există evaluări

- ABAQUS Tutorial Example PresentationDocument7 paginiABAQUS Tutorial Example PresentationBhushanRajÎncă nu există evaluări

- Joint DetailingDocument1 paginăJoint DetailingBhushanRajÎncă nu există evaluări

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- A Technical Guide On DerailmentsDocument142 paginiA Technical Guide On Derailmentsdkaviti100% (2)

- Analytical Predictions of OOP Strength of Masonry WallsDocument12 paginiAnalytical Predictions of OOP Strength of Masonry WallsBhushanRajÎncă nu există evaluări

- 000 Diseño Por Capacidad - 2003 - Myths and Fallacies in Earthquake Engineering - Priestley Pag20Document98 pagini000 Diseño Por Capacidad - 2003 - Myths and Fallacies in Earthquake Engineering - Priestley Pag20Roberto UrrutiaÎncă nu există evaluări

- Subroutine For Cohesive ElementDocument41 paginiSubroutine For Cohesive ElementBhushanRaj100% (1)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (120)

- ESE 2014 Final Vacancy PositionDocument4 paginiESE 2014 Final Vacancy PositionBhushanRajÎncă nu există evaluări

- Kaleidagraph ManualDocument325 paginiKaleidagraph ManualBhushanRajÎncă nu există evaluări

- UpdateJul2007 3julDocument10 paginiUpdateJul2007 3julAnshul SinghÎncă nu există evaluări

- Krishna TejaDocument71 paginiKrishna TejaHimanshu GaurÎncă nu există evaluări

- Furniture AnnexDocument6 paginiFurniture AnnexAlaa HusseinÎncă nu există evaluări

- PID Marcado Operación Del Paquete Del Compresor de Hidrogeno PHP-K-002 PDFDocument7 paginiPID Marcado Operación Del Paquete Del Compresor de Hidrogeno PHP-K-002 PDFDenisÎncă nu există evaluări

- S4 Computer Sciences Exercises PDFDocument2 paginiS4 Computer Sciences Exercises PDFHenriette Desanges UwayoÎncă nu există evaluări

- 2023 2024 Syllabus PDFDocument23 pagini2023 2024 Syllabus PDFRika DianaÎncă nu există evaluări

- Nursing Assessment in Family Nursing PracticeDocument22 paginiNursing Assessment in Family Nursing PracticeHydra Olivar - PantilganÎncă nu există evaluări

- Pre-Paid Customer Churn Prediction Using SPSSDocument18 paginiPre-Paid Customer Churn Prediction Using SPSSabhi1098Încă nu există evaluări

- Lesson 1 Concepts About Educational TechnologyDocument17 paginiLesson 1 Concepts About Educational TechnologyMarvin ContigaÎncă nu există evaluări

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Nascsa - Sponsor Solicitation List: January 06, 2021Document35 paginiNascsa - Sponsor Solicitation List: January 06, 2021Prasoon SimsonÎncă nu există evaluări

- Free ConvectionDocument4 paginiFree ConvectionLuthfy AditiarÎncă nu există evaluări

- Gold Loan Application FormDocument7 paginiGold Loan Application FormMahesh PittalaÎncă nu există evaluări

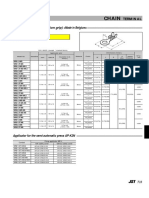

- Chain: SRB Series (With Insulation Grip)Document1 paginăChain: SRB Series (With Insulation Grip)shankarÎncă nu există evaluări

- Structure of NABARD Grade ADocument7 paginiStructure of NABARD Grade ARojalin PaniÎncă nu există evaluări

- PV Power To Methane: Draft Assignment 2Document13 paginiPV Power To Methane: Draft Assignment 2Ardiansyah ARÎncă nu există evaluări

- Sips 1328Document64 paginiSips 1328Jean Claude De AldánÎncă nu există evaluări

- NA ReadingStrategies U5M11L03Document1 paginăNA ReadingStrategies U5M11L03Lila AlwaerÎncă nu există evaluări

- Lesson Plan Letter SDocument4 paginiLesson Plan Letter Sapi-317303624100% (1)

- Performance Task 2Document3 paginiPerformance Task 2Edrose WycocoÎncă nu există evaluări

- Class 1 KeyDocument3 paginiClass 1 Keyshivamsingh.fscÎncă nu există evaluări

- Effective TeachingDocument94 paginiEffective Teaching小曼Încă nu există evaluări

- Chromatographic Separation PDFDocument7 paginiChromatographic Separation PDFNicolle CletoÎncă nu există evaluări

- Pipe Freezing StudyDocument8 paginiPipe Freezing StudymirekwaznyÎncă nu există evaluări

- The Perception of Luxury Cars MA Thesis 25 03Document60 paginiThe Perception of Luxury Cars MA Thesis 25 03Quaxi1954Încă nu există evaluări

- Level I 2018 2019 Program Changes PDFDocument2 paginiLevel I 2018 2019 Program Changes PDFMuhammad BurairÎncă nu există evaluări

- Monster Hunter: World - Canteen IngredientsDocument5 paginiMonster Hunter: World - Canteen IngredientsSong HoeÎncă nu există evaluări

- Or HandoutDocument190 paginiOr Handoutyared haftu67% (6)

- Construction Drawing: Legend Notes For Sanitary Piping Installation General Notes NotesDocument1 paginăConstruction Drawing: Legend Notes For Sanitary Piping Installation General Notes NotesrajavelÎncă nu există evaluări