Documente Academic

Documente Profesional

Documente Cultură

Calibration and Operation Procedure of DCA

Încărcat de

Imdadul MilonDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Calibration and Operation Procedure of DCA

Încărcat de

Imdadul MilonDrepturi de autor:

Formate disponibile

Recommended DCA Operation Procedure for Using WinDCA

The Cahn Dynamic Contact Angle (DCA) analyzer is an instrument used to measure the surface properties of solid and liquid samples, consisting of a highly sensitive balance, a moving stage mechanism and a control station. WinDCA is a Windows based software program used to control the DCA system, collect data and perform data analysis. It is designed in such a way that the DCA experiments are controlled through experimental steps. There are five sampling techniques available in the WinDCA program. These five sampling techniques are: contact angle, surface tension (liquid), interfacial tension (liquids), wicking and CMC (Critical Micelle Concentration). Since each sampling technique serves a different purpose, there are different experimental steps involved. It is also necessary to understand that the experimental steps are only one part of the WinDCA method. Each WinDCA method has four parts: one for the DCA system configuration, one for the experimental set-up, one for the data collection option, and one for the experimental steps. A new WinDCA method can be created by choosing the Methods/New function in the WinDCA main menu. Once completed, the method can then be saved as a method file and loaded later. It is the purpose of this product note to provide additional information about the experimental steps for these five sampling techniques and calibration related information. Note: It is assumed that the user has some basic knowledge about the DCA and WinDCA. CALIBRATION In order to obtain accurate measurements, it is always recommended that the DCA system be calibrated regularly. There are two parts that need to be calibrated. One is the balance, and the other is the motor. The balance calibration ensures that an accurate weight reading will be recorded, and the motor calibration guarantees that the correct sample position will be attained. These calibrations can be performed by selecting DCA/Calibrate/Balance and DCA/Calibrate/Motor functions. Since the WinDCA software allows the calibration results to be saved into different calibration files, the following procedure should be used in order to ensure that the correct calibration factors are used: 1. Create a new method file with the correct system configuration, or load an existing method file, or edit the loaded or created method and save the changed method file. 2. Calibrate the balance and/or the motor of the DCA system. Save the new calibration file and update it into the method file. 1

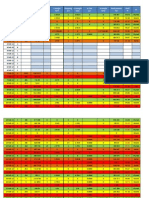

3. Perform the experiments. Important: The calibration of the DCA system should be performed AFTER the method file has been loaded or created. It is also recommended, to ensure that the weight readings are correct, that you check them by using the DCA/Record or DCA/Weight function prior to running the experiments. Contact Angle Under this sampling technique, both advancing and receding contact angles are measured. Typically, three different methods are utilized. The first method performs experiments with one cycle (multiple experimental steps) and one loop (a set of advancing and receding steps). The second method has one cycle with multiple loops. The third method consists of multiple cycles and loops. The recommended steps for these three methods are listed as follows: Single Cycle and Single Loop Single Cycle and Multiple Cycles and (default method) Multiple Loops Loops Recommended Set Speed Same as the Single different cycles which Experimental Tare Balance Cycle and Single Loop can be a combination of Steps Detect ZDOI method, but with more the previous two Advance than one advance/recede methods. Dwell (optional) loops before the Return Recede to Zero Position step. Return to Zero Position The first method is sufficient for most applications. The later two are useful for many other applications, such as the testing of a samples cleanliness, or the re-orientation of the molecules on the samples surfaces. In addition, the operator can create special experimental conditions for certain applications. Surface Tension In this application, there are two different solid probes that can be used for measuring the liquids surface tension. One is a Wilhelmy Plate, made of glass or platinum. Another is the DuNouy ring, made of platinum-iridium. When using a Wilhelmy plate, two different methods can be used. One method has a simple advance and recede cycle where the surface tension value is taken from the receding step. Another, more accurate and recommended method, has a Read Weight/Time until Weight Stable step at the ZDOI (Zero Depth Of Immersion) position which gives the surface tension value. A simple advance and recede loop method is used with the DuNouy ring. The following table provides an example of the method steps. Wilhelmy Plate DuNouy Ring Simple Recommended (default method) Experimental Set Speed Set Speed Set Speed Steps Tare Balance Tare Balance Tare Balance Detect ZDOI Detect ZDOI Detect ZDOI * * Advance Advance Advance* Dwell (optional) Dwell (optional) Dwell (optional) Recede Recede to ZDOI Return to Zero Return to Zero Read Weight/Time until Position Position Weight Stable Return to Zero Position 2

The solid probe should be advanced into the liquid deep enough so that the Wilhelmy plate is partially, or the DuNouy ring is completely, immersed.

Even though both the Wilhelmy plate and DuNouy ring can be used for many kinds of liquids, we recommend you use the DuNouy ring method with highly viscose liquids (viscosity of 1000 cP or higher). However, when the DuNouy ring method is used, it is also necessary to know the density of the liquid. Interfacial Tension Similar to the Surface Tension technique, both the Wilhelmy plate and DuNouy ring can be used as the solid probe to measure the interfacial tension between two liquids, a light liquid on top of a heavier liquid. It is required that the solid probe pass only once between the interface of the two liquids, typically from the heavier to the lighter liquid. The experimental steps, however, are more complicated than those of a surface tension measurement. We recommend you use two beakers for the experiment and use the following experimental procedure: Step DCA Method Step 1 Set Speed 2 Wait for Operator Ready 3 4 Tare Balance Wait for Operator Ready PC Screen Press the OK button, once the operator finishes the step(s) in the right column Press the OK button, once the operator finishes the step(s) in the right column Operator Immerse the solid probe totally* inside the light liquid (beaker 1), by using the manual stage height adjustment. Remove the solid probe, have it cleaned and reinstalled. Remove beaker 1 and replace with beaker 2 containing the heavier liquid underneath the solid probe.

5 6 7

Detect ZDOI Advance (make sure that the solid probe breaks the surface of the heavier liquid, so that the Wilhelmy plate is partially, or the DuNouy ring is completely, immersed) Wait for Operator Press the OK button, once Pour the light liquid slowly into beaker 2. Ready the operator finishes the Make sure there is enough light liquid to step(s) in the right column allow the solid probe to be completely immersed in the light liquid after the next step(s). Return procedures are the same as those of a surface tension measurement. For Wilhelmy plate probe, use Recede and Return to Zero Position for the simple method, or Return to ZDOI, Read Weight/Time until Weight Stable and Return to Zero Position under the recommended method. For DuNouy ring probe, use Return to Zero Position. If a Wilhelmy plate is used, all of the plate should be immersed in the light liquid. Only the ring itself should be immersed in the liquid, if a DuNouy ring is used. This is to ensure that the probe returns to the same position once its pulled out of the heavier liquid and returned to the zero position. 3

A Thermo Electron Company

Principles of Operation

Specifications

A1 small ofinterchanged. sample (< 1 ml) Step is placed Hencky strains: up the to 0 = 10 Steps andquantity 2 can be 2 can even be eliminated from method, but the solid probe between two circular plates. The top plate is Strain rate range: . must be immersed infrom the light liquid plate prior at toathe start of the data collection. It is < also that 0 < suggested 300 s-1 rapidly separated the bottom userImposed strain rate 0.01 . -5 -1 several trial runs be made in order to optimize the experimental conditions and the amount of liquids Fluid strain rate: 10 < s selected strain rate, thereby forming an unstable 0 < 10 Shear Viscosity range: 10-106 mPas fluid filament by imposing an instantaneous level needed for the experiment. Plate diameter: of extensional strain on the fluid sample. After 4 < Dplate < 8 mm, standard = 6 mm cessation of stretching, the fluid at the mid-point Wicking Temperature range: 0 - 80 C of the filament undergoes an extensional strain Diameter resolution: 10 m rate defined by the extensional properties of the System response time: 10 msare of interest, you fluid. laser micrometer monitors the midpoint When theAamounts of liquid being adsorbed by solid samples, porous or powder, 40 x 34 x 60 cm Dimension (instrument only): diameter of the gradually thinning fluid filament will perform a wicking experiment. Under this technique, solid samples will be immersed and held just as a function of time. The competing effects of below the liquids and thetransfer weightand change recorded as a function of time. Therefore, the surface tension,surface viscosity, mass experimental steps Set Speed, Tare Balance, elasticity can be are: quantified using the model fittingDetect ZDOI, Advance, Tare Balance (optional but Software analysis included in Weight/Time the software. The automated recommended), Read until Weight Stable, Return to Zero Position. experimental analysis and model comparison Windows 95/98/NT/2000/XP compatible software provides rapid determination of the following The parameters: motor speed should be set to a highelasticity, value in orderto immerse the solid into the liquid quickly. The Range of models for parameter extraction Viscosity, surface tension, distance for the advance step should be time. set to a low value large enough to ensure that solid will be in relaxation times and filament breakup Data export to ASCII file

contact with liquid throughout the run, since the liquid level will drop due to adsorption by the solid sample. CMC

Features

Completely computer controlled Basically, a CMC experiment is a series of experiments where a surface tension measurement is Easy to operate performed after making aand surfactant concentration change. With an understanding of the surface tension Easy sample loading measurement cleaning steps (please refer to the surface tension section), it is easy to create the CMC Class 1 laser micrometer experimental steps by adding the proper dosing related commands. There are three modes for dosing, Linear motor drive with linear (default), fast, and manual. It is recommended you use the fast mode to optimize the dosing variable speed parameters, once the surface tension measurement steps are optimized. After the optimum parameters Automatic repeated testing are obtained, the default method can then be used for a CMC measurement. Closed temperature-controlled sample chamber Exchangeable geometries Should you have any further questions, please feel free to contact Cahn at (800)244-6305. Thanks for stretched in the User defined strains using DCA. volume (< 1 ml) R. Cahn Small sample

A Thermo Electron Company

International Thermo Haake Dieselstr. 4 76227 Karlsruhe Germany Tel. +49(0)721 40 94-0 Fax +49(0)721 40 94-300 Hotline +49(0)18050 HAAKE info@thermohaake.com www.thermohaake.com

USA Thermo Haake 5225 Verona Road Madison, WI 53711 Tel. 608-327-6777 Fax 608-273-6827 infousa@thermohaake.com www.thermohaake.com

France Thermo Rheo 99 route de Versailles 91160 Champlan Tel. +33(0)1 64 54 01 01 Fax +33(0)1 64 54 01 87 info@thermorheo.com www.thermorheo.com

UK Thermo PRISM Emerald Way Stone Business Park, Stone Staffordshire ST15 0SR Tel.+44(0)1785 813 648 Fax +44(0)1785 814 633 info@thermoprism.com www.thermoprism.com

CaBER is a registered trade mark of Cambridge Polymer Group. A patent for the CaBER is pending. The product information in this document was correct at the time of printing, however specifications are subject to alteration without notice, due to the Thermo Haake philosophy of continual product innovation and development and any information contained herein should not be construed as a contractual commitment by Thermo Haake. All orders are accepted subject to our current Conditions of Sale, copies of which are available on request. Thermo Haake / April.2002 623-2058

S-ar putea să vă placă și

- Alumina 6061 T6Document1 paginăAlumina 6061 T6Imdadul MilonÎncă nu există evaluări

- Amorphization of Ceramic Materials by Ion Beam IrradiationDocument8 paginiAmorphization of Ceramic Materials by Ion Beam IrradiationImdadul MilonÎncă nu există evaluări

- Thermal DCA TutorialDocument28 paginiThermal DCA TutorialImdadul MilonÎncă nu există evaluări

- Nanocomposite Layers of Ceramic Oxides and Metals Prepared by ReactiveDocument7 paginiNanocomposite Layers of Ceramic Oxides and Metals Prepared by ReactiveImdadul MilonÎncă nu există evaluări

- Daily production reportDocument8 paginiDaily production reportImdadul MilonÎncă nu există evaluări

- Higher Algebra - Hall & KnightDocument593 paginiHigher Algebra - Hall & KnightRam Gollamudi100% (2)

- Higher Algebra - Hall & KnightDocument593 paginiHigher Algebra - Hall & KnightRam Gollamudi100% (2)

- Higher Algebra - Hall & KnightDocument593 paginiHigher Algebra - Hall & KnightRam Gollamudi100% (2)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (894)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Categoria ApiDocument61 paginiCategoria ApiHector MARTINEZ DEL ANGELÎncă nu există evaluări

- Slip and Crystallographic TexturesDocument34 paginiSlip and Crystallographic TexturesSunkulp GoelÎncă nu există evaluări

- Beam and Slab DesignDocument41 paginiBeam and Slab DesignSridhara MunimakulaÎncă nu există evaluări

- EMB 20100301 Mar 2010Document156 paginiEMB 20100301 Mar 2010agnithiumÎncă nu există evaluări

- Manual JX PDFDocument263 paginiManual JX PDFArvind KumarÎncă nu există evaluări

- Plasmon CD-R ReviewDocument11 paginiPlasmon CD-R Reviewgrudva2Încă nu există evaluări

- PBM and PBZ Crown Techniques ComparedDocument6 paginiPBM and PBZ Crown Techniques ComparedDonanguyenÎncă nu există evaluări

- Chapter 1 XXXDocument8 paginiChapter 1 XXXChristelle Mary Sabile SabanalÎncă nu există evaluări

- Queen Sala Celinda Del Rosario LECCION2 Actividad de Produccion 2.4Document4 paginiQueen Sala Celinda Del Rosario LECCION2 Actividad de Produccion 2.4Salustino AbreuÎncă nu există evaluări

- Contact Centre CapabilityDocument2 paginiContact Centre CapabilityshyamchepurÎncă nu există evaluări

- Making Your Chain Run For Longer: Effective Chain Maintenance Advice From Renold JeffreyDocument2 paginiMaking Your Chain Run For Longer: Effective Chain Maintenance Advice From Renold JeffreyCương Phạm NgọcÎncă nu există evaluări

- Improved M16A2 - A3 - A4 Zero TargetDocument6 paginiImproved M16A2 - A3 - A4 Zero Targetbeetho1990Încă nu există evaluări

- Electrical Power Transmission & DistributionDocument18 paginiElectrical Power Transmission & DistributionMd Saif KhanÎncă nu există evaluări

- 15 Suspensions PDFDocument57 pagini15 Suspensions PDFSASWAT MISHRAÎncă nu există evaluări

- Q7 Running GearDocument54 paginiQ7 Running GearJoseph MorantÎncă nu există evaluări

- Ficha Tecnica Komatsu 400 - 7Document52 paginiFicha Tecnica Komatsu 400 - 7bariciado1Încă nu există evaluări

- Civil Engineering Faculty Hydraulics Division: HydrologyDocument2 paginiCivil Engineering Faculty Hydraulics Division: HydrologyENA CO LTD100% (1)

- Netsys NVF-200EKIT User Guide 1.0.6Document19 paginiNetsys NVF-200EKIT User Guide 1.0.6pkramellaÎncă nu există evaluări

- Multisite ErpDocument5 paginiMultisite ErparavindhsekarÎncă nu există evaluări

- M103C 10/11 Meter Maximum Beam AntennaDocument9 paginiM103C 10/11 Meter Maximum Beam AntennaRádio Técnica AuroraÎncă nu există evaluări

- RDSS L2 Pert Chart - PKG-04 - Joynagar.... 21082023Document5 paginiRDSS L2 Pert Chart - PKG-04 - Joynagar.... 21082023sourish69Încă nu există evaluări

- Effect of Crystallinity On Electrical Properties of ElectronDocument4 paginiEffect of Crystallinity On Electrical Properties of Electronapi-3837841Încă nu există evaluări

- ManualDocument14 paginiManualnas_hoÎncă nu există evaluări

- Cooling Tower PDFDocument3 paginiCooling Tower PDFmaimslapÎncă nu există evaluări

- SUN 72M Mono Crystalline Module PerformanceDocument2 paginiSUN 72M Mono Crystalline Module PerformanceFernando VieiraÎncă nu există evaluări

- Phaser3300MFP Firmware Upgrade Instructions CWISDocument2 paginiPhaser3300MFP Firmware Upgrade Instructions CWISAlgenis De Leon RamirezÎncă nu există evaluări

- Article ASI Magazine September 2014 Fumed Silica in Adhesives and Sealants FormulationsDocument4 paginiArticle ASI Magazine September 2014 Fumed Silica in Adhesives and Sealants FormulationsdombaraÎncă nu există evaluări

- Inductance Measurements For Synchronous MachinesDocument2 paginiInductance Measurements For Synchronous MachinesYusuf YaşaÎncă nu există evaluări

- Monopoly - Indian Railways: - Anand Dube - Darshna Chande - Karan Sobti - Sriaditya Kasula - Vinay ChaudhariDocument52 paginiMonopoly - Indian Railways: - Anand Dube - Darshna Chande - Karan Sobti - Sriaditya Kasula - Vinay ChaudhariKristamRajuÎncă nu există evaluări

- De-Emulsifier - Clay Stabilizer Foreecs: UralplastDocument3 paginiDe-Emulsifier - Clay Stabilizer Foreecs: UralplastNinaÎncă nu există evaluări