Documente Academic

Documente Profesional

Documente Cultură

Results, Discussion, Recommendations, Appendix

Încărcat de

pc_renewDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Results, Discussion, Recommendations, Appendix

Încărcat de

pc_renewDrepturi de autor:

Formate disponibile

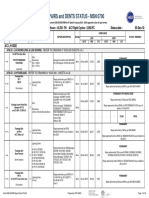

RESULTS Table 1.

Determination of the pressure drop (p) and filter medium resistance (Rm) Volume (V), L t/V, s/L2 0.5 34.20 1.3 42.15 1.6 45.69 Table 1 shows the t/V and V data of the plate and frame filtration. These two groups of data will be used to calculate for the pressure drop and filter medium resistance of the filtration process by plotting t/V vs. V (from equation 8) then obtaining the slope and the y-intercept of the generated line which are a function of the pressure drop and medium resistance.

46 44 42 40 t/V, s/L 38 36 34 32 30 0.4 0.6 0.8 1 V, L 1.2 1.4 1.6 y = 10.34x + 28.96 R = 0.998

Figure 1. Graph of t/V vs. V for determination of p and Rm The figure below shows the plot of t/V vs. V. The slope of the said line is 10.34 s/L2 with a y-intercept of 28.96 s/L. The coefficient of determination (R2) has a value of 0.998 which is very close to one which would then imply that t/V and V has a strong direct relationship between each other and the slopes and y-intercepts could be used without much error from the actual.

Table 2. Determination of mass ratio of wet cake to dry cake (m) Trial Mass Wet Cake, g Mass Dry Cake, g m 1 41 37 1.11 2 107 98 1.09 3 108 100 1.08 4 221 208 1.06 Table 2 shows the determination of mass ratio between the wet cake to the dry cake. The average ratio between the two masses is 1.085. This value will be used to solve for the mass of particles deposited in the filter per unit volume of filtrate (c) through equation 7.

Table 3. Summary output of the plate and frame filtration process Slope, s/L2 10.34 Y-intercept, s/L 28.96 Pressure drop p, Pa 916.46 Filter medium resistance Rm, m-1 4.01 x 109 Table 3 shows the desired results for the plate and frame filtration. Plotting t/V vs. V would generate a slope of 10.34 with a y-intercept of 28.96. Using equation 8 and the definition of its parameters, the pressure drop of the process is 916.46 Pa with a filter medium resistance of 4.01 x 109 m-1.

DISCUSSION From equation 8, plotting t/V vs. V would give a slope of Kc/2 and a y-intercept of 1/qo. From results, these values are 10.34 s/L2 and 28.96 s/L. Using equations 9 and 10, the pressure drop and the filter medium resistance was determined with values of 916.46 Pa and 4.01 x 109 m1 . For the calculation of the two, refer to the appendix. Pressure drop exist because there are resistances brought by filter medium and filter cake which is gradually forming as filtration goes on. Thus, the pressure before the slurry is filtered should be not equal (lesser) compared to the pressure of the slurry after it has filtered. Hence the constant pressure drop that is used to push the slurry to overcome the resistance brought by the constant filter medium resistance (4.01 x 109 m-1) and the increasing cake resistance is 916.46 Pa. This pressure drop is almost negligible compared to the atmospheric pressure (101,325 Pa) which is the basis for measurement of most of the pressure meters. This is the reason why the pressure gauge in the plate and frame filter press (inserted to a pipe which guides the lime slurry to the filter press) does not move because it (pressure) is too small to be detected. To increase the pressure drop of the filter press, either (1) one uses a finer filter cloth (smaller mesh size) in order to build up more cake in the filter medium which would hinder the flow of the slurry (thus increasing the pressure drop needed to

overcome the resistance), (2) increase the lime concentration of the slurry to increase the cake build-up or (3) decrease the filter medium area. One assumption made in order to calculate for the pressure drop of the system is that the cake is incompressible which means that the cake resistance is independent on the pressure drop of the slurry. In reality, this is impossible to achieve because the resistance brought by the cake is affected by the pressure drop of the system. The cake resistance is the resistance brought by the filtered cake. Thus, additional pressure drop is needed to overcome this resistance together with the resistance of the medium. Again, this cake resistance increases as the filtration process continues because the filter cake builds-up in the medium.

CONCLUSION AND RECOMMENDATIONS Filtration is the process of removal of solid particles from liquids or gases with the help of a filter medium (septum). One common equipment used for filtration in industrial plants is the plate and frame filter press. In this type of filtering equipment, the filter medium is inserted between the plates. The slurry moves (with a help of a pump) to the medium via a hole in the plate. Thus, the solids would deposit on the medium (filter cake) and the filtrate would be less concentrated with the solid. In the experiment, the time it would take for a certain volume of the filtrate was obtained. By plotting t/V vs. V from the data gathered, one could calculate for the pressure drop of the system and the constant filter medium resistance. The pressure drop of the system is 916.46 Pa and the filter medium resistance is equivalent to 4.01 x 109 m-1. One bold assumption made by the experimenters is that the specific cake resistance is independent to the pressure drop of the system. The experimenters believed that though in reality, the said proposition is impossible to occur, still the error between the pressure drop calculated from its true value is small to consider. The actual pressure drop should be obtained manually through the experiments but because of the limited pressure meter devices in the laboratory, it could not be obtained. From these results, the experimenters formulated these recommendations to achieve the best results for the next experimenters. 1. The pressure drop between the slurry before it is filtrated and after it is filtrated (filtrate) could be obtained through the use of pressure meter devices such as pressure gauges. Pressure gauges must be available with scaling ranging from 10000 Pa to 1000000 Pa. 2. Incompressible cake is a very bold assumption made in this experiment. This is done for ease in the calculation of the pressure drop and cake resistance. The next experimenters should develop equations relating the pressure drop to cakes of compressible condition because this will result into the true pressure drop. 3. Use a standard filter cloth to ensure the validity of the results obtained.

S-ar putea să vă placă și

- ACT 9 Filter Grp1Document8 paginiACT 9 Filter Grp1Junn Edgar LibotÎncă nu există evaluări

- 5Document31 pagini5shihabzÎncă nu există evaluări

- Filtration Questions)Document8 paginiFiltration Questions)Evan CarniyanÎncă nu există evaluări

- Plate and Frame Filter Press: Instruction ManualDocument8 paginiPlate and Frame Filter Press: Instruction ManualYatharth SahuÎncă nu există evaluări

- FiltrationDocument37 paginiFiltrationMoyikaa MargaaÎncă nu există evaluări

- Filtration (Final Report)Document13 paginiFiltration (Final Report)Noel Jeffrey PintonÎncă nu există evaluări

- Filtration ProcessDocument32 paginiFiltration ProcessKrishna YeoleÎncă nu există evaluări

- Comp Pipe Lab 100331Document4 paginiComp Pipe Lab 100331Omoshola BrightÎncă nu există evaluări

- Lab Report 1Document17 paginiLab Report 1CyrilÎncă nu există evaluări

- Assessment of Venturi Nozzle For Filter Bag Cleaning in PDFDocument0 paginiAssessment of Venturi Nozzle For Filter Bag Cleaning in PDFUmanath R PoojaryÎncă nu există evaluări

- Filtration ExperimentDocument15 paginiFiltration Experimentkudzai100% (1)

- Digest 2024 01 04 135858Document1 paginăDigest 2024 01 04 135858Rizka Dwi AprilianiÎncă nu există evaluări

- F1 Filter Press Lab ManualDocument4 paginiF1 Filter Press Lab Manualgravity_coreÎncă nu există evaluări

- Filtros A PresionDocument14 paginiFiltros A PresionTomás Barrientos BrunaÎncă nu există evaluări

- Consolidated Undrained Triaxial Compression Test For Undisturbed SoilsDocument9 paginiConsolidated Undrained Triaxial Compression Test For Undisturbed SoilsMasriflin TandeanÎncă nu există evaluări

- Lab ManuelDocument79 paginiLab ManuelMarty SmurdaÎncă nu există evaluări

- A Filter PressDocument0 paginiA Filter Pressraneshkumar1992Încă nu există evaluări

- Fluid Mechanics-Surface Tension ExperimentDocument6 paginiFluid Mechanics-Surface Tension ExperimentCengiz KöseoğluÎncă nu există evaluări

- Experiment 3-Flow Past A Circular CylinderDocument15 paginiExperiment 3-Flow Past A Circular CylinderNguyen Duy Thao75% (4)

- Lab Air 06032019Document10 paginiLab Air 06032019Nur AnissaÎncă nu există evaluări

- Procedure For Pore Volume and Pore Volume Distribution by Mercury Intrucsion PorosimetryDocument4 paginiProcedure For Pore Volume and Pore Volume Distribution by Mercury Intrucsion PorosimetryShyamÎncă nu există evaluări

- CPB 20104 Mass Transfer 2 UniKL MICET Experiment 3: Plate and Frame Filter Press Full Lab ReportDocument13 paginiCPB 20104 Mass Transfer 2 UniKL MICET Experiment 3: Plate and Frame Filter Press Full Lab ReportSiti Hajar Mohamed100% (4)

- P&FDocument10 paginiP&FPia SalapantanÎncă nu există evaluări

- Boundary LayersDocument15 paginiBoundary LayersRo Win100% (1)

- Valerie Lab ReportDocument10 paginiValerie Lab ReportvalerieÎncă nu există evaluări

- FiltrationDocument12 paginiFiltrationNicholas AngÎncă nu există evaluări

- Pressure FiltersDocument14 paginiPressure FiltersNok Thya AugsemaÎncă nu există evaluări

- Rotary Vacuum FilterDocument17 paginiRotary Vacuum FilterGhilandy RamadhanÎncă nu există evaluări

- Filtration TheoryDocument6 paginiFiltration TheoryTimothy van KuijkÎncă nu există evaluări

- Gas Phase KineticsDocument7 paginiGas Phase KineticsBrio Chemical0% (1)

- 135 457 1 PBDocument9 pagini135 457 1 PBPitri YantiÎncă nu există evaluări

- Lab Report On AirflowDocument13 paginiLab Report On AirflowDavid Ella Inalegwu50% (4)

- The University of Nottingham Malaysian Campus: Laboratory ReportDocument10 paginiThe University of Nottingham Malaysian Campus: Laboratory ReportXinyi TanÎncă nu există evaluări

- Experiment 3.Document6 paginiExperiment 3.tracyymendozaÎncă nu există evaluări

- NO. Title Allocated MARKS (%) MarksDocument22 paginiNO. Title Allocated MARKS (%) MarksjufferyÎncă nu există evaluări

- E 128 - 99 - RteyoaDocument3 paginiE 128 - 99 - RteyoaSaurabh ChoudhariÎncă nu există evaluări

- Fluid Flow Measurement Lab: ObjectDocument9 paginiFluid Flow Measurement Lab: ObjectAboodÎncă nu există evaluări

- Cylone SeparatorDocument11 paginiCylone SeparatorAzrol Azmir Long100% (8)

- Cap 09 FiltracionDocument30 paginiCap 09 FiltracionJesus J Paniagua SegoviaÎncă nu există evaluări

- FiltrationDocument7 paginiFiltrationElajah ZaragozaÎncă nu există evaluări

- Unsteady Pressure Measurements On A 5:1 Rectangular CylinderDocument8 paginiUnsteady Pressure Measurements On A 5:1 Rectangular CylinderOkke BronkhorstÎncă nu există evaluări

- MEM311 Manual 09192014Document77 paginiMEM311 Manual 09192014Sam Yang SunÎncă nu există evaluări

- Pressure Measurements NotesDocument15 paginiPressure Measurements NotesManjunath MohiteÎncă nu există evaluări

- RG 2020Document20 paginiRG 2020Vikash ShuklaÎncă nu există evaluări

- The Sample Is Sealed Inside A Rubber Membrane and Then Surround With WaterDocument6 paginiThe Sample Is Sealed Inside A Rubber Membrane and Then Surround With WaterhabiÎncă nu există evaluări

- Nozzle Thrust ExperimentDocument2 paginiNozzle Thrust Experimentvidic971Încă nu există evaluări

- Laboratory Mechanical Process Engineering: FiltrationDocument7 paginiLaboratory Mechanical Process Engineering: FiltrationUmesh Kumar Sharma RamamoorthiÎncă nu există evaluări

- Solar Grain Dryer Dr. George OwinoDocument11 paginiSolar Grain Dryer Dr. George OwinoGeorge OparÎncă nu există evaluări

- Venturimeter ExpDocument12 paginiVenturimeter ExpAmoluck BhatiaÎncă nu există evaluări

- PlantDocument5 paginiPlantLucas LethukuthulaÎncă nu există evaluări

- Experiment 13 Ultrafiltration UnitDocument13 paginiExperiment 13 Ultrafiltration UnitKishen NaniÎncă nu există evaluări

- Journal of Nuclear Science and TechnologyDocument4 paginiJournal of Nuclear Science and TechnologyZavaleta RedlerÎncă nu există evaluări

- P1 Lab ReportDocument7 paginiP1 Lab ReportElyse Kymberly TeohÎncă nu există evaluări

- Flux Improvement by Dean Vortices: Ultra®ltration of Colloidal Suspensions and Macromolecular SolutionsDocument22 paginiFlux Improvement by Dean Vortices: Ultra®ltration of Colloidal Suspensions and Macromolecular Solutionskkfuruichi2218Încă nu există evaluări

- Pressure Distribution Over CylinderDocument4 paginiPressure Distribution Over CylinderAshok YadavÎncă nu există evaluări

- Lab CO1: Fundamentals of Pressure, Viscosity: and Surface Tension of Fluids BMM 3521 Engineering Fluid MechanicsDocument21 paginiLab CO1: Fundamentals of Pressure, Viscosity: and Surface Tension of Fluids BMM 3521 Engineering Fluid MechanicsIr Mathan RajÎncă nu există evaluări

- Flow Past A Circular Cylinder: William J. DevenportDocument16 paginiFlow Past A Circular Cylinder: William J. DevenportShiva UÎncă nu există evaluări

- Cavitation Characteristics of Restriction OrificesDocument8 paginiCavitation Characteristics of Restriction Orificesrogel_ganaÎncă nu există evaluări

- Resumen C37 010 Aplicacion de Breaker Disenados IC Simetrica PDFDocument9 paginiResumen C37 010 Aplicacion de Breaker Disenados IC Simetrica PDFglendathais100% (1)

- Datasheet Ark XH Battery System EngDocument2 paginiDatasheet Ark XH Battery System EngLisa CowenÎncă nu există evaluări

- Class 12 - Maths - MatricesDocument87 paginiClass 12 - Maths - MatricesAishwarya MishraÎncă nu există evaluări

- Pythagorean Theorem WorksheetDocument11 paginiPythagorean Theorem WorksheetJames ChanÎncă nu există evaluări

- Egt Margen From The Best ArticalDocument6 paginiEgt Margen From The Best ArticalakeelÎncă nu există evaluări

- By This Axe I Rule!Document15 paginiBy This Axe I Rule!storm0% (1)

- Bolt Action Italian Painting GuideDocument7 paginiBolt Action Italian Painting GuideTirmcdhol100% (2)

- Upaam 1135891 202105060749199700Document18 paginiUpaam 1135891 202105060749199700Kartik KapoorÎncă nu există evaluări

- Adaptive Cruise ControlDocument5 paginiAdaptive Cruise ControlIJIRSTÎncă nu există evaluări

- Disectie AnatomieDocument908 paginiDisectie AnatomieMircea SimionÎncă nu există evaluări

- In-Service Welding of Pipelines Industry Action PlanDocument13 paginiIn-Service Welding of Pipelines Industry Action Planعزت عبد المنعم100% (1)

- 9701 w09 QP 21Document12 pagini9701 w09 QP 21Hubbak KhanÎncă nu există evaluări

- Bahir Dar University BIT: Faculity of Mechanical and Industrial EngineeringDocument13 paginiBahir Dar University BIT: Faculity of Mechanical and Industrial Engineeringfraol girmaÎncă nu există evaluări

- IPC's 2 Edition of Guidance Manual For Herbs and Herbal Products Monographs ReleasedDocument1 paginăIPC's 2 Edition of Guidance Manual For Herbs and Herbal Products Monographs ReleasedRakshaÎncă nu există evaluări

- ChipmunkDocument19 paginiChipmunkema.nemec13Încă nu există evaluări

- Earth Science (Metamorphic Rocks)Document8 paginiEarth Science (Metamorphic Rocks)MA. ALEXIS LAURENÎncă nu există evaluări

- Aircraft Design Course PhillStocking 4.2Document48 paginiAircraft Design Course PhillStocking 4.2ugurugur1982Încă nu există evaluări

- 4 5803133100506483687Document245 pagini4 5803133100506483687Malik HamidÎncă nu există evaluări

- Sudip Praposal - 1Document20 paginiSudip Praposal - 1Usha BbattaÎncă nu există evaluări

- c083c282a43655ec69532f2704c3993aDocument12 paginic083c282a43655ec69532f2704c3993aAneilRandyRamdialÎncă nu există evaluări

- Aluminium Alloy - Wikipedia, The Free EncyclopediaDocument12 paginiAluminium Alloy - Wikipedia, The Free EncyclopediaAshishJoshi100% (1)

- Guidelines For The Management of Brain InjuryDocument26 paginiGuidelines For The Management of Brain InjuryfathaÎncă nu există evaluări

- Binder 3 of 4 Dec-2018Document1.169 paginiBinder 3 of 4 Dec-2018Anonymous OEmUQuÎncă nu există evaluări

- Armor MagazineDocument32 paginiArmor Magazine"Rufus"100% (1)

- Moses ManualDocument455 paginiMoses ManualDadypeesÎncă nu există evaluări

- Lc420euf Sda1 LGDocument41 paginiLc420euf Sda1 LGjavierÎncă nu există evaluări

- Energy Transfer in Cell During Exercise and Oxygen Metabolism and Transport - PalakDocument85 paginiEnergy Transfer in Cell During Exercise and Oxygen Metabolism and Transport - Palakpalooo4Încă nu există evaluări

- L GH Catalog PullingDocument60 paginiL GH Catalog PullingLuis LuperdiÎncă nu există evaluări

- History of Flash Part - 2Document7 paginiHistory of Flash Part - 2YOGESHWER NATH SINGHÎncă nu există evaluări

- Abdominal Examination OSCE GuideDocument30 paginiAbdominal Examination OSCE Guideزياد سعيدÎncă nu există evaluări