Documente Academic

Documente Profesional

Documente Cultură

Carbon Film Resistors: NCF Series

Încărcat de

nica_florin87Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Carbon Film Resistors: NCF Series

Încărcat de

nica_florin87Drepturi de autor:

Formate disponibile

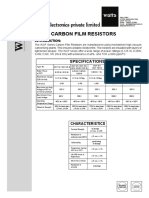

Carbon Film Resistors

FEATURES

NCF Series

ECONOMICALLY PRICED FOR COMMERCIAL AND INDUSTRIAL APPLICATIONS WIDE SELECTION OF POWER RATINGS AND RESISTANCE VALUES EIA COLOR CODING RESISTANT TO INDUSTRIAL SOLVENTS AVAILABLE ON TAPE AND REEL FOR AUTOMATIC INSERTION AND BULK PACK FOR SMALLER PRODUCTION RUNS NEW REDUCED SIZES AT HIGHER POWER RATINGS includes all homogeneous materials 5% TOLERANCE STANDARD

RoHS Compliant

STANDARD TYPES, RATINGS AND AVAILABILITY

*See Part Number System for Details

Type NCF25R NCF25 NCF50 NCF50R NCF100 NCF200 Power Rating at 70C 0.25W 0.25W 0.50W 0.50W 1.0W 2.0W Max. Working Voltage at 70C 250V 250V 350V 350V 500V 750V Max. Overload Voltage at 70C 500V 500V 700V 700V 1000V 1500V Resistance Range 5% (J) Tol. 1.0~10Meg 0.5~10Meg 1.0~10Meg 1.0~10Meg 1.0~10Meg 1.0~10Meg Resistance Value Availability E-24 E-24 E-24 E-24 E-24 E-24

PERFORMANCE CHARACTERISTICS

Requirements Performance Test Method & Conditions Operating Temperature Range -55 ~ +155C (derated above +70C - see chart) JIS C5202 MIL-R-10509F (ppm/C) 0.25W & Over NCF25R 0 ~ -450 <100K <22K Temperature 5.2 0 ~ -700 Coefficient 110K ~ 1meg 24K ~ 470K 4.6.12 1- to = 80C (ppm/C) 0 ~ -1000 1.1meg ~ 2.2meg 510K ~ 2.2meg 0 ~ -1300 2.4meg ~ 10meg 2.2meg ~ 10meg (NCF25R) 0.25W & Over (V/V) 0.1 0.5 ~ 10K JIS C5202 5.9 0.3 1.0 ~ 10K 11 ~ 91K Noise (V/V) Method II 0.5 11 ~ 91K 100K ~ 1meg 1.0 100K ~ 10meg 1.1meg ~ 10meg Short Time Overload 5.5 Cond. A 4.6.6 R < (1%+0.05) Temperature Cycling 7.4-55C/+85C 4.6.4 R < (0.5%+0.05) Soldering Effect 6.4 350C 3 sec. 4.6.10 R < (1%+0.05) Vibration 6.3 Cond. A 4.6.16 R < (0.5%+0.05) R > 100K R < 5% Moisture 7.9 40C 4.6.11 Resistance 90-95%RH 1000hrs R < 100K R < (3%+0.05) R > 100K 7.10 R < 3% Load Life 4.6.13 R < 100k 70C 1000hrs R < (3%+0.05)

* Maximum allowable continuous voltage (Vdc or rms) for all resistors is the lower of the two values: MAXIMUM WORKING VOLTAGE as specified, or Power rating (WATTS x Resistance (OHMS)

Derating Curve

100 PERCENTAGE RATED LOAD 80 50 40 20 0 20 40 60 80 100 120 140 160 180 155

70oC

AMBIENT TEMPERATURE (oC)

60

NIC COMPONENTS CORP.

www.niccomp.com

www.lowESR.com

www.RFpassives.com

www.SMTmagnetics.com

Carbon Film Resistors

DIMENSIONS (mm)

Type NCF25R NCF25 NCF50 NCF50R NCF100 NCF200 D 1.8 0.2 2.5 0.5 3.5 0.5 2.3 0.5 4.5 0.5 5.5 0.5 L 3.3 0.4 6.3 0.5 9.0 0.5 6.5 0.5 11.0 0.5 15.0 0.5 d 0.05 0.45 0.56 0.65 0.56 0.80 0.80

d

NCF Series

25 Min.

25 Min.

COLOR CODING

Color Black Brown Red Orange Yellow Green Blue Violet Grey White Gold Silver Significant Figure 1st 2nd 3rd 0 0 0 1 1 1 2 2 2 3 3 3 4 4 4 5 5 5 6 6 6 7 7 7 8 8 8 9 9 9 Multiplier Tolerance 1 10 F (1%) 100 G (2%) 1,000 10,000 100,00 D 0.5%) 1,000,000 C (0.25%) 10,000,000 B (0.1%) 0.1 J (5%) 0.01 K (10%)

SIGNIFICANT VALUES OF NOMINAL RESISTANCE E-24 5% (J)

1.0 1.1 1.2 1.3 1.5 1.6 1.8 2.0 2.2 2.4 2.7 3.0 3.3 3.6 3.9 4.3 4.7 5.1 5.6 6.2 6.8 7.5 8.2 9.1

PART NUMBER SYSTEM

NCF 25 J 103 TR F

RoHS compliant parts TR = Tape and Reel Resistance Code: First 2 digits are significant, 3rd digit is multiplier, R indicates decimal on values below 10 OHMS Tolerance Code: G = 2% (Opt.) J = 5% STD. Power Rating (Wattage Code) 25 = .25W 50 = .50W 25R = .25W 50R = .50W Series 100 = 1 WATT 200 = 2WATT

CARBON FILM

PACKAGING & REEL QUANTITIES Tape and Reel - 5K NCF25R, 25 and 50R 2.5K NCF50 2K NCF100 1K for NCF200

Zero-Ohm Resistors

FEATURES STANDARD 1/8 WATT AND 1/4 WATT SIZES FOR JUMPERS OR CROSSOVERS ON PCBS TAPE AND REEL FOR AUTOMATIC INSERTION SINGLE BLACK BAND INDICATES ZERO RESISTANCE SPECIFICATIONS OPERATING TEMPERATURE RANGE: 55OC to +155OC RESISTANCE: 0.01 OHM or less CURRENT RATING: 2.5 AMPS (55OC to +70OC) DERATED GRAPH BELOW

ZERO OHM RESISTORS CURRENT RATING OVER TEMPERATURE NZO25R & NZO25 PARTS. 2.5AMP 2.0AMP 1.5AMP 1.0AMP 0.5AMP

NZO Series

d

25 Min.

25 Min.

DIMENSIONS (mm)

Type NZO25R NZO25 D 1.8 0.1 2.3 0.2

L 3.2 0.2 6.5 0.5

d 0.05 0.5 0.6

PART NUMBER SYSTEM

NZO 25 TR F

RoHS compliant TR = Tape and Reel

-55OC

-25OC

O 0OC +25OC +50OC +75OC +100OC+125OC +155 C

Size: 25R = 1/8W Size 25 = 1/4W Size Series

NIC COMPONENTS CORP.

www.niccomp.com

www.lowESR.com

www.RFpassives.com

www.SMTmagnetics.com

61

Resistor Taping Specications & Mechanical Characteristics

TAPE TAPE DIMENSIONS (mm)

Power Rating (Wattage)

B

A 52 1.0 52 1.0 52 1.0 52.4 1.5 63.5 1.5 52.4 1.5 63.5 1.5

B 5 0.5 5 0.5 5 0.5 5 0.6 5 0.6 10 1.0

C 6 0.3 6 0.3 6 0.3 6 0.3 6 0.3

D max. 0.6 0.6 0.6 0.6 0.6

E max. 1.2 1.2 1.2 1.2 1.2

1/8W 1/4W 1/2W 1W

E

2W

REEL DIMENSIONS (mm)

Power Rating A max. B C ref. D max. E max F 1.0 1/8W ~ 2W 40 ~ 100 15 60 16 312 53 3W 70 10 14.5

REEL

Label C Recess Depth B

F Arbor Hole Dia. E Hub Recess I.D.

MECHANICAL CHARACTERISTICS

LEAD PULL TEST The lead wire shall withstand steady pull of the following weight axially to the lead wire for the minimum period of 10 seconds without any breakage or damage:

Nom. Lead Diameter Steady Weight 0.4mm 1.0Kgs. 0.5mm 1.0Kgs. 0.6mm 1.5Kgs 0.7mm 2.0Kgs. 0.8mm & over 2.5Kgs.

LEAD BEND TEST The lead wire shall withstand minimum 4 bends of 90o rotation without any breakage or damage, when the resistor is placed in a vertical position and is applied with a weight of 0.5Kgs for 0.4 - 0.5omm or 1.1Kgs for 0.6omm and over lead wire. SOLDERABILITY The lead wire is immersed into 10% methanol or isopropyl alcohol of rosin by weight for a period of 2 0.5 seconds. Then, it shall be dipped into molten solder melted at 230 5oC for a period of 5 1 seconds approximately 1.5mm from the body of the resistor. A new adhering coating of solder shall cover minimum 95% of the surface being dipped into solder. RESISTANCE TO CLEANING SOLVENTS Color coating or marking shall remain legible after cleaning by solvents such as isopropyl alcohol, trichloroethylene, freon TF/TAX, xyliene etc., in form of liquid or gas.

72

NIC COMPONENTS CORP. www.niccomp.com

www.lowESR.com

www.RFpassives.com

www.SMTmagnetics.com

S-ar putea să vă placă și

- Newnes Circuit Calculations Pocket Book: with Computer ProgramsDe la EverandNewnes Circuit Calculations Pocket Book: with Computer ProgramsÎncă nu există evaluări

- NIC Components NCM SeriesDocument2 paginiNIC Components NCM SeriesNICCompÎncă nu există evaluări

- NIC Components NMR SeriesDocument2 paginiNIC Components NMR SeriesNICCompÎncă nu există evaluări

- Capacitor Selection Technical NoteDocument4 paginiCapacitor Selection Technical NoteSagarÎncă nu există evaluări

- Type CRGP Series: SMD Precision Pulse Thick Film Chip ResistorDocument10 paginiType CRGP Series: SMD Precision Pulse Thick Film Chip Resistorm3y54mÎncă nu există evaluări

- NIC Components NEXT SeriesDocument1 paginăNIC Components NEXT SeriesNICCompÎncă nu există evaluări

- Film Resistors GuideDocument1 paginăFilm Resistors GuideGeorge RibeiroÎncă nu există evaluări

- NIC Components NSRZ SeriesDocument4 paginiNIC Components NSRZ SeriesNICCompÎncă nu există evaluări

- MULTILAYER CERAMIC CAPACITORS EPOXY COATED RADIAL TYPEDocument3 paginiMULTILAYER CERAMIC CAPACITORS EPOXY COATED RADIAL TYPEJosé Vicente GarridoÎncă nu există evaluări

- NIC Components NEDR SeriesDocument3 paginiNIC Components NEDR SeriesNICCompÎncă nu există evaluări

- NIC Components NMC High CV SeriesDocument4 paginiNIC Components NMC High CV SeriesNICCompÎncă nu există evaluări

- NIC Components NRE-LW SeriesDocument5 paginiNIC Components NRE-LW SeriesNICCompÎncă nu există evaluări

- BZX55C Series Zener Diode Voltage Range and FeaturesDocument4 paginiBZX55C Series Zener Diode Voltage Range and FeaturesElio JimenezÎncă nu există evaluări

- C3 Catalog CE Miniatura ElraDocument3 paginiC3 Catalog CE Miniatura ElraSneezy DwarfÎncă nu există evaluări

- NIC Components NRE-HDocument6 paginiNIC Components NRE-HNICCompÎncă nu există evaluări

- NIC Components NCD Class II & III SeriesDocument3 paginiNIC Components NCD Class II & III SeriesNICCompÎncă nu există evaluări

- NIC Components NEDL SeriesDocument3 paginiNIC Components NEDL SeriesNICCompÎncă nu există evaluări

- Surface Mount Aluminum Electrolytic Capacitors: NACE SeriesDocument5 paginiSurface Mount Aluminum Electrolytic Capacitors: NACE SeriesNICCompÎncă nu există evaluări

- NIC Components NRE-LX SeriesDocument6 paginiNIC Components NRE-LX SeriesNICCompÎncă nu există evaluări

- SBSM Data SheetDocument4 paginiSBSM Data SheetAlex JonesÎncă nu există evaluări

- NIC Components NRWY SeriesDocument8 paginiNIC Components NRWY SeriesNICCompÎncă nu există evaluări

- General Type: Metal Film ResistorsDocument3 paginiGeneral Type: Metal Film ResistorsKirill ErokhinÎncă nu există evaluări

- NIC Components NMC Y5V SeriesDocument2 paginiNIC Components NMC Y5V SeriesNICCompÎncă nu există evaluări

- NIC Components NRE-HS SeriesDocument6 paginiNIC Components NRE-HS SeriesNICCompÎncă nu există evaluări

- NIC Components NACS SeriesDocument3 paginiNIC Components NACS SeriesNICCompÎncă nu există evaluări

- SERIES - Lead Terminal: FeaturesDocument4 paginiSERIES - Lead Terminal: FeaturesVenu Gopal Rao AggressÎncă nu există evaluări

- NIC Components NRWS SeriesDocument6 paginiNIC Components NRWS SeriesNICCompÎncă nu există evaluări

- NIC Components NAWP SeriesDocument3 paginiNIC Components NAWP SeriesNICCompÎncă nu există evaluări

- NIC Components NCMA SeriesDocument2 paginiNIC Components NCMA SeriesNICCompÎncă nu există evaluări

- Carbon Film / Metal Film Resistors: ResistorDocument5 paginiCarbon Film / Metal Film Resistors: ResistorSanjay BoregowdaÎncă nu există evaluări

- Res lvk-3082595Document4 paginiRes lvk-3082595f4bxwÎncă nu există evaluări

- Capa Panasonic Low EsrDocument5 paginiCapa Panasonic Low EsrClovis APOVOÎncă nu există evaluări

- NIC Components NCSP SeriesDocument2 paginiNIC Components NCSP SeriesNICCompÎncă nu există evaluări

- NIC Components NSPE-H SeriesDocument3 paginiNIC Components NSPE-H SeriesNICCompÎncă nu există evaluări

- NIC Components NMC NPO SeriesDocument3 paginiNIC Components NMC NPO SeriesNICCompÎncă nu există evaluări

- 01 EBG Series PCS 2019Document1 pagină01 EBG Series PCS 2019Islam El-saiedÎncă nu există evaluări

- Componete ElectronicoDocument5 paginiComponete ElectronicoStuxnetÎncă nu există evaluări

- NIC Components NAWE SeriesDocument4 paginiNIC Components NAWE SeriesNICCompÎncă nu există evaluări

- Honeywell Sensing Airflow Sensors Awm700 Series Datasheet 32301627 B en PDFDocument7 paginiHoneywell Sensing Airflow Sensors Awm700 Series Datasheet 32301627 B en PDFAlejandro Palomino AmaroÎncă nu există evaluări

- Leaded Metal Film ResistorsDocument2 paginiLeaded Metal Film ResistorsAsma SabriÎncă nu există evaluări

- Sfr16S/25/25H: Vishay BccomponentsDocument11 paginiSfr16S/25/25H: Vishay BccomponentsMuhammad BilalÎncă nu există evaluări

- TE SeriesDocument8 paginiTE SeriesANIL ŞENÎncă nu există evaluări

- NIC Components NACEN SeriesDocument3 paginiNIC Components NACEN SeriesNICCompÎncă nu există evaluări

- NIC Components NRE-L SeriesDocument5 paginiNIC Components NRE-L SeriesNICCompÎncă nu există evaluări

- NIC Components NTR-C SeriesDocument4 paginiNIC Components NTR-C SeriesNICCompÎncă nu există evaluări

- 2017 Through Hole Resistor Catalogue June 2017 PDFDocument70 pagini2017 Through Hole Resistor Catalogue June 2017 PDFAjay YashÎncă nu există evaluări

- Kendeil PDFDocument7 paginiKendeil PDFBrunophb2012Încă nu există evaluări

- Metallized Polyester Film Capacitor MMX: FeaturesDocument4 paginiMetallized Polyester Film Capacitor MMX: FeaturesMarcos Antonio SantanderÎncă nu există evaluări

- Carbon Film ResistorsDocument2 paginiCarbon Film ResistorsGopichandÎncă nu există evaluări

- High Voltage MLC Chips: For 600V To 5000V ApplicationsDocument2 paginiHigh Voltage MLC Chips: For 600V To 5000V ApplicationsJoseph Abou El OulaÎncă nu există evaluări

- RDE Vitrohm PDFDocument2 paginiRDE Vitrohm PDFtecnico4 tecnico4Încă nu există evaluări

- SR Passives T910Document1 paginăSR Passives T910Gato KurroÎncă nu există evaluări

- RDE Vitrohm PDFDocument2 paginiRDE Vitrohm PDFtecnico4 tecnico4Încă nu există evaluări

- NIC Components NRE-HW SeriesDocument6 paginiNIC Components NRE-HW SeriesNICCompÎncă nu există evaluări

- NIC Components NSPU SeriesDocument2 paginiNIC Components NSPU SeriesNICCompÎncă nu există evaluări

- NIC Components NCSR SeriesDocument5 paginiNIC Components NCSR SeriesNICCompÎncă nu există evaluări

- MWR CapsDocument4 paginiMWR CapsMartien BakkerÎncă nu există evaluări

- NIC Components NSTL SeriesDocument2 paginiNIC Components NSTL SeriesNICCompÎncă nu există evaluări

- NIC Components NMC-L SeriesDocument4 paginiNIC Components NMC-L SeriesNICCompÎncă nu există evaluări

- Jumper Wires JW: DimensionsDocument1 paginăJumper Wires JW: DimensionsCaptain AmericaÎncă nu există evaluări

- Surface Mount Aluminum Electrolytic Capacitors: NACE SeriesDocument5 paginiSurface Mount Aluminum Electrolytic Capacitors: NACE SeriesNICCompÎncă nu există evaluări

- Surface Mount Aluminum Electrolytic Capacitors: NACE SeriesDocument5 paginiSurface Mount Aluminum Electrolytic Capacitors: NACE SeriesNICCompÎncă nu există evaluări

- NIC Component Series NPIS - LSDocument11 paginiNIC Component Series NPIS - LSNICCompÎncă nu există evaluări

- NIC Components NCSP SeriesDocument2 paginiNIC Components NCSP SeriesNICCompÎncă nu există evaluări

- NIC Component Series NTC-R NTP-RDocument3 paginiNIC Component Series NTC-R NTP-RNICCompÎncă nu există evaluări

- Technical Support: TPMG@Document1 paginăTechnical Support: TPMG@NICCompÎncă nu există evaluări

- RoHS Makes Impact On Circuit DesignDocument3 paginiRoHS Makes Impact On Circuit DesignNICCompÎncă nu există evaluări

- NIC Component Series NACKADocument4 paginiNIC Component Series NACKANICCompÎncă nu există evaluări

- HTTP:WWW - Niccomp.com Technical Inquiries: TPMG@Document2 paginiHTTP:WWW - Niccomp.com Technical Inquiries: TPMG@NICCompÎncă nu există evaluări

- NIC Component Series NTIDocument4 paginiNIC Component Series NTINICCompÎncă nu există evaluări

- NIC Press Release NSPE x0210Document2 paginiNIC Press Release NSPE x0210NICCompÎncă nu există evaluări

- NIC Components Corp.Document4 paginiNIC Components Corp.NICCompÎncă nu există evaluări

- Web Exclusive: An Introduction To Low ESRDocument3 paginiWeb Exclusive: An Introduction To Low ESRNICCompÎncă nu există evaluări

- NIC Components NRSNE SeriesDocument2 paginiNIC Components NRSNE SeriesNICCompÎncă nu există evaluări

- NIC Components NACH SeriesDocument3 paginiNIC Components NACH SeriesNICCompÎncă nu există evaluări

- NIC Components NSPE-Y SeriesDocument2 paginiNIC Components NSPE-Y SeriesNICCompÎncă nu există evaluări

- NIC Components NSPE-S SeriesDocument3 paginiNIC Components NSPE-S SeriesNICCompÎncă nu există evaluări

- NIC Components NCB-H SeriesDocument3 paginiNIC Components NCB-H SeriesNICCompÎncă nu există evaluări

- NIC Components NACH SeriesDocument3 paginiNIC Components NACH SeriesNICCompÎncă nu există evaluări

- NIC Components NRE-WY SeriesDocument7 paginiNIC Components NRE-WY SeriesNICCompÎncă nu există evaluări

- NIC Components NRE-HS SeriesDocument6 paginiNIC Components NRE-HS SeriesNICCompÎncă nu există evaluări

- NIC Components NMC-Q SeriesDocument7 paginiNIC Components NMC-Q SeriesNICCompÎncă nu există evaluări

- NIC Components NACEN SeriesDocument3 paginiNIC Components NACEN SeriesNICCompÎncă nu există evaluări

- NIC Components Current Sensing Resistor GuideDocument1 paginăNIC Components Current Sensing Resistor GuideNICCompÎncă nu există evaluări

- NIC Components NSPE-U SeriesDocument2 paginiNIC Components NSPE-U SeriesNICComp100% (2)

- NIC Components NSPE-H SeriesDocument3 paginiNIC Components NSPE-H SeriesNICCompÎncă nu există evaluări

- NIC Components NSPE-T SeriesDocument3 paginiNIC Components NSPE-T SeriesNICComp100% (2)

- Guide To Hand SolderingDocument1 paginăGuide To Hand SolderingNICComp100% (1)

- NIC Components NMC-H X2/Y3 SeriesDocument2 paginiNIC Components NMC-H X2/Y3 SeriesNICCompÎncă nu există evaluări

- NIC Components NPIM - C SeriesDocument6 paginiNIC Components NPIM - C SeriesNICCompÎncă nu există evaluări