Documente Academic

Documente Profesional

Documente Cultură

Ijst 120605

Încărcat de

srinathgudur11Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Ijst 120605

Încărcat de

srinathgudur11Drepturi de autor:

Formate disponibile

International Journal of Science & Technology www.ijst.co.

in

ISSN (online): 2250-141X Vol. 2 Issue 3, June 2012

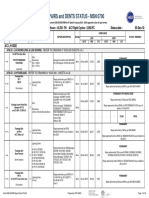

Automatic Control of Temperature and Level of CSTR Using PLC and SCADA

Bhagyashri R. Bhagwat #1, Prof. Vinayak G. Asutkar*2 # Department of Instrumentation Engineering, Shri .Guru Gobind Singhji Institute Of Engineering And Technology Nanded-431606 1 bhagyashri3086@gmail.com Abstract This paper presents an automatic control of temperature and level of Continues Stirred Tank Reactor (CSTR) using PLC and SCADA. The CSTR is heated using heating-coil and its temperature and level are measured by RTD and float type level sensor respectively. The accurate control of temperature and level are the realistic feature of this system and balances the process. Automation required gaining the complete control of manufacturing process to achieve consistency in manufacturing with increased productivity by shortening manufacturing time. In this paper we consider both Batch and Continues process control using PLC and SCADA. The PLC and SCADA control the process parameters with good accuracy and results are found to be satisfactorily. This is a simple automated process and can be applied in many mixing processes used in industries. Keywords CSTR, PLC & SCADA HARDWARE

I.

Fig. 1. Hardware Setup This figure shows the hardware of the process. There are no disturbances in the process. It works continuous as well as batch process which we will require.

II .PROCESS The process consists of mixing of liquid and controlling the temperature and level of the CSTR. Process takes following steps to complete. Step-1: When start button is pushed pump1 is I . SCOPE OF WORK ON up to the high level of Tank1,then heater1 is A work done in this paper can be divided ON and temperature is measured using temperature into several parts. First of all, the programmable transmitter up to the desired set point. logic controller (PLC) , Supervisory Control And Step-2: When temperature reaches up to the Data Acquisition (SCADA) and its applications desired temperature of tank1 solenoid valve1 is ON have to be studied on Allen Bradley Micrologix up to the high level of Tank2. 1200 PLC. Step-3: As soon as the low level reaches in tank2, Next, the ladder diagram has to be constructed to pump2 is on up to the high level of tank 2 the desired system, and for developing SCADA Step-4: When high level is reached in tank2, mimics RS View32 SCADA software used. Then, heater of tank2 is ON and temperature is measured the system need to be tested and modify the ladder using temperature transmitter up to the desired set diagram to the hardware point. Step-5: The Transmitter detects the Font of Entire Document temperature of both tanks and float type

Copyright IJST 2011

35

International Journal of Science & Technology www.ijst.co.in

ISSN (online): 2250-141X Vol. 2 Issue 3, June 2012

level sensor senses the levels of tanks and we get VI. RESULTS the final product. This are real time results . And again next process is started. Thus the batch and the continues process carried out. This process For process 1 is done in industrial level also Set point at 35 C: Temperature measurement between Low Level 1 and High Level 1 III. FLOW CHART

Push Button Start Start system Pump1 On Check level

High Level 1 Pump 1 Stop Heater 1 ON Stirrer 1 ON SV1 ON Temp. Sensor 1.checks temp

If Temp=50C

Pu sh Button Start

Heater 1 On Stirred On SV1 off Chemical Flow To Tank 2 Low level reached T1 Pump 2 ON Check Level of T 2 High Level 2

Pump 1 off

Start system Pump1 On Check level

High Level 1 Pump 1 Stop Heater 1 ON Stirrer 1 ON SV1 ON Temp. Sensor 1.checks temp

Fig 2.1: Temperature at 31 C for Tank 1

If temp =50 0c Temp=50C Pump 1 off Heater 1 On Stirred On SV1 off

Chemical Flow To Tank 2

Low level reached T1

Pump 2 ON

Fig 2.2 :Temperature at 33 C for Tank 1

Check Level of T 2 High Level 2

Pump 2 off Heater 2 On Stirred 2On SV2 off

Temp. Sensor 2 checks Temp.

If Temp=75C

Pump 2 off Heater 2 Off Stirred 2Off SV2 On

Fig 2.3: Temperature at 36 C for Tank 1 For process 2 Results: Set point at 40 C

Product Flow To reservoir

Low level 2 reached of T2

Stop system

Copyright IJST 2011

36

International Journal of Science & Technology www.ijst.co.in

ISSN (online): 2250-141X Vol. 2 Issue 3, June 2012

reliable and versatile system for temperature and level control. IV. REFERENCES [1] A Continuous Stirred Tank Heater Simulation Model With Applications, Nina F. Thornhill Sachin C. Patwardhan , Sirish L. Shah Centre for Process Systems Engineering, Department of Chemical Engineering, Imperial College London, London SW7 2AZ, UK Department of Chemical Engineering, I.I.T. Bombay, Powai, Mumbai 400 076, India Department of Chemical and Materials Engineering, University of Alberta, Edmonton, Canada T6G 2G6 Received 18 December 2006;recived in revised from 2july 2007;accepted 11July 2007. [2] Madhuchandan Mitra, Samarjit Sen. Gupta. Programmable Logic Controller and Industrial Automation An Introduction. [3] Keith Stouffer, Joe Falco, Karen Kent. Guide to Supervisory Control and Data Acquisition (SCADA) and Industrial Control Systems security. [4] Gary Dunning. Introduction to Programmable Logic Controllers 2nd edition. [5] D.E.Seborg, T.E.Edgar, Process dynamic And Control, second ed., John Wiley, Hoboken, NJ, 2004. [6] M.L.Luyben, B.D.Tyreus, W.L.luyben, Plant wide control design procedure ,AICh Journal 43(1997)3161-3174. [7] J.J.Downs, E.F.Vogal, A plant wide Industrial Process control Problem, computer and Chemical Engineering 17(1993),245-255. [8] L.A.Bryan, E.A.Bryanprogrammable controllers theory and implementation second ed..

Fig 2.4: Temperature at 32C for tank 2

Fig 2.5 : Temperature at 57C for Tank 2 The systems can successfully gave results without problem regarding the controller and software performance. The system graphics showed a result with too minor faults in system immediately indicates on the graphic display by using the PLC and SCADA communication. All the figures 2.1 to 2.5 shows the linear graph of the process. Using the RTD Temperature sensor. From that graph we can control the temperature and level using automation. IV. CONCLUSION In this paper we have discussed the realization of PLC and SCADA based industrial control system for CSTR . And can be concluded that the temperature and level control using Automation. This work can also be extended by realizing the same using DCS and Matlab .The PLC carried out the sequential batch process and continuous process control. The Allen Bradley PLC/SCADA and the logic circuitry provide a safe,

Copyright IJST 2011

37

S-ar putea să vă placă și

- Advanced Temperature Measurement and Control, Second EditionDe la EverandAdvanced Temperature Measurement and Control, Second EditionÎncă nu există evaluări

- Automatic Controls for Heating and Air Conditioning: Principles and ApplicationsDe la EverandAutomatic Controls for Heating and Air Conditioning: Principles and ApplicationsEvaluare: 4 din 5 stele4/5 (2)

- Pangya 2018 J. Phys. Conf. Ser. 1144 012160Document6 paginiPangya 2018 J. Phys. Conf. Ser. 1144 012160KarwanBarzngyÎncă nu există evaluări

- Temperature Control Lab Report MuzDocument18 paginiTemperature Control Lab Report MuzAhmad Muzammil75% (8)

- Lab Report Heat ExchangerDocument17 paginiLab Report Heat ExchangerFirdaus Zainal AbidinÎncă nu există evaluări

- Hvac ExperimentDocument9 paginiHvac ExperimentShadan MuÎncă nu există evaluări

- RIDWAN'S COMPLETE PROJECT (CHPT 1-5) - CorrectedDocument22 paginiRIDWAN'S COMPLETE PROJECT (CHPT 1-5) - CorrectedRidwanÎncă nu există evaluări

- 10 11648 J Acis 20140201 11 PDFDocument5 pagini10 11648 J Acis 20140201 11 PDFEric DiazÎncă nu există evaluări

- Temperature Control Hatchery Incubator Using Microcontroller PDFDocument7 paginiTemperature Control Hatchery Incubator Using Microcontroller PDFCuong MaiÎncă nu există evaluări

- LM35 PLC PDFDocument5 paginiLM35 PLC PDFsawanÎncă nu există evaluări

- 10 11648 J Acis 20140201 11 PDFDocument5 pagini10 11648 J Acis 20140201 11 PDFwsa wsaÎncă nu există evaluări

- Sensor and Actuator Temperature Control SystemDocument11 paginiSensor and Actuator Temperature Control SystemAnang MarufÎncă nu există evaluări

- PID Based Temperature Control of A Plant Heat Exchanger System-239Document5 paginiPID Based Temperature Control of A Plant Heat Exchanger System-239Mark Anthony CaroÎncă nu există evaluări

- Control of Boiler Operation Using PLC - SCADADocument9 paginiControl of Boiler Operation Using PLC - SCADARoshan RaiÎncă nu există evaluări

- Semester 4 Lab 2 Experiment 1Document8 paginiSemester 4 Lab 2 Experiment 1Chan Chun YuanÎncă nu există evaluări

- Temperature Control Trainer: Experiment No: 04Document3 paginiTemperature Control Trainer: Experiment No: 04Musa KhanÎncă nu există evaluări

- Thermo KitaDocument4 paginiThermo KitaJohn SafuanÎncă nu există evaluări

- Project Temperature Sensor Using Pid Controller: Linear Control Systems (Lab)Document6 paginiProject Temperature Sensor Using Pid Controller: Linear Control Systems (Lab)Arkam AliÎncă nu există evaluări

- Conclusion and Recommendation Heat ExchangersDocument2 paginiConclusion and Recommendation Heat ExchangersAzura Bahrudin0% (1)

- Bytronic SistemDocument6 paginiBytronic SistemSedat IriçÎncă nu există evaluări

- Heat Exchanger2Document5 paginiHeat Exchanger2Motaz Ahmad AmeenÎncă nu există evaluări

- Project ProgressDocument19 paginiProject ProgressJawaharGanesh99Încă nu există evaluări

- Lab 1 - Open Loop Temp Control - SignedDocument10 paginiLab 1 - Open Loop Temp Control - SignedShashitharan PonnambalanÎncă nu există evaluări

- CPB30004 Process Dynamics and Control Experiment 5: Heat Exchanger Process Control Lab ReportDocument24 paginiCPB30004 Process Dynamics and Control Experiment 5: Heat Exchanger Process Control Lab ReportSiti Hajar Mohamed100% (1)

- Heat Exchanger ExampleDocument7 paginiHeat Exchanger ExampleBrian MasonÎncă nu există evaluări

- Temperature ControlDocument9 paginiTemperature ControlMauricio López NúñezÎncă nu există evaluări

- SynopsisDocument6 paginiSynopsisPooja GÎncă nu există evaluări

- Computer Controlled Heat Conduction Unit, With SCADA and PID ControlDocument15 paginiComputer Controlled Heat Conduction Unit, With SCADA and PID Controlmohamadreza1368Încă nu există evaluări

- Fluid Mechanics ManualDocument11 paginiFluid Mechanics ManualDanish IlyasÎncă nu există evaluări

- Industrial Temp ControlDocument17 paginiIndustrial Temp ControlPooja GÎncă nu există evaluări

- Introduction To Process InstrumentationDocument15 paginiIntroduction To Process Instrumentationtaufikrezza85Încă nu există evaluări

- Two Tank Non-Interacting Liquid Level SystemDocument9 paginiTwo Tank Non-Interacting Liquid Level SystemHimanshu JatÎncă nu există evaluări

- PHE Control Mechanism PDFDocument6 paginiPHE Control Mechanism PDFNaren VmdÎncă nu există evaluări

- Or As Telecommunications, Water and Waste Control, Energy, Oil and Gas Refining and TransportationDocument5 paginiOr As Telecommunications, Water and Waste Control, Energy, Oil and Gas Refining and TransportationRoshan RaiÎncă nu există evaluări

- PID Control of Heat Exchanger SystemDocument6 paginiPID Control of Heat Exchanger SystemTuấn Anh Nguyễn100% (1)

- Irjet V7i5176Document3 paginiIrjet V7i5176sagarvivek kothapalliÎncă nu există evaluări

- Concepts of Computer Control: Example: Production of Sheet Steel-There Are Various Types of Steel LikeDocument28 paginiConcepts of Computer Control: Example: Production of Sheet Steel-There Are Various Types of Steel LikepratibhahegdeÎncă nu există evaluări

- Feedback Docu ProjectDocument35 paginiFeedback Docu ProjectAnonymous rgNIr9SYÎncă nu există evaluări

- Process Dynamics and Control Experiment 5 Heat Exchanger Process Control Lab ReportDocument25 paginiProcess Dynamics and Control Experiment 5 Heat Exchanger Process Control Lab Reportfareez aqmalÎncă nu există evaluări

- Temperature Measurement of Dynamic ObjectDocument5 paginiTemperature Measurement of Dynamic Objectbelvinthomas8095Încă nu există evaluări

- Water Purification and BottlingDocument47 paginiWater Purification and BottlingAdnan HashmiÎncă nu există evaluări

- Exp 1Document12 paginiExp 1Anonymous T7vjZG4otÎncă nu există evaluări

- PLC Based Sequential Batch Process Control SystemDocument11 paginiPLC Based Sequential Batch Process Control SystemAmol PawarÎncă nu există evaluări

- Modeling and Designing A Control System Using PID Controller & Fuzzy Logic Controller With Matlab/SimulinkDocument24 paginiModeling and Designing A Control System Using PID Controller & Fuzzy Logic Controller With Matlab/SimulinkothmanÎncă nu există evaluări

- App lm35Document11 paginiApp lm35yahya vhsÎncă nu există evaluări

- CnI Problem Statement 1Document1 paginăCnI Problem Statement 1Wonda 005Încă nu există evaluări

- Biochemical Engineering B.SC, University of DebrecenDocument6 paginiBiochemical Engineering B.SC, University of DebrecenArifuzzamanÎncă nu există evaluări

- Aplikasi Sistem Kendali Pid Pada Tangki Pemanas Air Sebagai Teknologi Pemanas Berbasis Mikrokontroler Atmega32Document12 paginiAplikasi Sistem Kendali Pid Pada Tangki Pemanas Air Sebagai Teknologi Pemanas Berbasis Mikrokontroler Atmega32bayu prasetyoÎncă nu există evaluări

- A125703 288 PDFDocument7 paginiA125703 288 PDFTimothy FieldsÎncă nu există evaluări

- Experiment 8: Temperature Control: 8.1 Objective of The ExperimentDocument11 paginiExperiment 8: Temperature Control: 8.1 Objective of The ExperimentHemavathy RtÎncă nu există evaluări

- Temperature Control Water Bath System Using PID ControllerDocument5 paginiTemperature Control Water Bath System Using PID Controllerprapya pokharelÎncă nu există evaluări

- Horizontal Book Rev.E 02.12Document72 paginiHorizontal Book Rev.E 02.12Leonel Losada CardozoÎncă nu există evaluări

- Labview Based PaperDocument5 paginiLabview Based PaperitsmeboovarÎncă nu există evaluări

- Cascaded PID Controller Design For Heating Furnace Temperature ControlDocument8 paginiCascaded PID Controller Design For Heating Furnace Temperature ControlInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- PID Control Implementation in Multiple Input and Multiple Output (MIMO) Water Mixing Tank Via Ziegler-Nichols and Direct Synthesis MethodsDocument5 paginiPID Control Implementation in Multiple Input and Multiple Output (MIMO) Water Mixing Tank Via Ziegler-Nichols and Direct Synthesis MethodsbijejournalÎncă nu există evaluări

- Microcontroller Based Intelligent Temperature Controller For GreenhouseDocument5 paginiMicrocontroller Based Intelligent Temperature Controller For GreenhouseresearchinventyÎncă nu există evaluări

- Kendali Level Air PDFDocument15 paginiKendali Level Air PDFAhmadi Nur IntanÎncă nu există evaluări

- Exp 6 Gas Temperature Process ControlDocument13 paginiExp 6 Gas Temperature Process Controlmohamad ashaziq100% (8)

- The Prediction of Fatigue Life Based On Four Point Bending TestDocument12 paginiThe Prediction of Fatigue Life Based On Four Point Bending TeststrongerstÎncă nu există evaluări

- Journal of Materials Processing Tech. 279 (2020) 116575Document11 paginiJournal of Materials Processing Tech. 279 (2020) 116575srinathgudur11Încă nu există evaluări

- Robotic Additive Manufacturing Along Curved Surface - A Step Towards Free-Form FabricationDocument6 paginiRobotic Additive Manufacturing Along Curved Surface - A Step Towards Free-Form Fabricationsrinathgudur11Încă nu există evaluări

- 1 Basics of X-Ray Powder DiffractionDocument110 pagini1 Basics of X-Ray Powder DiffractionAnonymous Waw8C0qkAAÎncă nu există evaluări

- Vibratory Residual Stress Relieving-A Review: S. N. ShaikhDocument4 paginiVibratory Residual Stress Relieving-A Review: S. N. Shaikhsrinathgudur11Încă nu există evaluări

- Additive Manufacturing LettersDocument8 paginiAdditive Manufacturing Letterssrinathgudur11Încă nu există evaluări

- In-Process Height Displacement Measurement Using Crossed Line Beams For Process Control of Laser Wire DepositionDocument13 paginiIn-Process Height Displacement Measurement Using Crossed Line Beams For Process Control of Laser Wire Depositionsrinathgudur11Încă nu există evaluări

- Cat thermoMETER Infrared enDocument56 paginiCat thermoMETER Infrared ensrinathgudur11Încă nu există evaluări

- Optics and Laser Technology: Full Length ArticleDocument9 paginiOptics and Laser Technology: Full Length Articlesrinathgudur11Încă nu există evaluări

- Recent Special Issues 2011 Computer Aided DesignDocument2 paginiRecent Special Issues 2011 Computer Aided Designsrinathgudur11Încă nu există evaluări

- MTAB Book AllDocument52 paginiMTAB Book AllNaresh Kumar Reddy100% (1)

- Visibility Based Conformal Cooling Channel Generation For Rapid Tooling 2011 Computer Aided DesignDocument16 paginiVisibility Based Conformal Cooling Channel Generation For Rapid Tooling 2011 Computer Aided Designsrinathgudur11Încă nu există evaluări

- A Layers-Overlapping Strategy For Robotic Wire and Arc Additive Manufacturing of Multi-Layer Multi-Bead Components With Homogeneous LayersDocument14 paginiA Layers-Overlapping Strategy For Robotic Wire and Arc Additive Manufacturing of Multi-Layer Multi-Bead Components With Homogeneous Layerssrinathgudur11Încă nu există evaluări

- Editorial Board 2011 Computer Aided DesignDocument1 paginăEditorial Board 2011 Computer Aided Designsrinathgudur11Încă nu există evaluări

- 2017 ME5010 Assgn6Document3 pagini2017 ME5010 Assgn6srinathgudur11Încă nu există evaluări

- Visibility Based Conformal Cooling Channel Generation For Rapid Tooling 2011 Computer Aided DesignDocument18 paginiVisibility Based Conformal Cooling Channel Generation For Rapid Tooling 2011 Computer Aided Designsrinathgudur11Încă nu există evaluări

- Calendar 2011 Computer Aided DesignDocument1 paginăCalendar 2011 Computer Aided Designsrinathgudur11Încă nu există evaluări

- Partial Shape Preserving Splines 2011 Computer Aided DesignDocument16 paginiPartial Shape Preserving Splines 2011 Computer Aided Designsrinathgudur11Încă nu există evaluări

- Designing Functional Beauty Through Additive Manufacturing: Prototyping of Running-Specific Prostheses Using Selective Laser SinteringDocument19 paginiDesigning Functional Beauty Through Additive Manufacturing: Prototyping of Running-Specific Prostheses Using Selective Laser Sinteringsrinathgudur11Încă nu există evaluări

- Recent Special Issues 2011 Computer Aided DesignDocument2 paginiRecent Special Issues 2011 Computer Aided Designsrinathgudur11Încă nu există evaluări

- Visibility Based Conformal Cooling Channel Generation For Rapid Tooling 2011 Computer Aided DesignDocument18 paginiVisibility Based Conformal Cooling Channel Generation For Rapid Tooling 2011 Computer Aided Designsrinathgudur11Încă nu există evaluări

- Indian Institute of Technology Bhilai ME5010/ ME5110 Assignment 5Document1 paginăIndian Institute of Technology Bhilai ME5010/ ME5110 Assignment 5srinathgudur11Încă nu există evaluări

- 3D Welding and Milling: Part II-optimization of The 3D Welding Process Using An Experimental Design ApproachDocument7 pagini3D Welding and Milling: Part II-optimization of The 3D Welding Process Using An Experimental Design Approachsrinathgudur11Încă nu există evaluări

- Time Table MAE Aug-Dec2017 v7Document9 paginiTime Table MAE Aug-Dec2017 v7srinathgudur11Încă nu există evaluări

- Cost Efficient Design and Planning For Additive Manufacturing TechnologiesDocument20 paginiCost Efficient Design and Planning For Additive Manufacturing Technologiessrinathgudur11Încă nu există evaluări

- Ms Subbulakshmi - Deva Devam BhajeDocument1 paginăMs Subbulakshmi - Deva Devam Bhajesrinathgudur11Încă nu există evaluări

- 001 Tedia DoneDocument20 pagini001 Tedia Donesrinathgudur11Încă nu există evaluări

- 009 Aguilera DoneDocument3 pagini009 Aguilera Donesrinathgudur11Încă nu există evaluări

- 006Document12 pagini006srinathgudur11Încă nu există evaluări

- Industrial Automation: David O'Sullivan WWW - Owl.ieDocument33 paginiIndustrial Automation: David O'Sullivan WWW - Owl.ieruby_evangelinÎncă nu există evaluări

- 04 SAMSS 005 Check ValvesDocument9 pagini04 SAMSS 005 Check ValvesShino UlahannanÎncă nu există evaluări

- 09.tracheostomy Management by Speech Language Pathologists in SwedenDocument12 pagini09.tracheostomy Management by Speech Language Pathologists in SwedenCarlonchaCáceresÎncă nu există evaluări

- Food Biotechnology in Ethical PerspectiveDocument340 paginiFood Biotechnology in Ethical Perspectivemojtaba2500100% (2)

- Lc420euf Sda1 LGDocument41 paginiLc420euf Sda1 LGjavierÎncă nu există evaluări

- 1ST SUMMATIVE TEST FOR G10finalDocument2 pagini1ST SUMMATIVE TEST FOR G10finalcherish austriaÎncă nu există evaluări

- Binder 3 of 4 Dec-2018Document1.169 paginiBinder 3 of 4 Dec-2018Anonymous OEmUQuÎncă nu există evaluări

- Sci NB Mod 2 LSN 3Document4 paginiSci NB Mod 2 LSN 3Ramses octavio Rodriguez ocanasÎncă nu există evaluări

- Prawn ProcessingDocument21 paginiPrawn ProcessingKrishnaÎncă nu există evaluări

- Uji Efektivitas Mikroba Rumpun BambuDocument7 paginiUji Efektivitas Mikroba Rumpun BambuUse Real ProjectÎncă nu există evaluări

- Updating - MTO I - Unit 2 ProblemsDocument3 paginiUpdating - MTO I - Unit 2 ProblemsmaheshÎncă nu există evaluări

- L GH Catalog PullingDocument60 paginiL GH Catalog PullingLuis LuperdiÎncă nu există evaluări

- Natural Disasters Vocabulary Exercises Fun Activities Games Icebreakers Oneonone Activiti 42747Document2 paginiNatural Disasters Vocabulary Exercises Fun Activities Games Icebreakers Oneonone Activiti 42747Andrea Tercero VillarroelÎncă nu există evaluări

- Drug Study LidocaineDocument15 paginiDrug Study LidocaineFrancym R. BatengaÎncă nu există evaluări

- Aesculap Saw GD307 - Service ManualDocument16 paginiAesculap Saw GD307 - Service ManualFredi PançiÎncă nu există evaluări

- Chapter Three: 1 - The Coarse Grain SoilsDocument21 paginiChapter Three: 1 - The Coarse Grain SoilsSalih MohayaddinÎncă nu există evaluări

- Marvell 88F37xx Product Brief 20160830Document2 paginiMarvell 88F37xx Product Brief 20160830Sassy FiverÎncă nu există evaluări

- GLP BmsDocument18 paginiGLP BmsDr.Subhashish TripathyÎncă nu există evaluări

- JHS 182Document137 paginiJHS 182harbhajan singhÎncă nu există evaluări

- Exp6.Single Phase Bridge Inverter Using PWMDocument6 paginiExp6.Single Phase Bridge Inverter Using PWMAbdullah MohammedÎncă nu există evaluări

- Chapter 10 - The Mature ErythrocyteDocument55 paginiChapter 10 - The Mature ErythrocyteSultan AlexandruÎncă nu există evaluări

- Moses ManualDocument455 paginiMoses ManualDadypeesÎncă nu există evaluări

- YellowstoneDocument1 paginăYellowstoneOana GalbenuÎncă nu există evaluări

- Abdominal Examination OSCE GuideDocument30 paginiAbdominal Examination OSCE Guideزياد سعيدÎncă nu există evaluări

- Accuity: High Speed Automated 2D & 3D Optical Gauging Single Click Setup and InspectionDocument4 paginiAccuity: High Speed Automated 2D & 3D Optical Gauging Single Click Setup and InspectionAPPLEÎncă nu există evaluări

- Serving North Central Idaho & Southeastern WashingtonDocument12 paginiServing North Central Idaho & Southeastern WashingtonDavid Arndt100% (3)

- Motor CAT C13 AcertDocument3 paginiMotor CAT C13 AcertJosé Gonzalez100% (4)

- MATLAB Fundamentals Quick ReferenceDocument43 paginiMATLAB Fundamentals Quick ReferenceCarlos Manuel Cardoza EspitiaÎncă nu există evaluări

- American University of BeirutDocument21 paginiAmerican University of BeirutWomens Program AssosciationÎncă nu există evaluări

- Shell Gadus: Designed To Do More. Just Like Our Greases - Shell GadusDocument2 paginiShell Gadus: Designed To Do More. Just Like Our Greases - Shell Gadusperi irawanÎncă nu există evaluări

- Adaptive Cruise ControlDocument5 paginiAdaptive Cruise ControlIJIRSTÎncă nu există evaluări