Documente Academic

Documente Profesional

Documente Cultură

Fatty Acids

Încărcat de

Muhammad Agus TianDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Fatty Acids

Încărcat de

Muhammad Agus TianDrepturi de autor:

Formate disponibile

78.

PROFILE ON PRODUCTION OF FATTY ACIDS

78-2

TABLE OF CONTENTS

PAGE

I.

SUMMARY

78-3

II.

PRODUCT DESCRIPTION & APPLICATION

78-3

III.

MARKET STUDY AND PLANT CAPACITY A. MARKET STUDY B. PLANT CAPACITY & PRODUCTION PROGRAMME

78-3 78-3 78-6

IV.

MATERIALS AND INPUTS A. RAW MATERIALS B. UTILITIES

78-6 78-6 78-7

V.

TECHNOLOGY & ENGINEERING A. TECHNOLOGY B. ENGINEERING

78-7 78-7 78-8

VI.

MANPOWER & TRAINING REQUIREMENT A. MANPOWER REQUIREMENT B. TRAINING REQUIREMENT

78-10 78-10 78-10

VII.

FINANCIAL ANALYSIS A. TOTAL INITIAL INVESTMENT COST B. PRODUCTION COST C. FINANCIAL EVALUATION D. ECONOMIC BENEFITS

78-11 78-11 78-12 78-13 78-14

78-3

I.

SUMMARY

This profile envisages the establishment of a plant for the production of fatty acids with a capacity of 6,000 tonnes per annum.

The present demand for the proposed product is estimated at 7,656 per annum. The demand is expected to reach at 26,431 by the year 2025.

The plant will create employment opportunities for 44 persons.

The total investment requirement is estimated at about Birr 15.89 million, out of which Birr 9.54 million is required for plant and machinery.

The project is financially viable with an internal rate of return (IRR) of 27 % and a net present value (NPV) of Birr 12.55 million discounted at 8.5%.

II.

PRODUCT DESCRIPTION AND APPLICATION

Fatty acid is a product manufactured by splitting oils and fats. It is mainly used for the industrial production of soaps. Both saturated (e.g., steric acid) and unsaturated (e.g., oleic acid) fatty acids have long been employed in many industries as both free acids, and more frequently as salts. The salts are used in the manufacture of lubricating greases, and paper sizing. Fatty acids are also important raw materials in the production of higher alcohols and synthetic surfactants (detergents). In the present study, the main use of fatty acids is envisaged to be as a raw materials for the soap industries.

III.

MARKET STUDY AND PLANT CAPACITY

A.

MARKET STUDY

1.

Past Supply and Present Demand

The major application of fatty acids is in the manufacturing of soap. However, even though

78-4 the local soap manufacturing industry is expanding rapidly, the demand for the product is met through import. Table 3.1 shows annual import of fatty acid during the period 2000 to 2006.

Table 3.1 IMPORT OF FATTY ACID ( TONNE)

Year 2000 2001 2002 2003 2004 2005 2006

Import 12916 13144 4103 10390 6079 8710 5445

Source; External Trade Statistics.

As shown in Table 3.1, import of fatty acid fluctuates from year to year without any discernible growth trend. Hence, in the absence of a trend in the import data, it is considered as reasonable to assume that the average import during the last four years (2003 2006) approximates the present (2007) demand for the product. Accordingly, the present demand for fatty acid is estimated at 7656 tonnes.

2.

Projected Demand

The future demand for fatty acid depends mainly on the growth of end user industries. Hence, future demand for the product is contingent upon growth of the national economy, especially the manufacturing sector.

Assuming that the manufacturing sector will grow by a rate higher than the average national economic growth rate of 6-7% in the recent past, future demand for fatty acid is projected to grow by 10% annually. The demand projection executed with this assumption is as shown in Table 3.2.

78-5

Table 3.2 PROJECTED DEMAND FOR FATTY ACIDS (TONNES)

Year 2008 2009 2010 2011 2012 2013 2014 2015 2016 2017 2018 2019 2020

Projected Demand 8,422 9,264 10,190 11,209 12,330 13,563 14,919 16,411 18,052 19,858 21,843 24,028 26,431

3.

Pricing and Distribution

Based on the average CIF value of imported dextrin and other costs (duty, port handling, inland transport and bank charges) the ex factory price is proposed to be Birr 4,750 per tonne.

Since fatty acid is an intermediate product, the distribution of the product is more convenient if it is direct. Penetration of domestic market will be facilitated through

advertisement by creating awareness as well as sales promotional measures.

78-6 B. PLANT CAPACITY AND PRODUCTION ON PROGRAMME

1.

Plant Capacity

Considering to cover about 60% of the projected demand , it is proposed to establish a processing plant with a daily capacity of 20 tonnes or about 6000 tonnes of fatty acids per year considering 300 working days and providing the remaining days of the year for maintenance and unexpected down times.

2.

Production Programme

The plant is envisaged to operate in two shifts per day for 300 working days per year. Considering the time required to acquire plant operation experience and market penetration, it is envisaged that the plant will start production at 75% of its full capacity in the first year, and at 85% and l00% during the second and the third years of its operation, respectively.

IV.

MATERIALS AND INPUTS

A.

RAW MATERIALS

Natural oils, such as palm oil, and rapeseed oil are good raw materials from which fatty acids can be produced. Palm oil is not locally produced, therefore, has to be imported. Rape seed oil is locally produced. However, it is used for cooking and moreover, it is expensive for use as a raw material for the production of fatty acids. The production of fatty acids will, therefore, be based on imported palm oil which is much cheaper than the locally available rape seed oil. Natural oil, palm oil in this case, is the only raw material required for the production of fatty acids.

The finished fatty acid is filled in drums or in tank truck and sold to the local soap manufacturing plants. The by-product, called "sweet water", is also sold in the same way.

The annual requirement of palm oil is estimated to be 7320 tonnes. Taking a price of Birr 3000 per tonne of palm oil delivered to Addis Ababa, the total cost is estimated to be Birr 22 million per annum. It is assumed that 50% of the product will be sold in recycled drums and this requires about 500

78-7 drums per month which cost about Birr 100,000. In total, the annual cost of materials is estimated at about Birr 22.l million.

B.

UTILITIES

The plant requires steam (3M Pa), electricity, water and fuel oil for its operation. The annual requirement of utilities is estimated to be about 6,400 tonnes of steam, 31753 kWh of electricity, 127,010 m3 of water and 536 tonnes of fuel-oil. The total annual cost of utilities is valued at Birr 717,020.

V.

TECHNOLOGY AND ENGINEERING

A.

TECHNOLOGY

1.

Process Description

There are two basic types of processes for the splitting (or hydrolysis) of natural oils to produce fatty acids. These are batch and continuous processes. The batch process is a process in which natural oil, water and steam are injected in a splitting autoclave and the hydrolysis reaction is completed in the autoclave batch-by-batch wise. The continuous process employs heat

exchangers and a battery of continuous splitting autoclaves which make the hydrolysis process continuous.

Batch process is preferred for capacities below 50 tonnes of oil processed per day. Accordingly, a batch process is selected for the present project which will process about 25 tonnes of oil (20 tonnes of fatty acids) per day.

In the selected batch process, palm oil from storage is first pumped into a splitting autoclave into which water and steam are also injected. After completion of the hydrolysis reaction, the content of the reactor (autoclave) is transferred through expansion vessel into settlers. After proper separation by settling, the fatty acids are removed from the settlers.

78-8 The hydrolysis reaction also produces glycerine. The glycerine formed during the reaction is l0l5% of the oil and is contained in the water phase. The glycerine ("sweet water") is concentrated to a glycerine content of l5-20% and, after separation by a centrifuge, is transferred to a storage tank.

2.

Source of Technology

The technology for the production of fatty acids is widely available in China and India.

B.

ENGINEERING

1.

Machinery and Equipment

The major machineries and equipment required for the plant are listed in Table 5.1. The total cost of the machinery and equipment (landed in Addis Ababa) is estimated at Birr 9,545,000.

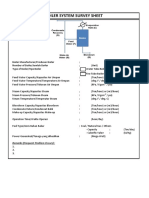

78-9 Table 5.1 LIST OF MACHINERY & EQUIPMENT REQUIRED FOR FATTY ACIDS MANUFACTURING PLANT

No. l 2 3 4 5 6 7 8 9 10 11 12 13 14 15 l6

Item Natural oil measuring vessel Oil pumps Autoclaves Pumps Flashing vessels Settling tanks Separators Centrifuge Condenser Water demineralizing equipment Fatty acids storage tank "sweet water" storage tank Demineralize water tank Natural Oil tanks Oil pumps Steam boiler

Quantity (pcs.) 1 2 2 2 1 2 2 1 1 1 (Set) 1 1 1 2 2 1

2.

Land, Building and Civil Works

The total land area required for the plant including open is estimated at 2400 m2. The covered area is estimated to be 300 m2. The production area could be partly of an open - air construction. However, a small building for control room, laboratory, social services and offices will be erected.

The building is assumed to be constructed from concrete hollow-blocks. The cost of building and other civil works is estimated at Birr 750,000. The annual cost of land rent is Birr 1,200.

78-10 3. Proposed Location

The envisaged plant shall be located in Tepi town, Yeki Woreda of Sheka Zone.

VI.

MANPOWER AND TRAINING REQUIREMENTS

A.

MANPOWER REQUIREMENT

The total manpower requirement of the plant is estimated at 44 persons. The breakdown is shown in Table 6.1. The total cost of manpower, including benefits, is about Birr l90, 500 per annum.

Table 6.1 MANPOWER REQUIREMENT AND LABOUR COST (BIRR)

Sr. No. 1 2 3 4 5 6 7 8

Category Number Plant Manager Industrial Chemist Machine operators Assistant operator Technicians Assistant Technician Clerical & administration Guards and cleaners Total l l 12 14 4 4 4 4 44

Monthly Salary 2,500 l,500 12x400 14x250 4 x 700 4 x 500 4x 350 4 x 200 19300

Annual Salary

30,000 18000 57600 42000 33,600 24000 16800 9600 231,600

B.

TRAINING REQUIREMENT

On-the-job training is required for proper operational skill development of the workers. The total cost of training is estimated at Birr 50,000.

78-11

VII.

FINANCIAL ANALYSIS

The financial analysis of the fatty acid project is based on the data presented in the previous chapters and the following assumptions:-

Construction period Source of finance

1 year 30 % equity 70 % loan

Tax holidays Bank interest Discount cash flow Accounts receivable Raw material local Raw material, import Work in progress Finished products Cash in hand Accounts payable

3 years 8% 8.5% 30 days 30 days 90 days 5 days 30 days 5 days 30 days

A.

TOTAL INITIAL INVESTMENT COST

The total investment cost of the project including working capital is estimated at Birr 15.89 million, of which 29 per cent will be required in foreign currency.

The major breakdown of the total initial investment cost is shown in Table 7.1.

78-12

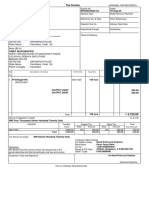

Table 7.1 INITIAL INVESTMENT COST

Sr. No. 1 2 3 4 5 6 7 Cost Items Land lease value Building and Civil Work Plant Machinery and Equipment Office Furniture and Equipment Vehicle Pre-production Expenditure* Working Capital Total Investment cost Foreign Share

Total Cost (000 Birr) 96.0 750.0 9,545.0 125.0 450.0 824.6 4,100.2 15,890.9 29

* N.B Pre-production expenditure includes interest during construction ( Birr 674.63 thousand ) training (Birr 50 thousand ) and Birr 100 thousand costs of registration, licensing and formation of the company including legal fees, commissioning expenses, etc.

B.

PRODUCTION COST

The annual production cost at full operation capacity is estimated at Birr 24.90 million (see Table 7.2). The material and utility cost accounts for 91.61 per cent, while repair and

maintenance take 0.60 per cent of the production cost.

78-13 Table 7.2 ANNUAL PRODUCTION COST AT FULL CAPACITY ('000 BIRR)

Items Raw Material and Inputs Utilities Maintenance and repair Labour direct Factory overheads Administration Costs Total Operating Costs Depreciation Cost of Finance Total Production Cost

Cost 22,100.00 717.02 150 138.96 46.32 92.64 23,244.94 1124.5 538.22 24,907.66

% 88.73 2.88 0.60 0.56 0.19 0.37 93.32 4.51 2.16 100

C.

FINANCIAL EVALUATION

1.

Profitability

According to the projected income statement, the project will start generating profit in the first year of operation. Important ratios such as profit to total sales, net profit to equity

(Return on equity) and net profit plus interest on total investment (return on total investment) show an increasing trend during the life-time of the project.

The income statement and the other indicators of profitability show that the project is viable.

78-14

2.

Break-even Analysis

The break-even point of the project including cost of finance when it starts to operate at full capacity ( year 3) is estimated by using income statement projection.

BE =

Fixed Cost Sales Variable Cost

= 51 %

3.

Pay Back Period

The investment cost and income statement projection are used to project the pay-back period. The projects initial investment will be fully recovered within 4 years.

4.

Internal Rate of Return and Net Present Value

Based on the cash flow statement, the calculated IRR of the project is 27% and the net present value at 8.5% discount rate is Birr 12.55 million.

D.

ECONOMIC BENEFITS

The project can create employment for 44 persons.

In addition to supply of the domestic

needs, the project will generate Birr 8.28 million in terms of tax revenue. The establishment of such factory will have a foreign exchange saving effect to the country by substituting the current imports.

S-ar putea să vă placă și

- Boiler System Survey Sheet Complete PDFDocument2 paginiBoiler System Survey Sheet Complete PDFMuhammad Agus TianÎncă nu există evaluări

- Boiler System Survey Sheet PDFDocument1 paginăBoiler System Survey Sheet PDFMuhammad Agus TianÎncă nu există evaluări

- PSB 4O PI ED 0018 V Painting Procedure.2 28Document27 paginiPSB 4O PI ED 0018 V Painting Procedure.2 28Muhammad Agus TianÎncă nu există evaluări

- Vinyl Chloride Production Plant DesignDocument9 paginiVinyl Chloride Production Plant Designsatyendraparmar091425che100% (1)

- Boiler System Survey Sheet Complete PDFDocument2 paginiBoiler System Survey Sheet Complete PDFMuhammad Agus TianÎncă nu există evaluări

- CV in EnglishDocument5 paginiCV in EnglishAyah MochieÎncă nu există evaluări

- Process Water Production From River Water by Ultrafiltration and Reverse OsmosisDocument13 paginiProcess Water Production From River Water by Ultrafiltration and Reverse OsmosislarasaticandraÎncă nu există evaluări

- Initial BoilerDocument15 paginiInitial BoilerMuhammad Agus TianÎncă nu există evaluări

- Abstrak 11Document5 paginiAbstrak 11Muhammad Agus TianÎncă nu există evaluări

- Abstrak 11Document5 paginiAbstrak 11Muhammad Agus TianÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Theory of Karma ExplainedDocument42 paginiTheory of Karma ExplainedAKASH100% (1)

- Bravo Jr. v. BorjaDocument2 paginiBravo Jr. v. BorjaMaria AnalynÎncă nu există evaluări

- Mendoza CasesDocument66 paginiMendoza Casespoiuytrewq9115Încă nu există evaluări

- Junior Instructor (Computer Operator & Programming Assistant) - Kerala PSC Blog - PSC Exam Questions and AnswersDocument13 paginiJunior Instructor (Computer Operator & Programming Assistant) - Kerala PSC Blog - PSC Exam Questions and AnswersDrAjay Singh100% (1)

- Direct InstructionDocument1 paginăDirect Instructionapi-189549713Încă nu există evaluări

- Unit-2 Fourier Series & Integral: 2130002 - Advanced Engineering MathematicsDocument143 paginiUnit-2 Fourier Series & Integral: 2130002 - Advanced Engineering MathematicsDarji DhrutiÎncă nu există evaluări

- C++ Project On Library Management by KCDocument53 paginiC++ Project On Library Management by KCkeval71% (114)

- Intertrigo and Secondary Skin InfectionsDocument5 paginiIntertrigo and Secondary Skin Infectionskhalizamaulina100% (1)

- Mar 2021Document2 paginiMar 2021TanÎncă nu există evaluări

- Unit 3 Test A Test (Z Widoczną Punktacją)Document4 paginiUnit 3 Test A Test (Z Widoczną Punktacją)Kinga WojtasÎncă nu există evaluări

- Chinnamasta Sadhana PDFDocument1 paginăChinnamasta Sadhana PDFSayan Majumdar100% (2)

- Self Respect MovementDocument2 paginiSelf Respect MovementJananee RajagopalanÎncă nu există evaluări

- The Emergence of India's Pharmaceutical IndustryDocument41 paginiThe Emergence of India's Pharmaceutical Industryvivekgupta2jÎncă nu există evaluări

- Boston Consulting Group Portfolio Analysis MatrixDocument16 paginiBoston Consulting Group Portfolio Analysis MatrixNimish SharmaÎncă nu există evaluări

- Orbit BioscientificDocument2 paginiOrbit BioscientificSales Nandi PrintsÎncă nu există evaluări

- 8086 ProgramsDocument61 pagini8086 ProgramsBmanÎncă nu există evaluări

- Aromatic Saturation Catalysts: CRI's Nickel Catalysts KL6564, KL6565, KL6515, KL6516Document2 paginiAromatic Saturation Catalysts: CRI's Nickel Catalysts KL6564, KL6565, KL6515, KL6516Ahmed SaidÎncă nu există evaluări

- Doña PerfectaDocument317 paginiDoña PerfectadracbullÎncă nu există evaluări

- KG Technologies Inc Metric: K119X-DX024P-1AT-90A-C399Document2 paginiKG Technologies Inc Metric: K119X-DX024P-1AT-90A-C399Bhushan PAwarÎncă nu există evaluări

- Mech Course HandbookDocument20 paginiMech Course Handbookbrody lubkeyÎncă nu există evaluări

- English 2Document53 paginiEnglish 2momonunu momonunuÎncă nu există evaluări

- Concept of Intestate SuccessionDocument9 paginiConcept of Intestate SuccessionBodhiratan BartheÎncă nu există evaluări

- EDU101 Solution FileDocument2 paginiEDU101 Solution FileTahaÎncă nu există evaluări

- Endoplasmic ReticulumDocument4 paginiEndoplasmic Reticulumnikki_fuentes_1100% (1)

- W220 Engine Block, Oil Sump and Cylinder Liner DetailsDocument21 paginiW220 Engine Block, Oil Sump and Cylinder Liner DetailssezarÎncă nu există evaluări

- Isha Hatha Yoga - Program Registration FormDocument2 paginiIsha Hatha Yoga - Program Registration FormKeyur GadaÎncă nu există evaluări

- Review Activity For The Final Test - 6 Level: 1. Match Phrasal Verbs and Match To The MeaningDocument3 paginiReview Activity For The Final Test - 6 Level: 1. Match Phrasal Verbs and Match To The MeaningGabrielle CostaÎncă nu există evaluări

- 5.3.2 Generation of Dislocations: Dislocations in The First Place!Document2 pagini5.3.2 Generation of Dislocations: Dislocations in The First Place!Shakira ParveenÎncă nu există evaluări

- Syntax - English Sentence StructureDocument2 paginiSyntax - English Sentence StructurePaing Khant KyawÎncă nu există evaluări

- Times Leader 04-10-2013Document37 paginiTimes Leader 04-10-2013The Times LeaderÎncă nu există evaluări