Documente Academic

Documente Profesional

Documente Cultură

Sustain Release

Încărcat de

g20kpTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Sustain Release

Încărcat de

g20kpDrepturi de autor:

Formate disponibile

journal of

ELSEVIER

controlled release

Journal of Controlled Release 33 ( 1995 ) 143-152

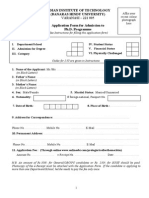

Structure and behaviour in hydrophilic matrix sustained release dosage forms: 3. The influence of pH on the sustained-release performance and internal gel structure of sodium alginate matrices

Alison C. Hodsdon a, John R. Mitchell b, Martyn C. Davies a, Colin D. Melia a'*

aDepartment of PharmaceuticalSciences, Nottingham University, Nottingham NG7 2RD, UK "Department of Applied Biochemistry and Food Science, Nottingham University, UniversityPark, Nottingham NG7 2RD, UK

Received 4 January 1994; accepted 6 July 1994

Abstract

The effect of pH and drug solubility on the release kinetics of sodium alginate matrices has been studied. Release of a highly soluble model drug, chlorpheniramine maleate, was significantly faster in simulated gastric fluid (SGF) than in simulated intestinal fluid (SIF), whereas the opposite effect was observed for hydrochlorothiazide, a drug of poor solubility. These results could be explained in terms of the internal microscopic structure of the hydrated surface layer formed on matrix hydration and by the different hydration kinetics of the polymer in these two media. Cryogenic electron microscopy revealed the hydrated surface layer formed by alginate matrices in SGF to be particulate and porous in nature, in contrast to the highly hydrated continuous gel layer formed in SIF. Drug release mechanisms were discussed with respect to drug solubility and the structure and properties of the surface layers formed by alginate matrices when hydrated in different pH media.

Keywords: Sodium alginate; Hydrophilic matrixes; Sustained release; Tablet; Cryogenic scanning electron microscopy; Hydration; pH

1. Introduction

Sodium alginate is a natural hydrophilic polysaccharide derived from seaweed. The ability of this polymer to rapidly form viscous solutions and gels on contact with aqueous media has been exploited by the pharmaceutical industry, in its wide application as a carrier in hydrophilic matrix controlled release oral dosage forms. Matrices incorporating either a single alginate salt or a combination of salts have been employed to successfully sustain release of many drugs in vitro and in vivo [ 1-4]. Drug release from hydrophilic matrix tablets is controlled by the formation of a hydrated viscous layer

* Corresponding author. 0168-3659/95/$09.50 1995 Elsevier Science B.V. All rights reserved

around the tablet, after ingestion of the dosage form [5,6]. The surface layer acts as a barrier to drug release by opposing penetration of water into the tablet and also the movement of dissolved solutes out of the matrix [ 7 ]. Water-soluble drugs are released primarily by diffusion of dissolved drug molecules across the gel layer, whilst poorly water-soluble drugs are released predominantly by erosion mechanisms [ 8 ]. The contribution of each release mechanism to the overall drug release process is influenced both by drug solubility and also by the physical and mechanical properties of the gel barrier that forms around the tablet. Sodium alginate is the sodium salt of alginic acid [ 9], a high molecular weight linear random copolymer consisting of blocks of 1 --->4, linked D-mannuronic

SSDIOI68-3659(94)OOO76-X

144

A.C. Hodsdon et al. / Journal of Controlled Release 33 (1995) 143-152

acid (MM) and L-guluronic acid residues (GG), in addition to regions in which the two uronic acid residues alternate [10-13]. By virtue of the carboxyl groups on the component uronic acid residues, the pKa of alginic acid ranges between 3.4 and 4.4, depending on the type of alginate and the salts present in the mixture [ 14]. Therefore, changes in pH over the region of pH 3 to 4, from more neutral pH values, influence polymer hydration and alginate gel rheology, due to the ready interconversion of carboxylate anions (sodium alginate) to free carboxyl groups (alginic acid), as the concentration of hydrogen ions increases [ 15,16]. At neutral pH sodium alginate is soluble and hydrates to form viscous solutions, but below pH 3, alginic acid, water swellable but insoluble, is rapidly formed. Since the hydration characteristics of the polymer and the subsequent physical properties of the hydrated gel layer may critically influence drug release [17], any change in the properties of the hydrated surface layer caused by a change in pH, is likely to influence the performance of sodium alginate as a sustained release carrier. This paper studies the effect of pH on the release of two drugs of differing water-solubility from sodium alginate matrices. Cryogenic scanning electron microscopy (cryo-SEM) and liquid uptake studies were employed to explain the pH-dependent differences observed in drug release, in terms of the internal microscopic structure of the gel layer and the hydration kinetics of the polymer.

2.2. Matrix preparation

Tablets were prepared containing 49% sodium alginate, 20% drug, 30.25% lactose and 0.75% w/w magnesium stearate, by mixing the powders for 15 min without lubricant and for a further 5 min after addition of magnesium stearate. The blends were directly compressed on a Manesty F3 single punch tableting machine using 11 mm diameter flat-faced punches, to a weight of 350 mg and a compression force of 40___2 kN (6-7 kg tablet hardness). Pure polymer tablets were also manufactured, to a compression force of 15 + 0.5 kN, equivalent to a tablet porosity of 34.5 ___1% (6.8100-

a0-

6O-

.~ .L.

4O-

2OO 01

S1F ( pH 7.5 )

Time

( Hours

Fig. 1. Effect ofpH on the release of chlorpheniramine maleate from sodium alginate matrices (mean ( n = 6 ) + 1 SD; for SGF results, all SD<2%).

2. Materials and methods

80'

2.1. Materials

60"

Sodium alginate (Keltone HV TM, Kelco, Division of Merck, San Diego, CA) was used as supplied. Chlorpheniramine maleate (Sigma Chemical Co., St. Louis, MO), hydrochlorothiazide (Lancaster Research Chemicals, Morecambe, UK), lactose fast-rio USP (Zeparox, Lactochem, Chester, UK) and magnesium stearate BP (BDH, Poole, UK) were used in the particle size range 125-180/xm, obtained by sieving. Simulated gastric fluid USP (SGF) and simulated intestinal fluid USP (SIF) without enzymes, were used in the hydration studies and as the dissolution media.

=,

._~ S m O. 40"

2O"

"--'11-- SIF (pHT.5)

0~" 1 2 3 0.s )

Square

root of time ( Hours

Fig. 2. Release of chlorpheniramine maleate, plotted as a function of the square root of time (mean (n---6) + 1 SD).

A.C. Hodsdonet al. / Journal of ControlledRelease33 (1995)143-152

145

7.3 kg tablet hardness), for cryo-SEM and liquid uptake studies.

2.3. Dissolution studies

Drug release was measured using the rotating basket dissolhtion method (USP dissolution apparatus 1) at a basket rotation speed of 100 rev m i n - 1, in 900 ml SGF (pH 1.2) or SIF (pH 7.5), at 37C. Chlorpheniramine maleate concentration was measured spectrophotometrically at 264 nm and 261 nm in SGF and SIF respectively, and hydrochlorothiazide concentration at 271 nm, in both media. Results are shown as a mean + 1 SD of six tablets.

2.4. Cryogenic scanning electron microscopy (cryoSEM)

face of the tablet. The specimen was then positioned on the sample holder, so as to present a cross-section of the tablet to the microscope. The sample was then rapidly frozen in nitrogen slush ( - 2 1 0 C ) , freezefractured with a cold knife, etched under vacuum ( - 80C) and gold-coated. Images were obtained at 25 keV on a Philips 505 scanning electron microscope equipped with a Hexland CTI000 cryostation, maintaining the specimen at - 180C throughout.

2.5. Liquid uptake studies

Tablets were hydrated in SGF or SIF at 37C using the dissolution apparatus. After 1 h, samples were carefully removed from the baskets and sectioned through an undisturbed portion of the gel formed from the fiat

Tablet hydration kinetics were investigated using the liquid volume uptake method of Wan et al. [ 18]. The apparatus consisted of a sintered glass filter overlaid with wet filter paper and connected to a horizontal graduated capillary containing either SGF or SIF. The whole assembly was equilibrated and maintained at 37C and covered to prevent evaporation. Single tablets were placed centrally on the filter and the volume of liquid taken up into the single face of the tablet in

Fig. 3. Micrographof the outer 1 mm of the surfacehydratedlayerof a sodiumalginatetablet, hydratedfor 1 h in SIF ( X 101).

146

A.C. Hodsdon et al. / Journal of ControlledRelease 33 (1995) 143-152

contact with the filter, was monitored over one hour. Results are shown as a m e a n _ 1 SD of five tablets.

3. Results and discussion

3.1. Effect o f p H on the release of a highly watersoluble drug f r o m alginate matrices

The release profiles of chlorpheniramine maleate from sodium alginate matrices, into SGF (pH 1.2) and SIF (pH 7.5) are shown in Fig. 1. Both the initial rate of drug release, and the overall shape of the release profiles differed markedly in the two different media. The differences were manifest immediately, with drug release being significantly more rapid into SGF within the first hour of dissolution (Mann-Whitney U test; P < 0.01 ). The release profile at pH 7.5 was linear with time up to 4 h, whereas at pH 1.2, drug release was linear with the square root of time (Fig. 2) up to 80% drug release. This last finding suggests that in acid pH

the release mechanism is predominantly diffusion-controlled [19,20], whereas at pH 7.5, deviation from linearity of the root time plot, indicates significant contribution from other release mechanisms, such as erosion [21]. Drug solubility studies confirmed that chlorpheniramine maleate remained highly soluble in both buffers (determined to be 225 g 1- ~ in SGF and 201 g 1-1 in SIF, 37C), meaning drug dissolution was unlikely to be rate-limiting in either medium [ 7 ]. Hence, although these effects may have been partly due to differences in drug solubility, cryo-SEM results indicate that the differences observed may be more a result of a change in the quality and integrity of the gel barrier formed under acid conditions. The conversion of sodium alginate to alginic acid at low pH is known to directly affect polymer solubility and rheology. Cryo-SEM micrographs of the internal morphology of sodium alginate tablets after 1 hour hydration in SGF and SIF are shown in Figs. 3--6. These illustrate the microscopic structure

Fig. 4. Micrographat higher magnificationof the inner hydratedregionsof a sodiumalginatetablet, hydratedfor 1 h in SIF ( 406).

A.C. Hodsdon et al. / Journal of Controlled Release 33 (1995) 143-152

147

Fig. 5. Micrographof the outer 1 mm of the surface hydratedlayer on an alginatetablet, hydratedfor 1 h in SGF ( X 101). of different regions of the tablet gel layer under different conditions of pH. Fig. 3 is a low magnification micrograph of the outer 1 mm of the surface gel layer of a sodium alginate tablet hydrated in SIF. There is extensive ice crystal formation, representing a high level of hydration, at the periphery of the outer gel surface. At higher magnifications, the inner gel regions show less extensive and less homogeneous hydration (Fig. 4). This overall structure of the gel layer is typical in appearance of the continuous, viscous surface gel layer formed from particles that are hydrating and coalescing, as observed previously in other hydrophilic matrix systems [ 22 ]. In the case of hydration of a sodium alginate tablet in SGF, on retrieval of this type of tablet from the dissolution vessel, the outer hydrated surface layer formed around the tablet could be seen, by eye, to possess a very different consistency to that formed around sodium alginate tablets which were hydrated in SIF. The SGF-hydrated layer was not viscous and adhesive in nature, but possessed a tough and rubbery texture. The outermost gel formed a tough 'rind' which always separated from the gel bulk on cryo-sectioning. Figs. 5 and 6 show the internal structure of the hydrated surface layer of a sodium alginate tablet, hydrated in SGF. Low magnification micrographs of the outer 1 mm region of this layer (Fig. 5) showed it to be composed of a matrix of fibrous alginate particles and higher magnifications revealed the presence of ice crystals interspersed between discrete, recognisable polymer fibres. This structure was apparent throughout the gel; Fig. 6 clearly shows how particles of poorly hydrated polymer are bounded by areas of ice crystal growth, which represent a highly hydrated (dilute) gel. The presence of this dilute gel indicates that even under acid conditions, some of the polymer has dissolved and appears to form an interstitial 'glue' between the poorly hydrated regions. This structure explains why pure alginate tablets formed a coherent surface barrier layer which held together, in an environment in which disintegration would otherwise be expected.

148

A. C. Hodsdon et al. / Journal of Controlled Release 33 (1995) 143-152

Fig. 6. Micrographof inner hydratedregionsof an alginatetablet, hydratedfor 1 h in SGF ( 203). At pH 1.2, sodium alginate is rapidly converted to alginic acid, which has the ability to swell on hydration but which is virtually insoluble. The generation of swelling forces without surface stickiness is the basis for the use of alginic acid as a tablet disintegrant. In order to form the dilute gel seen in the micrograph, some dissolution of the polymer must have occurred and it is postulated that this may be the result of a temporarily raised pH within the hydrating matrix as a result of the intrinsic buffering capacity of sodium alginate [ 23 ]. The overall result is an intact, but relatively porous, composite hydrated layer, in which much of the polymer is undissolved and does not contribute to the diffusional barrier. The faster drug release observed at pH 1.2 is therefore almost certainly a reflection of the inferior barrier properties of this composite layer, relative to those of the continuous gel layer formed at pH 7.5. This proposal is reinforced by the fact that alginate matrices in SGF released CPM more rapidly than they did in SIF, even though they were competing against significantly faster-eroding systems in SIF, and further supporting evidence is provided by the liquid uptake studies. The gel layer also provides a barrier to the ingress of hydrated liquid into the core. Fig. 7 shows how acidic

3O

20

10.

----O--

SGF ( p H { 2 )

~.

2'

Time ( Minutes

)

,'o

e'o

Fig. 7. Effect of pH on liquid uptake into sodium alginate tablets

(mean ( n = 5 ) rain). 1 SD; for SGF results, all S D < 3 % from 1 0 ~ 0

A.C. Hodsdon et al. / Journal of Controlled Release 33 (1995) 143-152

149

Fig. 8. Micrograph of

the outer surface hydrated layer of

chlorpheniraminemaleate-containingalginate matrix, hydratedfor 1 h

in SGF

( X406). medium was absorbed significantly more quickly (Mann-Whitney U test; P < 0.01, at 10-60 min), into sodium alginate tablets than its neutral counterpart, which substantiates the proposal that a more porous, less retarding barrier layer is formed around alginate tablets hydrated at pH 1.2. Whilst pure polymer compacts may be used to illustrate the behaviour of the polymer in a matrix undergoing hydration, the alginate matrices used in the dissolution studies also contained drug and tableting excipients whose presence may also influence the tablet hydration characteristics and the properties of the surface gel layer. Therefore, the internal structure of the gel formed around these matrices, which contained not only polymer but also chlorpheniramine maleate, lactose and magnesium stearate, was examined with the aim of confirming that sodium alginate behaves similarly, in more realistic, complex hydrophilic matrix formulations. SEM micrographs showed that these tablets exhibited similar gel microstructures to those seen previously in the pure polymer matrices, except that the gel layer formed in acid, particularly the outer surface, was rather less particulate in nature than the gel formed by pure alginate tablets. Fig. 8 and 9 show typical examples of the composite gel layer formed in SGF and the continuous gel layer formed in SIF, respectively, after 1 h hydration of these tablets. Even with the relatively high amounts of soluble excipients present, the structure and integrity of the gel layer formed by alginate matrices appears to differ greatly in different pH media, and in these examples it is predominantly the hydration characteristics of the hydrophilic polymer within a matrix dosage form, that dictates the structure of the hydrated layer.

3.2. Effect o f p H on the release o f a poorly watersoluble drug f r o m alginate matrices

These studies have explained the faster release of a highly water-soluble model drug into acid medium mainly on the basis of an increased porosity of the

150

A,C. Hodsdon et al. / Journal of Controlled Release 33 (1995) 143-152

Fig. 9. Micrographof the outer surfacehydratedlayerofa chlorpheniraminemaleate-containingalginatematrix,hydratedfor 1 h in S1F ( X406). hydrated layer, at this pH, enabling faster solute outgress. However, the porous hydrated structure formed at pH 1.2 also possessed markedly different mechanical properties to those produced at neutral pH. A tough and rubbery 'rind' was produced in contrast to the viscous, gelatinous layer formed around the tablet at pH 7.5. This difference in gel barrier integrity manifests itself as differences in the susceptibility of the hydrated layers to erosion, on agitation of the tablet and is therefore likely to influence the release rate of poorly-soluble drugs which depend predominantly on surface erosion for their release [ 7 ]. Fig. 10 shows how the release profiles of hydrochlorothiazide from alginate matrices differ in SGF and SIF. Although the solubility of this drug is slightly higher in acid pH (determined as 1.18 g l - l , 37C) than in pH 7.5 buffer (determined as 1.14 g 1- l, 37oc), drug release was dramatically faster in SIF, the opposite scenario as seen for CPM. 83% of hydrochlorothiazide was released into SIF after 4 h, compared with only 15% into SGF. Visual observation of the matrices during dissolution testing, revealed that those hydrated in SIF had eroded significantly after only 30 min, whereas in SGF, there was no visible evidence of matrix erosion

100-

--

----O--- SGF ( pH 1.2 )

20-

0 2 4 6 8 10 12

Time ( Hours )

Fig. 10, Effect of pH on the release of hydrochlorothiazidefrom sodium alginate matrices (mean (n=6)+SD; all SD<5%, for times after 30 rain).

A. C. Hodsdon et al. / Journal of Controlled Release 33 (1995) 143-152

151

after 12 h dissolution testing, at the end of which a strong rubbery matrix remained. These results indicate that hydrochlorothiazide relies predominantly on mechanisms of erosion for release, from alginate matrices. Evidently, the tough mechanical properties of the particulate hydrated layer formed at acid pH rendered the matrix very resistant to erosion, a factor which was responsible for the greatly retarded and limited release of hydrochlorothiazide from alginate matrices, over 12 h, into an acid environment. In SIF, however, the outermost layer of the viscous gel barrier that was formed, was much less resistant to attrition, resulting in much more rapid release of hydrochlorothiazide at neutral pH, due to the matrix progressively eroding and releasing the drug. A plot of the cube root of the weight of drug released from tablets, as a function of time, revealed that the Hixson-Crowell cube root equation for dissolution control of drug release [24], adequately described the release of hydrochlorothiazide into SIF, over the range of 16% to 96% cumulative per cent drug released. This finding supports the hypothesis that hydrochlorothiazide relies mainly on erosion for release from hydrophilic matrix tablets. Chlorpheniramine maleate which as a highly soluble drug is believed to rely predominantly on diffusion mechanisms for release, exhibited no such Hixson-Crowell kinetics.

in the internal structure of the surface hydrated layer may affect the extent to which different mechanisms of drug release contribute towards the overall release kinetics.

Acknowledgements

The authors would like to thank Kelco Division of Merck and Co., Inc., for their financial support in funding this work and in particular Mr. George Colegrove, Mr. Brian Lockwood and Mr. John Fitzpatrick for their support and assistance.

References

l 1] M. Nakano and A. Ogata, Examination of natural gums as matrices for sustained-release of theophylline, Chem. Pharm. Bull., 32 (1984) 782-785. [2] J.R. Howard and P. Timmins, Pharmaceutical controlledrelease tablets containing basic drugs having pH-independent drug release, United States Patent, 4,792,452 (1988). [3] F. Seiyaku, Sustained-release dilazep hydrochloride tablets containing sodium alginate, Japanese Patent 01025721 (English summary) (1989). [4] H. Viernstein, Retarded-release drug tablet with alginic acidsodium aiginate matrix, Austrian Patent 385200 (English summary) (1988). 15l G.L. Christenson and L.B. Dale, Sustained release tablet, US Patent 3,065,143 (1962). [61 H.E. Huber, L.B. Dale and G.L. Christenson, Utilization of hydrophilic gums for the control of drug release from tablet formulations. I. Disintegration and dissolution behaviour, J. Pharm. Sci., 55 (1966) 974-976. [7] M. Bamba, F. Puisieux, J.P. Marty, and J.T. Carstensen, Release mechanisms in gel forming sustained release preparations, Int. J. Pharm., 2 (1979) 307-315. [81 D.A. Alderman, A review of cellulose ethers in hydrophilic matrices for oral controlled-release dosage forms, Int. J. Pharm. Tech. Prod. Mfr., 5 (1984) 1-9. [9] E.C.C. Stanford, British Patent, 142 (1881). [10] E. Hirst and D.A. Rees, The structure of alginic acid. Part. V. Isolation and unambiguous characterization of some hydrolysis products of the methylated polysaccharide, J. Chem. Soc., (1965) 1182-1187. [111 D.A. Rees and J.W. Samuel, The structure of alginic acid. Part VI. Minor features and structural variations, J. Chem. Soc., C (1967) 2295-2298. [12l A. Hang, B. Larsen and O. Smidsrod, A study of the constitution of alginic acid by partial acid hydrolysis, Acta Chem. Scand., 20 (1966) 183-190. [131 A. Haug, B. Larsen and O. Smidsrod, Studies on the sequence of uronic acid residues in alginic acid, Acta Chem. Scand., 21 (1967) 691-704.

4. Conclusions The results obtained in this study show that the internal structure of the surface hydrated layer formed by sodium alginate matrices in SGF, differs markedly from the structure formed in SIF. The hydration kinetics of sodium alginate compacts were also found to differ in the two different pH media. These differences in matrix gel morphology and polymer hydration characteristics in the two different pH media are thought to be a consequence of the pH-dependent solubility of sodium alginate. This contrasting behaviour of sodium alginate in forming the hydrated surface layer, on matrix hydration, is thought to be primarily responsible for the differences observed in drug release behaviour from sodium alginate matrices, in SGF and SIF. Drug release kinetics were seen to depend on the solubility of the drug and also the pH of the dissolution medium, suggesting that for a particular drug, changes

152

A. C. Hodsdon et al. / Journal of Controlled Release 33 (1995) 143-152

114| W.H. McNeely and D.J. Pettitt, Algin. In: R.L. Whistler and J.N. Bemiller (Eds.), Industrial Gums, 2nd edn., 1973, Academic Press, New York. [15] I.W. Cottrell and P. Kovacs, Alginates. In: R.L. Davidson (Ed.), Handbook of Water-Soluble Gums a n d Resins, 1980, pp. 2.9-2.14. [16] A.H. King, Brown Seaweed Extracts (Alginates). In: M. Glicksman (Ed.), Food Hydrocolloids Volume II, CRC Press, Inc., Boca Raton, Florida, 1983, chapter 6. [ 17] C.D. Melia, Hydrophilic matrix sustained release systems based on polysaccharide carriers, Crit. Rev. Ther. Drug Carr. Syst., 8 (1991) 395-421. [ 18] L.S.C. Wan and Y.L. Choong, The effect of excipients on the penetration of liquid into tablets, Pharm. Acta Helv., 61 (1986) 150-156. [ 19 ] W.I. Higuchi, Analysis of data on the medicament release from ointment, J. Pharm. Sci., 51 (1962) 802-804.

[20] E. Touitou and M. Donbrow, Influence of additives on (hydroxyethyl)methylcellulose properties: relation between gelation temperature change, compressed matrix integrity and drug release profile, Int. J. Pharm., 11 (1982) 131-148. [21] J.L. Ford, M.H. Rubinstein and J.E. Hogan, Formulation of sustained release promethazine hydrochloride tablet using hydroxypropylmethylcellulose matrices. Int. J. Pharm., 24 (1985) 327-338. [22] C.D. Melia, A.R. Rajabi-Siahboomi and M.C. Davies, The development of structural features in the surface gel layer of hydrating HPMC hydrophilic matrices, Proceed. Intern. Symp. Control. Rel. Bioact. Mater., 19 (1992) 28-29. [231 P. Gacesa, Alginates, Carbohydr. Polym., 8 (1988) 161-182. [24] A.W. Hixson and J.H. Crowell, Dependence of reaction velocity upon surface and agitation, Ind. Engng. Chem., 23 ( 1931 ) 923-931.

S-ar putea să vă placă și

- AlcoholDocument13 paginiAlcoholg20kpÎncă nu există evaluări

- Antihypertensive Drugs NoteDocument8 paginiAntihypertensive Drugs Noteg20kpÎncă nu există evaluări

- Novel Benzimidazole-Linked Pyrazolines as Potential Antimicrobial AgentsDocument9 paginiNovel Benzimidazole-Linked Pyrazolines as Potential Antimicrobial Agentsg20kpÎncă nu există evaluări

- Ijpar 1Document6 paginiIjpar 1g20kpÎncă nu există evaluări

- Summer Internship Project ReportDocument80 paginiSummer Internship Project ReportManish Singh80% (10)

- 2017 Journal Citation Reports by Thomson Reuters: July 2017Document251 pagini2017 Journal Citation Reports by Thomson Reuters: July 2017vlad lupasteanuÎncă nu există evaluări

- Training Report GuidelinesDocument7 paginiTraining Report Guidelinesg20kpÎncă nu există evaluări

- GitamDocument1 paginăGitamg20kpÎncă nu există evaluări

- Edible VaccinesDocument1 paginăEdible Vaccinesg20kpÎncă nu există evaluări

- Health & Nutrition Classification of FoodDocument10 paginiHealth & Nutrition Classification of Foodg20kpÎncă nu există evaluări

- MozillaDocument6 paginiMozillag20kpÎncă nu există evaluări

- Poser Presentation NamesDocument2 paginiPoser Presentation Namesg20kpÎncă nu există evaluări

- S.No Name of The Item QTY Unit Rate Total Amount Material Suppliers Bill No& DC No&Date Signature of The Incharge Purchasing Authority RemarksDocument1 paginăS.No Name of The Item QTY Unit Rate Total Amount Material Suppliers Bill No& DC No&Date Signature of The Incharge Purchasing Authority Remarksg20kpÎncă nu există evaluări

- Physostigmine Carbamate Derivatives from EseretholesDocument7 paginiPhysostigmine Carbamate Derivatives from Eseretholesg20kpÎncă nu există evaluări

- Kadiyapulanka: Sri Durga NurseryDocument7 paginiKadiyapulanka: Sri Durga Nurseryg20kpÎncă nu există evaluări

- Oral Drug Delivery:: Packaging Technology, Dispensing Devices & Advanced FormulationsDocument24 paginiOral Drug Delivery:: Packaging Technology, Dispensing Devices & Advanced Formulationsg20kpÎncă nu există evaluări

- UV method for estimating mefenamic acidDocument2 paginiUV method for estimating mefenamic acidg20kpÎncă nu există evaluări

- Cognocy PaperDocument1 paginăCognocy Paperg20kpÎncă nu există evaluări

- Sustain Release PDFDocument6 paginiSustain Release PDFg20kpÎncă nu există evaluări

- IIT BHU Ph.D. ApplicationDocument13 paginiIIT BHU Ph.D. Applicationg20kpÎncă nu există evaluări

- Oral Iron Chelator PDFDocument7 paginiOral Iron Chelator PDFg20kpÎncă nu există evaluări

- ParacetamolDocument24 paginiParacetamolg20kp33% (3)

- Hand Book On Ayurvedic Medicines With Formulae Processes Their Uses H Panda.07111 - 1contents PDFDocument5 paginiHand Book On Ayurvedic Medicines With Formulae Processes Their Uses H Panda.07111 - 1contents PDFg20kpÎncă nu există evaluări

- Finar New Price List 2011-12 PDFDocument43 paginiFinar New Price List 2011-12 PDFg20kpÎncă nu există evaluări

- Pathogenic Bacteria PDFDocument29 paginiPathogenic Bacteria PDFg20kpÎncă nu există evaluări

- Oral Sustained Release Drug Delivery Systems OverviewDocument0 paginiOral Sustained Release Drug Delivery Systems Overviewg20kpÎncă nu există evaluări

- Guidance for Industry Nonsterile Semisolid Dosage Forms Scale-Up and Postapproval ChangesDocument40 paginiGuidance for Industry Nonsterile Semisolid Dosage Forms Scale-Up and Postapproval Changesdavidarbelo35Încă nu există evaluări

- Chapter 4Document62 paginiChapter 4g20kpÎncă nu există evaluări

- Medicinal PlantDocument3 paginiMedicinal Plantg20kpÎncă nu există evaluări

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- First Summative Test in Math 5 (First Quarter)Document1 paginăFirst Summative Test in Math 5 (First Quarter)Marlene Tagavilla-Felipe Diculen100% (1)

- Reso Course PlannerDocument2 paginiReso Course PlannerSnehasishGhosh100% (1)

- Chapter 2 - Exercises - Econometrics2Document2 paginiChapter 2 - Exercises - Econometrics2Mai AnhÎncă nu există evaluări

- Quantitative Reasoning: Factors, HCF & LCM, FactorialsDocument2 paginiQuantitative Reasoning: Factors, HCF & LCM, FactorialsNaman JainÎncă nu există evaluări

- Heliosit OrthodonticDocument20 paginiHeliosit OrthodonticAndhika Galih PrasetyoÎncă nu există evaluări

- Chapter 1. Griffiths-Vector Analysis - 1.1 1.2Document24 paginiChapter 1. Griffiths-Vector Analysis - 1.1 1.2Hazem TawfikÎncă nu există evaluări

- Homework Labs Lecture01Document9 paginiHomework Labs Lecture01Episode UnlockerÎncă nu există evaluări

- Airy stress function enables determination of stress components in pure beam bendingDocument19 paginiAiry stress function enables determination of stress components in pure beam bendingmaran.suguÎncă nu există evaluări

- Ordinary Dierential Equations Principles and ApplicationsDocument349 paginiOrdinary Dierential Equations Principles and ApplicationsSokratis Spyrou100% (1)

- Data Assigment 1Document32 paginiData Assigment 1Sukhwinder Kaur100% (1)

- Wiring Diagram SCH17: Service InformationDocument16 paginiWiring Diagram SCH17: Service Informationابو حمزة صبريÎncă nu există evaluări

- A Tour Through Mathematical Logic: Robert S. WolfDocument4 paginiA Tour Through Mathematical Logic: Robert S. WolfUrahara JefÎncă nu există evaluări

- Tapered Vector Spiral in InkscapeDocument5 paginiTapered Vector Spiral in InkscapejeanÎncă nu există evaluări

- Experimental Noize Guitar Set 1 Effects PedalDocument2 paginiExperimental Noize Guitar Set 1 Effects PedalSingani Titicaca100% (1)

- L6565 DatasheetDocument17 paginiL6565 DatasheetJose BenavidesÎncă nu există evaluări

- OOPS using C++ Question BankDocument32 paginiOOPS using C++ Question BankPushpa Bg100% (1)

- X 09 CDX 09 High Security LocksDocument8 paginiX 09 CDX 09 High Security LocksBenoit CarrenandÎncă nu există evaluări

- DNV Os C104 2014Document40 paginiDNV Os C104 2014Moe LattÎncă nu există evaluări

- Design of RC Building - ExerciseDocument6 paginiDesign of RC Building - Exercisesajeerala100% (1)

- 93C66 Microwire EepromDocument13 pagini93C66 Microwire EepromadrianramonÎncă nu există evaluări

- CmeDocument41 paginiCmekhalis@hotmail.com100% (1)

- A Short Guide To Arrows in ChemistryDocument1 paginăA Short Guide To Arrows in ChemistryJefferson RibeiroÎncă nu există evaluări

- Problem Set Ee8205 PDFDocument4 paginiProblem Set Ee8205 PDFksajjÎncă nu există evaluări

- Lime Manual PDFDocument60 paginiLime Manual PDFKenny RuizÎncă nu există evaluări

- External DC fuse board for Sunny Island battery invertersDocument2 paginiExternal DC fuse board for Sunny Island battery invertersrhadammantysÎncă nu există evaluări

- UNIT 7 - Atomic TransactionsDocument30 paginiUNIT 7 - Atomic TransactionslavanyatumuÎncă nu există evaluări

- Huawei Site Design GuidelineDocument7 paginiHuawei Site Design GuidelineHeru BudiantoÎncă nu există evaluări

- Structural Geology From Barmer Basin (India)Document12 paginiStructural Geology From Barmer Basin (India)Sankhajit SahaÎncă nu există evaluări

- 0620 Chemistry: MARK SCHEME For The March 2015 SeriesDocument6 pagini0620 Chemistry: MARK SCHEME For The March 2015 SeriesDark GreenÎncă nu există evaluări

- Evaluasi Mutu Fisik, Total Bakteri, Dan Sensori Minuman Sari Tempe Dengan Penambahan Bunga KecombrangDocument12 paginiEvaluasi Mutu Fisik, Total Bakteri, Dan Sensori Minuman Sari Tempe Dengan Penambahan Bunga KecombrangJosua PakpahanÎncă nu există evaluări