Documente Academic

Documente Profesional

Documente Cultură

Indian Railway Specification

Încărcat de

Er Harsh MahajanTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Indian Railway Specification

Încărcat de

Er Harsh MahajanDrepturi de autor:

Formate disponibile

IRS/T-40 -1985

INDIAN RAILWAYS STANDARD SPECIFICATION FOR SPECIAL GRADE CEMENT FOR USE IN CONCRETE SLEEPERS ADOPTED, 1985

0. FOREWORD

0.1

This specification is issued under the fixed serial number T40-1985, the final number indicates the year of original adoption as standard, or in case of revision, the year of last revision. References made to IS: 650, IS: 3535, IS: 4031 and IS: 4032 in this specification, relate to the latest version of these standards.

0.2

1.

SCOPE

1.1

This specification covers the manufacture, chemical and physical requirements of special grade cement required for manufacture of concrete sleepers for Indian Railways.

2.

MANUFACTURE

2.1

Special grade cement shall be manufactured by intimately mixing together calcareous and argillaceous and/or other silica, alumina or iron oxide bearing materials, burning them at a clinkering temperature and grinding, the resultant clinker so as to produce a cement capable of complying with this specification. No material shall be added after burning other than gypsum or water or both, and not more than 1% of air-entraining agents or other agents which have proved not to be harmful.

3.

CHEMICAL REQUIREMENTS

3.1

When tested in accordance with the methods given in IS: 4032-1968, special grade cement shall comply with the chemical requirements given below in Table-I:

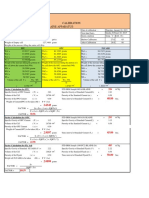

IRS/T-40 -1985 S. No. Characteristics i) Requirements

Ratio of percentage of lime to percentage of Not greater then 1.02 and not less silica, alumina and iron oxide, when than 0.8. calculated by the formula: CaO 0.7 SO3 2.8 SiO2 + 1.2 Al2O3 + 0.65 Fe2O3 Ratio of percentage or alumina to that of Not less than 0.66. iron oxide. Insoluble residue. Not more than 2% by mass. Magnesia (MgO) percentage by mass. Not more than 5% Total sulphur content calculated as Not more than 3.5% sulphuric anhydride (SO3), percentage by mass. Total loss on ignition. Not more than 4% Tricalcium Aluminate content (C3A). Not more than 10% Tricalcium Silicate content (C3S). Not less than 45%

ii) iii) iv) v)

vi) vii) vii)

NOTE: The tricalcium aluminate (C3A) and tricalcium silicate (C3S) contents are calculated by the formulae: C3A = 2.65 (Al2 O3) 1.69 (Fe2 O3) C3S = 4.07(CaO) -7.6(SiO2) - 6.72(Al2O3) - 1.43 (Fe2O3) 2.85 (SO3) Where each symbol in bracket refers to the percent (by mass of total cement) of the oxide, excluding any contained in insoluble residue referred to at S. No. (iii). 4. 4.1 PHYSICAL REQUIREMENTS Fineness

4.1.1 When tested for fineness by Blaines air permeability method as described in IS: 4031 1968, the specific surface of cement shall not be less than 3700 cm2/g. 4.2 Soundness

4.2.1 When tested by the Le Chatelier method described in IS: 4031-1968, unaerated cement shall not have an expansion or more than 5mm. 4.2.2 Unaerated special grade cement having a magnesia content more than 3% shall be tested for soundness by Autoclave Test described in IS: 4031-1968 and shall not have an expansion of more than 0.8 percent. Cement having a magnesia content of less than or equal to 3% need not be tested for Autoclave Expansion.

IRS/T-40 1985 4.3 Setting Time

4.3.1 The setting time of cement when tested by the Vicat apparatus method described in IS: 4031-1968 shall conform to the following requirements: a) b) Initial Not less than 60 minutes. Final -- Not more than 600 minutes.

4.3.2 Cement shall not exhibit the property of false set. 4.4 Compressive Strength

4.4.1 The average compressive strength of at least three mortar cubes (area of face of 50 cm2) composed of one part of cement, three parts of standard sand (conforming to IS: 650-1966) by mass and P percent (of combined, mass of cement plus sand) water, prepared, stored and tested in the manner described in IS: 4031-1968 shall be as follows: After 7 days Min. 375 kg/cm2

Note: P is the percentage of water required to produce a paste of standard consistency.

4.4.2 Not withstanding the strength requirements, specified in 4.4.1 above, cement shall show a progressive increase in strength from the strength at 7 days. 5. 5.1 STORAGE The cement shall be stored in such a manner as to permit easy access for proper inspection and in a suitable weather-tight building to protect the cement from dampness and to minimize warehouse deterioration. MANUFACTURERS CERTIFICATE The manufacturer shall satisfy himself that the cement conforms to the requirements of this specification and shall furnish a certificate to this effect to the purchaser or his representative within ten days of dispatch of the cement. The certificate shall indicate specifically the values of MgO, setting time (initial and final), fineness in terms of specific surface, compressive strength at 7 days and expansion of cement. DELIVERY The cement shall be packed in bags, jute, jute laminated (CRI type), multi-ply paper or poly-ethylene lined bearing the manufacturers name or his registered trademark, if any, and the works Special Grade Cement. Net mass of the cement shall be legibly and indelibly marked on each bag. Bags shall be in good condition at the time of inspection.

6. 6.1

7. 7.1

IRS/T-40 1985 7.2 The net mass of each bag shall be 50 kg. The permissible tolerance on the mass of cement supplied in bags shall be -2.5% per bag with an overall tolerance of 0.5% per wagonload of 20 to 25 tonnes. SAMPLING Sample for testing and by whom to be taken

8. 8.1

8.1.1 A sample or samples for testing may be taken in accordance with IS: 3535-1966 by the purchaser or his representative or by any person appointed to superintendent the work for the purpose of which the cement is required or by the latters representative. 8.1.2 The samples shall be taken just after manufacture of cement or within one week of the delivery and all the tests shall be commenced within one week of sampling. 8.2 Facilities for sampling & identification

8.2.1 The manufacturer or supplier shall afford every facility and shall provide all labour and materials for taking and packing the samples for testing the cement and for subsequent identification of the cement samples. 9. 9.1 TESTS Independent testing

9.1.1 If the purchaser or his representative requires independent tests, the samples shall be taken before or immediately after delivery at the option of the purchaser or his representative, and the tests shall be carried out in accordance with this standard on written instructions of the purchaser or his representative. 9.2. Cost of testing

9.2.2 The manufacturer shall supply, free of charge, the cement required for testing, unless otherwise specified in the Purchase Order. 10. 10.1 REJECTION Cement may be rejected if it does not comply with any of the requirements of this specification. Cement remaining in bulk storage at the mill, prior to loading, for more than 6 months, or cement in bags in local storage in the hands of vendor for more than 3 months after completion of tests, may be rejected before use and may be rejected, if it fails to conform to any of the requirements in this specification.

10.2

S-ar putea să vă placă și

- Durability Design of Concrete Structures: Phenomena, Modeling, and PracticeDe la EverandDurability Design of Concrete Structures: Phenomena, Modeling, and PracticeÎncă nu există evaluări

- Paving Bitumen - Specification: Indian StandardDocument2 paginiPaving Bitumen - Specification: Indian StandardDevela Avinash100% (1)

- Design Mix M 30 PPC - CP2659-41Document2 paginiDesign Mix M 30 PPC - CP2659-41Sathish AnandakumarÎncă nu există evaluări

- M40 Mix DesignDocument13 paginiM40 Mix DesignVk Rai100% (1)

- Is 4031 (Part-3) Method of Physical Tests For Hydraulic CemeDocument6 paginiIs 4031 (Part-3) Method of Physical Tests For Hydraulic CemeRamarraju KalidindiÎncă nu există evaluări

- IRC-SP-49-1998 Guidelines For The Use of Dry Lean Concrete As Sub-Base For Rigid PavementDocument17 paginiIRC-SP-49-1998 Guidelines For The Use of Dry Lean Concrete As Sub-Base For Rigid PavementDarshan Cr50% (2)

- Is:2386 1Document22 paginiIs:2386 1Ramesh0% (1)

- PMB - Is 15462 - 2019Document20 paginiPMB - Is 15462 - 2019vinayaka.vr100% (1)

- Is 9142 Part 1 2018Document14 paginiIs 9142 Part 1 2018Varun GuggilamÎncă nu există evaluări

- Is 15388 (2003) - Specification For Silica FumeDocument13 paginiIs 15388 (2003) - Specification For Silica FumeN GANESAMOORTHYÎncă nu există evaluări

- BS 00812 114 1989 2011Document14 paginiBS 00812 114 1989 2011KEVIN100% (1)

- Designed Concrete MixDocument6 paginiDesigned Concrete MixniceseshaÎncă nu există evaluări

- Morth Section 900Document256 paginiMorth Section 900VikasMauryaÎncă nu există evaluări

- PW .KR B Èku JK (K&Lhesav B V Fof'Kf"V: HKKJRH EkudDocument11 paginiPW .KR B Èku JK (K&Lhesav B V Fof'Kf"V: HKKJRH EkudANMSÎncă nu există evaluări

- NHAI 4-Laning Cholapuram to Thanjavur Section NH-45CDocument1 paginăNHAI 4-Laning Cholapuram to Thanjavur Section NH-45CDwijendra Chanumolu100% (2)

- 269 2015 Reff2020Document13 pagini269 2015 Reff2020sunil kumar sharmaÎncă nu există evaluări

- Eiffic/Efuf (T:, RFRDT (FrrtfuDocument17 paginiEiffic/Efuf (T:, RFRDT (FrrtfuRamasubba RajuÎncă nu există evaluări

- MIX DESIGN DBM Well SpunDocument30 paginiMIX DESIGN DBM Well SpunTarun100% (2)

- Accelerated carbonation test methodDocument12 paginiAccelerated carbonation test methodMaulik PanseriyaÎncă nu există evaluări

- 2017Document12 pagini2017ਸੁਖਬੀਰ ਸਿੰਘ ਮਾਂਗਟÎncă nu există evaluări

- Mastic Asphalt Design (With Ca)Document36 paginiMastic Asphalt Design (With Ca)Soundar Pachiappan100% (1)

- Dry lean concrete mix designDocument3 paginiDry lean concrete mix designKunal Paul100% (2)

- SMART TITLEDocument47 paginiSMART TITLErajibchattarajÎncă nu există evaluări

- (Kmatk Mkyus Osq Fy, Mkej Fof'Kf"V: HKKJRH EkudDocument6 pagini(Kmatk Mkyus Osq Fy, Mkej Fof'Kf"V: HKKJRH Ekudvinayaka.vrÎncă nu există evaluări

- DLC-Dry Lean Concrete Sub-base for Cement Concrete PavementDocument14 paginiDLC-Dry Lean Concrete Sub-base for Cement Concrete PavementvijayÎncă nu există evaluări

- IS: 73 - 1992 Paving Bitumen - SpecificationDocument7 paginiIS: 73 - 1992 Paving Bitumen - SpecificationKarthikeyan Vedi83% (6)

- Is 15388 2003 PDFDocument13 paginiIs 15388 2003 PDFrahulÎncă nu există evaluări

- Coarse and Fine Aggregate ManualDocument14 paginiCoarse and Fine Aggregate Manualjitender100% (1)

- Is 3117Document17 paginiIs 3117Amit Prasad100% (1)

- Calibrate Blaine apparatusDocument1 paginăCalibrate Blaine apparatusVijay Bhan100% (3)

- Is 383 2016Document22 paginiIs 383 2016Meena MurmuÎncă nu există evaluări

- DLC Design Mix Stipulation1Document8 paginiDLC Design Mix Stipulation1abhishek negiÎncă nu există evaluări

- IRC SP 112-2017 Manual For Quality Control in Road - Bridge WorksDocument221 paginiIRC SP 112-2017 Manual For Quality Control in Road - Bridge WorksjitendraÎncă nu există evaluări

- Is 12894: 1990Document6 paginiIs 12894: 1990mukaslam100% (7)

- NH-208 Widening ProjectDocument20 paginiNH-208 Widening ProjectAbhishek pathakÎncă nu există evaluări

- Irc Gov in SP 102 2014 PDFDocument80 paginiIrc Gov in SP 102 2014 PDFPari Athouba100% (4)

- Irc 107 - 2013 PDFDocument24 paginiIrc 107 - 2013 PDFRudranath BhattacharyaÎncă nu există evaluări

- Cement Treated Base Test Results Summary: National Highways Authority of India (Ministry of Road Transport & Highways)Document61 paginiCement Treated Base Test Results Summary: National Highways Authority of India (Ministry of Road Transport & Highways)Fariha Azad100% (1)

- Is 8887-2018Document13 paginiIs 8887-2018Anant GuptaÎncă nu există evaluări

- BC Job MixDocument3 paginiBC Job MixSOIGNE ENGINEERING CONSULTANTSÎncă nu există evaluări

- Mix Design Using RAP 30Document4 paginiMix Design Using RAP 30Raghav100% (2)

- Is 13311 - 2Document9 paginiIs 13311 - 2Sravan KumarÎncă nu există evaluări

- Dense Bitumen Macadam (DBM) LayerDocument12 paginiDense Bitumen Macadam (DBM) LayerPathankot MandiÎncă nu există evaluări

- B65 Micro Concrete Mix DesignDocument1 paginăB65 Micro Concrete Mix Designsadi3013Încă nu există evaluări

- M20 Kerb - Mix Design Calculation: Volume of Cementicious Materials+Water+AdmixtureDocument1 paginăM20 Kerb - Mix Design Calculation: Volume of Cementicious Materials+Water+Admixturevdbshamsabad labÎncă nu există evaluări

- (With Flyash) : M-20 KERBDocument8 pagini(With Flyash) : M-20 KERBNaveen SinghÎncă nu există evaluări

- DIN1048 Part 5 PDFDocument8 paginiDIN1048 Part 5 PDFRuwan Sampath WickramathilakaÎncă nu există evaluări

- Annexure 5.14 Mix DesignDocument10 paginiAnnexure 5.14 Mix Designmiesty50% (2)

- Morth Clause of Bitumen MasticDocument5 paginiMorth Clause of Bitumen Masticm_k_tripathyÎncă nu există evaluări

- Trial 1 Analysis of Report (DBM 2)Document12 paginiTrial 1 Analysis of Report (DBM 2)JaneshaÎncă nu există evaluări

- Specification For 53 Grade Ordinary Portland CementDocument7 paginiSpecification For 53 Grade Ordinary Portland Cementsukanta420Încă nu există evaluări

- Semen PDFDocument324 paginiSemen PDFpaimannÎncă nu există evaluări

- Portland Slag Cement-Specification: Indian Standard (Fourth Revision)Document15 paginiPortland Slag Cement-Specification: Indian Standard (Fourth Revision)Bilal AhmadÎncă nu există evaluări

- Grade Ordinary Portland Cement - Specification (: Indian Standard 43 Firs-T Revision)Document20 paginiGrade Ordinary Portland Cement - Specification (: Indian Standard 43 Firs-T Revision)kundank_32Încă nu există evaluări

- LIBYAN Cement STANDARD LSS 340 - 2009Document13 paginiLIBYAN Cement STANDARD LSS 340 - 2009Pedja100% (3)

- Concrete GuideDocument38 paginiConcrete GuideAdnan JadoonÎncă nu există evaluări

- Specifications ConcreteDocument54 paginiSpecifications ConcreteAjay MalurÎncă nu există evaluări

- SECTION 5 (Concrete Steel Structures) (FINAL)Document240 paginiSECTION 5 (Concrete Steel Structures) (FINAL)Mohammad SahmoudÎncă nu există evaluări

- Ordinary Portland Cement, 33 Grade - Specification: Indian StandardDocument12 paginiOrdinary Portland Cement, 33 Grade - Specification: Indian StandardAmbrishÎncă nu există evaluări

- SECTION 5 (Concrete Steel Structures) (FINAL)Document241 paginiSECTION 5 (Concrete Steel Structures) (FINAL)Yasmin AkramÎncă nu există evaluări

- Inspection and Maintenance of Steel Girders-11Document10 paginiInspection and Maintenance of Steel Girders-11vpmohammedÎncă nu există evaluări

- Inspection and Maintenance of Steel Girders-5Document10 paginiInspection and Maintenance of Steel Girders-5vpmohammedÎncă nu există evaluări

- Inspection and Maintenance of Steel Girders-13Document10 paginiInspection and Maintenance of Steel Girders-13vpmohammedÎncă nu există evaluări

- Inspection and Maintenance of Steel Girders-12Document10 paginiInspection and Maintenance of Steel Girders-12vpmohammedÎncă nu există evaluări

- Inspection and Maintenance of Steel Girders-4Document10 paginiInspection and Maintenance of Steel Girders-4vpmohammedÎncă nu există evaluări

- Inspection and Maintenance of Steel Girders-8Document10 paginiInspection and Maintenance of Steel Girders-8vpmohammedÎncă nu există evaluări

- Inspection and Maintenance of Steel Girders-11Document10 paginiInspection and Maintenance of Steel Girders-11vpmohammedÎncă nu există evaluări

- Inspection and Maintenance of Steel Girders-12Document10 paginiInspection and Maintenance of Steel Girders-12vpmohammedÎncă nu există evaluări

- Inspection and Maintenance of Steel Girders-11Document10 paginiInspection and Maintenance of Steel Girders-11vpmohammedÎncă nu există evaluări

- Inspection and Maintenance of Steel Girders-5Document10 paginiInspection and Maintenance of Steel Girders-5vpmohammedÎncă nu există evaluări

- Maintaining steel FOB structuresDocument10 paginiMaintaining steel FOB structuresvpmohammedÎncă nu există evaluări

- Railway Bridge Steel Girder ClassificationsDocument10 paginiRailway Bridge Steel Girder Classificationsvpmohammed100% (1)

- Inspection and Maintenance of Steel Girders-10Document10 paginiInspection and Maintenance of Steel Girders-10vpmohammedÎncă nu există evaluări

- Maintaining steel FOB structuresDocument10 paginiMaintaining steel FOB structuresvpmohammedÎncă nu există evaluări

- Inspection and Maintenance of Steel Girders-6Document10 paginiInspection and Maintenance of Steel Girders-6vpmohammedÎncă nu există evaluări

- Inspection and Maintenance of Steel Girders-7Document10 paginiInspection and Maintenance of Steel Girders-7vpmohammedÎncă nu există evaluări

- IECRN Building Orientation-5 - 1Document10 paginiIECRN Building Orientation-5 - 1vpmohammedÎncă nu există evaluări

- Inspection and Maintenance of Steel Girders-7Document10 paginiInspection and Maintenance of Steel Girders-7vpmohammedÎncă nu există evaluări

- IECRN Building Orientation-5 - 1Document10 paginiIECRN Building Orientation-5 - 1vpmohammedÎncă nu există evaluări

- IECRN Building Orientation-5 - 1Document10 paginiIECRN Building Orientation-5 - 1vpmohammedÎncă nu există evaluări

- Inspection and Maintenance of Steel Girders-1Document10 paginiInspection and Maintenance of Steel Girders-1vpmohammedÎncă nu există evaluări

- Inspection and Maintenance of Steel Girders-2Document10 paginiInspection and Maintenance of Steel Girders-2vpmohammedÎncă nu există evaluări

- Building Orientation 3 1Document10 paginiBuilding Orientation 3 1vpmohammedÎncă nu există evaluări

- Railway Curves 3 1Document10 paginiRailway Curves 3 1vpmohammedÎncă nu există evaluări

- Fundamentals of Building Orientation 1-1Document10 paginiFundamentals of Building Orientation 1-1vpmohammedÎncă nu există evaluări

- Fundamentals of Building Orientation 1-2Document11 paginiFundamentals of Building Orientation 1-2vpmohammedÎncă nu există evaluări

- Fundamentals of Building Orientation-4-2Document12 paginiFundamentals of Building Orientation-4-2vpmohammedÎncă nu există evaluări

- Rail Steel 5Document18 paginiRail Steel 5vpmohammedÎncă nu există evaluări

- Fundamentals of Building Orientation 1-1Document10 paginiFundamentals of Building Orientation 1-1vpmohammedÎncă nu există evaluări

- Rail Steel 4Document6 paginiRail Steel 4vpmohammedÎncă nu există evaluări

- An Architect's Guide to Construction: Tales from the Trenches Book 1De la EverandAn Architect's Guide to Construction: Tales from the Trenches Book 1Încă nu există evaluări

- A Place of My Own: The Architecture of DaydreamsDe la EverandA Place of My Own: The Architecture of DaydreamsEvaluare: 4 din 5 stele4/5 (241)

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationDe la EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationEvaluare: 4 din 5 stele4/5 (18)

- Building Construction Technology: A Useful Guide - Part 2De la EverandBuilding Construction Technology: A Useful Guide - Part 2Evaluare: 5 din 5 stele5/5 (1)

- Nuclear Energy in the 21st Century: World Nuclear University PressDe la EverandNuclear Energy in the 21st Century: World Nuclear University PressEvaluare: 4.5 din 5 stele4.5/5 (3)

- The Complete Guide to Alternative Home Building Materials & Methods: Including Sod, Compressed Earth, Plaster, Straw, Beer Cans, Bottles, Cordwood, and Many Other Low Cost MaterialsDe la EverandThe Complete Guide to Alternative Home Building Materials & Methods: Including Sod, Compressed Earth, Plaster, Straw, Beer Cans, Bottles, Cordwood, and Many Other Low Cost MaterialsEvaluare: 4.5 din 5 stele4.5/5 (6)

- Asset Integrity Management for Offshore and Onshore StructuresDe la EverandAsset Integrity Management for Offshore and Onshore StructuresÎncă nu există evaluări

- Engineering Critical Assessment (ECA) for Offshore Pipeline SystemsDe la EverandEngineering Critical Assessment (ECA) for Offshore Pipeline SystemsÎncă nu există evaluări

- Markup & Profit: A Contractor's Guide, RevisitedDe la EverandMarkup & Profit: A Contractor's Guide, RevisitedEvaluare: 5 din 5 stele5/5 (11)

- The Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseDe la EverandThe Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseEvaluare: 5 din 5 stele5/5 (3)

- Building Construction Technology: A Useful Guide - Part 1De la EverandBuilding Construction Technology: A Useful Guide - Part 1Evaluare: 4 din 5 stele4/5 (3)

- A Welder's Guide to Handrails and Railing Codes: Everything You Need to Know about Handrails and the Building Codes That Regulate ThemDe la EverandA Welder's Guide to Handrails and Railing Codes: Everything You Need to Know about Handrails and the Building Codes That Regulate ThemÎncă nu există evaluări

- Industrial Piping and Equipment Estimating ManualDe la EverandIndustrial Piping and Equipment Estimating ManualEvaluare: 5 din 5 stele5/5 (7)

- Field Guide for Construction Management: Management by Walking AroundDe la EverandField Guide for Construction Management: Management by Walking AroundEvaluare: 4.5 din 5 stele4.5/5 (3)

- 1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideDe la Everand1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideEvaluare: 3.5 din 5 stele3.5/5 (7)

- Shipping Container Homes: The complete guide to shipping container homes, tiny houses, and container home plans!De la EverandShipping Container Homes: The complete guide to shipping container homes, tiny houses, and container home plans!Încă nu există evaluări

- How to Estimate with RSMeans Data: Basic Skills for Building ConstructionDe la EverandHow to Estimate with RSMeans Data: Basic Skills for Building ConstructionEvaluare: 4.5 din 5 stele4.5/5 (2)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedDe la EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedEvaluare: 5 din 5 stele5/5 (1)

- The E-Myth Contractor: Why Most Contractors' Businesses Don't Work and What to Do About ItDe la EverandThe E-Myth Contractor: Why Most Contractors' Businesses Don't Work and What to Do About ItEvaluare: 4 din 5 stele4/5 (16)

- Well Control for Completions and InterventionsDe la EverandWell Control for Completions and InterventionsEvaluare: 4 din 5 stele4/5 (10)

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ADe la EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AÎncă nu există evaluări