Documente Academic

Documente Profesional

Documente Cultură

B43ib20c e Cobrix3 Servicebook

Încărcat de

frank0213Descriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

B43ib20c e Cobrix3 Servicebook

Încărcat de

frank0213Drepturi de autor:

Formate disponibile

M

e

a

s

u

r

e

,

w

h

a

t

|

s

m

e

a

s

u

r

a

b

|

e

,

a

n

d

m

a

k

e

m

e

a

s

u

r

a

b

|

e

t

h

a

t

w

h

|

c

h

|

s

n

o

t

.

G

a

|

|

|

e

o

G

a

|

|

|

e

|

1

5

6

4

-

1

6

4

2

}

Service Manual

COBRIX3 & COBRIX3 multibev

On-line Beverage Analyzer

Service Manual

COBRIX3 & COBRIX3 multibev

On-line Beverage Analyzer

While every precaution has been taken in the preparation of this document, Anton Paar GmbH assumes

no responsibility for technical or printing errors or omissions.

Nor is any liability assumed for damages resulting from the use of the information contained in this

instruction manual.

Anton Paar GmbH does not make a commitment to update the information in this manual. Specifications

are subject to change without notice.

All rights reserved (including translation). No part of this document may be translated, reproduced or

distributed in any form (print, photocopy, microfilm or any other process) without the prior written

permission of Anton Paar GmbH.

Trade marks may be used in this instruction manual without being marked as such. These are the

property of their respective owners and are legally protected.

Published by Anton Paar GmbH. Printed in Austria.

Copyright 2004 Anton Paar GmbH, Graz, Austria

Contact: Anton Paar GmbH

Anton-Paar-Str. 20

A-8054 Graz / Austria - Europe

Tel: +43 316 257-0

Fax: +43 316 257-257

E-mail: info@anton-paar.com

Web: www.anton-paar.com

Date: 31.12.2004

Document number: B43IB20C.fm

B43IB20 5

Contents

1 System Overview............................................................................................................................. 7

1.1 Versions of COBRIX3.............................................................................................................. 7

1.2 Functional Components/Spare Part List .................................................................................. 8

2 Safety Instructions......................................................................................................................... 17

3 Symbols in the Service Manual .................................................................................................... 19

4 Reference Manuals........................................................................................................................ 21

5 Service and Maintenance.............................................................................................................. 23

6 Cleaning the COBRIX3 .................................................................................................................. 25

7 Disconnecting the COBRIX3......................................................................................................... 27

7.1 Stopping the COBRIX3.......................................................................................................... 27

7.2 Disconnecting the Power Supply........................................................................................... 27

7.3 Disconnecting the Compressed Air Supply ........................................................................... 28

7.4 Closing the Bypass Valve...................................................................................................... 28

7.5 Disconnecting the COBRIX3 from the Product Line.............................................................. 29

7.6 Removing the Stainless Steel Covers ................................................................................... 29

7.7 Opening the Stainless Steel Housing Rear Door................................................................... 29

8 Checking the Pump Motor Overload Relay ................................................................................. 31

9 Relay for the Liquid Sensor .......................................................................................................... 35

10 24V Switched Mode Power Supply............................................................................................... 39

11 Line Protector................................................................................................................................. 41

12 Additional Alarm Relay.................................................................................................................. 43

13 Alarm/Warning Light...................................................................................................................... 47

14 LED Display.................................................................................................................................... 49

15 Replacing the CARBO 2100 CO2 Transducer ............................................................................. 53

16 Replacing the DPRn or DSRn Transducer................................................................................... 57

17 Replacing the Shaft Seal of the Pump......................................................................................... 61

18 Replacing the Pump ...................................................................................................................... 67

19 Disconnecting the Pump Cable.................................................................................................... 69

20 Wetted Parts................................................................................................................................... 75

21 List of Spare Parts for 1 Year of Operation................................................................................. 77

22 List of Tools.................................................................................................................................... 79

23 Troubleshooting............................................................................................................................. 81

24 Document Numbers....................................................................................................................... 83

Appendix A: Service/Maintenance Report .................................................................................... 84

Appendix B: Feedback Form.......................................................................................................... 90

6 B43IB20

1 System Overview

B43IB20 7

1 System Overview

1.1 Versions of COBRIX3

There are 2 versions of the COBRIX3:

COBRIX3 multibev Beverage Analyzer:

All-round version with DSRn for

sugared and diet beverages

sugared beverages with sugar inversion compensation

beverages with alcohol (alcoholic lemonades, malternatives, etc.)

beer

wine

COBRIX3 Beverage Analyzer:

Basic version with DPRn for sugared and diet beverages.

1 System Overview

8 B43IB20

1.2 Functional Components/Spare Part List

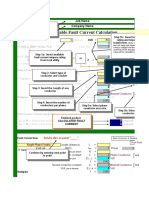

Fig. 1.1 - 1 Side view of COBRIX3

Alarm lamp

Warning lamp

Main switch

Switch box including

mPDS evaluation unit

Bypass with liquid

Production

line

Stainless steel (SS)

protection cover

Front door

CO

2

transducer

CARBO 2100

DPRn or DSRn

density/sound velocity

transducer (see warning 3

sensor and valves

Rear door

Lock (see warning 1 below)

Pump (see

warning 2

below)

below)

(see warning 4

below)

Handles (see warning 5 below)

1 System Overview

B43IB20 9

Warning1:

High voltage. Danger of electric shock. Before removing outside covers,

switch off the instrument and disconnect it from the mains.

Service procedures may only be carried out by authorized and fully trained

service personnel.

Warning 2:

The pump may be under pressure. Before opening the pump, disconnect the

pump from the product line and exhaust it.

Service procedures may only be carried out by authorized and fully trained

service personnel.

Warning 3:

The product line may be under pressure. Before opening the DPRn or DSRn,

disconnect it from the product line.

Service procedures may only be carried out by authorized and fully trained

service personnel.

Warning 4:

The product line may be under pressure. Before opening the CARBO 2100,

disconnect it from the product line.

Service procedures may only be carried out by authorized and fully trained

service personnel.

Warning 5:

To remove the cover, use the handles. Do not use the handles for carrying the

COBRIX3.

Warning 6:

Hot product or hot CIP liquid may come out of the sample valve.

Wear protective gloves to open and clsoe the sample valve.

Take care not to get in touch with the hot rinsing liquid or hot product.

1 System Overview

10 B43IB20

Alarm lamp

Measuring value

Optional displays for Brix / %Diet,

CO

2

and alcohol or temperature

Warning lamp

Pump start

storage button Alarm Reset Button

button

Main switch

Optional product

selector switch

Pump ON/OFF

switch

Fig. 1.1 - 2 Operator Interface of COBRIX3

1 System Overview

B43IB20 11

Fig. 1.1 - 3 Parts of COBRIX3

12 B43IB20

7045

12864 11040

11039

Fig. 1.1 - 4 Options for COBRIX3

Bottle counter

Flow monitor Product selector switch

3 LED Displays

1 System Overview

B43IB20 13

COBRIX3 MultiBev beverage analyzer with Density-Sound Transducer:

10765 COBRIX3 MULTIBEV BEVERAGE ANALYZER 115V WITH DSRn

10764 COBRIX3 MULTIBEV BEVERAGE ANALYZER 230V WITH DSRn

Consists of:

DSRn 427 density/sound velocity transducer

CARBO 2100 CO

2

transducer

mPDS 2000 V3

By-pass Product Pump

Liquid Sensor

COBRIX3 beverage analyzer with Density Transducer:

10763 COBRIX3 BEVERAGE ANALYZER 115V WITH DPRn

10762 COBRIX3 BEVERAGE ANALYZER 230V WITH DPRn

Consists of:

DPRn 427 density transducer

CARBO 2100 CO

2

transducer

mPDS 2000 V3

By-pass Product Pump

Liquid Sensor

Option:

75504 DAVIS DATA ACQUISITION SOFTWARE

7045 BOTTLE COUNTER

12864 FLOW MONITOR COBRIX3

11039 3 LED DISPLAYS COBRIX3 MOUNTED

11040 EXTERNAL PRODUCT SELECTOR SWITCH COBRIX3

12865 MOUNTING SET SAWA PUMP COBRIX3

Accessories:

1151 ELBOW TUBE 45 DN 25 TRICLAMP

1 System Overview

14 B43IB20

77390 ELBOW TUBE 90 DN 25 TRICLAMP

5107 TRI-CLAMP FILTER DN25 EPDM

12995 CONVERTER KIT PC RS232-RS485

Spare parts for "Speck pump NPY 2051":

77385 CENTRIFUGAL PUMP NPY-2051 115V 50/60HZ

77506 CENTRIFUGAL PUMP NPY-2051 230V 50/60HZ

77953 SHAFT SEAL FOR NPY-2051

O-RING FOR NPY-2051 CASE

77954

77957 IMPELLER NPY-2051 50/60 Hz

77507 WASHER G3/4" PCTFE

Spare parts for "Sawa Pump":

8428 CENTRIFUGAL PUMP SAWA 230V 50HZ

8429 CENTRIFUGAL PUMP SAWA 115V 60HZ

9404 SHAFT SEAL SLIP RING SAWA PUMP

9405 SHAFT SEAL LIP RING SAWA PUMP

8433 TRICLAMP WASHER SMALL 25MM EPDM

8432 TRICLAMP BRACKET DA 25mm 1.4301

10394 FLEXIBLE HOSE COBRIX3 SAWA PUMP-DPR DN10X260

8424 FLEXIBLE HOSE COBRIX3 MAIN LINE-SAWA PUMP DN12X800

Spare parts for COBRIX3 - bypass etc.:

70768 CLAMP 25mm DIN 32676 1.4301

70769 WASHER 25MM DIN 32676 EPDM

10767 LIQUID SENSOR RELAY 115V

10766 LIQUID SENSOR RELAY 230V

10790 LIQUID SENSOR COBRIX3

77514 WASHER G3/8" PCTFE

1910 BUTTERFLY VALVE DN25 CLAMP / WELDING END

10393 FLEXIBLE HOSE COBRIX3 MAIN LINE-SPECK PUMP DN12X830

4254 FLEXIBLE HOSE PUMP/DPR 3/4" DN10 3/8" 400 MM

10396 FLEXIBLE HOSE COBRIX3 CARBO-MAIN LINE DN10X1500

1 System Overview

B43IB20 15

10775 SAMPLE VALVE COBRIX3 TRICLAMP DN10

10395 FLEXIBLE HOSE COBRIX3 DPR-CARBO DN10X395

16 B43IB20

2 Safety Instructions

B43IB20 17

2 Safety Instructions

This service manual does not claim to address all of the safety issues

associated with the service and operation of the COBRIX3 and samples. It is

the service technicians responsibility to ensure all health and safety

regulations are met for the persons concerned prior to starting service and

maintenance work.

Before servicing the COBRIX3, read this manual completely.

Anton Paar GmbH only warrants the proper functioning of the COBRIX3 if

no unauthorized adjustments have been made to mechanical parts,

electronic parts and software, and the following points are adhered to.

Follow all hints, warnings and instructions in the manual to ensure the

correct and safe functioning of the COBRIX3.

Do not handle the COBRIX3 other than described in the manual. Anton Paar

GmbH is not liable for damages caused by incorrect handling of the

COBRIX3.

The installation procedure must only be carried out by authorized personnel

who are familiar with the installation instructions.

Do not operate the COBRIX3 if a malfunction is suspected, or damages,

injuries or loss of life cannot be excluded under all circumstances.

The COBRIX3 is not an explosion-proof instrument and therefore must not

be operated in areas where there is a risk of explosion.

Use only original spare parts and parts explicitly indicated as parts for repair.

Service or repair work must only be carried out by qualified personnel,

authorized service centers, professional workshops or by Anton Paar GmbH.

Use only recommended and appropriate tools.

Ensure that all operators are fully trained to use the COBRIX3 correctly and

safely.

Due to the nature of the measurement, the measuring results do not only

depend on the correct use and functioning of the COBRIX3, but may also be

influenced by other factors. We therefore advise that the analysis results are

plausibility tested before consequential actions are taken.

Repair and service procedures may only be carried out by authorized

personnel or by Anton Paar GmbH.

18 B43IB20

If the safety appliances of the COBRIX3 are opened, changed or interrupted

during the service, a safety check must be performed after the repair.

Never install the COBRIX3 Beverage Analyzer and the evaluation unit in

areas where strong electromagnetic fields are present.

Before carrying out any service procedures, the COBRIX3 Beverage

Analyzer must be disconnected from the mains, product line and

compressed air supply.

The COBRIX3 Beverage Analyzer contains electrostatically sensitive

devices. When handling modules/components of the instrument they must

be protected from electrostatic discharge. Use a grounded wristband when

handling these components. If you return modules for repair, use appropriate

packaging which protects these modules from electrostatic discharge.

Do not touch areas marked with this symbol (yellow) when the power is

turned on. This "Warning" sign on the instrument means "Carefully read

the accompanying documents".

3 Symbols in the Service Manual

B43IB20 19

3 Symbols in the Service Manual

The following symbols are used in the instruction manual:

Warning:

The "Warning" sign indicates a hazard.

It calls attention to an operating procedure, practice, etc. which, if not correctly

performed or adhered to, could result in injury or loss of life.

Do not proceed beyond a "Warning" sign until the indicated conditions are

fully understood and met.

Important:

The "Important" sign indicates a hazard.

It calls attention to an operating procedure, practice, etc. which, if not correctly

performed or adhered to, could result in damage or destruction of the

instrument or parts of it.

Do not proceed beyond an "Important" sign until the indicated conditions are

fully understood and met.

Hint:

The "Hint" sign calls attention to any additional information which might be

of use to the operator.

20 B43IB20

4 Reference Manuals

B43IB20 21

4 Reference Manuals

The standard COBRIX3 on-line beverage analyzer consists of:

the mPDS 2000V3 evaluation unit

the DPRn density transducer or DSRn density/sound velocity transducer

(multibev)

the CARBO 2100 CO

2

transducer

For detailed information concerning these instruments please refer to the

following manuals.

mPDS 2000V3

Instruction Manual

mPDS 2000V3

Program Description Beverages

mPDS 2000V3

Service Manual

CARBO 2100 CO

2

transducer

Instruction Manual

CARBO 2100 CO

2

transducer

Service Manual

DPRn density transducer

Instruction Manual

DSRn density & sound velocity transducer

Instruction Manual

22 B43IB20

5 Service and Maintenance

B43IB20 23

5 Service and Maintenance

To ensure reliable and trouble-free operation, the COBRIX3 must be checked,

serviced and cleaned periodically.

The COBRIX3 service and maintenance intervals depend on the operating

conditions. The following is recommended as a general maintenance procedure.

Daily

Check daily for error messages on the display of the evaluation unit.

Once a week

Check the inside of the stainless steel cover (SS cover) once a week for

leaks.

Check (visually) the condensate level in the pressure regulator.

Check the set pressure of the pressure regulator. The set pressure must be

4.5 bar.

Process instruments are often exposed to extreme working conditions such

as pressure shock, sudden changes in temperature, aggressive samples,

etc. which may cause drifts or failure. Therefore, it is essential to periodically

compare the measured results to reference values and readjust the

measuring system if required.

Check the indicated concentration of the product.

Check the indicated CO

2

concentration.

Check the indicated temperature of the product

Check the indicated line pressure.

Pump maintenance:

The maintenance interval depends on the process and operating conditions of the

pump. We recommend checking the following:

- Sample residues on the pump and motor

Clean the pump and motor

Although the pump and motor are protected by stainless steel covers,

product or rinsing liquid may get under the cover e.g. through the opening

5 Service and Maintenance

24 B43IB20

on the bottom. Remove product residues from the pump and motor using

warm water. This prevents the motor becoming blocked and ensures

proper cooling of the motor.

- Leakage at the COBRIX3 hoses

Tighten all fittings

We use high quality seal rings for all fittings of the COBRIX3. Immediately

after start up some leakage may occur due to the initial compression of

the seal rings.

- Leakage at the shaft seal

Replace the shaft seal

During normal operation there should be no leakage at the shaft seal.

Foreign substances or wear can damage the shaft seal causing leakage.

In this case, the shaft seal must be replaced.

Continuous leakage at the shaft seal may destroy the motor of the pump.

Every 6 month

Replace the diaphragms:

The diaphragms of the CARBO 2100 are mechanically stressed and will

wear out. They should be replaced after a period of 4 months up to half a

year. The period depends on the operating conditions.

Check the CARBO 2100 impeller visually and replace it if necessary.

Check the drives of the diaphragm valves visually and replace if necessary.

For more detailed service and maintenance information concerning the

CARBO 2100 CO

2

transducer, mPDS 2000V3 evaluation unit and DPRn or DSRn

transducer, please refer to the respective manual:

CARBO 2100 CO

2

transducer service manual.

mPDS 2000V3 service manual.

DPRn density transducer instruction manual or DSRn density & sound

velocity transducer instruction manual.

6 Cleaning the COBRIX3

B43IB20 25

6 Cleaning the COBRIX3

The COBRIX3 cleaning interval depends on the operating conditions. We

recommend cleaning the COBRIX3 at least once a week.

Check if any sample is visible on the instrument and clean if necessary.

Use water or warm water as the cleaning agent.

Warning:

See chapter 7: Disconnecting the COBRIX3.

See chapter 7.1: Stopping the COBRIX3.

See chapter 7.2: Disconnecting the Power Supply.

See chapter 7.4: Closing the Bypass Valve.

See chapter 7.6: Removing the Stainless Steel Covers.

26 B43IB20

7 Disconnecting the COBRIX3

B43IB20 27

7 Disconnecting the COBRIX3

7.1 Stopping the COBRIX3

Before carrying out any service procedures, it is necessary to STOP the

COBRIX3. Perform the following steps:

Inform the production manager that the COBRIX3 will be stopped

Turn off the power for the rotary pump using the Pump ON/OFF switch (see

Fig. 1.2).

Turn off the main switch (see Fig. 1.2)

7.2 Disconnecting the Power Supply

1. Turn off the main switch

The lower part of the COBRIX3 contains the transducers. For service or

maintenance work on the lower part of the COBRIX3, turn off the main switch of

the COBRIX3 (see Fig. 1.2)

2. Turn off the circuit breaker

Turn off the main switch. The upper part of the COBRIX3 contains the evaluation

unit and the electrical equipment. For service or maintenance work on the upper

part of the COBRIX3, the circuit breaker must be turned off. The circuit breaker is

located in a switch cabinet outside the COBRIX3. Please contact the plant

electrician.

Warning:

Before carrying out any service procedures, the COBRIX3 Beverage Analyzer

must be disconnected from the mains, product line and compressed air

supply.

7 Disconnecting the COBRIX3

28 B43IB20

7.3 Disconnecting the Compressed Air Supply

Disconnect the compressed air hose from the inlet at the pressure regulator of the

CARBO 2100 transducer.

7.4 Closing the Bypass Valve

Close the bypass valves to separate the COBRIX3 from the product line (see

Fig. 1.1-3).

Open the sample valve to relieve the pressure in the bypass (see Fig. 1.1-3).

Warning:

Only fully trained and authorized technicians may carry out this

procedure.

The COBRIX3 is supplied with line voltage which may be life-threatening if

handled improperly.

Make sure that the line voltage is turned off when handling the power

cable.

Warning:

Compressed air can be hazardous.

Turn off the compressed air supply before disconnecting the hose!

Fig. 7.3-1 Pressure regulator

7 Disconnecting the COBRIX3

B43IB20 29

For service or maintenance for the transducers, first separate them from the

product line.

7.5 Disconnecting the COBRIX3 from the Product

Line

For a safe separation of the COBRIX3 from the product line, we recommend

disconnecting the bypass from the product line completely.

7.6 Removing the Stainless Steel Covers

Tools:

Allen screwdriver 3mm

Remove the stainless steel (SS) covers for service or maintenance work on the

lower part of the COBRIX3.

Open the screws of the SS protection covers.

Use the handles to remove the SS protection covers (see Fig. 1.1-3).

7.7 Opening the Stainless Steel Housing Rear Door

Tools:

Key for the lock of the electronic housing

For service or maintenance procedures on the electronics it is necessary to open

the SS housing rear door.

Open the lock of the rear door (see Fig. 1.1-1).

After shipment the key for the lock is located behind the front door (see Fig.

7.7-1).

W

Warning:

The product line may be under pressure.

Close the bypass valves.

Open the sample valve to relieve the pressure.

Disconnect the bypass from the product line by opening the Triclamp at

the bypass hoses (see Fig.1.1-3).

7 Disconnecting the COBRIX3

30 B43IB20

Warning:

High voltage. Danger of electric shock. Before opening the rear door, switch

off the main switch and the circuit breaker. Service procedures may only be

carried out by authorized and fully trained service personnel.

Fig. 7.7 - 1 Key for rear door

8 Checking the Pump Motor Overload Relay

B43IB20 31

8 Checking the Pump Motor Overload

Relay

Tools:

Key for the lock of the housing rear door (see chapter 7.7).

W

Warning:

See chapter 7: Disconnecting the COBRIX3.

See chapter 7.1: Stopping the COBRIX3.

See chapter 7.2: Disconnecting the Power Supply.

See chapter 7.7: Opening the Stainless Steel Housing Rear Door.

Fig. 8 - 1

32 B43IB20

A The trip current must be adjusted to the rated current of the pump motor

Typical values are mentioned in the following table:

B Push to test the overload relay

C B A

D

Fig. 8 - 2

Warning:

The rated current of the pump must be taken from the label directly on the

pump. A wrong setting can destroy the pump in case of a malfunction.

Type of pump (cat. No, voltage, ...) Typical current

77506,230 VAC, SPECK NPY 2051 2,5 A

77385, 115 VAC,SPECK NPY 2051 3,8 A

8428, 230 VAC, SAWA 1,8 A

8429, 115 VAC, SAWA 4,35 A

8 Checking the Pump Motor Overload Relay

B43IB20 33

C Trip indicator window: If the yellow indicator is visible, the overload relay has

tripped.

D Man mode of operation is selected. Push to reset the relay.

34 B43IB20

9 Relay for the Liquid Sensor

B43IB20 35

9 Relay for the Liquid Sensor

Spare parts:

10766 LIQUID SENSOR RELAY 230V

10767 LIQUID SENSOR RELAY 115V

Tools:

Key for the lock of the housing rear door (see chapter 7.7).

Slotted screwdriver 3mm

A The resistance value is set to 20 kOhm.

Warning:

See chapter 7: Disconnecting the COBRIX3.

See chapter 7.1: Stopping the COBRIX3.

See chapter 7.2: Disconnecting the Power Supply.

See chapter 7.7: Opening the Stainless Steel Housing Rear Door.

Fig. 9 - 1

A

36 B43IB20

Function:

After the relay is supplied with power, the LED (U) is ON. The liquid sensor is

connected to terminals C and MAX. If product is in the sensor, the relay contact

will be closed (terminals 11 and 14) and the LED (R) is ON. It is possible to check

this function using a short circuit between terminals C and MAX.

Fig. 9 - 2

U

Fig. 9 - 3

R

Warning:

High voltage. Danger of electric shock. The terminals A1 and A2 are

supplied with high voltage which is life-threatening. Service and maintenance

may only be carried out by authorized and fully trained personnel.

9 Relay for the Liquid Sensor

B43IB20 37

Replacement:

See chapter 7.2: Disconnecting the Power Supply.

Reconnect the cables to the correct terminals.

The cable ties are used to make a safe separation between circuits with high

and SELV voltage. Therefore, the cable ties must not be changed.

Mount the plastic screw to terminal 12 of the new relay.

38 B43IB20

10 24V Switched Mode Power Supply

B43IB20 39

10 24V Switched Mode Power Supply

Spare parts:

10782 POWER SUPPLY 85-264VAC 24VDC 2,1A

Tools:

Key for the lock of the housing rear door (see chapter 7.7).

A The switched mode power supply has a rated power of 50W. It is the power

supply for the:

- CARBO 2100 15W

- Alarm and Warning Lamps 20W

- COBRIX3 Electronics 10 W

- mPDS2000V3 24V circuits 5W

Warning:

See chapter 7: Disconnecting the COBRIX3.

See chapter 7.1: Stopping the COBRIX3.

See chapter 7.2: Disconnecting the Power Supply.

See chapter 7.7: Opening the Stainless Steel Housing Rear Door.

Fig. 10 - 1

A

G

R

40 B43IB20

Function:

Green LED (G) is ON if the output voltage is active.

Red LED (R) is ON if the output has a short circuit.

11 Line Protector

B43IB20 41

11 Line Protector

Tools:

Key for the lock of the housing rear door (see chapter 7.7).

The line protector has a rated current of 10A. If the current is higher the protector

will trip.

A Lever

Position up: the protector is ON.

Position down: tripped.

B Trip indicator window:

Red: the protector is ON.

Green: tripped.

Warning:

See chapter 7: Disconnecting the COBRIX3.

See chapter 7.1: Stopping the COBRIX3.

See chapter 7.2: Disconnecting the Power Supply.

See chapter 7.7: Opening the Stainless Steel Housing Rear Door.

Fig. 11 - 1

A

B

42 B43IB20

12 Additional Alarm Relay

B43IB20 43

12 Additional Alarm Relay

Spare parts:

8434 RELAY 24V 1A EMG 12-REL/KSR

Tools:

Key for the lock of the housing rear door (see chapter 7.7).

Slotted screw driver 3mm

A Additional alarm relay

Terminal 13 and 14.

Warning:

See chapter 7: Disconnecting the COBRIX3.

See chapter 7.1: Stopping the COBRIX3.

See chapter 7.2: Disconnecting the Power Supply.

See chapter 7.7: Opening the Stainless Steel Housing Rear Door.

Fig. 12 - 1

A

12 Additional Alarm Relay

44 B43IB20

Function:

The additional alarm relay works simultaneously to the alarm Light. It can be used

to connect the alarm light signal to a PLC or other process control unit. A LED

within the relay indicates when the contact is closed.

Technical data:

Requirements for the circuit connected to this relay:

- Rated voltage: 24V

- Rated power: 10W

- Safety: connect only SELV circuits

- Safety: the isolation between the additional alarm relay circuit and circuits

with live voltage must be double insulation.

Fig. 12 - 2

12 Additional Alarm Relay

B43IB20 45

Replacement:

See chapter 7.2: Disconnecting the Power Supply.

Reconnect the conductors to the correct terminals.

The cable ties are used to make a safe separation between circuits with high

and SELV voltage. Therefore, the cable ties must not be changed.

Warning:

Use a cable with double insulation when installing the additional alarm

circuit. Use cable ties to make a safe separation between the alarm circuit

and circuits with high voltage.

The installation may only be carried out by authorized and fully trained

personnel.

46 B43IB20

13 Alarm/Warning Light

B43IB20 47

13 Alarm/Warning Light

Spare parts:

10779 LAMP 24V 10 W

To replace the lamp of the alarm or warning light, open the light housing:

3. Rotate the black ring in the direction "open".

4. Lift the housing.

5. The lamp is located at the top of the housing.

6. Replace the lamp.

Warning:

See chapter 7: Disconnecting the COBRIX3.

See chapter 7.1: Stopping the COBRIX3.

See chapter 7.2: Disconnecting the Power Supply.

Fig. 13 - 1

13 Alarm/Warning Light

48 B43IB20

Lamp

Fig. 13 - 2

14 LED Display

B43IB20 49

14 LED Display

If it is necessary to change the default settings of the optional LED displays follow

the instructions bellow:

Settings of the mPDS2000V3 (e.g.: AO#1)

1. Set the format of the analog output #1 to 0-20 mA.

[Config] [AO-Format] [AO1-Form] [0-20mA]

2. Assign one measuring value to the analog output.

[Config] [Assign] [AnalogOut] [AO1]

3. Enter the product specific scaling of the selected value.

[Prod-Spec] [AO-Scale] [AO1-0/4mA]/ [AO1-20mA]

Connection mPDS 2000 to LEDs

It is not recommended to change the wiring of the LEDs:

the left LED is connected to AO#1

the LED in the middle is connected to AO#2 and

the right LED is connected to AO#3 of the mPDS

Set the position of the decimal point

Open the protection cover on the rear of the LED.

It is possible to change the position of the decimal point with jumpers 10, 11 and

12.

Important:

The scaling must be entered for all products in use.

Jumper on position 10: 000.0

Jumper on position 11: 00.00

Jumper on position 12: 0.000

14 LED Display

50 B43IB20

Adjust the scaling of the display

Example I.:

0-20 mA 0.0.0.0 - 0.9.9.9 or 0.0.0.0 1.9.9.9

Set jumpers 2 and 8, and connect a current of about 20 mA to input terminals

4 and 5 of the display.

Remove the red front cover of the display.

There are 3 adjustment potentiometers:

Adjust the displayed value with the ADJ screw on the front until it matches

the target value. The target value is the one displayed on the mPDS 2000 or

if you use an external current source, it is the value on a reference ampere

meter in the current loop.

Example II:

0-20 mA 0.0.0.0 0.5.0.0

Set jumpers 3 and 8, and carry out the steps described in the above

example.

Put on the cover again.

ADJ maximum range adjustment

LZ minimum range adjustment screw (zero point, not used)

BRIGHT contrast adjustment

Important:

The LED is able to display numbers between 0 1999.

Numbers 2000 can only be displayed with 3 digits (0200).

Make sure to assemble the protection cover on the rear and the front

cover after finishing the setting.

14 LED Display

B43IB20 51

Short description of the manufacturer

- +

24VDC

analog output

of mPDS

52 B43IB20

15 Replacing the CARBO 2100 CO2 Transducer

B43IB20 53

15 Replacing the CARBO 2100 CO

2

Transducer

Spare parts:

77514 WASHER G3/8" PCTFE

Tools:

Open-end wrench 10, 14 and 19 mm

Disconnect the hose at the inlet (I).

Disconnect the hose at the outlet (O).

Disconnect the analog and digital cables (see Fig. 14-2).

Warning:

See chapter 7: Disconnecting the COBRIX3.

See chapter 7.1: Stopping the COBRIX3.

See chapter 7.2: Disconnecting the Power Supply.

See chapter 7.3: Disconnecting the Compressed Air Supply.

See chapter 7.4: Closing the Bypass Valve.

See chapter 7.5: Disconnecting the COBRIX3 from the Product Line.

See chapter 7.6: Removing the Stainless Steel Covers.

Fig. 14 - 1

I

O

15 Replacing the CARBO 2100 CO2 Transducer

54 B43IB20

Replace the CARBO 2100 CO

2

transducer. The transducer is fixed with four

nuts.

To open the nut located at the lower left side (DL) it is necessary to remove

the air regulator. To remove the air regulator open the black nut (BN) of the

air regulator.

Disconnect the analog and digital cables.

Fig. 14 - 2

Fig. 14 - 3

BN

15 Replacing the CARBO 2100 CO2 Transducer

B43IB20 55

Fig. 14 - 4

DL

Hint:

Use new seals when remounting the hoses. Part number: 77514 WASHER

G3/8" PCTFE

Important:

Install a connection cable between terminals 17 and 20 on the mPDS 2000V3

if there is not already a connection cable.

Fig. 14 - 5

56 B43IB20

16 Replacing the DPRn or DSRn Transducer

B43IB20 57

16 Replacing the DPRn or DSRn

Transducer

Spare parts:

77514 WASHER G3/8" PCTFE

Tools:

Open-end wrench 14, 17 and 19 mm

Slotted screwdriver 3 mm

Pozidrive screwdriver (PZ 2x100)

Disconnect the hose at the inlet (I: see Fig. 15-1).

Disconnect the hose at the outlet (O: see Fig. 15-1).

Disconnect the DPRn or DSRn cable.

Warning.

See chapter 7: Disconnecting the COBRIX3.

See chapter 7.1: Stopping the COBRIX3.

See chapter 7.2: Disconnecting the Power Supply.

See chapter 7.3: Disconnecting the Compressed Air Supply.

See chapter 7.4: Closing the Bypass Valve.

See chapter 7.5: Disconnecting the COBRIX3 from the Product Line.

See chapter 7.6: Removing the Stainless Steel Covers.

Fig. 15 - 1

O

I

16 Replacing the DPRn or DSRn Transducer

58 B43IB20

Replace the DPRn or DSRn transducer. The transducer is fixed with four

nuts and screws (4N). .

Fig. 15 - 2

Fig. 15 - 3

O

I

4N

Warning:

As the DPRn or DSRn transducer is very heavy (30 kg), two persons are

necessary to replace the transducer: One person fixes the transducer while

the other person removes the nuts. Afterwards, both people replace the old

transducer with the new transducer.

Hint:

Use new seals when remounting the hoses. Part number: 77514 WASHER

G3/8" PCTFE

16 Replacing the DPRn or DSRn Transducer

B43IB20 59

The standard DPRn or DSRn transducer is delivered with a PG9 cable gland. In

this case the cable gland must be replaced by the M12 plug. Connect the GND

cable to the housing (G), the + wire to the terminal with the red label (R) and the

"- wire to the terminal with the blue label.

Important:

When ordering a DPRn or DSRn transducer as a replacement, please specify

that it is required for a COBRIX3. It will then be shipped with the plug (P) for

the DPR cable connector.

Fig. 15 - 3

P

Fig. 15 - 4

16 Replacing the DPRn or DSRn Transducer

60 B43IB20

Fig. 15 - 5

R

G

17 Replacing the Shaft Seal of the Pump

B43IB20 61

17 Replacing the Shaft Seal of the Pump

Spare Parts:

77953 SHAFT SEAL for NPY 2051

77954 O-RING FOR NPY-2051 CASE

77957 IMPELLER NPY-2051 50/60 Hz

77507 WASHER G3/4" PCTFE

Tools:

Open-end wrench 10mm

Slotted screw driver 3mm

Cutting pliers

Retaining ring pliers

Disconnect the hose at the inlet (I).

Disconnect the hose at the outlet (O).

Warning:

See chapter 7: Disconnecting the COBRIX3.

See chapter 7.1: Stopping the COBRIX3.

See chapter 7.2: Disconnecting the Power Supply.

See chapter 7.4: Closing the Bypass Valve.

See chapter 7.5: Disconnecting the COBRIX3 from the Product Line.

See chapter 7.6: Removing the Stainless Steel Covers

Fig. 16 - 1

I

O

17 Replacing the Shaft Seal of the Pump

62 B43IB20

(1): Lock ring

(2): Disk

(3): Spring

(4): Shaft seal part

(5): Counter ring

(6): O-ring

Fig. 16 - 2

Fig. 16 - 3

Open the pump cover:

Remove the hexagon

screws from the pump

casing. Take off the casing

cover using the two

screwdrivers from the pump

casing.

Fig. 16 - 4

Remove the Impeller:

Remove the feather key. Pull off

the impeller using the two

screws. Remove the locking

ring (1), disk (2) and spring (3).

17 Replacing the Shaft Seal of the Pump

B43IB20 63

Fig. 16 - 5

Fig. 16 - 6

Remove the casing:

Remove the pump casing

from the motor shaft using

the two screwdrivers.

Fig. 16 - 7

17 Replacing the Shaft Seal of the Pump

64 B43IB20

Press out the counter ring:

Press the counter ring (5) of the

mechanical seal out the pump

casing.

Fig. 16 - 8

Clean parts:

Clean the pump parts and the

motor shaft. Clean the shaft with

a lint-free cloth.

Fig. 16 - 9

Mount the shaft seal counter

ring (5):

Lubricate the O-ring (6) with oil

and press it into the pump

casing. Place the pump casing

on the motor flange and center

it. Press the counter ring (5)

over the motor shaft into the

casing.

Fig. 16 - 10

17 Replacing the Shaft Seal of the Pump

B43IB20 65

Check the smooth running of the pump by rotating the fan.

Fig. 16 - 11

Lubricate the seal rubber (4):

Lubricate the rubber of the shaft

seal part (4) with oil. Caution:

Do not lubricate the slide faces.

Mount the shaft seal part (4):

Press the part (4) slightly and

without interruption up to the

shaft seal counter part (5).

Fig. 16 - 12

Fig. 16 - 13

Mount the spring (3), disk (2)

and lock ring (1). Insert the

feather key into the shaft.

Caution: Push to fit. Place the

cover with the O-ring on the

casing. Caution Observe the

direction of the channel.

Tighten the hexagon screws

over cross.

17 Replacing the Shaft Seal of the Pump

66 B43IB20

Hint:

Use new seals when remounting the pump:

77954 O-RING FOR NPY-2051 CASE

77507 WASHER G3/4" PCTFE

Check the impeller visually and replace it if necessary:

77957 IMPELLER NPY-2051 50/60 Hz

18 Replacing the Pump

B43IB20 67

18 Replacing the Pump

Spare Parts:

77385 CENTRIFUGAL PUMP NPY-2051 115V 50/60HZ

77506 CENTRIFUGAL PUMP NPY-2051 230V 50/60HZ

77507 WASHER G3/4" PCTFE

Tools:

Open-end wrench 10, 19 and 32 mm

Cutting pliers

Snap-blade knife

Disconnect the hose at the inlet (I).

Disconnect the hose at the outlet (O).

Disconnect the pump cable (C).

Warning:

See chapter 7: Disconnecting the COBRIX3.

See chapter 7.1: Stopping the COBRIX3.

See chapter 7.2: Disconnecting the Power Supply.

See chapter 7.4: Closing the Bypass Valve.

See chapter 7.5: Disconnecting the COBRIX3 from the Product Line.

See chapter 7.6: Removing the Stainless Steel Covers

I

C

O

Fig. 17 - 1

18 Replacing the Pump

68 B43IB20

Open the four screws (4S).

Replace the pump.

Important:

To disconnect the pump cable it is not necessary to open the electronic box of

the pump. Refer to chapter 18 Disconnecting the Pump Cable.

Fig. 17 - 2

4S

Hint:

Use new seals when remounting the pump:

77507 WASHER G3/4" PCTFE

19 Disconnecting the Pump Cable

B43IB20 69

19 Disconnecting the Pump Cable

Tools:

Open-end wrench 19 mm

Cutting pliers

Snap-blade knife

For the pump cable a quick connection system is used. Therefore, the cable (C)

can be removed without opening the electronic box of the pump.

Removing the cable:

Open the gland.

Remove the conductor.

Warning:

See chapter 7: Disconnecting the COBRIX3.

See chapter 7.1: Stopping the COBRIX3.

See chapter 7.2: Disconnecting the Power Supply

See chapter 7.4: Closing the Bypass Valve.

See chapter 7.5: Disconnecting the COBRIX3 from the Product Line.

See chapter 7.6: Removing the Stainless Steel Covers

Fig. 18 - 1

C

70 B43IB20

The conductor can be removed from the terminal point by pulling on the

conductor.

Surplus insulation must be removed before repeated connection.

Connecting the cable:

Observe in particular the following steps:

Strip the sheath to a length of approx. 15 mm (see Fig. 18-2 part 1) and slide

the union nut (1), the cap (2) and the rubber seal (3) onto the conductor.

Slide the rubber seal as far as the rim of the insulation and then slide the cap

onto the rubber seal. This provides the strain relief for the conductor (see

Fig. 18-2 part 2).

Insert the core ends into the feedthrough of the splice ring (see Fig. 18-2 part

3). To guarantee a clear assignment of the cores, the individual core

feedthroughs of the splice ring are numbered (1, 2, ..).

Cut off the projecting core ends. Make sure that the core ends are flush with

the splice ring: They can protrude by up to 3 mm but must not be too short.

Insert the prepared conductor into the contact carrier (4) (see Fig. 18-2 part

1). Turn the conductor with splice ring until the coding pins fit exactly into the

corresponding guides (see Fig. 18-2 part 4).

Close the gland by tightening the union nut. This presses the core ends into

the insulation displacement terminal blocks, cuts open the core insulation

and creates the electrical contact.

19 Disconnecting the Pump Cable

B43IB20 71

union nut

cap

rubber seal

contact carrier

splice ring

Fig. 18 - 2 Connecting the pump cable

19 Disconnecting the Pump Cable

72 B43IB20

Core assignment for COBRIX3 with Serial Numbers below 672

Connect the pump cable to the contacts as explained above. The internal

connection in the electronic box of the pump is already carried out and must not

be changed.

Core assignment for COBRIX3 with Serial Numbers 672 and higher

Connect the pump cable to the contacts as explained above. The internal

connection in the electronic box of the pump is already carried out and must not

be changed.

1

2

3

Front view:

Connect the wires of the pump cable to the

cutting contacts as shown at the drawing.

The wires muat be inserted at the following

positions at the splice ring:

1 ... L

2 ... Protective conductor

3 ... N

Protective conductor

N

L

19 Disconnecting the Pump Cable

B43IB20 73

3

4

2 1

Front view:

Conect the wires of the pump cable to the

cutting contacts as shown at the drawing .

The wires must be inserted at the following

positions at the splice ring:

1 ... L

2 ... Protective conductor

3 ... N

4 ... not used

N

Protective conductor

not used

L

74 B43IB20

20 Wetted Parts

B43IB20 75

20 Wetted Parts

Part.No Item Material

1 1910 BUTTERFLY VALVE DN25 SS 1.4571

SS 1.4302

EPDM

2 70769 WASHER 25MM DIN 32676 EPDM EPDM

3 10790 LIQUID SENSOR COBRIX3 PSU

SS 1.4571

EPDM

4 77390 ELBOW TUBE 90 DN 25 TRICLAMP SS 1.4404

SS 1.4301

5 / FLEXIBLE HOSES SS 1.4571

PTFE

6 77385

77506

CENTRIFUGAL PUMP 115V

CENTRIFUGAL PUMP 230V

SS 1.4581

SS 1.4122

SiC/ C/ Viton

EPDM

Peek

7 / DPRn or DSRn TRANSDUCER Hastelloy

C276

8 / CARBO 2100 CO

2

TRANSDUCER

Refer to the CARBO 2100 service

manual

/

9 10775 SAMPLE VALVE COBRIX3 SS 1.4571

SS 1.4404

76 B43IB20

21 List of Spare Parts for 1 Year of Operation

B43IB20 77

21 List of Spare Parts for 1 Year of

Operation

Wearing parts:

The washers are wearing parts which should be replaced after opening the

connection.

Part.No Item Quantity/

1 System

Quantity/

5 Systems

77385 CENTRIFUGAL PUMP NPY-2051

115V 50/60HZ

1

77506 CENTRIFUGAL PUMP NPY-2051

230V 50/60HZ

1

77953 SHAFT SEAL

FOR NPY-2051

1 2

77954 O-RING

FOR NPY-2051 CASE

1 2

77507 WASHER G3/4" PCTFE 2 6

77514 WASHER G3/8" PCTFE 4 12

70769 WASHER

25MM DIN 32676 EPDM

3 9

10767 LIQUID SENSOR RELAY 115V 1

10766 LIQUID SENSOR RELAY 230V 1

10790 LIQUID SENSOR COBRIX3 1

10782 POWER SUPPLY 85-264VAC

24VDC 2.1A

1

10779 LAMP 24V 10 W

Warning, Alarm

3

8434 RELAY 24V 1A EMG 12-REL/KSR 2

Hint:

For spare parts of the CARBO 2100 refer to the service manual CARBO 2100.

21 List of Spare Parts for 1 Year of Operation

78 B43IB20

All other spare parts:

We suggest you keep the spare parts listed above on stock. Process equipment

is often exposed to extreme working conditions which may cause unexpected

failure.

22 List of Tools

B43IB20 79

22 List of Tools

Item Fig.

Key for the lock of the electronic housing 21-1

Cutting pliers 21-1

Retaining ring pliers 21-1

Snap-blade knife 21-1

Slotted screwdriver (3mm) 21-2

Allen screwdriver (3mm) 21-2

Pozidrive screwdriver (PZ 2x100) 21-2

Open-end wrench 10 mm 21-3

Open-end wrench 14 mm 21-3

Open-end wrench 17 mm 21-3

Open-end wrench 19 mm 21-3

Open-end wrench 32 mm 21-3

Fig. 21 - 1

22 List of Tools

80 B43IB20

Fig. 21 - 2

Fig. 21 - 3

23 Troubleshooting

B43IB20 81

23 Troubleshooting

General requirements:

- Liquid sensor

The pump starts automatically if the liquid sensor defects sensor detects

liquid in the line. Make sure that the liquid sensor is properly installed and

that it switches the pump on when liquid is in the line.

- Empty lines at line shut down

The COBRIX3 and bypass hoses must be installed so that the product runs

out of the COBRIX3 bypass when the main line is empty.

If the COBRIX3 bypass is not completely empty the liquid sensor switches

the pump on and off frequently within a short time.

This may cause the pump to overheat.

- Cleaning before emptying the line

After production and before line shut down, all tubes and hoses must be

properly cleaned with CIP. If CIP is not carried out product residues may

stay in the pump and could clog the shaft seal. If a pump with clogged shaft

seal is switched on, the retaining ring holding the shaft seal is stressed

beyond specifications. This may destroy the pump.

- Electrical ratings of the pump motor

Make sure that the power supply lies within the specified range given by

the label on the motor. Frequent power failures may cause the motor to

overheat.

Possible causes for motor failures and how to avoid them:

- Liquid entering the motor

The motor will be destroyed by liquid entering its housing.

The cover of the terminal box must be screwed on tightly.

Cable glands in the terminal box must be tight.

Absolutely no liquid must be splashed on the motor because liquid may

enter the pump through the bearings.

- Damaged motor bearings

If product or other liquids are splashed on the motor, the bearings may clog.

Always use the pump cover and do not splash any liquid on the motor.

Do not use steam jet cleaner!

- The pump periodically switching on and off

If the pump switches on and off several times within a short period the

motor may be overheated. Make sure that the liquid in the COBRIX3

23 Troubleshooting

82 B43IB20

bypass runs off when the main line is empty.

- Power supply

Frequent power failures can cause the motor to overheat.

Make sure that the specified power ratings are not exceeded.

If the mains voltage is unstable, use a UPS or take other measures to

stabilize the voltage.

- Clogged shaft seals

If the main line is emptied before cleaning, product residues may remain in

the pump.

This may clog the shaft seal. If a pump with clogged shaft seal is switched

on, the retaining ring holding the shaft is stressed beyond specifications.

This may destroy the pump.

Clean the bypass with CIP before line shut down!

- Solid particles in the pump

Solid particles (metal filings, etc.), as may occur during putting into

operation or after repair work, can damaged the impeller inside the pump.

Use the Triclamp filter when putting into operation and when changing the

piping anywhere along this main line.

Please refer to the following instruction manuals for further details:

1. COBRIX3 instruction manual

2. mPDS 2000V3 instruction manual

3. DPRn density transducer or

4. DSRn density sound velocity transducer instruction manual

5. CARBO 2100 CO

2

transducer instruction manual

24 Document Numbers

B43IB20 83

24 Document Numbers

Document number Date Comment

B43IB20A 10.04.2003 First release

B43IB20B 22.10.2003 Minor changes

B43IB20C 23.06.2004 Change the default settings of the

optional LED Display

Appendix A: Service/Maintenance Report

84 B43IB20

Appendix A: Service/Maintenance Report

see next pages:

Appendix A: Service/Maintenance Report

B43IB20 85

COBRIX3 Preventive Maintenance Protocol

Maintenance protocol

COBRIX serial number

Maintenance contract No.

Field of operation

Temperature range

Bypass pump

Type S/no.

Density/velocity of sound transducer

DPRn 427

DSRn 427

Serial number

CO

2

transducer

CARBO 2100

Serial number of transducer

COBRIX evaluation unit mPDS 2000 V

Serial number

Application program

Company:

Name:

Address:

Post code

City:

COBRIX

Anton Paar GmbH

Anton-Paar-Str. 20, A-8054 Graz, Austria Europe

Tel: +43 316 257-0, Fax: +43 316 257-257

E-mail: info@anton-paar.com

Instruments for: - Density and concentration measurement

- Rheometry and viscometry

- High-precision temperature measurement

- X-ray structure analysis

- Microhardness testing

- Sample preparation

- CO2 measurement

- Colloid science

Web: www.anton-paar.com

B43IE31B-E-MaintenanceProtocol-Cobrix3.doc Page 1 of 5

Appendix A: Service/Maintenance Report

86 B43IB20

COBRIX3 Preventive Maintenance Protocol

Cobrix

COBRIX

Accessories (connected to the Anton Paar COBRIX evaluation unit):

Flow monitor Filler stopped signal

Bottle counter 3# LED displays

Product selector Davis Software

Version

Additional measurements Type

Control functions Type

Regulating functions Type

External condition of the instrument before maintenance:

COBRIX housing and rack: OK not OK cleaned

CO

2

transducer: OK not OK cleaned

DPR/DSR transducer: OK not OK cleaned

Bypass pump: OK not OK cleaned

Comment:

Checking the configuration / Setting the parameters:

CARBO 2100 settings:

Unit: g/l vol

Prod.: BE SD MW SW CS

Presetting: Carbo-dV Carbo-dT Carbo-dP

Adjustment factors: CO

2

-Offset CO

2

-Gain

COBRIX evaluation unit:

Instrument constants DPR/DSR transducer

Acc. to data sheet from: OK not OK

Comment:

System data saved: yes no not applicable

File name:

After discussing with the customer, the COBRIX measuring system has been separated from the

production line

B43IE31B-E-MaintenanceProtocol-Cobrix3.doc Page 2 of 5

Appendix A: Service/Maintenance Report

B43IB20 87

COBRIX3 Preventive Maintenance Protocol

Cobrix

COBRIX

Checking / maintenance of the Carbo 2100

Checking / cleaning Cable connections Control valve for compressed air

Pneumatic connections Pneumatic valves Magnetic valves

Stirrer Temperature sensor Pressure sensor

Functional test

Checking / maintenance of the COBRIX evaluation unit

Visual check OK not OK

Contacts maintenance carried

out

yes no

Buffer battery OK not OK not measurable VDC

Digital inlets OK not OK not applicable

Analog inlets OK not OK not applicable

Digital outlets OK not OK not applicable

Analog outlets OK not OK not applicable

Counter inlets OK not OK not applicable

Relay outlets OK not OK not applicable

DPR/DSR inlet OK not OK not applicable

Product selection OK not OK not applicable

Checking / maintenance of the DPRn/DSRn transducer

Power supply voltage OK not OK VDC

Visual check of measuring electronics OK not OK

Seal on electronic housing OK not OK replaced

Checking / maintenance of the bypass pump

Mechanical seal replaced yes no

Functional test OK not OK

B43IE31B-E-MaintenanceProtocol-Cobrix3.doc Page 3 of 5

Appendix A: Service/Maintenance Report

88 B43IB20

COBRIX3 Preventive Maintenance Protocol

Cobrix

COBRIX

The customer was informed that the transducer has been separated from the production line for the

maintenance procedures and can only be operated again after successful cleaning (CIP):

yes no

Checking the Brix/Diet adjustment

Current product:

Reference method

Brix/Diet conc. reference Temp. C

Brix/Diet conc. COBRIX Temp. C

Deviation

Checking the CO

2

adjustment

Current product

Reference method

CO

2

conc. reference

CO

2

conc. Carbo P-Line bar P-Gas bar Temp. C

CO

2

deviation

Other maintenance carried out / comments:

Replaced parts for CARBO 2100:

PTFE pcs. 6924 Stirrer Igus/Two Wing pcs. 12745

Stirrer motor Igus pcs. 10745 valve Hubbegr. pcs. 6923

Absolute pressure sensor pcs. 6522 valve EPDM pcs. 12758

Temperature sensor pcs. 6521 EPDM pcs. 12759

Interface card new pcs. 9116 EPDM pcs. 13881

Magnetic valve pcs. 6525 EPDM pcs. 16772

B43IE31B-E-MaintenanceProtocol-Cobrix3.doc Page 4 of 5

Appendix A: Service/Maintenance Report

B43IB20 89

COBRIX3 Preventive Maintenance Protocol

Cobrix

COBRIX

Replaced parts (DPR/DSR/mPDS...):

Seal 120x220 pcs. 6812 O-ring 290x6 FPM 80 pcs. 54241

Coil A43 pcs. 60691 Battery mPDS4000 pcs. 59746

Liquid sensor capacitive pcs.76435

Replaced parts for the bypass pump NPY-2051 ( Speck pump):

Mechanical seal pcs. 77953 O-Ring for Speck pump pcs. 77954

Impeller pcs. 77957

Other replaced parts:

For the service engineer:

Name:

Company:

Date: Signature:

For the customer:

Name:

Company:

Date: Signature:

B43IE31B-E-MaintenanceProtocol-Cobrix3.doc Page 5 of 5

Appendix B: Feedback Form

90 B43IB20

Appendix B: Feedback Form

Please help us improve this service manual and our service to you!

If you have any suggestions, comments or problems concerning the contents of

this service manual, please do not hesitate to contact us:

E-mail: info@anton-paar.com or copy and fax this form to: +43-316-257-257

Service manual for instrument type:...................................................................

Name and address: .......................................................................................

...............................................................................................................................

...............................................................................................................................

...............................................................................................................................

The service manual should contain more information on:

...............................................................................................................................

...............................................................................................................................

...............................................................................................................................

...............................................................................................................................

...............................................................................................................................

...............................................................................................................................

The following sections are difficult to understand:

...............................................................................................................................

...............................................................................................................................

...............................................................................................................................

...............................................................................................................................

...............................................................................................................................

...............................................................................................................................

Other comments:

...............................................................................................................................

...............................................................................................................................

...............................................................................................................................

...............................................................................................................................

...............................................................................................................................

...............................................................................................................................

.............................................................................................................................

Thank you for your feedback!

S-ar putea să vă placă și

- B47ib34e e Carbo2100 TransducerDocument40 paginiB47ib34e e Carbo2100 Transducerhailatey100% (1)

- DPRN 427S (I) & DSRN 427S: Instruction ManualDocument73 paginiDPRN 427S (I) & DSRN 427S: Instruction ManualMBOÎncă nu există evaluări

- Vol 4ge Version 3 0x B64is79 DDocument32 paginiVol 4ge Version 3 0x B64is79 DSylwia MaciakÎncă nu există evaluări

- A90ib33f e Profibus For MpdsDocument106 paginiA90ib33f e Profibus For MpdsSalvador Castellanos León75% (4)

- C73IB001EN U OT ROT RefGuideDocument93 paginiC73IB001EN U OT ROT RefGuideJosemiguel FernandezÎncă nu există evaluări

- ICPMS-2030: Pre-Installation RequirementsDocument17 paginiICPMS-2030: Pre-Installation Requirementspilar100% (1)

- CTD 450 Service ManualDocument38 paginiCTD 450 Service ManualDiego BouÎncă nu există evaluări

- Density Meter ManualDocument152 paginiDensity Meter ManualyogiÎncă nu există evaluări

- Abbemat 350/550: Measure What Is Measurable and Make Measurable That Which Is NotDocument42 paginiAbbemat 350/550: Measure What Is Measurable and Make Measurable That Which Is NotXavier Arévalo100% (2)

- C48ib001en y Mpds 5 RefguideDocument220 paginiC48ib001en y Mpds 5 Refguidesam wongÎncă nu există evaluări

- Anton-Paar - Multiwave ProDocument14 paginiAnton-Paar - Multiwave ProKhổngMinhÎncă nu există evaluări

- CARBOCAP TechnologyDescriptionDocument2 paginiCARBOCAP TechnologyDescriptionRoxana Gonzàlez100% (1)

- ThermoregulationDocument64 paginiThermoregulationapi-3703371Încă nu există evaluări

- ETHOS One Rev 00-2010 PDFDocument14 paginiETHOS One Rev 00-2010 PDFAlida MatousekÎncă nu există evaluări

- Manual de Usuario Peachimetro Orion 3 Star PH PortableDocument299 paginiManual de Usuario Peachimetro Orion 3 Star PH PortabledyanezÎncă nu există evaluări

- Agilent 240FS PDFDocument6 paginiAgilent 240FS PDFValentino Budi PratamaÎncă nu există evaluări

- Carbo 510 Smart Sensor: Measure What Is Measurable and Make Measurable That Which Is NotDocument32 paginiCarbo 510 Smart Sensor: Measure What Is Measurable and Make Measurable That Which Is NotJosemiguel FernandezÎncă nu există evaluări

- Measure What Is Measurable and Make Measurable That Which Is NotDocument31 paginiMeasure What Is Measurable and Make Measurable That Which Is NotXavier ArévaloÎncă nu există evaluări

- C48IB01B MPDS5 Instruction ManualDocument138 paginiC48IB01B MPDS5 Instruction ManualEnrique MoyaÎncă nu există evaluări

- Hirayama Brochure HICLAVE PDFDocument2 paginiHirayama Brochure HICLAVE PDFDwi Putri Apriyanti50% (2)

- Anton Paar Manual PDFDocument34 paginiAnton Paar Manual PDFSadegh SoltaniÎncă nu există evaluări

- XPAIB006EN I RefGuide InstrSW WebDocument41 paginiXPAIB006EN I RefGuide InstrSW WebXavier ArévaloÎncă nu există evaluări

- Pico PH and Conductivity MeterDocument2 paginiPico PH and Conductivity Meterjangri100% (1)

- IB-05G Service Manual Temperature TroubleshootingDocument47 paginiIB-05G Service Manual Temperature Troubleshootingjose navaÎncă nu există evaluări

- Alcolyzer Plus Beer Reference ManualDocument131 paginiAlcolyzer Plus Beer Reference ManualThanh Nguyen Van DangÎncă nu există evaluări

- Agilent 7820A Gas Chromatograph Illustrated Parts BreakdownDocument102 paginiAgilent 7820A Gas Chromatograph Illustrated Parts BreakdownRuy Santana Jr.Încă nu există evaluări

- G10&G10S Product Family Service ManualDocument135 paginiG10&G10S Product Family Service ManualPranish Pradhan100% (1)

- G1969 90006 TOF Maintenance v4Document150 paginiG1969 90006 TOF Maintenance v4Jeramiah SpencerÎncă nu există evaluări

- Thermo Electron North America LLC Lot 1 Equipment & InstrumentsDocument66 paginiThermo Electron North America LLC Lot 1 Equipment & Instrumentsproyectos serimetcÎncă nu există evaluări

- Operation Manual Spectro UV-2602Document24 paginiOperation Manual Spectro UV-2602Cesar Alfonso Saldivar Montoya100% (1)

- URIT-800 URIT-800 URIT-800 URIT-800 Installation Installation Installation Installation Procedure Procedure Procedure ProcedureDocument6 paginiURIT-800 URIT-800 URIT-800 URIT-800 Installation Installation Installation Installation Procedure Procedure Procedure ProcedureArnoldo FelixÎncă nu există evaluări

- GDE NexION 1000 2000 ICP MS Preparing Your Lab 012773 01Document9 paginiGDE NexION 1000 2000 ICP MS Preparing Your Lab 012773 01СтепанÎncă nu există evaluări

- New CFA BrochureDocument8 paginiNew CFA BrochureAnonymous HKuYF6kÎncă nu există evaluări

- Hettich Rotina 420 - RepairDocument97 paginiHettich Rotina 420 - RepairVtn VoÎncă nu există evaluări

- Unique Density & Concentration Meters for Process IndustriesDocument8 paginiUnique Density & Concentration Meters for Process IndustriesXavier ArévaloÎncă nu există evaluări

- Eppendorf MasterCycler ManualDocument65 paginiEppendorf MasterCycler ManualmtrnbhÎncă nu există evaluări

- All in One Solution For BeerDocument7 paginiAll in One Solution For BeerTank Top 2Încă nu există evaluări

- Librito de Partes WatersDocument312 paginiLibrito de Partes WatersJonathanCubillosSerratoÎncă nu există evaluări

- LC-20A ProminenceDocument40 paginiLC-20A Prominencemian allÎncă nu există evaluări

- Service Manual I A Me RexDocument31 paginiService Manual I A Me Rexgabo2516100% (2)

- Operating Manual: Model: Serial No.Document52 paginiOperating Manual: Model: Serial No.Lailly KurniaÎncă nu există evaluări

- CHIRANA - European Quality: Made in SlovakiaDocument9 paginiCHIRANA - European Quality: Made in SlovakiaAn VanÎncă nu există evaluări

- Broch BIOSTAT-A SBI1518-e PDFDocument14 paginiBroch BIOSTAT-A SBI1518-e PDFBrian VasquezÎncă nu există evaluări

- User Manual 06/2013 Edition 2: © HACH Company, 2012, 2013. All Rights Reserved. Printed in GermanyDocument156 paginiUser Manual 06/2013 Edition 2: © HACH Company, 2012, 2013. All Rights Reserved. Printed in GermanyFlorin Neacsu100% (1)

- Master GC Service Manual 20070919R6 1.3 ENGDocument173 paginiMaster GC Service Manual 20070919R6 1.3 ENGKhalid Zghear100% (1)

- B-324 Operationmanual en D LowresDocument32 paginiB-324 Operationmanual en D LowresOchie Yusuf100% (1)

- ABBEMAT EnglishDocument4 paginiABBEMAT EnglishelectrozonecorpÎncă nu există evaluări

- PE 560 Atomic Absorption Spectrophotometer ManualDocument176 paginiPE 560 Atomic Absorption Spectrophotometer ManualDavid Allan100% (1)

- Service: ManualDocument28 paginiService: ManualAngelaÎncă nu există evaluări

- Biochrom Microplate-Washers Atlantis ManualDocument73 paginiBiochrom Microplate-Washers Atlantis ManualPaulo Henrique EvangelistaÎncă nu există evaluări

- Ps 73319 HPLC Vanquish Autosampler Ps73319 enDocument4 paginiPs 73319 HPLC Vanquish Autosampler Ps73319 enRuri YuliantiÎncă nu există evaluări

- Agilent MSDDocument60 paginiAgilent MSDMohammed Nabil Ahmed0% (1)

- Bs 800 Chemistry Analyzer PDFDocument1 paginăBs 800 Chemistry Analyzer PDFДимонÎncă nu există evaluări

- 1577un 2026-01Document79 pagini1577un 2026-01ngovantienÎncă nu există evaluări

- M Series Flowdiagram For TrainingDocument20 paginiM Series Flowdiagram For TrainingRupendra SahuÎncă nu există evaluări

- MA180-005 SubPUR-duoPUR User ManualDocument34 paginiMA180-005 SubPUR-duoPUR User ManualSukrisdianto DiantoÎncă nu există evaluări

- Manual Uv VisDocument84 paginiManual Uv VisLucas Oliveira100% (1)

- Cobas B 221 System: Service ManualDocument368 paginiCobas B 221 System: Service ManualCássio Menezes Godói100% (1)

- Medical Electronic Laboratory Equipment 1967-68: Pergamon Electronics Data SeriesDe la EverandMedical Electronic Laboratory Equipment 1967-68: Pergamon Electronics Data SeriesÎncă nu există evaluări

- COBRIX3 & COBRIX3 Multibev: Service ManualDocument90 paginiCOBRIX3 & COBRIX3 Multibev: Service ManualYohn Deivi Espinoza ZarateÎncă nu există evaluări

- ALT UserManual ENGDocument86 paginiALT UserManual ENGfrank0213Încă nu există evaluări

- Docengoee21sp2 Oee Gettingstarted EngDocument58 paginiDocengoee21sp2 Oee Gettingstarted Engfrank0213Încă nu există evaluări

- Opcenter Connect MOM 33 Release Preview1Document12 paginiOpcenter Connect MOM 33 Release Preview1frank0213Încă nu există evaluări

- PM-ANALYZE Docu v1.0 enDocument82 paginiPM-ANALYZE Docu v1.0 enfrank0213Încă nu există evaluări

- Fsai Food Safety Management Training GuideDocument52 paginiFsai Food Safety Management Training GuideDavidÎncă nu există evaluări

- Terms Test CalcadDocument1 paginăTerms Test Calcadfrank0213Încă nu există evaluări

- 2019-01-16 - Calendar File - Partner Town Hall - Siemens PLM SoftwareDocument1 pagină2019-01-16 - Calendar File - Partner Town Hall - Siemens PLM Softwarefrank0213Încă nu există evaluări

- Configuring Proficy Historian 7 And/or Plant Applications 7 Universal Client For SSL Signed CertificatesDocument10 paginiConfiguring Proficy Historian 7 And/or Plant Applications 7 Universal Client For SSL Signed Certificatesfrank0213Încă nu există evaluări

- Simatic: Product InformationDocument4 paginiSimatic: Product Informationfrank0213Încă nu există evaluări

- Terms Test CalcadDocument1 paginăTerms Test Calcadfrank0213Încă nu există evaluări

- Training Guide 3 2016 Final AccessibleDocument3 paginiTraining Guide 3 2016 Final Accessiblefrank0213Încă nu există evaluări

- CP4 Device List 135 145E1Document40 paginiCP4 Device List 135 145E1frank0213Încă nu există evaluări

- Pcspro e PDFDocument25 paginiPcspro e PDFfrank0213Încă nu există evaluări

- Slides SIMOTION Converting Library V2 1 0Document43 paginiSlides SIMOTION Converting Library V2 1 0frank0213Încă nu există evaluări

- Access SQL database in WinCC Runtime using scriptsDocument25 paginiAccess SQL database in WinCC Runtime using scriptsfrank0213Încă nu există evaluări

- NCM S7profibusDocument93 paginiNCM S7profibusyukaokto2Încă nu există evaluări

- Integrity Check Universo TeamspecDocument43 paginiIntegrity Check Universo Teamspecfrank0213Încă nu există evaluări

- Simotion Example For Beginners d435 en PDFDocument87 paginiSimotion Example For Beginners d435 en PDFfrank0213Încă nu există evaluări

- PCS7 Technik Englisch 2004Document132 paginiPCS7 Technik Englisch 2004frank0213Încă nu există evaluări

- Test IncDocument1 paginăTest Incfrank0213Încă nu există evaluări

- Technical Instructions For Configuring A TCP ConnectionDocument25 paginiTechnical Instructions For Configuring A TCP Connectionwong_arifÎncă nu există evaluări

- AN2020 Compressor Control Setpoint1&2Document4 paginiAN2020 Compressor Control Setpoint1&2frank0213Încă nu există evaluări

- McAfee KnowledgeBase - Required Exclusions For Running VirusScan Enterprise 8Document1 paginăMcAfee KnowledgeBase - Required Exclusions For Running VirusScan Enterprise 8frank0213Încă nu există evaluări

- 101 Problems and Reports in Webi Report With Solutions PDFDocument17 pagini101 Problems and Reports in Webi Report With Solutions PDFfrank0213Încă nu există evaluări

- Vission 20/20 Micro-Controller: Operation and Service ManualDocument120 paginiVission 20/20 Micro-Controller: Operation and Service Manualfrank0213Încă nu există evaluări

- Ppa Kpi Without PM v20 enDocument90 paginiPpa Kpi Without PM v20 enfrank0213Încă nu există evaluări

- Batch DiagnosticsDocument47 paginiBatch Diagnosticsfrank0213Încă nu există evaluări

- Simatic IT Unilab Database Job StructuresDocument17 paginiSimatic IT Unilab Database Job Structuresfrank0213Încă nu există evaluări

- ET200SDocument53 paginiET200Sfrank0213Încă nu există evaluări

- Fire Alarm ChecklistDocument2 paginiFire Alarm ChecklistiifudinÎncă nu există evaluări

- Application Answers:: Dual-Gradient DrillingDocument4 paginiApplication Answers:: Dual-Gradient Drillinglich_tran01Încă nu există evaluări

- Proceedings of The Inter-ISC 18 PDFDocument240 paginiProceedings of The Inter-ISC 18 PDFLiviu GruiaÎncă nu există evaluări

- Statistical Quality ControlDocument6 paginiStatistical Quality ControlAtish JitekarÎncă nu există evaluări

- Bbe 57Document2 paginiBbe 57tutucas100% (1)

- DX200 MML CommandDocument3 paginiDX200 MML Commanddedeputra01Încă nu există evaluări

- 02.lecture - 02 - Intro To IC EngineDocument112 pagini02.lecture - 02 - Intro To IC Enginemahbububur rahmanÎncă nu există evaluări

- AI Based Design of A FLC Scheme For 2Document19 paginiAI Based Design of A FLC Scheme For 2Kafar KhanÎncă nu există evaluări

- Ecw437/Ecw421 Laboratory Manual 2016Document3 paginiEcw437/Ecw421 Laboratory Manual 2016Syahir HamidonÎncă nu există evaluări

- BECK USA Electrical ActuatorsDocument56 paginiBECK USA Electrical ActuatorsnprashanÎncă nu există evaluări

- Katalog Pipa HDPE Wavin BlackDocument2 paginiKatalog Pipa HDPE Wavin BlackChristian MakigaweÎncă nu există evaluări

- PRACTICAL RESERVOIR MONITORING AND WATERFLOODINGDocument51 paginiPRACTICAL RESERVOIR MONITORING AND WATERFLOODINGDuddi Dennisuk100% (3)

- ISO 9001 Clause 7.5.2 Validation of Special ProcessesDocument3 paginiISO 9001 Clause 7.5.2 Validation of Special Processeseconchan100% (1)

- Welding Guide PDFDocument24 paginiWelding Guide PDFJán KožičkaÎncă nu există evaluări

- 360 Degree Feedback Form Template: (Mouseover This Cell To See Notes)Document1 pagină360 Degree Feedback Form Template: (Mouseover This Cell To See Notes)Rizky Ramadhany SaputraÎncă nu există evaluări

- C172 EmergencyDocument2 paginiC172 Emergencyjgills240100% (2)

- Cpci Education Recourses Brian HallDocument22 paginiCpci Education Recourses Brian HallMahmoud Abu-eidehÎncă nu există evaluări

- Detail Biofile 1Document1 paginăDetail Biofile 1Rully SaputraÎncă nu există evaluări

- Bosch P-Pump Fuel Injection - Diesel Tech - Diesel Power MagazineDocument2 paginiBosch P-Pump Fuel Injection - Diesel Tech - Diesel Power Magazinerxhughes100% (3)

- Quantum Tech Fest 2024, Saveetha Institute of Medical and Technical Sciences Engineering, Technical Symposium, ChennaiDocument1 paginăQuantum Tech Fest 2024, Saveetha Institute of Medical and Technical Sciences Engineering, Technical Symposium, Chennaimf42gcb8bdÎncă nu există evaluări

- Quantity SurveyDocument6 paginiQuantity Surveypmm05479Încă nu există evaluări

- Rosenbauer Turrets: Reliable Firefighting Equipment for Airports, Industry & MunicipalitiesDocument12 paginiRosenbauer Turrets: Reliable Firefighting Equipment for Airports, Industry & Municipalitiesdiegoh_silvaÎncă nu există evaluări