Documente Academic

Documente Profesional

Documente Cultură

Jagary

Încărcat de

Kundan KumawatTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Jagary

Încărcat de

Kundan KumawatDrepturi de autor:

Formate disponibile

World Journal of Agricultural Sciences 7 (2): 157-160, 2011 ISSN 1817-3047 IDOSI Publications, 2011

Effect of Different Particle Sizes of Jaggery Powder on Storability

1

P.A. Unde, 1P.V. Adagale, 2Syed Imran Hashmi and 3Abdul Raheem

Department of Agricultural Processing Engineering, Faculty of Agriculture, M.P. K.V. Rahuri-413722, Dist. Ahmednagar (MS) India 2 Department of Food Trade and Business Management, College of Food Technology, M.A.U., Parbhani (MS) India 3 Department of Food Chemistry and Nutrition, Rajeev Gandhi College of Food Technology, Parbhani (MS) India

Abstract: The investigations were carried out to study the effect of different particle size and packaging materials on storability of jaggery powder on the basis of changes in chemical composition and organoleptic characteristics. Jaggery powder of three different grades viz., coarse (0.500 -0.708 mm), medium (0.351 - 0.420 mm) and fine (0.211 - 0.296 mm) were prepared and packed in 100 gauge polyethylene bag. The samples were stored at room temperature for the period of 6 months. In order to optimize the particle size of jaggery powder, the changes in chemical composition and organoleptic properties were evaluated during storage. The results revealed that change in chemical composition was lower in case of coarse jaggery powder. The coarse jaggery powder having particle size in the range 0.500-0.078 mm) was found more acceptable among all other powder sizes after storage period of six months in terms of its chemical properties and organoleptic characteristics. Key words: Jaggery % Powder % Storability % Particle size INTRODUCTION Jaggery is one of the most important sweeteners in India. Jaggery (also known as gur) is a traditional unrefined non-centrifugal sugar consumed in Asia, Africa, Latin America and the Caribbean [1]. It is a concentrated product of cane juice without separation of the molasses and crystals and can vary from golden brown to dark brown in color. It contains up to 50% sucrose, up to 20% invert sugars with some other insoluble matter such as ash, proteins and bagasse fibers [2]. It is directly consumed by human and used in animal feed mixtures. Jaggery is a natural sweetener made by the concentration of sugarcane juice prepared without the use of any chemicals [3]. Jaggery has great nutritive and medicinal value. Jaggery purifies the blood, prevents the rheumatic afflictions and disorders of bile and process properties of higher order [4, 5]. Jaggery contains proteins, vitamins and minerals, which are essential constituents for the body. It is also a potent source of iron and copper [6]. Jaggery is an energy food that is said to purify blood, regulate liver function and keep the body healthy. It has also been prescribed in various diseases like jaundice, breathlessness and kidney problems [7]. Jaggery industry is the dominant decentralized cottage industry of India, which meets about 40 to 50% sweetener requirement of Indian population. About one third to one half jaggery produced needs to be stored every year [3]. Jaggery is usually available in the market in the form of one or half kg block. However, these blocks are not feasible for transportation and retailing. The loss of jaggery during storage ranged from 7 to 25% depending upon storage conditions [8]. Hence, in present investigation, efforts were made to convert jaggery into different particle sizes and further prepared jaggery powder is analyzed for its physicochemical and organoleptic characteristics during storage for the period of 6 months. MATERIALS AND METHODS The present research work entitled effect of different particle size of jaggery powder on storability was carried out in Department of Agricultural Process Engineering, M.P.K.V, Rahuri during the year 2005-06.

Corresponding Author: Syed Imran Hashmi, Department of Food Trade and Business Management, College of Food Technology, M.A.U., Parbhani (MS) India, Tel: +91-9766664157, E-mail: imran.foodresearch@gmail.com. 157

World J. Agric. Sci., 7 (2): 157-160, 2011

Experimental Analysis: The Jaggery (var. CO92005) was procured from Regional sugarcane and Jaggery Research Station, Kolhapur. It was free from impurities, light brown in color, grainy structure and uniform size. The pieces of solid jaggery were shed dried under controlled temperature of 27C till external surface becomes slightly rough and losses its smoothness. Size reduction was done by hammer (the beater of hammers mill that rotates in closed steel chamber at 3000 rpm and forces the ground through a screen of 18 meshes). The jaggery powder obtained was analyzed for its properties and quality. Three sizes of powder jaggery (i.e. course, medium and fine) were obtained on the basis of sieve analysis of jaggery powder. The powder jaggery properties viz., sieve analysis [9], fineness modules [10] and uniformity index [11] were determined. Average particle size was calculated using equation [11]. Average particle size = 0.135 x (1.336)FM Packaging and Storage of Jaggery Powder: Jaggery powder (course, medium and fine) were further packed in 100 gauge polyethylene bags. These samples were further stored at room temperature (27C) in M.P.K.V., Rahuri. Physicochemical Properties: The physicochemical properties viz. reducing sugar, non reducing sugar, pH, colour and moisture content of jaggery powder were determined by using standard methods [12]. Colour of jaggery solution was measured on Klet summerson photoelectric colourimeter using green filter. Organoleptic Evaluation: Organoleptic evaluation was carried out every month during storage. A panel of 10 judges using Nine-point hedonic scale judges the colour, taste, texture, flavor and overall acceptability of samples. Method is given by Amerine et al. [13] was used for sensory evaluation. RESULTS AND DISCUSSION Chemical Composition of Jaggery Powder: The chemical composition of jaggery powder (var. Co 92005) was determined in Table 1. The moisture content, pH and colour found were 1.2 per cent, 6.6 and 0.18 per cent, respectively. The reducing sugar and non-reducing sugar obtained were 8.51 per cent and 78.56 per cent, respectively: The similar results were found by RSJRS, Kolhapur [14].

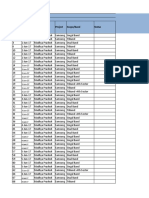

Table 1: chemical composition of jaggery powder Properties Moisture content,% pH Reducing sugar,% Non-reducing sugar,% Colour Table 2: Sieve analysis of jaggery powder Fineness Grading Coarse Medium Fine Size (mm) 0.500-0.708 0.351-0.420 0.211-0.296 4.14 0.45 5:2:3 Modulus Average Particle Uniformity Size (mm) Index Value 1.20 6.60 8.51 78.56 0.18

Grading of Jaggery Powder: The sieve analysis of jaggery powder for fineness modulus, size (average particle diameter) and uniformity index was done and data is tabulated in Table 2. Based on sieve analysis the jaggery powder was graded into three grades viz., coarse, medium and fine. The particle sizes of 0.500-0.708, 0,351-0.420 and 0.211-0.296 mm were considered coarse, medium and fine, respectively. The fineness modulus, average particle diameter and uniformity index found were 4.14, 0.45 and 5:2:3, respectively. Similar studies were done by Rathnayake [9] for rice products. Effect of Particle Size on Chemical Properties of Jaggery Powder: The data of effect of particle size of jaggery powder during storage on moisture content, pH, reducing sugar, non reducing sugar and colour of jaggery powder is depicted in Table 3. The results revealed that moisture content of jaggery powder significantly increased during the storage period. This may be due to the high water vapour transmission rate of 100 guage polyethylene bags due to which there was increase in moisture content of jaggery powder. The moisture content of jaggery powder ranged from 1.20 to 1.74 per cent. Maximum moisture was observed in case of fine jaggery powder stored for 6 months while minimum water absorption after 6 months of storage was observed in coarse particle sized jaggery powder. On the basis of moisture, it could be concluded that particle size is inversely related to moisture absorption in jaggery powder. The pH of samples varied from 6.60 to 6.48. pH of sample found to be reversibly related to storage period. pH decreased with increase in storage period and increased in particle size. The decrease in pH during storage may be due to change in chemical properties which are affected by storage conditions.

158

World J. Agric. Sci., 7 (2): 157-160, 2011

Table 3: Effect of particle size and storage on physic-chemical properties of jaggery powder Storage period (methods) ------------------------------------------------------------------------------------------------------------------------0 1 2 3 4 5 6 1.20 1.20 1.20 6.60 6.60 6.60 8.51 8.51 8.51 78.56 78.56 78.56 0.18 0.18 0.18 1.23 1.20 1.20 6.60 6.60 6.60 8.51 8.51 8.51 78.56 78.56 78.56 0.19 0.20 0.21 1.28 1.26 1.24 6.59 6.58 6.57 8.51 8.51 8.51 78.56 78.56 78.55 0.21 0.21 0.22 1.35 1.32 1.29 6.59 6.58 6.57 8.52 8.52 8.53 78.55 78.55 78.54 0.22 0.23 0.24 1.51 1.47 1.43 6.58 6.57 6.56 8.53 8.53 8.54 78.54 78.53 78.52 0.24 0.25 0.26 1.65 1.60 1.55 6.54 6.53 6.52 8.54 8.55 8.56 78.53 78.52 78.51 0.26 0.27 0.28 1.74 1.68 1.62 6.50 6.49 6.48 8.56 8.57 8.58 78.53 78.52 78.50 0.27 0.28 0.29

Sr. No. 1

Particular Moisture

Particle size Fine Medium Coarse Fine Medium Coarse Fine Medium Coarse Fine Medium Coarse Fine Medium Coarse

pH

Reducing sugar

Non reducing sugar

Colour

* Each value is average of 5 determinations

Fig. 1: Organoleptic Evaluation of Jaggery Powder The reducing sugar content of jaggery powder found to increase with increase in storage period and particle size. While, non reducing sugar decreased with increase in storage period and particle size. The colour of sample found to be maximum in case of coarse particle size which increased with increase in storage period. Effect of Particle Size and Storage on Organoleptic Properties of Jaggery Powder: The data on sensory attributes viz., colour, taste, texture, flavor and overall acceptability of jaggery powder is plotted and shown in Figure 1. The results revealed that there were no changes on taste with different particle sizes. However, colour and textural properties of jaggery powder changed drastically with increase in size of particles. The overall acceptability was ranged from 7.6 to 8.4 for all the particle sizes (Fig. 1). The overall acceptability was found to be maximum in case of coarse powder

159

(8.4), followed by medium (8.1) and minimum overall acceptability was seen in case of fine powder (7.6). On the basis of data generated on organoleptic evaluation, it could be predicted that coarse powder was found more acceptable compared to medium and fine powder with respect to organoleptic characteristics. CONCLUSION C Jaggery powder found to contains 1.20% moisture, 6.60 pH, 8.51% reducing sugar and 78.56% non reducing sugar. The colour of prepared jaggery powder found to be 0.18. The particle size significantly affected on the chemical properties of jaggery. With increase in particle size, moisture, reducing sugar and colour of jaggery increased while pH and non reducing sugar content was found to decrease.

World J. Agric. Sci., 7 (2): 157-160, 2011

Organoleptic evaluation of samples after 6 months of storage reported best quality of coarse particle size followed by medium and fine jaggery powder. In all, it could be concluded that jaggery powder with coarse particle size (0.500-0.708 mm) found to desirable amongst all the samples in terms of its physic-chemical properties and organoleptic evaluation. REFERENCES

5.

6.

7. 8.

1.

2.

3.

4.

Nevkar, G.S., N.J. Thakor, A.P. Patil and D.S. Patil, 2005. Influence of packaging material on quality characteristics of jaggery at Kolhapur region. 40th Annual Convection and Symposium of Indian Society of Agricultural Engineers. TNAU, Coimbature, 3-12. Ghosh, A.K. and M.P. Agrawal, 1983. Gur grading based on physical and chemical constituents. Maharashtra sugar, 8(12): 39-43. Kishan singh, 1985. Need for research and development in jaggery, Khandsari and brown sugar in India. National Seminar cum group discussion on jaggery manufacture and storage. IISR, Lucknow: 1-9. Sahu, A.P. and B.N. Paul, 1998. The role of dietary whole sugar-jaggery in prevention of respiratory toxicity of air toxics and in lung cancer. Toxicology Letters, 95(1): 154.

9.

10. 11.

12.

13.

14.

Sahu, A.P. and A.K. Saxena, 1994. Enhanced translocation of particles from lungs by jaggery. Environmental Health Perspective, 102(5): 211-214. Beguin G.S., 1978. Jaggery is natural high energy food source quickly replaces lost vigor. Journal of Food Science and Technol., 39(5): 549-551. Veldhyyzen-van Zenten, 1999. New uses for panela. Food Chain, (25): 11-13. Shinde, B.N., A.B. Marathe and S.K. Kadam, 1981. Effect of different wrapping materials and disinfectants on keeping quality of jaggery. Indian Sugar, 31(9): 609-615. Rathnayake, H.M.A.P. 2005. Studies on mill combination for quality rice flour and its extruded products. M. Tech thesis. M.P.K.V., Rahuri. Smith, D., 1978. Cane Sugar World. Polmer Publications: 328. Sahay, K.M. and K.K. Singh, 2001. Unit Operation of Agricultural Processing. Vikas Publication. New Delhi, 220-223. A.O.A.C. 1995. Official Methods of Analysis. Association of Official Analytical Chemists. 10th Edition. Washington (USA). Amerine, M.A., R.M. Pangborn and E.A. Rossler, 1965. Principles of sensory evaluation of Food. Academic Press, London, pp: 315. Anonymous. 2005. Report on Research Review Committeee Meeting., Mahatma Phule Krishi Vidyapeeth. Rahuri (MS) India, 132-139.

160

S-ar putea să vă placă și

- SpeechGeek H.I.-larious Volume 3Document9 paginiSpeechGeek H.I.-larious Volume 3SpeechGeekÎncă nu există evaluări

- Food Chemistry and Nutrition: A Comprehensive TreatiseDe la EverandFood Chemistry and Nutrition: A Comprehensive TreatiseEvaluare: 5 din 5 stele5/5 (1)

- Pega DevOps Release Pipeline OverviewDocument200 paginiPega DevOps Release Pipeline OverviewArun100% (1)

- Roundtracer Flash En-Us Final 2021-06-09Document106 paginiRoundtracer Flash En-Us Final 2021-06-09Kawee BoonsuwanÎncă nu există evaluări

- Foods: Microstructural, Textural, Sensory Properties and Quality of Wheat-Yam Composite Flour NoodlesDocument13 paginiFoods: Microstructural, Textural, Sensory Properties and Quality of Wheat-Yam Composite Flour NoodleslalallaÎncă nu există evaluări

- BBRC Vol 14 No 04 2021-25Document7 paginiBBRC Vol 14 No 04 2021-25Dr Sharique AliÎncă nu există evaluări

- Grain and Milling Quality of Barley and Their Suitability For Preparation of Traditional South Indian ProductsDocument5 paginiGrain and Milling Quality of Barley and Their Suitability For Preparation of Traditional South Indian ProductsIOSR Journal of PharmacyÎncă nu există evaluări

- 10.1007@s13197 020 04771 1Document10 pagini10.1007@s13197 020 04771 1Julio Almeida FuentesÎncă nu există evaluări

- Diversity, Physicochemical, and Structural Properties of Indonesian Aromatic Rice CultivarsDocument10 paginiDiversity, Physicochemical, and Structural Properties of Indonesian Aromatic Rice CultivarsLini SholihahÎncă nu există evaluări

- Process Optimisation and Shelf Life Extension of Fiber Enriched PaneerDocument3 paginiProcess Optimisation and Shelf Life Extension of Fiber Enriched Paneerkunduankit9800Încă nu există evaluări

- Lamdande2018 PDFDocument11 paginiLamdande2018 PDFsanket bhujabalÎncă nu există evaluări

- 47-Abstract With Title-212-1-10-20210106Document8 pagini47-Abstract With Title-212-1-10-20210106Nayeli MelendrezÎncă nu există evaluări

- Manufacturing of Mayonnaise With Pea Pod Powder As A Functional IngredientDocument12 paginiManufacturing of Mayonnaise With Pea Pod Powder As A Functional IngredientLiyana HalimÎncă nu există evaluări

- Process Optimization and Characterization of Popped Brown RiceDocument12 paginiProcess Optimization and Characterization of Popped Brown Ricea4558305Încă nu există evaluări

- Pengaruh Pemberian Jerami Padi Dengan Berbagai Perlakuan (Fisik, Kimia, Biologi Dan Kombinasi) Terhadap Performans Domba Lokal JantanDocument10 paginiPengaruh Pemberian Jerami Padi Dengan Berbagai Perlakuan (Fisik, Kimia, Biologi Dan Kombinasi) Terhadap Performans Domba Lokal Jantansela ismasariÎncă nu există evaluări

- Moschata Durchesne Ex Poir) DENGAN DAUN KELOR (Moringa Oleifera Lam.)Document10 paginiMoschata Durchesne Ex Poir) DENGAN DAUN KELOR (Moringa Oleifera Lam.)diky ermizaÎncă nu există evaluări

- Digestibility, Textural and Sensory Characteristics of Cookies Made From Residues of Enzyme-Assisted Aqueous Extraction of SoybeansDocument8 paginiDigestibility, Textural and Sensory Characteristics of Cookies Made From Residues of Enzyme-Assisted Aqueous Extraction of SoybeansJhosep Tolentino ChaconÎncă nu există evaluări

- 1 PBDocument6 pagini1 PBTeam Check88Încă nu există evaluări

- Mikroskop Tepung JagungDocument9 paginiMikroskop Tepung JagungPostakÎncă nu există evaluări

- Optimization of Rice Starch Hydrolysis For The Production of Rice Milk Using Pigmented Rice (Oryza Sativa) in Retort PackagingDocument28 paginiOptimization of Rice Starch Hydrolysis For The Production of Rice Milk Using Pigmented Rice (Oryza Sativa) in Retort PackagingShannice CabiliÎncă nu există evaluări

- PermenDocument9 paginiPermenLilis SulastriÎncă nu există evaluări

- Optimization of Rice Starch Hydrolysis For The Production of Rice Milk Using Pigmented Rice (Oryza Sativa) in Retort PackagingDocument21 paginiOptimization of Rice Starch Hydrolysis For The Production of Rice Milk Using Pigmented Rice (Oryza Sativa) in Retort PackagingShannice CabiliÎncă nu există evaluări

- Process Optimization and Characterization of Cereal Based Ready-To-Eat Extruded Snack FoodDocument8 paginiProcess Optimization and Characterization of Cereal Based Ready-To-Eat Extruded Snack FoodTJPRC PublicationsÎncă nu există evaluări

- 1 s2.0 S0023643817308034 MainDocument9 pagini1 s2.0 S0023643817308034 MainNelluri PujaÎncă nu există evaluări

- Foods 09 01654 v2Document12 paginiFoods 09 01654 v2Porula.PÎncă nu există evaluări

- ST1606 004Document5 paginiST1606 004Sandeep ElluubhollÎncă nu există evaluări

- Characterization of Cassava Starch and Its PotentiDocument10 paginiCharacterization of Cassava Starch and Its PotentiLucky SamsonÎncă nu există evaluări

- Milkfish FlourDocument8 paginiMilkfish FlourJinnie R. MamhotÎncă nu există evaluări

- The Effect of Soybean Varieties and Flavors On TemDocument12 paginiThe Effect of Soybean Varieties and Flavors On TemrinaÎncă nu există evaluări

- Sensory and Nutritional Properties of Millet Based High Fiber BiscuitDocument4 paginiSensory and Nutritional Properties of Millet Based High Fiber BiscuitShiny LiziaÎncă nu există evaluări

- Guava Toffee PAPER14Document14 paginiGuava Toffee PAPER14Winda100% (1)

- Ginger CandyDocument8 paginiGinger CandyRizka Arifani Kromodimedjo100% (2)

- J.ijbiomac.2020.07.310 Karakteristik Tepung SaguDocument31 paginiJ.ijbiomac.2020.07.310 Karakteristik Tepung SaguIndri YuliaÎncă nu există evaluări

- Kripik BekatulDocument11 paginiKripik BekatulAditya Dian TjokroatmodjoÎncă nu există evaluări

- Effects of Microbial Transglutaminase On Physicochemical Properties, Electrophoretic Patterns and Sensory Attributes of Veggie BurgerDocument11 paginiEffects of Microbial Transglutaminase On Physicochemical Properties, Electrophoretic Patterns and Sensory Attributes of Veggie BurgerRyan HaryoÎncă nu există evaluări

- Effect of Soaking and Roasting On The Physicochemical and Pasting Properties of Soybean FlourDocument11 paginiEffect of Soaking and Roasting On The Physicochemical and Pasting Properties of Soybean Flourdesy ratna purwantiÎncă nu există evaluări

- Yangular 2017 Effects of Green Banana Flour On The Physical, Chemical & Sensory Properties of Ice CreamDocument9 paginiYangular 2017 Effects of Green Banana Flour On The Physical, Chemical & Sensory Properties of Ice CreamWahyu Sekar Ramadhan wahyusekar.2017Încă nu există evaluări

- Effect of Incorporation of Soy Flour On The Quality of PapadDocument9 paginiEffect of Incorporation of Soy Flour On The Quality of PapadAlexander DeckerÎncă nu există evaluări

- Karakteristik Fisik, Kimia, Dan Organoleptik Selai Sawo (Achras Zapota L.) Dengan Penambahan Pektin Dan SukrosaDocument13 paginiKarakteristik Fisik, Kimia, Dan Organoleptik Selai Sawo (Achras Zapota L.) Dengan Penambahan Pektin Dan SukrosaRirin ClaudyaÎncă nu există evaluări

- 39-Main Article-205-1-10-20220930Document20 pagini39-Main Article-205-1-10-20220930Dhian ZhahirahÎncă nu există evaluări

- Effectsof Green Banana Flouronthe Physical ChemicalandDocument10 paginiEffectsof Green Banana Flouronthe Physical ChemicalandMiranda MonichaÎncă nu există evaluări

- Kaur 2007Document11 paginiKaur 2007kamali dikshithaÎncă nu există evaluări

- 1 - Vol 4 Issue 2Document12 pagini1 - Vol 4 Issue 2Komang Rai Artha WigunaÎncă nu există evaluări

- Porridge MixDocument9 paginiPorridge MixAlyssa NesianandaÎncă nu există evaluări

- Utilization of Banana Peel As A Functional Ingredient in Yellow NoodleDocument9 paginiUtilization of Banana Peel As A Functional Ingredient in Yellow NoodleKim GosengÎncă nu există evaluări

- RaniDocument16 paginiRaniNaman KaurÎncă nu există evaluări

- Characterization and Sensory Evaluation of Pomegranate MolassesDocument4 paginiCharacterization and Sensory Evaluation of Pomegranate MolassesRadwan AjoÎncă nu există evaluări

- Food Science and Biotechnology Volume 22 Issue 1 2013Document7 paginiFood Science and Biotechnology Volume 22 Issue 1 2013Fayzan LabÎncă nu există evaluări

- Bajra Paper 4Document12 paginiBajra Paper 4Poonam GurjarÎncă nu există evaluări

- Bottlegourd HalwaDocument6 paginiBottlegourd HalwaBhavana avhadÎncă nu există evaluări

- Jurnal 1 KolomDocument10 paginiJurnal 1 KolomMye LestÎncă nu există evaluări

- Artículo Cientifico IIIDocument15 paginiArtículo Cientifico IIICelia Chijchiapaza PacoÎncă nu există evaluări

- Standardization and Development of Instant Ragi Dosa Mix With Dehydrated Green Leafy VegetablesDocument5 paginiStandardization and Development of Instant Ragi Dosa Mix With Dehydrated Green Leafy VegetablesIOSRjournalÎncă nu există evaluări

- Extraction, Denaturation and Hydrophobic Properties of Rice Flour ProteinsDocument12 paginiExtraction, Denaturation and Hydrophobic Properties of Rice Flour ProteinsKishore SakhileÎncă nu există evaluări

- Lemon Grass DistillateDocument9 paginiLemon Grass DistillateJoe Joseph100% (1)

- Characterization of Jack Bean Butter (Canavalia Ensiformis L.) With Variation of Full Cream Milk AdditionDocument12 paginiCharacterization of Jack Bean Butter (Canavalia Ensiformis L.) With Variation of Full Cream Milk AdditionAnang WijayantoÎncă nu există evaluări

- ArticleinonlineDocument5 paginiArticleinonlinesumitjena180Încă nu există evaluări

- Ice CreamDocument5 paginiIce Creamirfan muhammadÎncă nu există evaluări

- Mechanism of Bridging and Interfering Effects of Tea Polyphenols On Starch MoleculesDocument13 paginiMechanism of Bridging and Interfering Effects of Tea Polyphenols On Starch MoleculesManoel Divino Matta Jr.Încă nu există evaluări

- 'Journal 4 PDFDocument6 pagini'Journal 4 PDFAw IiaaÎncă nu există evaluări

- Development of Arrowroot Flour and Taro Flour Snack Bar With Banana Bud Flour Supplementation As Snack For Diabetes PatientDocument7 paginiDevelopment of Arrowroot Flour and Taro Flour Snack Bar With Banana Bud Flour Supplementation As Snack For Diabetes PatientGina AshfihaniÎncă nu există evaluări

- 4434 12963 1 PBDocument13 pagini4434 12963 1 PBfadilababyonggo99Încă nu există evaluări

- Dhavalagi Pallavi Et AlDocument5 paginiDhavalagi Pallavi Et AlInternational Journal of Clinical and Biomedical Research (IJCBR)Încă nu există evaluări

- Sanjay Done SiteDocument20 paginiSanjay Done SiteKundan KumawatÎncă nu există evaluări

- DTR StatusDocument6 paginiDTR StatusKundan KumawatÎncă nu există evaluări

- Rjil@1234: Siteforge Account AshokyadavDocument2 paginiRjil@1234: Siteforge Account AshokyadavKundan KumawatÎncă nu există evaluări

- Circle PM/PL Need To Fill Daily Wip Details SR - No Date Circle Project Scope/Band StatusDocument53 paginiCircle PM/PL Need To Fill Daily Wip Details SR - No Date Circle Project Scope/Band StatusKundan KumawatÎncă nu există evaluări

- Circle PM/PL Need To Fill Daily Wip Details SR - No Date Circle Project Site Id Activity RateDocument8 paginiCircle PM/PL Need To Fill Daily Wip Details SR - No Date Circle Project Site Id Activity RateKundan KumawatÎncă nu există evaluări

- Cluster Name Site Id Cell Name Site Name LAT Long Antenna TypeDocument1 paginăCluster Name Site Id Cell Name Site Name LAT Long Antenna TypeKundan KumawatÎncă nu există evaluări

- Scope Work Band Site ID (Near End) : Growth I-MP-AMLA-ENB-9019 Growth I-MP-MLTI-ENB-H007Document4 paginiScope Work Band Site ID (Near End) : Growth I-MP-AMLA-ENB-9019 Growth I-MP-MLTI-ENB-H007Kundan KumawatÎncă nu există evaluări

- Ealth - Benefits - Immune - System - Html#Ixzz2P Mikyfo6: How A Fever Benefits Your HealthDocument4 paginiEalth - Benefits - Immune - System - Html#Ixzz2P Mikyfo6: How A Fever Benefits Your HealthKundan KumawatÎncă nu există evaluări

- Rail Route Drive - 18july'14Document13 paginiRail Route Drive - 18july'14Kundan KumawatÎncă nu există evaluări

- Activity - Tracker On 9-9-2014Document3 paginiActivity - Tracker On 9-9-2014Kundan KumawatÎncă nu există evaluări

- Kundan Kumawat ResumeDocument2 paginiKundan Kumawat ResumeKundan KumawatÎncă nu există evaluări

- Iron PillsDocument4 paginiIron PillsKundan KumawatÎncă nu există evaluări

- Lons'Kh HKKJR Ihbe V LV) LsokxzkeDocument16 paginiLons'Kh HKKJR Ihbe V LV) LsokxzkeKundan KumawatÎncă nu există evaluări

- BharatDocument1 paginăBharatKundan KumawatÎncă nu există evaluări

- Biotechnology: World Congress OnDocument1 paginăBiotechnology: World Congress OnKundan KumawatÎncă nu există evaluări

- Jackson R. Lanning: Profile StatementDocument1 paginăJackson R. Lanning: Profile StatementJacksonLanningÎncă nu există evaluări

- Concept of InsuranceDocument4 paginiConcept of InsuranceNazrul HoqueÎncă nu există evaluări

- Alma Matter SpeechDocument1 paginăAlma Matter Speechlariza gallegoÎncă nu există evaluări

- The Little MermaidDocument6 paginiThe Little MermaidBobbie LittleÎncă nu există evaluări

- Yusof Ishak Secondary School Humanities Study Tour Ho Chi Minh City, VietnamDocument19 paginiYusof Ishak Secondary School Humanities Study Tour Ho Chi Minh City, Vietnamadamant751Încă nu există evaluări

- Ekoplastik PPR Catalogue of ProductsDocument36 paginiEkoplastik PPR Catalogue of ProductsFlorin Maria ChirilaÎncă nu există evaluări

- E. What Was The Chinese POW Death Rate in WW2 and The Second Sino-Japanese WarDocument3 paginiE. What Was The Chinese POW Death Rate in WW2 and The Second Sino-Japanese WarPamela SantosÎncă nu există evaluări

- Curtis Mathes CM25020S by Samsung - Owner's ManualDocument49 paginiCurtis Mathes CM25020S by Samsung - Owner's ManualpadawerÎncă nu există evaluări

- HDMI To MIPI and LVDS To MIPI Converter Rotator Board Solutions From Q VioDocument2 paginiHDMI To MIPI and LVDS To MIPI Converter Rotator Board Solutions From Q VioSubham KumarÎncă nu există evaluări

- Cell Signaling - The ComponentsDocument7 paginiCell Signaling - The Componentsk10 Lớp Dinh DưỡngÎncă nu există evaluări

- Irshad KamilDocument11 paginiIrshad Kamilprakshid3022100% (1)

- FTec 150 - Intro To Meat ProcessingDocument51 paginiFTec 150 - Intro To Meat ProcessingJessa Silvano ArgallonÎncă nu există evaluări

- Statistics For EconomicsDocument58 paginiStatistics For EconomicsKintu GeraldÎncă nu există evaluări

- Product Management Mcnaughton - 0Document4 paginiProduct Management Mcnaughton - 0Andrey MatusevichÎncă nu există evaluări

- Basic DWDM Components.Document16 paginiBasic DWDM Components.Pradeep Kumar SahuÎncă nu există evaluări

- PL SQL Exercise6Document2 paginiPL SQL Exercise6Nishant AndhaleÎncă nu există evaluări

- Proceedings IndexDocument3 paginiProceedings IndexHumberto FerreiraÎncă nu există evaluări

- Packet Tracer - VLSM Design and Implementation Practice TopologyDocument3 paginiPacket Tracer - VLSM Design and Implementation Practice TopologyBenj MendozaÎncă nu există evaluări

- Examples of Consonant BlendsDocument5 paginiExamples of Consonant BlendsNim Abd MÎncă nu există evaluări

- Ed508-5e-Lesson-Plan-Severe Weather EventsDocument3 paginiEd508-5e-Lesson-Plan-Severe Weather Eventsapi-526575993Încă nu există evaluări

- Materials Science and Engineering-Chapter 11Document3 paginiMaterials Science and Engineering-Chapter 11JurgenÎncă nu există evaluări

- Report On Sonepur MelaDocument4 paginiReport On Sonepur Melakashtum23Încă nu există evaluări

- Board of DirectorsDocument2 paginiBoard of DirectorsjonahsalvadorÎncă nu există evaluări

- Ecosystems FYBCom PDFDocument41 paginiEcosystems FYBCom PDFShouvik palÎncă nu există evaluări

- Factors Influencing The Selection Of: MaterialsDocument22 paginiFactors Influencing The Selection Of: MaterialsMaulik KotadiyaÎncă nu există evaluări

- ECU MS 4 Sport ManualpdfDocument26 paginiECU MS 4 Sport ManualpdfLucas DuarteÎncă nu există evaluări

- 2015.15009.fundamental Principles of Physical Chemistry - Text PDFDocument782 pagini2015.15009.fundamental Principles of Physical Chemistry - Text PDFAnoif Naputo Aidnam100% (1)