Documente Academic

Documente Profesional

Documente Cultură

Water Treatment

Încărcat de

Anonymous 8ooQmMoNs1Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Water Treatment

Încărcat de

Anonymous 8ooQmMoNs1Drepturi de autor:

Formate disponibile

CIV3264: URBAN W ATER AND W ASTEWATER SYSTEMS Water and Wastewater Treatment

CONTENTS 0

Topic 5: Water Treatment

TABLE OF CONTENTS

5. WATER TREATMENT

5.1 5.2 5.3 5.4 5.5 The supply of drinking water Basic chemistry of natural water: hardness and alkalinity Regulations of drinking water quality Unit operations of water treatment Advanced water treatment processes Page No 1 1 2 3 4 18

Department of Civil Engineering, Monash University CIV3264 Revised 5/2012

CIV3264: URBAN W ATER AND W ASTEWATER SYSTEMS Water and Wastewater Treatment

5. WATER TREATMENT

Learning Outcomes of Topic 1 Water Treatment: (1) knowing two basic concepts related to natural water characteristics - hardness and alkalinity; (2) having an overall understanding about Australian Drinking Water Guidelines; knowing where to obtain the details of the document; and (3) understanding the working principles of major water treatment unit operations - pretreatment, coagulation and mixing, flocculation, softening, sedimentation, filtration, disinfection and fluoridation; and being capable of carrying out some basic calculations for conceptual design.

5.1 THE SUPPLY OF DRINKING WATER

Drinking water is defined as water intended primarily for human consumption and other domestic uses, e.g. drinking, food preparing, bathing, etc. first and foremost, the water must be safe (chemically, bacteriologically, and radiologically) to drink, although taste, odour, and appearance are also important issues. Drinking water is delivered to our homes via a drinking water supply system. In this context, it is defined as everything from the point of collection to the consumer (Figure 5.1), including: Water sources, Treatment systems, Storage towers/reservoirs an distribution network, Distribution systems and pipe network.

Figure 5.1: Diagram of water supply system in Orange City (USA)

Department of Civil Engineering, Monash University CIV3264 Revised 5/2012

CIV3264: URBAN W ATER AND W ASTEWATER SYSTEMS Water and Wastewater Treatment

5.2 BASIC CHEMISTRY OF NATURAL WATER: HARDNESS AND ALKALINITY

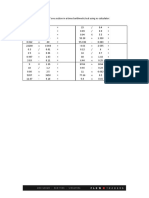

Water hardness. The term hardness is used to characterize a water that does not lather well causing a scum in the bathtub; and leaving hard, white, crusty deposits (scale) on coffee pots, tea kettles, and hot water heaters. As a result, if a water has high hardness value, it can not work efficiently for washing cloth. In addition, water hardness results in scaling on water pipes, kettles, valves, etc. Water hardness is defined as the sum of all polyvalent cations (see also CIV2263 Water Systems lecture notes). Although all polyvalent cations contribute to hardness, the most predominant contributors are calcium (Ca2+) and Magnesium (Mg2+) The most common unit to describe hardness is milligram per litre (mg L-1) as CaCO3. According Water Quality Association in the USA, different waters can be categorized from very soft to very hard as shown in Table 5.1. Table 5.1. Hardness Classification of Water

A common goal of drinking water treatment is to provide water with a hardness value in the range of 60-120 mg/L (expressed as CaCO3). Hardness (or total hardness) of water consists of carbonate hardness (e.g. Ca2+ and Mg2+ associated with HCO3- ion) and non-carbonate hardness (e.g. Ca2+ and Mg2+ not associated with HCO3- ion). For detail, see: Water and Wastewater Calculation Manual (S Lin, McGraw Hill, 2001, pp 388-395). Alkalinity. The Alkalinity value of water refers to the content of chemical species in the water that can neutralize acid, i.e. hydroxyl OH , carbonate CO2 3 , and bicarbonate HCO 3 ions. Similar to the expression of hardness (but bear in mind that hardness and alkalinity are two different water quality parameters), alkalinity can be expressed as mg/L CaCO 3 concentration (see also CIV2263 Water Systems lecture notes). The concepts of water hardness and alkalinity need to be understood, in order to understand softening and coagulation - two important unit operations in water treatment.

Department of Civil Engineering, Monash University CIV3264 Revised 5/2012

CIV3264: URBAN W ATER AND W ASTEWATER SYSTEMS Water and Wastewater Treatment

5.3 REGULATIONS OF DRINKING WATER QUALITY

In Australia, the Australian Drinking Water Guidelines (ADWG) (http://www.nhmrc.gov.au/publications/synopses/eh19syn.htm) provide communities and water industry with the guidance on what constitutes good quality drinking water. Following its endorsement in 1996, the ADWG has been subjected to a rolling-revision process that ensures the Guidelines represent the latest scientific evidence in relation to good quality drinking water (latest release October 2011). 5.3.1 Characteristics of Drinking Water Quality 1. Microbiological quality: the risks of presence of micro-organisms that can cause disease. Only a small number of microorganism species may cause an infection. Indicator organism is usually a group of microbes of the family Escherichia coli (E. coli or coliform bacteria), which are organisms normal to the digestive tracts of warm-blooded animals. Coliforms are plentiful, easily detected, generally harmless and hardy. If a large number of coliform are present, there is a good chance that the water MAY contain pathologic organisms. 2. Physical water quality characteristics are colour, odour, turbidity, hardness, solids, pH, temperature, taste, odour, dissolve oxygen. 3. Chemical water quality characteristics these are primary indicators of organic and inorganic constitutes in the water. 4. Radiological quality natural and artificial source. 5.3.2 Guaranteeing the Safety of Water Supplies 1. The use of effective barriers to prevent contamination (catchment protection from human activates; water pre-treatment; protection of water storage; water treatment including disinfection; disinfectant residual; secured distribution systems); 2. Regular inspections of catchment areas to manage the chemicals in use; 3. Control of industrial, mining, forestry, agricultural, etc, activates within the catchment bounders; 4. Maintenance of the water supply system; 5. Use of approved water treatment chemicals and materials in contact with water; 6. Use of skilled and trained personnel in the operation of water supply system; 7. Public education. Disinfection is the most important measure! Catchment management is central to maintaining water quality. Point sources of pollution (domestic and industrial discharges) are easily identified and managed. Diffuse sources of pollution (agricultural runoff, animal wastes, urban stormwater, etc) are more difficult to manage.

Department of Civil Engineering, Monash University CIV3264 Revised 5/2012

CIV3264: URBAN W ATER AND W ASTEWATER SYSTEMS Water and Wastewater Treatment

5.3.3 Monitoring Public Water Supplies Water quality is tested by taking water samples from points in the system and analysing them either in a lab or on-site. The following issues should be considered: what water quality characteristic; where in the system; how frequently to monitor; what methods and sampling techniques to use; how to analyse the results.

All this is prescribed by the guidelines. Regulations governing the quality drinking help to safeguard an outstanding record of water supply in most developed country since the early twentieth century.

5.4 UNIT OPERATIONS OF WATER TREATMENT

All water treatment plants can be classified as one of the following three types: (1) limited treatment, (2) coagulation plants, and (3) softening plants. The level and sophistication of treatment is determined by the quality of water at the source, as shown in Table 5.2. Table 5.2: Typical treatment options for water from different sources Class of water source High quality groundwater Occasional high quality upland water Typical groundwater Lowland rivers and reservoirs The source is downstream of urban development or industries Description of treatment Limited treatment (sometimes no treatment) Standard treatment: softening plants (sometimes combined with coagulation) Standard treatment: coagulation plants (sometimes combined with softening) Special water treatment: coagulation and softening (sometimes combined with advanced treatment)

Typical treatment trains for raw water from different sources are highlighted in Figure 5.2. For an urban region, each drinking water treatment plant is usually made up of a number of operation units. The most common treatment unit operations for freshwater include: (1) screening, (2) coagulation and mixing, (3) flocculation, (4) softening, (5) sedimentation, (6) filtration, (7) disinfection, and (8) fluoridation. The selection of theses treatment units is produced by raw water quality analysis that needs to be done in detail, and trials of the treatment process typically need to be carried out for no less than a year. Major unit operation processes for water treatment will be introduced in this section.

Department of Civil Engineering, Monash University CIV3264 Revised 5/2012

CIV3264: URBAN W ATER AND W ASTEWATER SYSTEMS Water and Wastewater Treatment

Figure 5.2: Unit process used in treatment of different water source classes 5.4.1 Pre-Treatment The role of pre-treatment is to prepare raw water for further treatment. When surface water is used as the source of drinking water, physical screening is normally the first step to remove coarse material and debris, as the raw water comes to the treatment plant. When ground water is used as the drinking water source, aeration or air stripping is typical used in the pre-treatment, because groundwater (although usually of better quality than surface water) is generally associated with high hardness. In the pre-treatment, the following unit operation can be used: Screening - Coarse screens (inclined bars of 25 mm diameter and 100 mm spacing) prevent large floating material from entering the treatment plat;

Department of Civil Engineering, Monash University CIV3264 Revised 5/2012

CIV3264: URBAN W ATER AND W ASTEWATER SYSTEMS Water and Wastewater Treatment

- Fine screens (mesh with openings about 6 mm in diameter) - Micro-screening (mesh openings from 20-40 m) are only used as the main treatment for relatively uncontaminated waters, or upstream of slow sand filters. Storage and neutralisation Storage tanks serve as a safety line in the event of river becoming polluted, as storage in times of low flow, or as a smaller reservoir to balance the flow through the plant (7-10 days of average water damned or just over 12 hours). They act as initial settling tanks. Raw water pH value is occasionally adjusted at this stage of the treatment. Aeration (common for groundwater) is used: - to remove trace volatile organic compounds (VOCs) in the raw water either from surface water or groundwater sources - to release excess H2S and CO2 in the raw water - to increase DO (good for both organic and inorganic pollution) Chemical pre-treatment - pre-chlorination is used for low turbidity water with a high coliform count. It oxidises Fe and Mn, reduces ammonia, and kill pathogenic organisms (expensive). - activated carbon can be used to remove photosynthetic algae, colour, odour, and selective organic compound. 5.4.2 Coagulation and Mixing In water treatment processes, coagulation takes place in a mixing tank (Figure 5.3). The objective of coagulation is to remove turbidity and colour-producing materials, which are mostly colloidal particles (1-200 millimicrons or nano-metres), in the raw water. These materials include algae bacteria, organic and inorganic substances, and clay particles.

Figure 5.3: Rapid mixing devices used for coagulation in water treatment

Department of Civil Engineering, Monash University CIV3264 Revised 5/2012

CIV3264: URBAN W ATER AND W ASTEWATER SYSTEMS Water and Wastewater Treatment

Most colloidal particles in raw waters and wastewaters are negatively charged. The mechanisms of coagulation are complex and often include neutralization by opposite charge, inter-particle bridging, and precipitation. If the chemical characteristics of the colloidal particles (such as the charge) are changed, the particles will attract each other, agglomerate, and settle as larger particle flocs. Coagulation process utilises what is known as a chemical coagulant (aluminium or iron salt) to promote the agglomeration of the colloidal particles. Aluminium sulphate (also known as alum) Al2(SO4), is the most common coagulant used in water treatment. Other materials that can also be used as coagulants include ferric chloride FeCl3, ferric sulphate Fe2(SO4)3, ferrous sulphate FeSO4 and lime Ca(OH)2. Alum can be purchased either as dry powders or solutions. When alum solution is used as the coagulant, it is pumped into and mixed with the raw water. The value of pH of the raw water plays an important role in coagulation. The reaction of coagulation process can be simplified and written in the following form:

Al 2 SO4

3

6HCO 3

2AL OH

6CO 2 3SO2 4

Eqn 5.1

When ferric chloride is used as the coagulant, the chemical reaction of coagulation process can be simplified and written as the following:

FeCl 3 3HCO 3 Fe OH

3

3CO 2 3Cl

Eqn 5.2

Example 5.1: Estimating the theoretical/minimum amount of coagulant needed in the coagulation process Raw river water with low alkalinity level of 12 mg/L as CaCO3 is treated in a water plant. For coagulation process, estimate the minimum concentration of alum to be dosed into the raw water in order to stimulate the agglomeration of colloidal solids. Solution: Coagulation with alum proceeds according to Eqn 5.1. To solve the question: 1. Find molar mass of CaCO3: 2. Find equivalent weight of CaCO3: 3. Find molar mass of HCO3-: 4. Find equivalent weight of HCO3-: 5. 12 mg/L CaCO3 is equivalent to: 6. Find molar mass of Al2 SO4 3 :

40 12 3 16 100 g / mol 100 / 2 50 g / mol 1 12 3 16 61 g mol 61 / 1 61 g / mol

12 61 14.6 mg L HCO 3 50

27 2 3 32 4 16

342 mg L

7. According to Eqn 5.1, alum concentration needed is:

14.6 342 13.6 mg L 6 61

Department of Civil Engineering, Monash University CIV3264 Revised 5/2012

CIV3264: URBAN W ATER AND W ASTEWATER SYSTEMS Water and Wastewater Treatment

Coagulant aids. The process of coagulation can be made more efficient by adding coagulant aid, in addition to coagulants. Three common types of coagulant aids are silica, clays and polymers. For further details, students should refer to text books given in the reference list in the unit guide. Rapid mixing. The efficiency of coagulant, which is used to simulate the agglomeration of colloidal particles so that they can be easily removed from the raw water, relies on good mixing of the coagulant with the raw water. Rapid mixing is probably the most important physical operation affecting coagulant dose efficiency. In water treatment process design, the size of the mixing/coagulation tank can be determined based on Eqn 5.3.

V Q C Ce 1 ln i K Ce

td

Eqn 5.3

td detention time of water in the rapid mixing tank, d V volume of the mixing tank, m3 Q water flow rate, m3 d-1 K a rate constant determined in lab experiment, d-1 Ci influent coagulant concentration, mg/L Ce effluent coagulant concentration, mg/L

Example 5.2: Estimating detention time and size of rapid mixing tank In a water treatment plant, alum of 50 mg/L concentration is used as coagulant. To save operating cost, it is required that the efficiency for the consumption of alum is no less than 90%. The rate constant for the mixing of alum in the raw water has been in laboratory as K=90 d-1. Calculate water detention required in the tank. How you may estimate the size of the rapid mixing tank? Solution: 1. Find effluent alum concentration: C e 2. Estimate detention time: 3. Estimate volume of the tank:

td

1 0.9 C i 5 mg L

C Ce 1 ln i K Ce

1 50 5 ln 90 5

0.0244 d

V t dQ

Determining the dimension of rapid mixing tank. The rapid mixing tank consists of an electric motor, gear-type speed controller, impeller (either turbine or axial types). Dimension of the tank is often determined by the following rules-of-thumb:

Department of Civil Engineering, Monash University CIV3264 Revised 5/2012

CIV3264: URBAN W ATER AND W ASTEWATER SYSTEMS Water and Wastewater Treatment

Volume of a single tank: Water depth in the tank: Impeller diameter: Vertical baffles (if used):

seldom exceed 8 m3 0.5-1.1 times the diameter (or width) of the tank 0.3-0.5 times the diameter (or width) of the tank should be 10% of the diameter (or width) of the tank

5.4.3 Flocculation While mixing and coagulation stimulate colloidal particles in raw water to agglomerate, the objective of unit operation flocculation is to allow the particle flocs to further collide, adhere to one another, and grow to a size that will settle readily. Note that the main objective of coagulation is to alter the surface charge of colloidal particle so that they may stick together to form particle flocs (or microflocs). The main objective of flocculation is to allow these flocs to grow bigger, so that they can become relatively easy to settle and remove from the water. Coagulation and flocculation normally take place in separate operation units, as shown in Figure 5.4.

Raw water Rapid mix unit Flocculation tank (flocculator)

To settling

Coagulant addition

Figure 5.4: Coagulation and flocculation Flocculation takes place in an operation unit called flocculator (Figures 5.5 and 5.6). Sufficient mixing is needed in the flocculator so that when particles/flocs collide, there is enough energy (through slow gentle mixing) for them to stick together, and the sizes of flocs will grow. On the other hand, the mixing cannot be excessive so as to avoid breaking flocs of particles apart; otherwise, the particle flocs would be too small to settle in the following sedimentation operation. Coagulation (mixing) and flocculation can take place in a single apparatus known as upflow solids contactor unit; thereby combining two unit operations of water treatment into one, as shown in Figure 5.7. The main advantage of upflow solids contact unit is its reduced size. While the detention time of raw water in rapid mixing tank (for coagulation) is typical in the range of 20s to several minutes, the typical water detention time in the range of 20-60 minutes. Additional substances (chemicals, polyelectrolytes, etc) can be added into the flocculator to assist the growth of flocs.

Department of Civil Engineering, Monash University CIV3264 Revised 5/2012

CIV3264: URBAN W ATER AND W ASTEWATER SYSTEMS Water and Wastewater Treatment

10

Figure 5.5: Paddle flocculator

Figure 5.6: Baffled chamber flocculator

Figure 5.7: Typical upflow solids contact unit

Department of Civil Engineering, Monash University CIV3264 Revised 5/2012

CIV3264: URBAN W ATER AND W ASTEWATER SYSTEMS Water and Wastewater Treatment

11

The main design parameter used in flocculation is the velocity gradient, G. This parameter describe the degree of mixing; the higher the G value, the more vigorous the mixing. Detailed calculation in regard to how velocity gradient G is used in flocculator design is beyond the scope of this unit. Students may refer to Water and Wastewater Calculation Manual (S Lin, McGraw Hill, 2001) which provide further detail and worked examples. 5.4.4 Softening In natural environment, water undergoes hydrological cycle that increases its hardness, as illustrated in Figure 5.8. As rain water enters topsoil, the respiration of microorganisms increases the CO2 content of the water. As shown in Figure 5.8, CO2 reacts with water to form carbonic acid H2CO3 in the water. Limestone, which is made up of solid CaCO3 and MgCO3, reacts with the carbonic acid to form calcium bicarbonate Ca(HCO3)2 and magnesium bicarbonate Mg(HCO3)2. Although CaCO3 and MgCO3 are both insoluble in water, Ca(HCO3)2 and Mg(HCO3)2 are quite soluble. As such, their formation increases the concentration of [Ca2+] and [Mg2+] in the water.

Figure 5.8: Natural processes by which water is made hard As a result of the process shown in Figure 5.8, many raw waters (especially those from groundwater sources) in the natural environment have hardness values greater than 150 mg/L CaCO3. In order to provide tap water with hardness value in the range of 60-120 mg/L, public water suppliers often need to soften the raw water a unit operation known as softening. Softening can be accomplished by either: (1) lime-soda process, or (2) ion exchange. Lime-soda softening In this softening process, water hardness is reduced by adding calcium hydroxide Ca(OH)2 and soda ash Na2CO3 into the water. Many treatment plants find it more economical to buy quicklime (CaO), commonly called lime. Mixed with water, CaO can produce a slurry of Ca(OH)2, which is added into the raw water. Figure 1.9 shows the diagram of a typical drinking water softening plant.

Department of Civil Engineering, Monash University CIV3264 Revised 5/2012

CIV3264: URBAN W ATER AND W ASTEWATER SYSTEMS Water and Wastewater Treatment

12

Figure 5.9: Diagram of a water softening plant Adding Ca(OH)2 and Na2CO3 into the raw water will incur the following reactions that reduce water hardness. Reaction 1: Neutralization of carbonic acid H2CO3. Free carbonic acid present in the raw water needs to be removed first before further reactions, although this reaction itself does not reduce hardness.

H 2 CO3 Ca OH

2

CaCO3

2H 2 O

Eqn 5.4

Reaction 2:

Precipitation of carbonate hardness due to calcium.

Ca 2 2HCO 3 Ca OH

2

2CaCO3

2H 2 O

Eqn 5.5

Reaction 3:

Precipitation of carbonate hardness due to magnesium.

Mg 2 Mg 2 2HCO 3

2 CO3

Ca OH Ca OH

2

MgCO3 CaCO3 Mg OH

3

2H 2 O

Eqn 5.6 Eqn 5.7

CaCO3

Reaction 4:

Removal of noncarbonate hardness due to calcium.

Ca 2 Na 2 CO3 CaCO3 2Na

Eqn 5.8

Reaction 5:

Removal of noncarbonate hardness due to magnesium.

Mg 2 Ca OH

2

Mg OH

Ca 2

Eqn 5.9

Ion-exchange softening Ion exchange is a unit process in which ions of a given species (such as Na+) are displaced from an insoluble exchange material (this material is represented by R in Eqn 5.10) by ions of a different species in solution. When ion-exchange is applied in water softening, sodium ions from a resin (i.e. the exchange material R) replace calcium and magnesium ions in the raw water, thus reducing the hardness of the water.

Department of Civil Engineering, Monash University CIV3264 Revised 5/2012

CIV3264: URBAN W ATER AND W ASTEWATER SYSTEMS Water and Wastewater Treatment

13

RNa 2

Ca 2 Mg 2 Fe 2

Ca R Mg Fe

2Na

Eqn 5.10

Ion exchange process typically is typically carried out in a series of columns packed with the exchange material (e.g. resin); removing close to 100% of water hardness. Resin is usually reactivated and reused after it maximum capacity has been reached. Example 5.3: Chemical requirement in lime-soda softening process Ground water from Yuhwa Aquifer contains 2.3 10-5 mol L-1 of dissolved CO2. The water is being pumped at a rate of 200 L s-1, to serve the residents of Haemosu town. Because of the high hardness of this water, it needs undergoes softening treatment process. Calculate the amount (in kg) of hydrated lime Ca(OH)2 that needs to be added each day to neutralize carbonic acid in the first stage of softening treatment, and how much calcium carbonate will be generated as a result. Solution: Eqn 5.4 shows that 1 mol of Ca(OH)2 is needed to neutralize 1 mol of carbonic acid: Ca(OH)2 needed per litre water is: Converting to mass (kg) per day: CaCO3 mass (kg) produced per day:

2.3 10

5

mol

5

2.3 10 2.3 10

74 200 60 60 24 1000 100 200 60 60 24 1000

29.4 kg d 39.7 kg d

5.4.5 Sedimentation After flocculation and/or softening treatment, the solids containing in the water need to be removed by sedimentation. Because water detention time in sedimentation basins (also called clarifiers or settling tanks) is normally in the range of 2-8 hours, only those particles that can settle in this time frame can be removed. Sedimentation basins are usually rectangular or circular shape, as shown in Figure 5.10. To reduce turbulences caused by the rushing water, as it leaves the sedimentation basins, a series of weirs are put in place to provide a large area for the water and minimize water flow velocity near the outlet zone of the basin. The weirs then feed into a central channel or pipe for transport of the settle water away the sedimentation basin. Design considerations Rectangular sedimentation basins (Fig. 5.10a) normally have a length-width ratio of 2.0 and depth of 1.5-6 m. Circular sedimentation basins (Fig. 5.10b) are normally 10-50 m in diameter and 2.5-6 m in depth.

Department of Civil Engineering, Monash University CIV3264 Revised 5/2012

CIV3264: URBAN W ATER AND W ASTEWATER SYSTEMS Water and Wastewater Treatment

14

Figure 5.10: Photos of operating sedimentation tanks: (a) rectangular, and (b) circular.

Department of Civil Engineering, Monash University CIV3264 Revised 5/2012

CIV3264: URBAN W ATER AND W ASTEWATER SYSTEMS Water and Wastewater Treatment

15

Effluent weir inlet zone settling zone outlet zone

outlet zone

Effluent weir

settling zone inlet zone sludge zone

sludge zone

Figure 5.11: Sketch of rectangular (left) and circular (right) sedimentation tanks Key parameters and typical values in design of sedimentation basins are: Surface overflow rate (flow to surface area ratio): 20-35 m d-1 Detention times: 2-8 h Weir overflow rate (flow to weir length ratio): 150-300 m2 d-1

Example 5.4: Estimating the weir length of sedimentation basin in water treatment A water treatment plant has intake of a low-turbidity freshwater. Its design weir over flow loading rate is 175 m3 d-1. If the freshwater flow rate is 0.044 m3 s-1, how much liner metre of weir is required? Solution:

0.044 60 60 24 175 21.7 m

5.4.6 Filtration As the water flows over the weirs to exist the sedimentation basins, it still carries particles that are too small to settle or, somehow, escape removal from the water due to fluid flow. These particles are filtered out; removed from the water through another unit operation filtration. Filtration devices (i.e. filters) can either be operated as slow or rapid sand filters. A slow sand filter conventionally uses only sand, with a supporting gravel layer at its bottom, while rapid filters can use a variety of media materials. Slow sand filters It is a rectangular concrete open box structure as outlined in Figure 5.12.

Department of Civil Engineering, Monash University CIV3264 Revised 5/2012

CIV3264: URBAN W ATER AND W ASTEWATER SYSTEMS Water and Wastewater Treatment

16

Figure 5.12: Sketch of a slow sand filter A slow filter contains: Supernatant layer of raw water that provides a head of water sufficient to drive the water through the sand filter while creating a detention time of several hours; Schmutzdecke layer composed of living and dead micro-organisms; Bed of fine sand, supported on a thin layer of gravel (particle size, d=0.15-0.3mm); System of under drains (for effluent collection); Inlet and outlet structures. Filtration rate is typically in the range of: 0.1-0.2 m h-1. Filtration mechanisms: The removal of impurities is thought to be primarily in the Schmutzdecke layer. It is both physical and biological process. Total coliform bacteria removal typically reach 99% or higher. Colour removal is typically around 25%. Turbidity removal can be effective except for very fine clay particles (e.g. from mountain runoff). Cleaning is required after 2-6 mounts - scraping off the top surface (6-12mm of sand from the top) and starting again about 2 days later. Rapid sand filters Rapid sand filters can have graded (layered) sand within the bed; they can also be designed as having dual media: sand and anthracite coal. Rapid sand filters remove suspended particles (turbidity) by simple physical method of filtration, but some biological activity may also occur (e.g. the transformation of ammonia into nitrate). Traditionally, rapid sand filters are designed to operate at a loading rate of 120-300 m d-1. Usually, a minimum of two filters are constructed; one being operated, the other being rested or cleaned. Cleaning is then achieved by forcing water flowing upwards through the bed surface this operating is called backwashing. Sand filters (slow or rapid) should have no more than 2.5 m depth of filter media (in the range of 0.5-2.5 m).

Department of Civil Engineering, Monash University CIV3264 Revised 5/2012

CIV3264: URBAN W ATER AND W ASTEWATER SYSTEMS Water and Wastewater Treatment

17

5.4.7 Disinfection Disinfection refers to operations aiming at killing or rendering microorganisms, especially pathogens but the number of harmless microorganisms is also reduced. The proceeding drinking water treatment processes (i.e. coagulation, flocculation, sedimentation, and filtration) typically remove around 90% of microorganisms. However, in order to meet strict drinking water standards, additional disinfection is required. The main characters of a good disinfectant are: (a) being toxic to microorganisms at concentrations well below the toxic threshold to humans and animals, (b) not making water unpalatable, (c) being effective to raw waters from various sources regardless of their compositions and conditions, (d) having a fast rate of disinfection, (e) being persistent enough to prevent re-growth of microorganisms in the distribution system, (f) must not form toxic by-products due to their reactions with any natural occurring materials in the water. The most commonly used industrial scale disinfection methods/disinfectants are: (1) Chlorine is the most commonly used disinfectant in water treatment. Typically, chlorine gas is injected into a tank or pipe, and undergoes rapid mixing followed by slow mixing in a downstream tank. (2) Chlorine dioxide (ClO2 - generated onsite through the combination of chlorine and sodium chloride) (3) Ozone (O3) (4) UV radiation 5.4.8 Fluoridation Water fluoridation is the intentional addition of fluoride to drinking water. During the past five decades, water fluoridation has been proven to be both wise and cost-effective in the prevention of dental decay. Fluoridation is normally accomplished by adding one of the following three compounds to drinking water: (1) sodium fluoride (NaF - powder form), (2) fluorosilicic acid (H2SiF6 - liquid form), or (3) sodium fluorosilicate (Na2SiF6 - powder form). Fluoridation is not needed (in fact, defluoridation is needed), when the naturally occurring fluoride level in the raw water exceeds certain limits. 5.4.9 Water Sludge Treatment Sludge generated in water treatment process, such as alum sludge produced in coagulation and flocculation, need to be sufficiently treated before being disposed (most commonly to landfills). The sludge process is similar to (somewhat easier than) sludge from wastewater treatment process. Sludge treatment has been discussed in detail in Chapter 4.

Department of Civil Engineering, Monash University CIV3264 Revised 5/2012

CIV3264: URBAN W ATER AND W ASTEWATER SYSTEMS Water and Wastewater Treatment

18

5.5 ADVANCED WATER TREATMENT PROCESSES

Although not employed in all treatment plants, advanced water treatment processes can be used in water treatment in order to: - improve water quality to an exceptionally high quality, as required by particular industries (such as beverage, pharmaceutical, etc). - treat raw water containing specific chemical or microbiological contaminants to an acceptable standard. Some of techniques used in advanced water treatment include the following: (1) Iron and manganese removal - both metals are essential for all living creatures, but excessive quantities could have negative effects. Chemical treatment and simple aeration are processes that can reduce Fe concentrations in groundwater. Mn2+ should be oxidised at pH=9-10. (2) Adsorption of organics - some contaminants can be adsorbed on to solid adsorbents. The adsorbent most commonly used in practice is activated carbon. (3) Membrane processes including reverse osmosis. Such processes further remove colloidal particles, ions, and microorganisms, thereby purifying the raw water. (4) Oxidation (including chemical oxidation) to remove the organic and chemical contaminants that are difficult to be removed by other unit operations.

FURTHER READING

Henry, J. G. and Heinke, G. W., 1996. Environmental Science and Engineering, Prentice-Hall, New Jersey, USA. US EPA 1993. Nitrogen Control Manual: EPA Report 625-R-93-010, Office of Research and Development, Environmental Protection Agency, USA. Forster, C. F., 2003. Wastewater Treatment and Technology, Thomas Telford Publishing, London, UK. Gray, N. F., 2004. Biology of Wastewater Treatment, 2nd Ed., Imperial College Press, London, UK. Lin, S., 2001. Water and Wastewater Calculations Manual. McGraw-Hill, New York, USA. Metcalf and Eddy, revised by Tchobanoglous, G., Burton, F. L., Stensel, H. D., 2003. Wastewater Engineering: Treatment and Reuse. 4th Ed., McGraw-Hill, New York, USA.

Department of Civil Engineering, Monash University CIV3264 Revised 5/2012

S-ar putea să vă placă și

- 3510 Prob - Set 4 (2017)Document3 pagini3510 Prob - Set 4 (2017)ShorOuq Mohammed MalkawiÎncă nu există evaluări

- Chapter 01 Solutions PalepuDocument3 paginiChapter 01 Solutions Palepuilhamuh67% (6)

- 2006 Stanford Consulting Case Interview PreparationDocument62 pagini2006 Stanford Consulting Case Interview Preparationr_oko100% (3)

- Water Treatment SchemesDocument26 paginiWater Treatment SchemesCao Xuan CanhÎncă nu există evaluări

- Participant Guide 060801 - Technical Lesson 1Document115 paginiParticipant Guide 060801 - Technical Lesson 1DaneAoneÎncă nu există evaluări

- Water QualityDocument41 paginiWater QualityPaschal MazikuÎncă nu există evaluări

- Low Cost Wastewater Bioremediation Technology: Innovative Treatment of Sulfate and Metal-Rich WastewaterDe la EverandLow Cost Wastewater Bioremediation Technology: Innovative Treatment of Sulfate and Metal-Rich WastewaterÎncă nu există evaluări

- Theory of Practice WaterDocument5 paginiTheory of Practice WaterTemimi Feras0% (1)

- CE405 Environmental Engineering - IDocument2 paginiCE405 Environmental Engineering - IChithraÎncă nu există evaluări

- Removal of Heavy Metals From Wastewater A Review PDFDocument4 paginiRemoval of Heavy Metals From Wastewater A Review PDFSilambarasan SivalingamÎncă nu există evaluări

- Cive3223 5 2015 2Document4 paginiCive3223 5 2015 2Yannick HowÎncă nu există evaluări

- Ammonium Feedback Control in Wastewater Treatment Plants PDFDocument258 paginiAmmonium Feedback Control in Wastewater Treatment Plants PDFalae1970Încă nu există evaluări

- ThesisDocument18 paginiThesisKadiwa Carig Cagayan South100% (2)

- Managing Food Industry Waste EffluentsDocument5 paginiManaging Food Industry Waste EffluentsAbiodun GbengaÎncă nu există evaluări

- Coagulation and Flocculation at Water Treatment PlantsDocument51 paginiCoagulation and Flocculation at Water Treatment PlantsKhalid RehmanÎncă nu există evaluări

- British Columbia Environmental Lab Manual PDFDocument844 paginiBritish Columbia Environmental Lab Manual PDFKharisma SetianingrumÎncă nu există evaluări

- Coagulation and Flocculation in Water and Wastewater Treatment - IWA Publishing PDFDocument27 paginiCoagulation and Flocculation in Water and Wastewater Treatment - IWA Publishing PDFНурбек КасимовÎncă nu există evaluări

- 1.85 Water and Wastewater Treatment Engineering Homework 8Document1 pagină1.85 Water and Wastewater Treatment Engineering Homework 8MuhammadUsmanÎncă nu există evaluări

- Advanced Oxidation Processes for Wastewater TreatmentDocument22 paginiAdvanced Oxidation Processes for Wastewater Treatmentจิรพัฒน์ทิพย์รัตน์0% (1)

- Biochemical Oxygen Demand (BOD) Chemical Oxygen Demand (COD)Document35 paginiBiochemical Oxygen Demand (BOD) Chemical Oxygen Demand (COD)wahyu hidayatÎncă nu există evaluări

- Wastewater CharacterizationDocument20 paginiWastewater CharacterizationFanilo Razafindralambo67% (3)

- Coagulation and Flocculation Processes in Water TreatmentDocument17 paginiCoagulation and Flocculation Processes in Water Treatmentguyii86Încă nu există evaluări

- Mohammed Saleh - STOAT ASM - Simulation Model of Wastewater Treatment ProcessesDocument104 paginiMohammed Saleh - STOAT ASM - Simulation Model of Wastewater Treatment ProcessesAnish Ghimire100% (1)

- Extend Aeration RFDocument27 paginiExtend Aeration RFMaria Hazel AbayaÎncă nu există evaluări

- Waste Water Treatment PlantsDocument5 paginiWaste Water Treatment Plantssharath100% (1)

- Environmental Engineering Assignment 2Document1 paginăEnvironmental Engineering Assignment 2Anonymous Vx9KTkM8nÎncă nu există evaluări

- WATER TREATMENT TECHNOLOGY (TAS 3010) LECTURE NOTES 9e - DisinfectionDocument17 paginiWATER TREATMENT TECHNOLOGY (TAS 3010) LECTURE NOTES 9e - Disinfectionmamat88Încă nu există evaluări

- Chapter 2 Sem 2021Document115 paginiChapter 2 Sem 2021Kamarul SyafiqÎncă nu există evaluări

- Chapter 7. Water QualityDocument34 paginiChapter 7. Water QualityCheng Chiv Ïï100% (1)

- Langelier Index Corrosion MineralizationDocument17 paginiLangelier Index Corrosion MineralizationdeyprasenÎncă nu există evaluări

- Unit 1. Itroduction To Wastewater TreatmentDocument28 paginiUnit 1. Itroduction To Wastewater Treatmentsssshekhar100% (1)

- 9004.1202EEII Chapter1 3Document76 pagini9004.1202EEII Chapter1 3पाँशुल जम्वाल राजपूतÎncă nu există evaluări

- Design a Completely Mixed Activated Sludge SystemDocument2 paginiDesign a Completely Mixed Activated Sludge SystemVipin YadavÎncă nu există evaluări

- Lesson Plan: How Do We Clean Polluted Water?Document15 paginiLesson Plan: How Do We Clean Polluted Water?Tarun MattaparthyÎncă nu există evaluări

- Water Treatment Lecture 4 EENVDocument35 paginiWater Treatment Lecture 4 EENVEllina TehÎncă nu există evaluări

- D399DDocument5 paginiD399DHilarie Jonathan100% (1)

- Problems of Drinking Water in Rural AreaDocument14 paginiProblems of Drinking Water in Rural AreaRoumyadeep ChakrabortyÎncă nu există evaluări

- Report TreatmentPond PDFDocument10 paginiReport TreatmentPond PDFSérgio Dos SantosÎncă nu există evaluări

- Foaming in Wastewater Treatment PlantDocument8 paginiFoaming in Wastewater Treatment PlantGeorge MarkasÎncă nu există evaluări

- Laboratory Methods For The Advancement of Wastewater Treatment MoDocument198 paginiLaboratory Methods For The Advancement of Wastewater Treatment MoAkshay Birajdar100% (1)

- Microbial Analysis of Water SampleDocument9 paginiMicrobial Analysis of Water SamplePalaysma AmrahsÎncă nu există evaluări

- DBDocument25 paginiDBAbhijit MondalÎncă nu există evaluări

- Dairy Wastewater ETP Removes 94% of PollutantsDocument6 paginiDairy Wastewater ETP Removes 94% of PollutantsMortezaÎncă nu există evaluări

- Waste Water TreatmentDocument3 paginiWaste Water TreatmentSana Saleem100% (1)

- Lab Waste WaterDocument10 paginiLab Waste WaterAriffÎncă nu există evaluări

- Collection Preservation of Water and Waste-Water SamplesDocument26 paginiCollection Preservation of Water and Waste-Water SamplesWaleed El-azabÎncă nu există evaluări

- Wastewater Treatment Methods Physical Unit Operations Chemical Unit Operations Biological Unit OperationsDocument34 paginiWastewater Treatment Methods Physical Unit Operations Chemical Unit Operations Biological Unit OperationsNumanÎncă nu există evaluări

- Water Supply and Treatment Lesson PlanDocument20 paginiWater Supply and Treatment Lesson PlanBedatrayee05Încă nu există evaluări

- Treatment of Grey Water Using Technique of PhytoremediationDocument8 paginiTreatment of Grey Water Using Technique of PhytoremediationAnonymous kw8Yrp0R5rÎncă nu există evaluări

- Unit II Primary TreatmentDocument48 paginiUnit II Primary TreatmentAmit AryanÎncă nu există evaluări

- Lecture 6 - Bilogical WWTDocument70 paginiLecture 6 - Bilogical WWTKiran JojiÎncă nu există evaluări

- Conventional Water TreatmentDocument16 paginiConventional Water TreatmentLucian ApostuÎncă nu există evaluări

- Ozonation of Drinking Water - Part I. Oxidation Kinetics and Product FormationDocument25 paginiOzonation of Drinking Water - Part I. Oxidation Kinetics and Product FormationArif HidayatÎncă nu există evaluări

- Environmental Engineering LabDocument54 paginiEnvironmental Engineering LabErhom NathÎncă nu există evaluări

- 10 Cum - DayDocument5 pagini10 Cum - DayAbhijit MondalÎncă nu există evaluări

- CH 9 - Attached Growth ProcessDocument30 paginiCH 9 - Attached Growth Processxuantra92100% (1)

- Lec 8 NeutralizationDocument32 paginiLec 8 Neutralizationhaseeb tahirÎncă nu există evaluări

- Silica Removal During Lime Softening in Water Treatment PlantDocument10 paginiSilica Removal During Lime Softening in Water Treatment PlantLouay MansourÎncă nu există evaluări

- WEEM 3510 Water and Wastewater Lab ManualDocument65 paginiWEEM 3510 Water and Wastewater Lab ManualMichael Huisa Taipe100% (1)

- Waste Water Treatment in Chemical IndustriesDocument23 paginiWaste Water Treatment in Chemical IndustriesAzman Bin KadirÎncă nu există evaluări

- Final Exam SMJC 3333Document6 paginiFinal Exam SMJC 3333azhani95Încă nu există evaluări

- Modeling of Activated Sludge With ASM1 Model, Case Study On Wastewater Treatment Plant of South of IsfahanDocument10 paginiModeling of Activated Sludge With ASM1 Model, Case Study On Wastewater Treatment Plant of South of IsfahanAnish GhimireÎncă nu există evaluări

- Treatment Process Flow SheetsDocument13 paginiTreatment Process Flow Sheetsapi-27499979100% (2)

- Municipal Wastewater Treatment: Evaluating Improvements in National Water QualityDe la EverandMunicipal Wastewater Treatment: Evaluating Improvements in National Water QualityÎncă nu există evaluări

- L6 - LeadershipDocument11 paginiL6 - LeadershipAnonymous 8ooQmMoNs1Încă nu există evaluări

- Ginsborg History of ItalyDocument8 paginiGinsborg History of ItalyAnonymous 8ooQmMoNs10% (1)

- L8 - Human Resource ManagementDocument6 paginiL8 - Human Resource ManagementAnonymous 8ooQmMoNs1Încă nu există evaluări

- L9 - Dynamics of Behaviour in OrganisationsDocument5 paginiL9 - Dynamics of Behaviour in OrganisationsAnonymous 8ooQmMoNs1Încă nu există evaluări

- Harry HearderDocument15 paginiHarry HearderAnonymous 8ooQmMoNs1Încă nu există evaluări

- Portelli Massacre at Fosse ArdeatineDocument9 paginiPortelli Massacre at Fosse ArdeatineAnonymous 8ooQmMoNs1Încă nu există evaluări

- L5 - OrganisingDocument13 paginiL5 - OrganisingAnonymous 8ooQmMoNs1Încă nu există evaluări

- L7 - Managing DiversityDocument5 paginiL7 - Managing DiversityAnonymous 8ooQmMoNs1Încă nu există evaluări

- L4 - Managerial Decision MakingDocument9 paginiL4 - Managerial Decision MakingAnonymous 8ooQmMoNs1Încă nu există evaluări

- Bill Niven War MemorialsDocument7 paginiBill Niven War MemorialsAnonymous 8ooQmMoNs1Încă nu există evaluări

- L1 - The Changing Paradigm of ManagementDocument8 paginiL1 - The Changing Paradigm of ManagementAnonymous 8ooQmMoNs1Încă nu există evaluări

- Weak & Strong FormsDocument77 paginiWeak & Strong FormsAnonymous 8ooQmMoNs1Încă nu există evaluări

- L3 - Planning and GoalsDocument9 paginiL3 - Planning and GoalsAnonymous 8ooQmMoNs1Încă nu există evaluări

- Bill Niven War MemorialsDocument7 paginiBill Niven War MemorialsAnonymous 8ooQmMoNs1Încă nu există evaluări

- Richard Osborne - MythDocument3 paginiRichard Osborne - MythAnonymous 8ooQmMoNs1Încă nu există evaluări

- Sontag Collective MemoryDocument7 paginiSontag Collective MemoryAnonymous 8ooQmMoNs1Încă nu există evaluări

- Lectures 1-3 COLOURDocument45 paginiLectures 1-3 COLOURAnonymous 8ooQmMoNs1Încă nu există evaluări

- Philip Taylor PropagandaDocument3 paginiPhilip Taylor PropagandaAnonymous 8ooQmMoNs1Încă nu există evaluări

- Grammar Guide 2018Document56 paginiGrammar Guide 2018Tony NguerezaÎncă nu există evaluări

- Arithmetic Test Example PDFDocument1 paginăArithmetic Test Example PDFAnonymous 8ooQmMoNs1Încă nu există evaluări

- Fit Interview 071712 PDFDocument14 paginiFit Interview 071712 PDFAnonymous 9W8HM1nqXBÎncă nu există evaluări

- Jock Reynolds J LT RookiesDocument14 paginiJock Reynolds J LT RookiesAnonymous 8ooQmMoNs1Încă nu există evaluări

- TJX Forecast ChangesDocument13 paginiTJX Forecast ChangesAnonymous 8ooQmMoNs1Încă nu există evaluări

- 06 AnsDocument4 pagini06 AnsAnonymous 8ooQmMoNs1Încă nu există evaluări

- 07 AnsDocument5 pagini07 AnsAnonymous 8ooQmMoNs10% (1)

- 05 AnsDocument8 pagini05 AnsAnonymous 8ooQmMoNs1Încă nu există evaluări

- 02 AnsDocument10 pagini02 AnsAnonymous 8ooQmMoNs1Încă nu există evaluări

- 04 AnsDocument20 pagini04 AnsAnonymous 8ooQmMoNs1Încă nu există evaluări

- Removal of MicroplasticsDocument13 paginiRemoval of Microplasticsrabeea ahmedÎncă nu există evaluări

- Water Quality Aspects in and Around Dhaka CityDocument4 paginiWater Quality Aspects in and Around Dhaka CityEmdad YusufÎncă nu există evaluări

- Heavy Metal (App, Procedure, Appendices)Document11 paginiHeavy Metal (App, Procedure, Appendices)Hanif NifÎncă nu există evaluări

- Filter Maintenance and Operation Guidelines ManualDocument758 paginiFilter Maintenance and Operation Guidelines Manualuemaapl100% (1)

- Agcaoili-Talania-Estrada Chapter 1 To 3 - H2O Ever Pure Water Refilling Management SystemDocument36 paginiAgcaoili-Talania-Estrada Chapter 1 To 3 - H2O Ever Pure Water Refilling Management SystemMarie Padilla AgcaoiliÎncă nu există evaluări

- Pwsid: Metropolitan 2591: SystemDocument4 paginiPwsid: Metropolitan 2591: SystemMonica DiazÎncă nu există evaluări

- Filter Operation Effects On Pathogen Passage PDFDocument332 paginiFilter Operation Effects On Pathogen Passage PDFJangchukÎncă nu există evaluări

- Binyam Kebede 2013 ThesisDocument93 paginiBinyam Kebede 2013 ThesisPastor MogollónÎncă nu există evaluări

- Water TreatmentDocument13 paginiWater TreatmentNikola Gulan100% (1)

- 5011) QUOTATION FOR R O PLANT 4000 LPH FOR Multan Chemical (Faisalabad) 27-07-2015Document5 pagini5011) QUOTATION FOR R O PLANT 4000 LPH FOR Multan Chemical (Faisalabad) 27-07-2015shahbaz shahÎncă nu există evaluări

- Clean Water For A Healthy WorldDocument33 paginiClean Water For A Healthy WorldMuhammed NazardeenÎncă nu există evaluări

- Rural Water SupplyDocument3 paginiRural Water SupplyRayarch WuÎncă nu există evaluări

- BOQ Water Treatment PlantDocument5 paginiBOQ Water Treatment PlantbuattugasmetlitÎncă nu există evaluări

- To Study and Compare Plant-Based Natural Coagulant in Water TreatmentDocument9 paginiTo Study and Compare Plant-Based Natural Coagulant in Water TreatmentIJRASETPublicationsÎncă nu există evaluări

- A Report On Analysis of Nepal Water Supply CorporationDocument55 paginiA Report On Analysis of Nepal Water Supply Corporationarjun_niroulaÎncă nu există evaluări

- Favila - MidsayapDocument2 paginiFavila - MidsayapPaw LabadiaÎncă nu există evaluări

- Water Treatment Plant OverviewDocument18 paginiWater Treatment Plant OverviewAnonymous hMech04fiÎncă nu există evaluări

- BWTP-Project Report-Final Corrected DraftDocument94 paginiBWTP-Project Report-Final Corrected DraftMAYURESH PATIL100% (2)

- Robert's Pacer II PKG Water TreatmentDocument3 paginiRobert's Pacer II PKG Water Treatmentmiguel_vera6592Încă nu există evaluări

- Survey Form For Collecting Reverse Osmosis Plant Operation DataDocument2 paginiSurvey Form For Collecting Reverse Osmosis Plant Operation DataJendayiÎncă nu există evaluări

- Holistic ExamDocument13 paginiHolistic ExamFiraol Oromo100% (1)

- DM PlantDocument93 paginiDM PlantPRAMOD KUMAR NANDAÎncă nu există evaluări

- Butuan City Water District 2020 Annual Report HighlightsDocument48 paginiButuan City Water District 2020 Annual Report HighlightsTivorshio MacabodbodÎncă nu există evaluări

- E Series RO 2000 LPH - Final NRP 27092021Document10 paginiE Series RO 2000 LPH - Final NRP 27092021Anand_HvacÎncă nu există evaluări

- WaterQuality ReportDocument25 paginiWaterQuality ReportIbnu SamsiÎncă nu există evaluări

- AWWA Alt Disnfec Fro THM RemovalDocument264 paginiAWWA Alt Disnfec Fro THM RemovalsaishankarlÎncă nu există evaluări

- KKS Guideline For Equipments-Rev1Document74 paginiKKS Guideline For Equipments-Rev1Dragos Ungureanu100% (1)

- Enve 300 Staj Raporu-Summer Practice ReportDocument24 paginiEnve 300 Staj Raporu-Summer Practice Reportmihrican302Încă nu există evaluări