Documente Academic

Documente Profesional

Documente Cultură

No.3chapter 1

Încărcat de

sknagarDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

No.3chapter 1

Încărcat de

sknagarDrepturi de autor:

Formate disponibile

1

CHAPTER 1 INTRODUCTION

You have undoubtedly heard about the wonders of fiber optics. AT & T, Sprint and other large telecommunication companies have saturated the airwaves and print media with advertisements heralding this bright new technology. Futurists talk about the marvels of light wave communications and photonic technology. Omni magazine writes about Fiberopolis. Long-distance telephone calls travel through optical fiber crossing the United States and spanning the oceans to connect the continents. The enthusiasm is not mere hype; fiber optic technology is real and important. From coast to coast, phone companies are laying fiber in the ground, pulling cable through manholes and stringing it between poles. The military is buying fiber for portable battlefield communications systems, due to its superior performance. Medical fiber optic systems allow physicians to peer inside the human body with out surgery. Very few technologies ever realize the fantastic growth rates predicted for them by market analyst. Fiber optics, however, has exceeded predictions. As we near the year 2000, fiber optics will become common in your everyday life. It will enter the office environment. In our home, it will provide services that would have been impractical without it: high-definition TV, secondary education classes in the comfort of your home, a paper-less, environmentally clean newspaper.

1.1 What is Fiber Optics

In its simplest terms, fiber optics is a medium for carrying information from one point to another in the form of light. Unlike the copper form of transmission, fiber optics is not electrical in nature. A basic fiber optic system consists of a transmitting device, which generates the light signal; an optical fiber cable, which carries the light; and a receiver, which accepts the light signal transmitted. The fiber itself is passive and does not contain any active, generative properties.

Corning Cable Systems manufactures and sells those components considered to be part of the passive fiber transmission subsystem; i.e., not active electronic components.

1.2 Basic Principles of Fiber Optics

Since its invention in the early 1970s, the use and demand of optical fiber has grown tremendously. The uses of optical fiber today are quite numerous. The most common are telecommunications, medicine, military, automotive, and industrial. Telecommunications applications are widespread, ranging from global networks to local telephone exchanges to subscribers' homes to desktop computers. These involve the transmission of voice, data, or video over distances of less than a meter to hundreds of kilometers, using one of a few standard fiber designs in one of several cable designs. Companies such as AT&T, MCI, and U.S. Sprint use optical fiber cable to carry plain old telephone service (POTS) across their nationwide networks. Local telephone service providers use fiber to carry this same service between central office switches at more local levels, and sometimes as far as the neighborhood or individual home. Optical fiber is also used extensively for transmission of data signals. Private networks are owned by firms such as IBM, Rockwell, Honeywell, banks, universities, Wall Street firms, and more. These firms have a need for secure, reliable systems to transfer computer and monetary information between buildings to the desktop terminal or computer, and around the world. The security inherent in optical fiber systems is a major benefit. Cable television or community antenna television (CATV) companies also find fiber useful for video services. The high information-carrying capacity, or bandwidth, of fiber makes it the perfect choice for transmitting signals to subscribers. Finally, one of the fastest growing markets for fiber optics is intelligent transportation systems, smart highways with intelligent traffic lights, automated toll booths, and changeable message signs to give motorists information about delays and emergencies.

These are only a few of the many applications possible with the use of optical fiber. We focus primarily on telecommunications uses of optical fiber.

1.3 Evolution of Optical Fiber Communication

During the last twenty years the staggering success of optical fibre communications has enabled people to communicate widely across the world as never before. In spite of the recent economic difficulties the sector in experiencing the underlying growth in optical fibre communications is strong and will surely stabilize. When fibre optical communications were introduced the network was based on copper transmission systems for both long haul (coaxial) and access (twisted pairs) and the fibers were effectively grafted on the existing network infrastructure. This approach did not take into account the salient features of optical transmission except capacity and link length. As the state of the art in fibre communications advanced in terms of components and systems it became clear that they could change completely the fabric of the network and provide a multiplicity of services to satisfy the demand of the broad band multi-media environment of the future. The purpose of this talk is to outline the current trends in optical networks and introduce the technologies that will enable the implementation of future optical networks. The talk begins with the current network trends that are shaped in a multimedia environment with broadband requirements and the expectations it imposes on future technologies in the context of an all optical network. The future enabling technologies will be outlined with emphasis on optical technology and optical and electronic signal processing.

1.3.1 Optical Communication History

The transmission of information by means of light has a much longer history than electrical communication. The first written evidence is at the end of the sixth century BC Aeschylus Oresteia where he mentioned passing the news on of Troys downfall by fire signals via a long chain of relay stations from Asia Minor to Argos. Three centuries after another Greek, Polybius described an arrangement by which the whole Greek alphabet could be transmitted by fire signals using a two-digit, five level codes. This was the first optical communication link that allowed the transmission of messages not previously agreed upon. At the end of the eighteen century AD Claude Chappes optical telegraph allowed the transmission of a signal over the 423 km distance from Paris to Strasbourg within a time of six minutes. In the middle of the nineteenth century, optical telegraphy was replaced by electrical telegraphy, which at this time allowed a faster signal transmission.

However, although optical communication exhibited low practical importance in the next decades, its development proceeded. An example is the report of Graham Bell in 1880 about the transmission of speech over a beam of light. The invention of laser boosted the development of optical communication and opened new sections of research. The main disadvantage of optical communication was the need for a high transmitter power and close repeater spacing because of the atmospheric phenomenon like fog, precipitation and turbulence in the air. The solution of this main disadvantage was the use of optical waveguides that not only gave a solution to the atmospheric disturbances but moreover force the laser beam to follow a certain path. A series of different ways, like continuously and discontinuous lightwave guidance, as well as different materials, like metallic and glass waveguides, has been used. In 1970 Kapron, Keck and Maurer achieved an attenuation value of only 20 dB/km with silica fibres. This event marked the first generation of OFCS.

First Generation_In this first generation the systems worked at 0.85 m wavelength because the semiconductor optical sources were light emitting diodes (LEDs) which emitted light at 0.85 m. At this wavelength the attenuation was high and has motivated farther investigation on attenuation values of silica-based fibers. At the beginning of 1978 the best measured attenuation values for silica-based monomode fibres where under 2 dB/km at 0.85 m wavelength, that has been already used, and under 0.5 dB/km at 1.3 m wavelength. Figure 1.2 shows the loss spectrum of a silica fibre.

Figure 1.1 Loss spectrum of a single-mode silica fibre

Second Generation_Therefore, optical communication proceeded to its next generation. The second generations systems worked at 1.3 m wavelength after Lasers has been developed to emit at that wavelength, where there is a minimum in the silica fibre attenuation curve.

Third Generation_The need for even bigger optical links by achieving an even lower minimum in the silica fibre attenuation curve leads us in the next generation. In the third generation the systems worked at 1.5 m wavelength. However, although the attenuation is low a new problem exists called chromatic dispersion. To overcome this, dispersion shifted fibres have been developed.

Figure 1.2 A modern repeater

Even with the small attenuation of the third generation the needs for optical link length was big therefore, other ways of extending the length of an optical length have been used. The solution was to use, an already used solution in electrical communications, repeaters. Optical repeater is just an electric filter and an amplifier that deducts the noise out of the received signal and then amplifies it between a receiver that receives the weak signal and a transmitter that transmits the amplified signal.

1.4 Block Diagram

mmMIC

MICROPHONE

SUPPLY SECTION

AMPLIFIER SECTION

OPTICAL FIBER

AMPLIFIER SECTION

SUPPLY SECTION

SPEAKER

Figure 1.3 Block Diagram

1.5 Circuit Diagram

Figure 1.4 Circuit Diagram

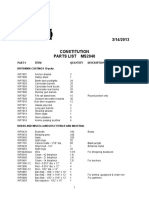

1.6 Component List

Item

1 2 3 4 5 6 7 8 9 10 11 12 13 14

Quantity

1 1 4 1 2 1 1 1 2 2 1 1 1 1

Reference

C1 C2 D1,D2,D3,D4 D5 J1,J2 J3 Q1 Q2 R1,R5 R2,R3 R4 R6 U1 VR1

Part

C CER 104 PF C EL10 100M/35V IN4007 LED RLMT(02M) RLMT(03M) BC547 BC558 R 4K7 R 10K R 1OOE R1K 741 POT10TV IM

1.7 Circuit Operation

Most fiber optic transmitters typically have and amplifier or buffer, driver, optical source, and sometimes an optical connector or interface. The transmitter in this circuit has an acoustic microphone for converting sound waves to an electrical signal, and requires a nine-volt battery with holder to provide electrical power. Pushing the momentary-close switch, SW1, activates the optical voice link by applying 9 volt battery power to the indicator light, microphone, audio circuits and fiber optic LED. The switch must be closed for the transmitter to operate by generating light to carry audio signals. In the diagram are the receiver circuit functions: photo detector, amplifier, adjustable volume control and miscellaneous electronics. Following a signal as it exits from the optical fiber, in the form of light. The circuit is basically an amplifier. The IR signals are picked up by the photodiode and converted into electrical variation which are amplified by the op-amp (operational Amplifier) IC-741 used in the inverting mode with a single supply using divider network of resistors. The gain of IC can be set by varying the feed back through VR resistance (can place a 2.2. M variable). Here the output of IC is further amplified by the push

10

pull amplifier using transistors BEL368/69 pair. The output of the amplifier is taken from emitter of two transistors, with a filter C from speaker.

1.8 Comparison Between Fiber Optic Cable and Copper Cable

FIBRE 1. Transmission with Photons 2. Does not radiate Radio Frequency interference (RFI) nor is susceptible to interference. 3. Fibre Optics Networks operate at speeds upto 2.5 GB per sec.. 4. Fibers have much higher bandwidth. Single mode > 100 GHz for 100m. 5. Signals can be transmitted over much longer distances > 40,000m for single mode. 6. Cost is up to 100 times more however, maintenance is very cheap.

COPPER 1. Transmission with Electrons. 2. Radiates signals capable of interfering with other electronic equipment. 3. Copper wire Networks operate at speeds up to 155 MB per sec. 4. Bandwidth is lower for 100m 10MHZ. 5. Signal attenuation and distortion is much higher hence distances are smaller about 100m. 6. Cost is low, but maintenance is expensive.

11

1.9 Other Applications of Optical Fiber

1.9.1 In Medicine

Recent growth in the use of optics technology for biomedical research and health care has been explosive. Using fibre optics in medical procedures allows things like MRI (Magnetic Resonance Imaging) and PET (Position Emission Tomography) images to be transmitted to anyone, anywhere. Using fibre optics equipment during surgery means using less invasive procedures. This reduces recovery time, is less traumatic on the body, and costs less for the procedure.

1.9.2 In Architecture

Fibre does not use electric current or have interference. Therefore, they can be exposed to water condition. ex. Lighting a pond or waterfall. Fibre optics lighting can also replace neon lights. It uses less energy, maintenance costs are lower and are easier to install.

1.9.3 In Airlines:

Fibre Optics cable is light, so there is no need for heavier cable to be on board an airline. Airplanes can have internal communication systems which are not exposed to outside elements. This enables pilots to see damage to certain parts of the plane without waiting to land.

12

1.9.4 In Automobiles

Automobiles today have bulky lighting systems. With fibre optics cable being small enough to maboeuvre around, automobile designers can have more freedom while designing their vehicle. Optical systems used in cars can control things like stereo, heat and air-conditioners. CATV is also adopting fibre optics, using a unique analogue transmission scheme, but the move to compressed digital video is already planned. Only fibre has the necessary band with for carrying voice, data and video simultaneously. The LAN has also become fibre based. Mainframes have discovered fibres. Only the desktop is currently a battlefield between copper and fibre. The Rs. 3500 Crore telephone cable industry in India has notched up a 30 % growth in 199798. The major constituents of this sector are the jelly filled telephone cables and optical fibre cables. Optical Fibre cables have only about six operators and another 14 more are expected to join in. As per the department of telecommunications (DOT) estimates, the total demand for other optical fibre cables was at 2, 19,700 fibre-km in 1997-98. The demand is stated to increase to 2, 85,600 fibre-km by 1997-98, and then go up to 8, 15,700 fibre-km by the end of the century. One of the main manufacturers in India is AT&T finolex fibre Optic Cables Ltd. which is a joint venture between Lecent Technologies, USA (erstwhile System and Technologies division of AT&T) and Finolex Cables Ltd. The future of fibre optics is the future of communications. With fibres, you have high bandwidth and lots of upgradeability. Applications like multimedia and video conferencing make high bandwidth very essential. Over wide area networks, the installed fibre optic infrastructure can be expanded to accommodate almost unlimited traffic. CATV operators are installing fibres very fast, since advanced digital TV will thrive in a fibre based environment. Even wireless communications need fibre, connecting local low powder cellular or PCS transceivers to the switching matrix.

13

CHAPTER 2 PRINTED CIRCUIT BOARDS

In electronics, printed circuit boards, or PCBs, are used to mechanically support and electrically connect electronic components using conductive pathways, or traces, etched from copper sheets laminated onto a non-conductive substrate. Alternative names are printed wiring board (PWB), and etched wiring board. Populating the board with electronic components forms a printed circuit assembly (PCA), also known as a printed circuit board assembly (PCBA). PCBs are rugged, inexpensive, and can be highly reliable. They require much more layout effort and higher initial cost than either wire-wrapped or point-to-point constructed circuits, but are much cheaper, faster, and consistent in high volume production.

2.1 Categories of PCB

2.1.1 Motherboard

The principal board that has connectors for attaching devices to the bus. Typically, the mother board contains the CPU, memory, and basic controllers for the system. On PCs, the motherboard is often called the system board or mainboard.

2.1.2 Expansion board

Any board that plugs into one of the computer's expansion slots. Expansion boards include controller boards, LAN cards, and video adapters.

14

Controller board_ A special type of expansion board that contains a controller for a peripheral device. When you attach new devices, such as a disk drive or graphics monitor, to a computer, you often need to add a controller board. Network Interface Card (NIC) _An expansion board that enables a PC to be connected to a local-area network (LAN). Video adapter_ An expansion board that contains a controller for a graphics monitor.

2.1.3 Daughter card

Any board that attaches directly to another board. Printed circuit boards are also called cards.

2.2 Manufacturing

2.2.1 Patterning (etching)

The vast majority of printed circuit boards are made by adhering a layer of copper over the entire substrate, sometimes on both sides, (creating a "blank PCB") then removing unwanted copper after applying a temporary mask (eg. by etching), leaving only the desired copper traces. A few PCBs are made by adding traces to the bare substrate (or a substrate with a very thin layer of copper) usually by a complex process of multiple electroplating steps. There are three common "subtractive" methods (methods that remove copper) used for the production of printed circuit boards:

15

1. Silk Screen Printing uses etch-resistant inks to protect the copper foil. Subsequent etching removes the unwanted copper. Alternatively, the ink may be conductive, printed on a blank (non-conductive) board. The latter technique is also used in the manufacture of hybrid circuits. 2. Photoengraving uses a photomask and chemical etching to remove the copper foil from the substrate. The photomask is usually prepared with a photoplotter from data produced by a technician using CAM, or computer-aided manufacturing software. Laser-printed transparencies are typically employed for phototools; however, direct laser imaging techniques are being employed to replace phototools for high-resolution requirements. 3. PCB Milling uses a two or three-axis mechanical milling system to mill away the copper foil from the substrate. A PCB milling machine (referred to as a 'PCB Prototyper') operates in a similar way to a plotter, receiving commands from the host software that control the position of the milling head in the x, y, and (if relevant) z axis. Data to drive the Prototyper is extracted from files generated in PCB design software and stored in HPGL or Gerber file format. "Additive" processes also exist. The most common is the "semi-additive process. In this version, the unpatterned board has a thin layer of copper already on it. A reverse mask is then applied. (Unlike a subtractive process mask, this mask exposes those parts of the substrate that will eventually become the traces.) Additional copper is then plated onto the board in the unmasked areas; copper may be plated to any desired weight. Tin-lead or other surface platings are then applied. The mask is stripped away and a brief etching step removes the now-exposed original copper laminate from the board, isolating the individual traces.The additive process is commonly used for multi-layer boards as it facilitates the plating-through of the holes (vias) in the circuit board.

16

2.2.2 Lamination

Some PCBs have trace layers inside the PCB and are called multi-layer PCBs. These are formed by bonding together separately etched thin boards.

2.2.3 Drilling

Holes, or vias, through a PCB are typically drilled with tiny drill bits made of solid tungsten carbide. The drilling is performed by automated drilling machines with placement controlled by a drill tape or drill file. These computer-generated files are also called numerically controlled drill (NCD) files or "Excellon files". The drill file describes the location and size of each drilled hole. When very small vias are required, drilling with mechanical bits is costly because of high rates of wear and breakage. In this case, the vias may be evaporated by lasers. Laser-drilled vias typically have an inferior surface finish inside the hole. These holes are called micro vias. It is also possible with controlled-depth drilling, laser drilling, or by pre-drilling the individual sheets of the PCB before lamination, to produce holes that connect only some of the copper layers, rather than passing through the entire board. These holes are called blind vias when they connect an internal copper layer to an outer layer, or buried vias when they connect two or more internal copper layers. The walls of the holes, for boards with 2 or more layers, are plated with copper to form plated-through holes that electrically connect the conducting layers of the PCB. For multilayer boards, those with 4 layers or more, drilling typically produces a smear comprised of the bonding agent in the laminate system. Before the holes can be plated through, this smear must be removed by a chemical de-smear process, or by plasma-etch.

17

2.2.4 Exposed Conductor Plating and Coating

The pads and lands to which components will be mounted are typically plated, because bare copper oxidizes quickly, and therefore is not readily solderable. Traditionally, any exposed copper was plated with solder. This solder was a tin-lead alloy, however new solder compounds are now used to achieve compliance with the RoHS directive in the EU, which restricts the use of lead. Other platings used are OSP (organic surface protectant), immersion silver, electroless nickel with immersion gold coating (ENIG), and direct gold. Edge connectors, placed along one edge of some boards, are often gold plated.

2.2.5 Solder resist

Areas that should not be soldered to may be covered with a polymer solder resist (solder mask) coating. The solder resist prevents solder from bridging between conductors and thereby creating short circuits. Solder resist also provides some protection from the environment.

2.2.6 Screen printing

Line art and text may be printed onto the outer surfaces of a PCB by screen printing. When space permits, the screen print text can indicate component designators, switch setting requirements, test points, and other features helpful in assembling, testing, and servicing the circuit board.Screen print is also known as the silk screen, or, in one sided PCBs, the red print.

18

2.2.7 Test Unpopulated boards may be subjected to a bare-board test where each circuit connection (as defined in a netlist) is verified as correct on the finished board. For high-volume production, a Bed of nails tester or fixture is used to make contact with copper lands or holes on one or both sides of the board to facilitate testing. A computer will instruct the electrical test unit to send a small amount of current through each contact point on the bed-of-nails as required, and verify that such current can be seen on the other appropriate contact points. For small- or medium-volume boards, flying-probe testers use moving test heads to make contact with the copper lands or holes to verify the electrical connectivity of the board under test.

2.2.8 Populating

After the PCB is completed, electronic components must be attached to form a functional printed circuit assembly, or PCA. In through-hole construction, component leads may be inserted in holes and electrically and mechanically fixed to the board with a molten metal solder, while in surface-mount construction, the components are simply soldered to pads or lands on the outer surfaces of the PCB.Often, through-hole and surface-mount construction must be combined in a single PCA because some required components are available only in surface-mount packages, while others are available only in through-hole packages. Again, JEDEC guidelines for PCB component placement, soldering, and inspection are commonly used to maintain quality control in this stage of PCB manufacturing. After the board is populated, the populated board may be tested with an in-circuit test system. To facilitate this test, PCBs may be designed with extra pads to make temporary connections. Sometimes these pads must be isolated with resistors. The in-circuit test may also exercise boundary scan test features of some components. In-circuit test systems may also be used to program nonvolatile memory components on the board. In boundary scan testing, test circuits integrated into various ICs on the board form temporary connections between the pcb traces to test that the ICs are mounted correctly. Boundary scan testing requires that all the ICs to be

19

tested use a standard test configuration procedure, the most common one being the Joint Test Action Group (JTAG) standard.

2.2.9 Protection and packaging

PCBs intended for extreme environments often have a conformal coat, which is applied by dipping or spraying after the components have been soldered. The coat prevents corrosion and leakage currents or shorting due to condensation. The earliest conformal coats were wax. Modern conformal coats are usually dips of dilute solutions of silicone rubber, polyurethane, acrylic, or epoxy. Some are engineering plastics sputtered onto the PCB in a vacuum chamber. Many assembled PCBs are static sensitive, and therefore must be placed in antistatic bags during transport. When handling these boards, the user must be earthed; failure to do this might transmit an accumulated static charge through the board, damaging or destroying it. Even bare boards are sometimes static sensitive. Traces have gotten so fine that it's quite possible to blow an etch off the board (or change its characteristics) with a static charge. This is especially true on non-traditional PCBs such as MCMs and microwave PCBs.

2.3 STEPS FOR MAKING PCB

Prepare the layout of the circuit (positive). Cut the photofilm (slightly bigger) of the size of the layout. Place the layout in the photoprinter machine with the photofilm above it. Make sure that the bromide (dark) side of the film is in contact with the layout. Switch on the machine by pressing the push button for 5 sec.

20

Dip the film in the solution prepared (developer) by mixing the chemicals A & B in equal quantities in water. Now clean the film by placing it in the tray containing water for 1 min. After this, dip the film in the fixer solution for 1 min. now the negative of the Circuit is ready.

Now wash it under the flowing water. Dry the negative in the photocure machine. Take the PCB board of the size of the layout and clean it with steel wool to make the surface smooth. Now dip the PCB in the liquid photoresist, with the help of dip coat machine. Now clip the PCB next to the negative in the photo cure machine, drying for approximate 10-12 minute. Now place the negative on the top of the PCB in the UV machine, set the timer for about 2.5 minute and switch on the UV light at the top. Take the LPR developer in a container and rigorously move the PCB in it. After this, wash it with water very gently. Then apply LPR dye on it with the help of a dropper so that it is completely covered by it. Now clamp the PCB in the etching machine that contains ferric chloride solution for about 10 minutes. After etching, wash the PCB with water, wipe it a dry cloth softly.

21

Finally rub the PCB with a steel wool, and the PCB is ready.

2.4 PCB Layout

Figure 2.1 a original view of PCB

22

Figure 2.1 b with componentslocation on PCB

23

CHAPTER 3 FUNDAMENTAL PARTS AND OPERATION

To establish communication through fiber optics the three main sections are transmitter section,receiver section and optical fiber.Besides these, we also require power supply and repeaters.In this chapter we will see each of these sections in detail along with their working.

3.1 Transmitter

Fiber optic transmitters are typically composed of a buffer, driver, and optical source. Often, optical connectors are also integrated into the final package. The buffer electronics provide both an electrical connection and isolation between the driver electronics and the electrical system supplying the data. The driver electronics provide electrical power to the optical source in a fashion that duplicates the pattern of data being fed to the transmitter. Finally, the optical source (LED in this kit) converts the electrical power to light energy with the same pattern.

3.2 Receiver

Once light energy from the fiber optic transmitter reaches the destination (receiver) it must be converted back to a form of electrical energy with the same information pattern that was fed to the transmitter by the person sending the message. Analog fiber optic receivers typically perform these functions using three elements: a photo detector, an amplifier and sometimes a buffer. As with fiber optic transmitter, an amplifier and sometimes a buffer. As with fiber optic transmitters, the optical connector is often integrated into the receiver package. The

24

photo detector converts light energy (optical power) to an electrical current. Any pattern or modulation imparted in the optical power (from, for instance, a fiber optic transmitter) will be reproduced as an electric current with the same pattern. Long lengths of fibers and other distribution losses can reduce the optical power, resulting in a comparatively weak electrical signal from the photo detector. To compensate of the electrical signal. Finally, buffer electronics isolate the photo detector and amplifier from any load the receiver is required to drive.

3.3 Circuit Operation

Most fiber optic transmitters typically have and amplifier or buffer, driver, optical source, and sometimes an optical connector or interface. The transmitter in this circuit has an acoustic microphone for converting sound waves to an electrical signal, and requires a nine-volt battery with holder to provide electrical power. Pushing the momentary-close switch, SW1, activates the optical voice link by applying 9 volt battery power to the indicator light, microphone, audio circuits and fiber optic LED. The switch must be closed for the transmitter to operate by generating light to carry audio signals. In the diagram are the receiver circuit functions: photo detector, amplifier, adjustable volume control and miscellaneous electronics. Following a signal as it exits from the optical fiber, in the form of light. The circuit is basically an amplifier. The IR signals are picked up by the photodiode and converted into electrical variations which are amplified by the op-amp (operational Amplifier) IC-741 used in the inverting mode with a single supply using divider network of resistors. The gain of IC1 can be set by varying the feedback through VR1 resistance (can place a 2.2. M variable). Here the output of IC is further amplified by the push pull amplifier using transistors BEL368/69 pair. The output of the amplifier is taken from emitter of two transistors, with a filter C2 from speaker.

3.4 Advantages of Fiber Optics System

Fiber optic transmission systems a fiber optic transmitter and receiver, connected by fiber optic cable offer a wide range of benefits not offered by traditional copper wire or coaxial cable. These include:

25

1.

The ability to carry much more information and deliver it with greater fidelity than either copper wire or coaxial cable. Fiber optic cable can support much higher data rates, and at greater distances, than coaxial cable, making it ideal for transmission of serial digital data. The fiber is totally immune to virtually all kinds of interference, including lightning, and will not conduct electricity. It can therefore come in direct contact with high voltage electrical equipment and power lines. It will also not create ground loops of any kind. As the basic fiber is made of glass, it will not corrode and is unaffected by most chemicals. It can be buried directly in most kinds of soil or exposed to most corrosive atmospheres in chemical plants without significant concern. Since the only carrier in the fiber is light, there is no possibility of a spark from a broken fiber. Even in the most explosive of atmospheres, there is no fire hazard, and no danger of electrical shock to personnel repairing broken fibers. Fiber optic cables are virtually unaffected by outdoor atmospheric conditions, allowing them to be lashed directly to telephone poles or existing electrical cables without concern for extraneous signal pickup. A fiber optic cable, even one that contains many fibers, is usually much smaller and lighter in weight than a wire or coaxial cable with similar information carrying capacity. It is easier to handle and install, and uses less duct space. (It can frequently be installed without ducts.) Fiber optic cable is ideal for secure communications systems because it is very difficult to tap but very easy to monitor. In addition, there is absolutely no electrical radiation from a fiber.

2.

3.

4.

5.

6.

7.

8.

3.5 Optical Fiber Communication

The birth of optical communications occurred in the 1970s with two key technology breakthroughs. The first was the invention of the semiconductor laser in 1962. The laser generates a tightly focused beam of light at a single pure wavelength, a spot small enough to be connected to fiber optics. The second breakthrough happened in September 1970, when a glass fiber with an attenuation of less than 20 dB/km was developed. In the 1960s, glass-clad

26

fibers had an attenuation of about 1 dB/m, which was sufficient for medical imaging applications, but was too high for telecommunications. With the development of optical fibers with an attenuation of 20 dB/km, the threshold to make fiber optics a viable technology for telecommunications was crossed. In 1977, AT&T installed the first optical fiber cables in Chicago. The first field deployments of fiber communication systems used Multimode Fibers (MMFs) with lasers operating in the 850 nm wavelength band. These systems could transmit several kilometers with optical losses in the range of 2 to 3 dB/km. A second generation of lasers operating at 1310 nm enabled transmission in the second window of the optical fiber where the optical loss is about 0.5 dB/km in a Single-Mode-Fiber (SMF). In the 1980s, the telecom carriers started replacing all their MMFs operating at 850 nm. Another wavelength window around 1550 nm was developed where a standard SMF has its minimum optical loss of about 0.22 dB/km. The development of fiber-based telecommunication systems in the 1990s focused on increasing their transmission capacity. This was done first by increasing the signal modulation speed from 155 Mb/s to 622 Mb/s, to 2.5 Gps, and finally to 10 Gb/s, todays modulation speed. The total available bandwidth of standard optical fibers is enormous; it is about 20 THz. Since it is impossible for a single-wavelength laser to utilize this enormous bandwidth, multiple single-wavelength laser transmitters are typically multiplexed and transmitted on a single fiber. This scheme, which was developed in the mid 1990s, is called Wavelength-Division-Multiplexing (WDM). Dense WDM (DWDM) optical communication systems with more than 60 wavelengths, where each wavelength carries 40 Gb/s data, have been demonstrated. Thus, the demonstrated total transmission capacity of an SMF is more than 2.5 Tb/s. Today, MMFs operating at 850 nm are primarily used for short distances in the enterprise as the least expensive method. An SMF at the 1310 nm wavelength band is primarily used for medium distances ranging from 2 km to 40 km. For long-haul telecommunications, WDM systems operating in the 1550 nm wavelength band windows are deployed. From 850 nm to long wavelength and WDM, higher performance is being offered, but each one comes with a higher price tag. Nowadays, the entire telecom infrastructure is fiber-based with the exception of the famous last miles to homes, which is still based on coaxial cables and copper-twisted pairs. Inside enterprise networks, fiber has been deployed since the early 1980s initially with supercomputers, and later in Local Area Networks (LANs) as well as more recently in Storage Area Networks (SANs). With continuously increasing demands for high-speed data, optical fibers and interconnects will continue to play an increasing role within the enterprise network.

27

3.6 The Fundamentals of Optical Components

Diode (LD) and the Light Emitting Diode (LEDs). All light emitters that convert electrical current into light are semiconductor based. They operate with the principle of the p-n semiconductor junction found in transistors. Historically, the first achievement of laser action in A basic optical communication link consists of three key building blocks: optical fiber, light sources, and light detectors. We discuss each one in turn.

3.6.1 Optical Fibers

In 1966, Charles Kao and George Hockmam predicted that purified glass loss could be reduced to below 20 dB per kilometer, and they set up a world-wide race to beat this prediction. In September 1970, Robert Maurer, Donald Keck, and Peter Schultz of Corning succeeded in developing a glass fiber with attenuation less than 20 dB/km: this was the necessary threshold to make fiber optics a viable transmission technology. The silica-based optical fiber structure consists of a cladding layer with a lower refractive index than the fiber core it surrounds. This refractive index difference causes a total internal reflection, which guides the propagating light through the fiber core. There are many types of optical fibers with different size cores and cladding. Some optical fibers are not even glass-based such as Plastic Optical Fibers (POFs), which are made for short-distance communication. For telecommunications, the fiber is glass based with two main categories: SMF and MMF. SMFs typically have a core diameter of about 9 m while MMFs typically have a core diameter ranging from 50 to 62.5 m. Optical fibers have two primary types of impairment, optical attenuation and dispersion. The fiber optical attenuation, which is mainly caused by absorption and the intrinsic Rayleigh scattering, is a wavelength-dependent loss with optical losses as low as 0.2 dB/km around 1550 nm for conventional SMF (i.e., SMF-28*).

The optical fiber is a dispersive waveguide. The dispersion results in Inter Symbol Interference (ISI) at the receiver. There are three primary types of fiber dispersions: modal dispersion, chromatic dispersion, and polarization-mode dispersion. The fiber modal dispersion depends on both the fiber core diameter and transmitted wavelengths. For a singlemode transmission, the step-index fiber core diameter (D) must satisfy the following condition:

28

where is the transmitted wavelength and n1 and n2 are the refractive indices of fiber core and cladding layer, respectively. Consequently, for a single-mode operation at 850 nm wavelength, the fiber must have a core diameter of 5 m. Since a conventional SMF has typically a core diameter of 9 m, single-mode operation can be only supported for wavelengths in the 1310 nm wavelength band or longer. The fiber chromatic dispersion is due to the wavelength-dependent refractive index with a zero-dispersion wavelength occurring at 1310 nm in conventional SMF. At 1550 nm, the fiber dispersion is about 17 ps/nm/km for SMF-28. When short duration optical pulses are launched into the fiber, they tend to broaden since different wavelengths propagate at different group velocities, due to the spectral width of the emitter. Optical transmission systems operating at rates of 10 Gb/s or higher and distances above 40 km are sensitive to this phenomenon. There are other types of SMFs such as Dispersion Shifted Fibers (DSFs) where the zero dispersion occurs at 1550 nm. Polarization-Mode Dispersion (PMD) is caused by small amounts of asymmetry and stress in the fiber core due to the manufacturing process and environmental changes such as temperature and strains. This fiber core asymmetry and stress leads to a polarizationdependent index of refraction and propagation constant, thus limiting the transmission distance of high speed ( 10 Gb/s) over SMF in optical communication systems. Standard SMF has a PMD value of less than 0.1 ps/km. Special SMFs were developed to address this issue. Optical fiber is never bare. The fiber manufacturer coats the fiber with a thin primary coating; then a cable manufacturer, not necessarily the fiber manufacturer, cables the fiber. There is a wide variety of cable construction. Simplex cable has a single fiber in the center while duplex cables contain two fibers. Composite cable incorporates both single-mode and multimode fiber. Hybrid cables incorporate mixed optical fiber and copper cable. In the enterprise, the MMF is housed in a cable with an orange colored jacket, and the SMF is housed in a yellow jacket cable.

29

3.6.2 Light Sources

The light source is often the most costly element of an optical communication system. It has the following key characteristics: (a) peak wavelength, at which the source emits most of its optical power, (b) spectral width, (c) output power, (d) threshold current, (e) light vs. current linearity, (f) and a spectral emission pattern. These characteristics are key to system performance. There are two types of light sources in widespread use: the Laser GaAs p-n junction was reported in 1962 by three groups. Both LEDs and LDs use the same key materials: Gallium Aluminum Arsenide (GaAIAs) for short-wavelength devices and Indium Gallium Arsenide Phosphide (InGaAsP) for long-wavelength devices. Semiconductor laser diode structures can be divided into the so-called edge-emitters, such as Fabry Perot (FP) and Distributed Feedback (DFB) lasers and vertical-emitters, such as Vertical Surface Emitting Lasers (VCSELs). When edge-emitters are used in optical fiber communication systems, they incorporate a rear facet photodiode to provide a means to monitor the laser output, as this output varies with temperature. In todays optical networks, binary digital modulation is typically used, namely on (i.e., light on) and off (no light) to transmit data. These semiconductor laser devices generate output light intensity which is proportional to the current applied to them, therefore making them suitable for modulation to transmit data. Speed and linearity are therefore two important characteristics. Modulation schemes can be divided into two main categories, namely, a direct and an external modulation. In a direct modulation scheme, modulation of the input current to the semiconductor laser directly modulates its output optical signal since the output optical power is proportional to the drive current. In an external modulation scheme, the semiconductor laser is operating in a Continuous-Wave (CW) mode at a fixed operating point. An electrical drive signal is applied to an optical modulator, which is external to the laser. Consequently, the applied drive signal modulates the laser output light on and off without affecting the laser operation. One important feature of the laser diode is its frequency chirp. The frequency of the output laser light changes dynamically in response to the changes in the modulation current. A typical DFB has a frequency chirp of about 100-MHz/mA. This spread of the wavelength interacts with the fiber dispersion. As previously mentioned, as the data rate is increased, this interaction limits the transmission distance of optical transmission systems due to the additional ISI generated at the receiver. Optical back-reflection is one of key issues when coupling the output light from a laser source to a fiber. The optical back-reflection disturbs the standing wave in the laser cavity,

30

increasing its noise floor, and thus making the laser unstable. One practical way to reduce the phenomenon of back-reflection is to place an isolator between the laser cavity and the fiber, which adds a significant additional cost to the laser [1, 4]. Temperature also affects the peak wavelength of the laser; threshold current also increases with temperature as slope efficiency decreases. For DWDM applications, which require very precise operating wavelengths, most of the current laser diode designs need to be cooled to within 0.3 C. As previously explained, the direct modulation of a laser diode has several limitations, including limited propagation distance due to the interaction between the laser frequency chirp and fiber dispersion. This is not an issue for enterprise networks which are short distance, but could be a serious limiting factor for telecommunications applications. To overcome this limitation, the laser diode is operated in a CW mode, and output light is externally modulated by an optical modulator. Intensity modulators can be divided into two main groups: Mach-Zehnder Interferometer (MZI) and Electro-Absorption (EA) modulators. In an MZI modulator, a single input waveguide is split into two optical waveguides by a 3 dB Y junction and then recombined by a second 3 dB Y junction into a single output. A Radio Frequency (RF) signal, which is applied to a pair of electrodes constructed along the waveguides, modulates the propagating optical beam. The modulator key parameters are its modulation bandwidth, linearity, and the required drive signal voltage for phase shift. MZI modulators based on LiNbO3 are high-performance modulators with a large form-factor (about 2.5 inches) that are not suitable for optical integration. EA modulators are based on a voltage-induced shift of the semiconductor bandgap so that the modulator becomes absorbing for the lasing wavelength. The advantages of an EA modulator are its low driving voltage, high-speed operation, and suitability for optical integration with InP-based laser diodes. A tunable laser is a new type of laser where its main lasing longitudinal mode can be tuned over a wide range of wavelengths such as the C band (1510 -1540 nm) of an Erbium-Doped Fiber Amplifier (EDFA), which is commonly used for DWDM systems. The use of tunable lasers is driven by the potential cost savings in DWDM transport networks since a significantly reduced inventory of fixed-wavelength lasers could be maintained for a robust network operation. The technical challenges are to provide both broad wavelength tunability and excellent wavelength accuracy over the laser life. A broadly tunable External Cavity Laser (ECL) employing micromachined, thermally tuned silicon etalons has been designed to achieve these goals.

3.6.3Light Detectors

Light detectors convert an optical signal to an electrical signal. The most common light detector is a photodiode. It operates on the principle of the p-n junction. There are two main

31

categories of photodetectors: a p-i-n (positive, intrinsic, negative) photodiode and an Avalanche Photodiode (APD), which are typically made of InGaAs or germanium. The key parameters for photodiodes are (a) capacitance, (b) response time, (c) linearity, (d) noise, and (e) responsivity. The theoretical responsivity is 1.05 A/W at a wavelength of 1310 nm. Commercial photodiodes have responsivity around 0.8 to 0.9 A/W at the same wavelength [1-4]. The dark photo-current is a small current that flows through the photo-detector even though no light is present because of the intrinsic resistance of the photo-detector and the applied reverse voltage. It is temperature sensitive and contributes to noise. Since the output electrical current of a photodiode is typically in the range of A, a Transimpedance Amplifier (TIA) is needed to amplify the electric current to a few mA. APDs provide much more gain than the pin photodiodes, but they are much more expensive and require a high voltage power to supply their operation. APDs are also more temperature sensitive than pin photodiodes.

3.7 Packaging: Optical Sub Assembly (OSA) and Optical Transceivers

As previously described, laser diodes and photodiodes are semiconductor devices. To enable the reliable operation of these devices, an optical package is required. In general, there are many discrete optical and electronic components, which are based on different technologies that must be optically aligned and integrated within the optical package. Optical packaging of laser diodes and photodiodes is the primary cost driver. These packages are sometimes called Optical Sub-Assemblies (OSAs). The Transmitter OSA package is called a TOSA and the Receiver OSA package is called a ROSA. Figure 3.1 shows, for example, a three-dimensional schematic view of a DFB laser diode mounted on a Thermo-Electric Cooler (TEC) inside a hermetically sealed 14-pin butterfly package with an SMF pigtail. Most of the telecom-grade laser diodes are available in the socalled TO can or butterfly packages. The standard butterfly package is a stable and highperformance package, but it has a relatively large form-factor and it is costly to manufacture. These packages are typically used for applications where cooling is required using a TEC.

32

Figure 3.1: Three-dimensional view of a DFB laser diode configuration with single-mode fiber pigtail

The TEC requires a large amount of power to regulate the temperature of a laser inside the package. This type of optical packaging was used for the early 10 Gb/s modules. More recently, tunable 10 Gb/s lasers are using a similar butterfly optical package. The butterfly package design uses a coaxial interface for passing broadband data into the package, which requires the use of a coaxial interface to the host Printed Circuit Board (PCB). Although coaxial cables and connectors have been reduced in size, they still consume valuable real estate in the optical transceiver. The evolution of optical module packages is toward smaller footprint packages. If relatively easy for receivers, the trend toward smaller packages is particularly challenging for laser transmitter modules due to the power and thermal dissipation constraints. Figure 3.2 shows the evolution of 10 Gb/s optical module packaging technology. To operate with highperformance, uncooled designs must be implemented with more advanced control systems that can adjust the laser and driver parameters over temperature. The smaller packages utilize a coplanar approach to the broadband interface, which more closely resembles a surfacemount component and enables much smaller RF interfaces. TO-can-based designs, which have been used extensively in lower data rate telecom and datacom systems up to 2 Gb/s as well as CD players and other high-volume consumer

33

applications, are now maturing to support high-performance 10 Gb/s optical links. Leveraging the fact that these packages are already produced in high volume will further reduce the cost of the 10 Gb/s optical modules in optical transceiver designs.

Figure 3.2: Trends in 10 Gb/s optical transmitter packaging technology. To decrease size and power dissipation, the trends are from cooled to uncooled packages, from coaxial to planar RF interfaces, and from pigtailed to pluggable optical interfaces.

The current TOSA/ROSA package form factors are trending toward smaller packages, and it will not end at the 10 Gb/s TO-can implementation. These TOSA/ROSA form factors are still too large and too expensive to compete in the market segment where today copper interconnects dominate. Leadframe-type packages could be an attractive choice for highspeed optical modules since similar packages are already in use in the semiconductor industry [10]. Using insert molded or pre-molded thermoplastic housing, different optical components can be passively aligned in a fully automated manufacturing process. For example, integrated modules with VCSEL and photodiodes in leadframe packages have been developed for the automobile industry, but are limited today in the 20 Mb/s bit rate. Additional research and development is needed to define the packaging specifications for optoelectronic modules based on size and cost.

3.7.1Optical Transceivers

For telecommunication applications, the optical transmitter and receiver modules are usually packaged into a single package called an optical transceiver. Figure 3 shows an example of different transceivers and Figure 4 shows an example of the printed circuit board of a

34

transceiver. There are several form factors for this optical transceiver depending on their operating speed and applications. The industry worked on a Multi-Source Agreement (MSA) document to define the properties of the optical transceivers in terms of their mechanical, optical, and electrical specifications. Optical transponders operating at 10 Gb/s, based on MSA, have been in the market since circa 2000, beginning with the 300-pin MSA, followed by XENPAK, XPAK, X2, and XFP. Table 1 summarizes the key MSA specifications for the different form-factor 10 Gb/s optical transceivers and their release dates.

The Most Popular Form-Factor Transceivers in the Enterprise_ For the 1/2/4 Gb/s transceivers, the Small Form-Factors (SFFs) and the small Form-Factor Pluggables (SFPs) are the most recently developed and the ones that are finding new sockets into systems. It should be noted, however, that the older GBIC form factors for 1 Gb/s Ethernet (GbE), despite no new development, is still shipping in large volumes due to the large installed base of this design. The SFF transceiver is used in a Network Interface Card (NIC) for the LAN or in the Host Bus Adaptor (HBA) in SANs. The SFP transceiver is typically used for enterprise switches such as Ethernet or Fiber-Channel (FC) switches. In these high-capacity switches, switching is done by electrical ICs while the optical transceivers provide optical-to-electrical electrical (O-E) or electrical-to-optical (E-O) conversion.

Figure 3.3 Next-generation 10 Gb/s enterprise optical transceivers: (from left) XFP, XPAK/X2, XENPAK. These modules are electrically hot-pluggable and optically pluggable

35

In general, not all the switches ports are populated with transceivers when they are shipped to customers. The customer has the option to buy these transceiver modules as the demand for ports increases. It also gives the customer the choice of optics: MMF or SMF. Therefore, these modules have been designed to be pluggable. The choice between the different 10 Gb/s form-factor optical transceiver packages is guided by reach, cost, and thermal and size constraints and requirements.

Table 3.1: Summary of different form-factor 10 Gb/s optical transceiver packages MSA MSA Date Application XENPAK March 2002 Enterprise switch XPAK/X2 March 2003 Enterprise Storage 4 bit XAUI switch XFP April 2003 NIC Telecom Datacom 1 bit XFI

Electrical Interface

4 bit XAUI

Optical interface SC pluggable

SC pluggable 2.7x1.4x0.4 5W

or

LC LC pluggable

Dimension Max Power

4.8x1.4x0.7 11W

3W

3.8 Photonics:A Key Future Prospect

Photonics is the technology associated with generating and harnessing light. One of the most important applications of photonics is the transmission of information as light through optical fibers. Photonics and optical communications should be seen as the principle enabling technology for developing broad-band communication systems, because optical fibers can

36

achieve data transmission at speeds far in excess of what can be obtained with conventional electronic communication systems. Some of the main projects currently being undertaken within the group are as follows:

3.8.1 Hybrid Radio/Fibre Systems for Broadband Access

As the demand for broadband mobile services such as mobile computing increases, so does the need to develop high capacity mobile communication networks. High capacity mobile networks of the future are likely to use microwave radio, operating at frequencies from 10GHz up to 100GHz as the access medium. To develop wireless networks of this type, it is anticipated that optical fibre will be used for distributing the microwave data from a central station to remote base stations. The goal of this project is to develop and test a complete radio over fibre communication system.

3.8.2 Optical Time Division Multiplexing Technologies

Limitations on the overall capacity of optical communication systems will be encountered in the near future due to rapid growth in demand for broadband services. The main approaches to increase the capacity of optical fibre are Wavelength Division Multiplexing (WDM) and Optical Time Division Multiplexing (OTDM). The main aim of this project has been to develop high-speed optical transmitter and receiver circuits that may be employed for data transmission in the high capacity optical communication systems of the future, and to examine the development of optical systems using hybrid WDM/OTDM technologies.

37

CHAPTER 4 COMPONENTSDESCRIPTION

Various components are used to establish communication through optical fiber.The components such as resistors,capacitors,transistors,LEDs and speaker are explained in detail in this chapter.

4.1 Capacitors

A capacitor or condenser is a passive electronic component consisting of a pair of conductors separated by a dielectric (insulator). When a potential difference (voltage) exists across the conductors, an electric field is present in the dielectric. This field stores energy and produces a mechanical force between the conductors. The effect is greatest when there is a narrow separation between large areas of conductor, hence capacitor conductors are often called plates. An ideal capacitor is characterized by a single constant value, capacitance, which is measured in farads. This is the ratio of the electric charge on each conductor to the potential difference between them. In practice, the dielectric between the plates passes a small amount of leakage current. The conductors and leads introduce an equivalent series resistance and the dielectric has an electric field strength limit resulting in a breakdown voltage. Capacitors are widely used in electronic circuits to block the flow of direct current while allowing alternating current to pass, to filter out interference, to smooth the output of power supplies, and for many other purposes. They are used in resonant circuits in radio frequency equipment to select particular frequencies from a signal with many frequencies.

38

Figure 4.1 Types of Capacitors

4.1.1Theory of operation

Figure 4.2 Working of Cpacitor

Charge separation in a parallel-plate capacitor causes an internal electric field. A dielectric (orange) reduces the field and increases the capacitance.

Figure 4.3 A Practical Approach

39

A capacitor consists of two conductors separated by a non-conductive region.The nonconductive substance is called the dielectric medium, although this may also mean a vacuum or a semiconductor depletion region chemically identical to the conductors. A capacitor is assumed to be self-contained and isolated, with no net electric charge and no influence from an external electric field. The conductors thus contain equal and opposite charges on their facing surfaces, and the dielectric contains an electric field. The capacitor is a reasonably general model for electric fields within electric circuits. An ideal capacitor is wholly characterized by a constant capacitance C, defined as the ratio of charge Q on each conductor to the voltage V between them

Sometimes charge buildup affects the mechanics of the capacitor, causing the capacitance to vary. In this case, capacitance is defined in terms of incremental changes:

In SI units, a capacitance of one farad means that one coulomb of charge on each conductor causes a voltage of one volt across the device.

4.1.2 Energy storage

Work must be done by an external influence to move charge between the conductors in a capacitor. When the external influence is removed, the charge separation persists and energy is stored in the electric field. If charge is later allowed to return to its equilibrium position, the energy is released. The work done in establishing the electric field, and hence the amount of energy stored, is given by:

4.1.3Current-voltage relation

The current i(t) through a component in an electric circuit is defined as the rate of change of the charge q(t) that has passed through it. Physical charges cannot pass through the dielectric layer of a capacitor, but rather build up in equal and opposite quantities on the electrodes: as each electron accumulates on the negative plate, one leaves the positive plate. Thus the accumulated charge on the electrodes is equal to the integral of the current, as well as being proportional to the voltage (as discussed above). As with any antiderivative, a constant of

40

integration is added to represent the initial voltage v (t0). This is the integral form of the capacitor equation,

. Taking the derivative of this, and multiplying by C, yields the derivative form,

. The dual of the capacitor is the inductor, which stores energy in the magnetic field rather than the electric field. Its current-voltage relation is obtained by exchanging current and voltage in the capacitor equations and replacing C with the inductance L.

4.1.4 DC circuits

Figure 4.5 A dc Circuit

A simple resistor-capacitor circuit demonstrates charging of a capacitor. A series circuit containing only a resistor, a capacitor, a switch and a constant DC source of voltage V0 is known as a charging circuit. If the capacitor is initially uncharged while the switch is open, and the switch is closed at t = 0, it follows from Kirchhoff's voltage law that

Taking the derivative and multiplying by C, gives a first-order differential equation,

41

At t = 0, the voltage across the capacitor is zero and the voltage across the resistor is V0. The initial current is then i (0) =V0 /R. With this assumption, the differential equation yields

where 0 = RC is the time constant of the system. As the capacitor reaches equilibrium with the source voltage, the voltage across the resistor and the current through the entire circuit decay exponentially. The case of discharging a charged capacitor likewise demonstrates exponential decay, but with the initial capacitor voltage replacing V0 and the final voltage being zero.

4.2 Resistor

Resistors are used to limit the value of current in a circuit. Resistors offer opposition to the flow of current. They are expressed in ohms for which the symbol is . Resistors are broadly classified as (1) (2) Fixed Resistors Variable Resistors

4.2.1 Fixed Resistors

The most common of low wattage, fixed type resistors is the molded-carbon composition resistor. The resistive material is of carbon clay composition. The leads are made of tinned copper. Resistors of this type are readily available in value ranging from few ohms to about 20M, having a tolerance range of 5 to 20%. They are quite inexpensive. The relative size of all fixed resistors changes with the wattage rating. Another variety of carbon composition resistors is the metalized type. It is made by deposition a homogeneous film of pure carbon over a glass, ceramic or other insulating core. This type of film-resistor is sometimes called the precision type, since it can be obtained with an accuracy of 1%.

42

Lead

Tinned Copper Material

Colour Coding

Molded Carbon Clay Composition

Figure 4.6 Fixed Resistor

A Wire Wound Resistor _It uses a length of resistance wire, such as nichrome. This wire is wounded on to a round hollow porcelain core. The ends of the winding are attached to these metal pieces inserted in the core. Tinned copper wire leads are attached to these metal pieces. This assembly is coated with an enamel coating powdered glass. This coating is very smooth and gives mechanical protection to winding. Commonly available wire wound resistors have resistance values ranging from 1 to 100K, and wattage rating up to about 200W.

Coding Of Resistor _Some resistors are large enough in size to have their resistance printed on the body. However there are some resistors that are too small in size to have numbers printed on them. Therefore, a system of colour coding is used to indicate their values. For fixed, moulded composition resistor four colour bands are printed on one end of the outer casing. The colour bands are always read left to right from the end that has the bands closest to it. The first and second band represents the first and second significant digits, of the resistance value. The third band is for the number of zeros that follow the second digit. In case the third band is gold or silver, it represents a multiplying factor of 0.1to 0.01. The fourth band represents the manufactures tolerance.

43

RESISTOR COLOUR CHART

0 black 1 brown 2 red 3 orange 4 yellow 5 green 6 blue 7 purple 8 silver 9 white

0 black 1 brown 2 red 3 orange 4 yellow

5 green

0 black 1 brown 2 red 3 orange 4 yellow 5 green 6 blue 7 purple 8 silver 9 white

0 black 1 brown 2 red 3 orange 4 yellow 5 green 6 blue 7 purple 8 silver 9 white

6 blue 7 purple 8 silver 9 white

Figure 4.7 Colour Coding of Resistors

For example, if a resistor has a colour band sequence: yellow, violet, orange and gold

Then its range will be

Yellow=4, violet=7, orange=10,

gold=5% =47K 5% =2.35K

Most resistors have 4 bands_ The first band gives the first digit. The second band gives the second digit. The third band indicates the number of zeros. The fourth band is used to show the tolerance (precision) of the resistor.

This resistor has red (2), violet So its value is 270000 = 270 k .

(7),

yellow

(4

zeros)

and

gold

bands.

44

The standard colour code cannot show values of less than 10 . To show these small values two special colours are used for the third band: gold, which means 0.1 and silver which means 0.01. The first and second bands represent the digits as normal.

For example_ red, violet, gold bands blue, green, silver bands represent 56 0.01 = 0.56 represent 27 0.1 = 2.7

The fourth band of the colour code shows the tolerance of a resistor. Tolerance is the precision of the resistor and it is given as a percentage. For example a 390 resistor with a tolerance of 10% will have a value within 10% of 390 , between 390 - 39 = 351 and 390 + 39 = 429 (39 is 10% of 390).

A special colour code is used for the fourth silver 10%, gold 5%, red 2%, If no fourth band is shown the tolerance is 20%.

band tolerance: brown 1%.

4.2.2VARIABLE RESISTOR In electronic circuits, sometimes it becomes necessary to adjust the values of currents and voltages. For n example it is often desired to change the volume of sound, the brightness of a television picture etc. Such adjustments can be done by using variable resistors.

Although the variable resistors are usually called rheostats in other applications, the smaller variable resistors commonly used in electronic circuits are called potentiometers.

Resistor shorthand_ Resistor values are often written on circuit diagrams using a code system which avoids using a decimal point because it is easy to miss the small dot. Instead the letters R, K and M are used in place of the decimal point. To read the code: replace the letter with a decimal point, then multiply the value by 1000 if the letter was K, or 1000000 if the letter was M. The letter R means multiply by 1. For example: 560R means 2K7 means 2.7 39K means 1M0 means 1.0 M = 1000 k 560 = 39

2700 k

45

4.2.3 Power Ratings of Resistors

Electrical energy is converted to heat when current flows through a resistor. Usually the effect is negligible, but if the resistance is low (or the voltage across the resistor high) a large current may pass making the resistor become noticeably warm. The resistor must be able to withstand the heating effect and resistors have power ratings to show this. Power ratings of resistors are rarely quoted in parts lists because for most circuits the standard power ratings of 0.25W or 0.5W are suitable. For the rare cases where a higher power is required it should be clearly specified in the parts list, these will be circuits using low value resistors (less than about 300 ) or high voltages (more than 15V). The power, P, developed in a resistor is given by: P = I R where: P = power developed in the resistor in or watts(W) P = I = current through the resistor in amps V/R (A) R = resistance of the resistor in ohms ( ) V = voltage across the resistor in volts (V)

Figure4.8 High power (5W top, 25W bottom)

resistors

Examples_

A 470 resistor with 10V across it, needs a power rating P = V/R = 10/470 = 0.21W. In this case a standard 0.25W resistor would be suitable. A 27 resistor with 10V across it, needs a power rating P = V/R = 10/27 = 3.7W. A high power resistor with a rating of 5W would be suitable.

4.3 Transistors

A transistor is an active device. It consists of two PN junctions formed by sandwiching either p-type or n-type semiconductor between a pair of opposite types. There are two types of transistor: 1. n-p-n transistor

46

2. p-n-p transistor

Figure 4.9 Transistors

An n-p-n transistor is composed of two n-type semiconductors separated by a thin section of p-type. However a p-n-p type semiconductor is formed by two p-sections separated by a thin section of n-type. Transistor has two pn junctions one junction is forward biased and other is reversed biased. The forward junction has a low resistance path whereas a reverse biased junction has a high resistance path. The weak signal is introduced in the low resistance circuit and output is taken from the high resistance circuit. Therefore a transistor transfers a signal from a low resistance to high resistance. Transistor has three sections of doped semiconductors. The section on one side is emitter and section on the opposite side is collector. The middle section is base.

4.3.1 Emitter

The section on one side that supplies charge carriers is called emitter. The emitter is always forward biased w.r.t. base.

47

4.3.2 Collector

The section on the other side that collects the charge is called collector. The collector is always reversed biased.

4.3.3 Base

The middle section which forms two pn-junctions between the emitter and collector is called base.

A transistor raises the strength of a weak signal and thus acts as an amplifier. The weak signal is applied between emitter-base junction and output is taken across the load Rc connected in the collector circuit. The collector current flowing through a high load resistance Rc produces a large voltage across it. Thus a weak signal applied in the input appears in the amplified form in the collector circuit.

4.4 Light Emitting Diode

A junction diode, such as LED, can emit light or exhibit electro luminescence. Electro luminescence is obtained by injecting minority carriers into the region of a pn junction where radiative transition takes place. In radiative transition, there is a transition of electron from the conduction band to the valence band, which is made possibly by emission of a photon. Thus, emitted light comes from the hole electron recombination. What is required is that electrons should make a transition from higher energy level to lower energy level releasing photon of wavelength corresponding to the energy difference associated with this transition. In LED the supply of high-energy electron is provided by forward biasing the diode, thus injecting electrons into the n-region and holes into p-region. The pn junction of LED is made from heavily doped material. On forward bias condition, majority carriers from both sides of the junction cross the potential barrier and enter the opposite side where they are then minority carrier and cause local minority carrier population

48

to be larger than normal. This is termed as minority injection. These excess minority carrier diffuse away from the junction and recombine with majority carriers.

In LED, every injected electron takes part in a radiative recombination and hence gives rise to an emitted photon. Under reverse bias no carrier injection takes place and consequently no photon is emitted. For direct transition from conduction band to valence band the emission wavelength. In practice, every electron does not take part in radiative recombination and hence, the efficiency of the device may be described in terms of the quantum efficiency which is defined as the rate of emission of photons divided by the rate of supply of electrons. The number of radiative recombination, that take place, is usually proportional to the carrier injection rate and hence to the total current flowing.

4.4.1 LED Materials

One of the first materials used for LED is GaAs. This is a direct band gap material, i.e., it exhibits very high probability of direct transition of electron from conduction band to valence band. GaAs has E= 1.44 eV. This works in the infrared region. GaP and GaAsP are higher band gap materials. Gallium phosphide is an indirect band gap semiconductor and has poor efficiency because band to band transitions are not normally observed. Gallium Arsenide Phosphide is a tertiary alloy. This material has a special feature in that it changes from being direct band gap material. Blue LEDs are of recent origin. The wide band gap materials such as GaN are one of the most promising LEDs for blue and green emission. Infrared LEDs are suitable for optical coupler applications.

4.4.2 ADVANTAGES OF LEDs Low operating voltage, current, and power consumption makes Leds compatible with electronic drive circuits. This also makes easier interfacing as compared to filament incandescent and electric discharge lamps. The rugged, sealed packages developed for LEDs exhibit high resistance to mechanical shock and vibration and allow LEDs to be used in severe environmental conditions where other light sources would fail.

49

LED fabrication from solid-state materials ensures a longer operating lifetime, thereby improving overall reliability and lowering maintenance costs of the equipment in which they are installed. The range of available LED colours-from red to orange, yellow, and green-provides the designer with added versatility. LEDs have low inherent noise levels and also high immunity to externally generated noise. Circuit response of LEDs is fast and stable, without surge currents or the prior warmup, period required by filament light sources. LEDs exhibit linearity of radiant power output with forward current over a wide range.

4.4.3 Limitations of LEDs

Temperature dependence of radiant output power and wave length. Sensitivity to damages by over voltage or over current. Theoretical overall efficiency is not achieved except in special cooled or pulsed conditions.

4.5 Speaker

A loudspeaker (or "speaker") is an electroacoustic transducer that produces sound in response to an electrical audio signal input. Non-electrical loudspeakers were developed as accessories to telephone systems, but electronic amplification by vacuum tube made loudspeakers more generally useful. The most common form of loudspeaker uses a paper cone supporting a voice coil electromagnet acting on a permanent magnet, but many other types exist. Where accurate reproduction of sound is required, multiple loudspeakers may be used, each reproducing a part of the audible frequency range. Miniature loudspeakers are found in devices such as radio and TV receivers, and many forms of music players. Larger loudspeaker systems are used for music, sound reinforcement in theatres and concerts, and in public address systems.

50

4.5.1 Driver design

Figure 4.10Cutaway View of a Dynamic Loudspeaker.

Figure 4.11 A Stamped Steel Loudspeaker Basket Frame is Clearly Visible

The most common type of driver, commonly called a dynamic loudspeaker, uses a lightweight diaphragm, or cone, connected to a rigid basket, or frame, via a flexible suspension, commonly called a spider, that constrains a coil of fine tinsel wire to move

51