Documente Academic

Documente Profesional

Documente Cultură

Crane

Încărcat de

Adrian Franco MolinaDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Crane

Încărcat de

Adrian Franco MolinaDrepturi de autor:

Formate disponibile

CONTROL SOLUTIONS

HYDRAULIC CRANES

HYDRAULIC CRANES

For over 50 years, HUSCO International has been designing and producing some of the most important custom hydraulic and electrohydraulic products in the construction industry. Today youll nd HUSCO products on a variety of premier off-highway equipment all over the world. Leading the way in the construction market, HUSCO engineers design customized, costeffective solutions to maximize the efciency and reliability of hydraulic cranes. We invest in tools and processes that ensure quality designs and reduced development time. And we install and test control solutions at HUSCO facilities.

Valves designed to enable crane performance to reach new levels.

With manufacturing facilities in North America, Europe and Asia, were positioned to bring you any product you need, anywhere in the world.

Flow

max lpm

Pressure

rating max

Actuation Manual Pilot E-H Page

Series

Valves

Type

(gpm)

bar (psi)

5000 5000CC 5000-6000 6000 5000CC/ 6000CC 6000CC 5610 7000CC

Controllers

Open-center PC/LS-CompChek Open-center Open-center PC/LS-CompChek PC/LS-CompChek PC/LS-CompChek PC/LS-CompChek

100 (25) 100 (25) 150 (40) 150 (40) 180 (48) 180 (48) 180 (48) 270 (70)

250 (3625) 250 (3625) 250 (3625) 275 (4000) 250 (3625) 250 (3625) 300 (4350) 250 (3625)

X X X X X X X X

X X X X X X X X

X X X X X X X X

2 3 4 5 6 7 8 9

Force Feedback HVD-808 HEC-808 E406 PPC

Electrohydraulic 8-PWM Driver 8-PWM Controller Electrical Joystick Pilot-Operated Controllers

n/a n/a n/a n/a n/a

n/a n/a n/a n/a n/a

n/a n/a n/a n/a n/a

n/a n/a n/a n/a n/a

n/a n/a n/a n/a n/a

10 11 12 13 14

5000 Open-Center Valve Series

SPECIFICATIONS:

Flow rate 100 lpm (25 gpm) Max pressure 250 bar (3,625 psi) Conguration sectional and open-center Circuitry parallel, tandem and series Actuation manual, pilot and electrohydraulic (including Force Feedback)

OPTIONS:

Main relief valve and load checks Mid-inlet for multi-pump systems Work port relief with vented anti-void capability Regeneration circuitry Integrated low-leak checks Priority ow divider for steering Mechanical joystick Electronic spool locks Hall effect sensor to measure spool position Microswitches

ADVANTAGES:

Compact, cost-effective valve series Low spool efforts Customized precision metering Flexible circuitry in a common package Proven design Integrated features, such as priority steering, reduce external plumbing

5000CC CompChek Valve Series

SPECIFICATIONS:

Flow rate 100 lpm (25 gpm) Max pressure 250 bar (3,625 psi) Conguration sectional, closed-center and load-sensing Circuitry parallel Actuation manual, pilot and electrohydraulic (including Force Feedback)

OPTIONS:

Unloading valve used with xed displacement pumps Load sense relief Work port relief with anti-void capability Priority ow divider for steering Regeneration circuitry Mechanical joystick Integrated low-leak checks for stabilizers Ability to generate pilot supply Electronic spool locks Hall effect sensor to measure spool position

ADVANTAGES:

Function speeds are independent of work port load (pressure compensated) Excellent multi-function ow sharing even when demand exceeds pump capacity (post-compensation) Compatible with xed or variable displacement pump systems Low spool efforts Customized precision metering Flexible circuitry in a common package Proven design

5000/6000 Open-Center Combination Valve

SPECIFICATIONS:

Flow rate 150 lpm (40 gpm) (high ow functions) Flow rate 100 lpm (25 gpm) (low ow functions) Max pressure 250 bar (3,625 psi) Conguration sectional, open-center Actuation manual, pilot and electrohydraulic (including Force Feedback)

OPTIONS:

Main relief valve and load checks Mid-inlet for multi-pump systems Work port relief with anti-void capability Priority ow divider for steering Regeneration circuitry Integrated low-leak checks for stabilizers Ability to generate pilot supply Hall effect sensor to measure spool position

ADVANTAGES:

Compact, cost-effective valve series Low spool efforts Customized precision metering Flexible circuitry in a common package Proven design Integrated features, such as priority steering, reduce external plumbing

6000 Open-Center Valve Series

SPECIFICATIONS:

Flow rate 150 lpm (40 gpm) Max pressure 275 bar (4,000 psi) Conguration sectional and open-center Circuitry parallel, tandem and series Actuation manual, pilot, air and electrohydraulic

OPTIONS:

Main relief valve and load checks Work port relief with anti-void capability Priority ow divider for steering Regeneration circuitry Integrated low-leak checks for stabilizers Ability to generate pilot supply Electronic spool locks

ADVANTAGES:

Compact, cost-effective valve series Low spool efforts Customized precision metering Flexible circuitry in a common package Proven design Integrated features, such as priority steering, reduce external plumbing

75

5000CC/6000CC CompChek Combination Valve Series

SPECIFICATIONS:

Flow rate 180 lpm (48 gpm) (lift function) Flow rate 100 lpm (25 gpm) (all other ow functions) Max pressure 250 bar (3,625 psi) Conguration sectional, closed-center and load sensing Circuitry parallel Actuation manual, pilot and electrohydraulic (including Force Feedback)

OPTIONS:

Unloading valve used with xed displacement pumps Mid-inlet for multi-pump systems Load sense relief Work port reliefs with anti-void capability Priority ow divider for steering Detent oat and regeneration circuitry Integrated low-leak checks for stabilizers Ability to generate pilot supply Electronic spool locks

ADVANTAGES:

Function speeds are independent of work port load (pressure compensated) Excellent multi-function ow sharing even when demand exceed the pump capacity (post-compensation) Compatible with xed or variable displacement pump systems Low spool efforts Customized precision metering Flexible circuitry in a common package Proven design Integrated features, such as low-leak checks, reduce external plumbing 6

6000CC CompChek Valve Series

SPECIFICATIONS:

Flow rate 180 lpm (48 gpm) Max pressure 250 bar (3,625 psi) Conguration sectional, closed-center and load-sensing Circuitry parallel Actuation manual, pilot and electrohydraulic

OPTIONS:

Unloading valve used with xed displacement pumps Load sense relief Work port relief with anti-void capability Regeneration circuitry Integrated low-leak checks for stabilizers Ability to generate pilot supply

ADVANTAGES:

Function speeds are independent of work port load (pressure compensated) Excellent multi-function ow sharing even when demand exceeds pump capacity (post-compensation) Compatible with xed or variable displacement pump systems Low spool efforts Customized precision metering Flexible circuitry in a common package Proven design

5610 Valve Series

SPECIFICATIONS:

Flow rate 180 lpm (45 gpm) Max pressure 300 bar (4,350 psi) Conguration sectional, closed-center and load sensing Circuitry parallel Actuation manual, pilot and electrohydraulic (including Force Feedback)

OPTIONS:

Unloading valve used with xed displacement pumps Load sense relief Work port relief with anti-void capability Priority ow divider for steering Detent oat and regen circuitry Manual ow control Ability to generate pilot supply

ADVANTAGES:

Function speeds are independent of work port load (pressure compensated) Excellent multi-function ow sharing even when demand exceeds pump capacity (post-compensation) Compatible with xed or variable displacement pump systems Integrated E-H capability reduces leak points and increases performance Low heat generation Low spool efforts Customized precision metering Integrated features, such as load-checks, reduce external plumbing

7000CC CompChek Valve Series

SPECIFICATIONS:

Flow rate 270 lpm (70 gpm) Max pressure 250 bar (3,625 psi) Conguration sectional, closed-center and load-sensing Circuitry parallel Actuation manual, pilot and electrohydraulic

OPTIONS:

Unloading valve used with a xed displacement pump Load sense relief valve Work port relief with anti-void capability Regeneration spool circuitry SAE 4-bolt ange ports Individual pilot pressure cut-off solenoids Low-leak check valve Pressure reducing valve for pilot supply

ADVANTAGES:

Function speeds are independent of work port load (pressure compensated) Excellent multi-function ow sharing even when demand exceeds pump capacity (post-compensation) Compatible with xed or variable displacement pump systems Low spool efforts Customized precision metering Cost-effective, high-ow valve series Integrated features, such as pilot supply, reduce external plumbing

9 11

Force Feedback Electronic Valve Actuation

Force Feedback is an electrohydraulic actuation for hydraulic control valves. This technology incorporates closed-loop mechanical spool positioning which provides high performance in a cost-effective package. Force Feedback can be used on HUSCO open-center or closed-center valve series.

ADVANTAGES:

Improved Performance Closed-loop spool positioning Reduced hysterisis Improved valve resolution Dynamic valve response Precision ne metering Cost-Effective No additional electronics for closed-loop spool control Requires only 1 PWM signal and one on/off signal per section Does not require a spool position transducer (LVDT) Flexible Compatible with majority of HUSCOs valve range Can be used on open-center or closed-center valves Manual overrides can be added without performance reduction Durable Proven technology High servo force to position spool Less sensitive to contamination and silting Less spool leakage than traditional E-H

10

HVD-808 Hydraulic Valve Driver

The Hydraulic Valve Driver is a cost-effective, rugged, electronic driver with the capability of driving up to 8 coils. This compact driver can be used in a variety of agricultural, construction, forestry and material handling applications.

SPECIFICATIONS:

IP67 rated Rugged aluminum housing 8-18 VDC operating voltage 6 analog inputs (8-bit resolution) 8 current controlled PWM signals with current feedback Integrated 5 VDC supply to drive external sensors

ADVANTAGES:

Compact, cost-effective valve series Robust, IP67 rated design Current feedback will maintain consistency regardless of coil temperature

11

HEC-808 Hydraulic Electronic Controller

SPECIFICATIONS:

CAN 2.0B capable 8 bit processor IP67 rated Rugged aluminum housing 8-18 VDC operating voltage 4 analog inputs (8-bit resolution) 3 digital inputs 8 current controlled PWM signals with current feedback Integrated 5 VDC supply to drive external sensors

ADVANTAGES:

Flexible CAN capable Can be used in combination with CAN joystick to control valve Compact, cost-effective valve series Robust, IP67 rated design Current feedback will maintain consistency regardless of coil temperature Designed to optimize valve performance

12

E406 Electronic Joystick

SPECIFICATIONS:

2- and 3-axis versions CAN 2.0B output according to J1939 standards Optional handle congurations 73mm below panel Operation voltage 10 VDC to 36 VDC 8 software conguration analog/digital inputs/outputs 12 inch ying leads (Deutsch is default connector)

ADVANTAGES

Robust/ Durable Long life greater than 5 million cycles Hall effect sensor for long life All steel upper mechanism High temperature range (-40C to 85C) IP67 rated electronics Safety Features Redundant sensing (two sensors per axis) EMC protect ESD > 25kV RFI > 100 V/m Performance Smooth proportional control Electromagnetic and mechanical detents 8 conguration analog/digital inputs/outputs to drive lights or read a switch

13 15

PPC Pilot-Operated Controller Series

Single-axis pilot-operated controllers Dual-axis pilot-operated controllers Three-axis pilot operated controllers Pilot-operated foot pedals 150 bar (2,175 psi) inlet pressure 35 bar (0-500 psi) outlet pressure

OPTIONS

4 mechanical detent positions 4 electromagnetic detent positions 4 feel detent positions Ability to link a dual-axis and single-axis

ADVANTAGES

Low lever efforts Compact, cost-effective series Compatible with a variety of grips including the HUSCO Integrated Handle Driver Unique detent technology Designed to optimize valve performance Customized pressure curves

14

CONTROL FOCUSED TECHNOLOGY DRIVEN

HYDRAULIC CRANES

EUROPE HUSCO International, Ltd. 6 Rivington Road Whitehouse Industrial Estate Runcorn, Cheshire WA7 3DT England Telephone +44-1928-701888 | Fax +44-1928-710813

AMERICA HUSCO International W239 N218 Pewaukee Road Waukesha, Wisconsin 53188 USA Telephone +01-262-513-4200 | Fax +01-262-513-4427 www.huscointl.com

ASIA HUSCO-Kayaba Hydraulics (Shanghai) Ltd. No. 235 Jiangtian Road East Song Jiang Industrial Zone Shanghai 201600 China Telephone +86-21-5774-6468 | Fax +86-21-3774-0186

S-ar putea să vă placă și

- LPV Hydraulic Pump Catalog PDFDocument20 paginiLPV Hydraulic Pump Catalog PDFJAGDEV PANESARÎncă nu există evaluări

- Husco PDFDocument70 paginiHusco PDFhamdaÎncă nu există evaluări

- Arbans Complete Conservatory Method For Trumpet Arbans Complete ConservatoryDocument33 paginiArbans Complete Conservatory Method For Trumpet Arbans Complete ConservatoryRicardo SoldadoÎncă nu există evaluări

- Variable Displacement Pump A7V: Extract From RE 92210/05.95Document2 paginiVariable Displacement Pump A7V: Extract From RE 92210/05.95Joana Meller100% (1)

- 5000CC HuscoDocument15 pagini5000CC HuscoNishith DuletÎncă nu există evaluări

- TH 360Document2 paginiTH 360Milorad ZelenovicÎncă nu există evaluări

- Designing and Drawing PropellerDocument4 paginiDesigning and Drawing Propellercumpio425428100% (1)

- Husco Split Spool Valve Operation02Document68 paginiHusco Split Spool Valve Operation02pablo caimanqueseba2016100% (2)

- 64 6500Document1 pagină64 6500coelhoclaudios100% (2)

- Valves Grese NDocument92 paginiValves Grese NYair Alexis Muñoz Rojas100% (1)

- Program Information Mobile Hydraulics, Mobile Electronics, GearsDocument27 paginiProgram Information Mobile Hydraulics, Mobile Electronics, GearsCem KoçakÎncă nu există evaluări

- Parker ºÔØÃô Ð ÅàÑ (L90LS)Document40 paginiParker ºÔØÃô Ð ÅàÑ (L90LS)George JhonsonÎncă nu există evaluări

- Eaton Complete Transaxle Repair Guide - Ea11whDocument45 paginiEaton Complete Transaxle Repair Guide - Ea11whSteve Nah100% (1)

- Valve Ls LindeDocument24 paginiValve Ls Lindele100% (1)

- Inspection and Adjustment of Pump Ls ControlDocument10 paginiInspection and Adjustment of Pump Ls ControlHai Van100% (1)

- Piston Pump High Pressure - HPRDocument20 paginiPiston Pump High Pressure - HPRAlawdin Grand HydraulicÎncă nu există evaluări

- Brahms Symphony No 4Document2 paginiBrahms Symphony No 4KlausÎncă nu există evaluări

- Hiab XS 144 CLX Capacity 14 TM: Basic DataDocument2 paginiHiab XS 144 CLX Capacity 14 TM: Basic DataFabian RamirezÎncă nu există evaluări

- Desarmado y Armado Hidrau 416CDocument99 paginiDesarmado y Armado Hidrau 416CedhuamÎncă nu există evaluări

- GMK5135Document20 paginiGMK5135Cesar Augusto Vera JaimesÎncă nu există evaluări

- Terex RH120-E - Specifications - M 121.3 (05-2007)Document8 paginiTerex RH120-E - Specifications - M 121.3 (05-2007)Craig Gordon100% (1)

- Sauer DanfossDocument72 paginiSauer DanfossRoberto Gomez100% (1)

- Asdooeidk 33201Document48 paginiAsdooeidk 33201Joze MartinezÎncă nu există evaluări

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGDe la EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGÎncă nu există evaluări

- Parker Valve Mobile VOAC L90LS Cat HY17-8504 L90LS PRPRTNL DC VLV PDFDocument44 paginiParker Valve Mobile VOAC L90LS Cat HY17-8504 L90LS PRPRTNL DC VLV PDFJIM CAMPBELL100% (1)

- PVG 32 Proportional Valves Technical InformationDocument80 paginiPVG 32 Proportional Valves Technical InformationHYDRAULICGURU100% (2)

- Sermon Manuscript Galatians 5:16-26Document9 paginiSermon Manuscript Galatians 5:16-26Nathaniel ParkerÎncă nu există evaluări

- Pavc100 Service Pm3240-04Document12 paginiPavc100 Service Pm3240-04MohamedSalahÎncă nu există evaluări

- Grove RT750Document18 paginiGrove RT750Thibeault MesiliÎncă nu există evaluări

- Linde (HPV 02) Variable Pump For Closed Loop CircuitDocument23 paginiLinde (HPV 02) Variable Pump For Closed Loop CircuitdionerodiguesÎncă nu există evaluări

- A 2008-10-27 CAT Test-AdjustDocument72 paginiA 2008-10-27 CAT Test-AdjustboudaoudÎncă nu există evaluări

- Sauer Danfoss PDFDocument68 paginiSauer Danfoss PDFJPJFÎncă nu există evaluări

- Bombas KawasakiDocument64 paginiBombas KawasakiPedro RodriguezÎncă nu există evaluări

- 4x1 Hydraulic Circuit - Loader Control Valve, 3 Sections - Na (Var.720725)Document2 pagini4x1 Hydraulic Circuit - Loader Control Valve, 3 Sections - Na (Var.720725)carlos santiagoÎncă nu există evaluări

- A - Power Split Hydro-Mechanical Variable Transmission (HVT) For Off-Highway ApplicationDocument12 paginiA - Power Split Hydro-Mechanical Variable Transmission (HVT) For Off-Highway ApplicationchuhuynhÎncă nu există evaluări

- OLS-OLSA-OLSB Parts Manual-HN29DD52 PDFDocument12 paginiOLS-OLSA-OLSB Parts Manual-HN29DD52 PDFliu zhao liu zhaoÎncă nu există evaluări

- Toshiba MotorsDocument16 paginiToshiba MotorsSergio Cabrera100% (1)

- 200706-PD-Overview-for Distributor TrainingDocument96 pagini200706-PD-Overview-for Distributor TrainingChester Dalitso MwanzaÎncă nu există evaluări

- Hydraulic Pumps & MotorsDocument54 paginiHydraulic Pumps & MotorsWagih AhmedÎncă nu există evaluări

- 432d Signal Resolver Network - CheckDocument6 pagini432d Signal Resolver Network - CheckDiego CatariÎncă nu există evaluări

- Tesmec Trenchers Catalogue 2016 en 1475 RHDocument2 paginiTesmec Trenchers Catalogue 2016 en 1475 RHDejan Pantic100% (1)

- UFO Yukon Spring 2010Document8 paginiUFO Yukon Spring 2010Joy SimsÎncă nu există evaluări

- A Case On Marketing Strategy of Xiaomi IndiaDocument39 paginiA Case On Marketing Strategy of Xiaomi IndiaSoumyajeet Rout0% (1)

- ALISON HIDRAULIC - Catalogue PDFDocument250 paginiALISON HIDRAULIC - Catalogue PDFbaba0% (1)

- Parker-Ser - Usadsadasdpravljanje Pumpi 176,183,29oDocument24 paginiParker-Ser - Usadsadasdpravljanje Pumpi 176,183,29oAleksa Milosavljevic AdzaÎncă nu există evaluări

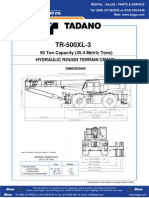

- TR500XL 3Document10 paginiTR500XL 3Nitish KumarÎncă nu există evaluări

- Allison Transmission BrochureDocument3 paginiAllison Transmission Brochurem mainÎncă nu există evaluări

- 13 - Servo Valve SV 10 - B (Boekwerk)Document36 pagini13 - Servo Valve SV 10 - B (Boekwerk)Ivan MaltsevÎncă nu există evaluări

- Overview Eng CD PDFDocument20 paginiOverview Eng CD PDFRafael Cortes100% (1)

- Mine TruckDocument2 paginiMine TruckyesÎncă nu există evaluări

- Unit 2: Intermediate Hydraulics - 950G Wheel LoaderDocument45 paginiUnit 2: Intermediate Hydraulics - 950G Wheel LoaderAlha DÎncă nu există evaluări

- Servodirectii OrbitaleDocument12 paginiServodirectii OrbitaleIonescu AngelÎncă nu există evaluări

- Especificaciones Convertidores de Torque Allison PDFDocument6 paginiEspecificaciones Convertidores de Torque Allison PDFAnonymous GjCOVlgÎncă nu există evaluări

- HPV 02 en PDFDocument36 paginiHPV 02 en PDFRamdani SaswikaÎncă nu există evaluări

- K8V Technical Brochure October 2017Document40 paginiK8V Technical Brochure October 2017juanchis650Încă nu există evaluări

- Parts Information: Char-LynnDocument5 paginiParts Information: Char-LynnRidha AbbassiÎncă nu există evaluări

- SAUER DANFOSS Series 45 E Frame Open Circuit Axial Piston Pumps Service IOM FOR TOLKO PDFDocument32 paginiSAUER DANFOSS Series 45 E Frame Open Circuit Axial Piston Pumps Service IOM FOR TOLKO PDFJAGDEV PANESARÎncă nu există evaluări

- 150 Ton Link Belt LS 238HSpecsDocument6 pagini150 Ton Link Belt LS 238HSpecsYosses Sang Nahkoda0% (1)

- Technical Proposal ECrane 1000 Series EH7359Document16 paginiTechnical Proposal ECrane 1000 Series EH7359Satrio Agung WijonarkoÎncă nu există evaluări

- Moto 14G-16GDocument21 paginiMoto 14G-16GRafael RodriguezÎncă nu există evaluări

- Compact Spaces Compact Loaders: Hydrostatic Drive Offers Flexibility in Off-Highway ApplicationsDocument4 paginiCompact Spaces Compact Loaders: Hydrostatic Drive Offers Flexibility in Off-Highway ApplicationsИван СивовÎncă nu există evaluări

- This Machine Offers Tremendous Stability and Is Shantui's Best SellerDocument2 paginiThis Machine Offers Tremendous Stability and Is Shantui's Best Sellermbsstart100% (1)

- Load Chart GRT 880 - 236006-1Document18 paginiLoad Chart GRT 880 - 236006-1mohamedÎncă nu există evaluări

- J-Gear Pumps CatalogueDocument21 paginiJ-Gear Pumps CatalogueturandotÎncă nu există evaluări

- Poclain Hydraulics Selection GuideDocument44 paginiPoclain Hydraulics Selection GuideM S GokulÎncă nu există evaluări

- Bermad - LisDocument66 paginiBermad - LisRamesh Kumar100% (1)

- Metering Pumps: (Gear Driven & Direct Drive)Document20 paginiMetering Pumps: (Gear Driven & Direct Drive)melihozdoganÎncă nu există evaluări

- Aisc S303Document27 paginiAisc S303Adrian Franco MolinaÎncă nu există evaluări

- HF PG 05Document24 paginiHF PG 05Adrian Franco MolinaÎncă nu există evaluări

- HF PG 05Document24 paginiHF PG 05Adrian Franco MolinaÎncă nu există evaluări

- Inafag Pasey30-N 4gqe58xcjp1lkjjpolfqq9dzaDocument1 paginăInafag Pasey30-N 4gqe58xcjp1lkjjpolfqq9dzaAdrian Franco MolinaÎncă nu există evaluări

- Tabla de Medidas de Agujeros para RoscasDocument1 paginăTabla de Medidas de Agujeros para RoscasAlejandro Rangel Bustamante100% (2)

- RSC Article Template-Mss - DaltonDocument15 paginiRSC Article Template-Mss - DaltonIon BadeaÎncă nu există evaluări

- Matrix PBX Product CatalogueDocument12 paginiMatrix PBX Product CatalogueharshruthiaÎncă nu există evaluări

- Roles and Responsibilities of An InstructorDocument4 paginiRoles and Responsibilities of An InstructorMohanlal SainiÎncă nu există evaluări

- Algorithms For Automatic Modulation Recognition of Communication Signals-Asoke K, Nandi, E.E AzzouzDocument6 paginiAlgorithms For Automatic Modulation Recognition of Communication Signals-Asoke K, Nandi, E.E AzzouzGONGÎncă nu există evaluări

- Data Network Unit 6 - UCDocument15 paginiData Network Unit 6 - UCANISHA DONDEÎncă nu există evaluări

- Consent Form: Republic of The Philippines Province of - Municipality ofDocument1 paginăConsent Form: Republic of The Philippines Province of - Municipality ofLucette Legaspi EstrellaÎncă nu există evaluări

- Directorate of Technical Education, Admission Committee For Professional Courses (ACPC), GujaratDocument2 paginiDirectorate of Technical Education, Admission Committee For Professional Courses (ACPC), GujaratgamailkabaaaapÎncă nu există evaluări

- Hannah Mancoll - Research Paper Template - 3071692Document14 paginiHannah Mancoll - Research Paper Template - 3071692api-538205445Încă nu există evaluări

- Sheltered 2 Item Recycle ListDocument5 paginiSheltered 2 Item Recycle ListRachel GÎncă nu există evaluări

- Latest ResumeDocument2 paginiLatest Resumesamy1234567Încă nu există evaluări

- Bgrim 1q2022Document56 paginiBgrim 1q2022Dianne SabadoÎncă nu există evaluări

- 21 Tara Mantra-Wps OfficeDocument25 pagini21 Tara Mantra-Wps OfficeAlteo FallaÎncă nu există evaluări

- PreviewpdfDocument29 paginiPreviewpdfSoemarlan ErlanÎncă nu există evaluări

- Lalit Resume-2023-LatestDocument2 paginiLalit Resume-2023-LatestDrew LadlowÎncă nu există evaluări

- Chapter 2.3.3 History of Visual Arts Modernism Post ModernismDocument17 paginiChapter 2.3.3 History of Visual Arts Modernism Post ModernismKim Ashley SarmientoÎncă nu există evaluări

- PGCRSM-01-BLOCK-03 Research Design ExperimentalDocument29 paginiPGCRSM-01-BLOCK-03 Research Design ExperimentalVijilan Parayil VijayanÎncă nu există evaluări

- Cambridge IGCSE: CHEMISTRY 0620/42Document12 paginiCambridge IGCSE: CHEMISTRY 0620/42Khairun nissaÎncă nu există evaluări

- Akilas Mebrahtom ResumeDocument1 paginăAkilas Mebrahtom ResumeAnonymous lLpBfQÎncă nu există evaluări

- Web-Based Attendance Management System Using Bimodal Authentication TechniquesDocument61 paginiWeb-Based Attendance Management System Using Bimodal Authentication TechniquesajextopeÎncă nu există evaluări

- Parallel Port Programming With DelphiDocument4 paginiParallel Port Programming With Delphiramadhan1933Încă nu există evaluări

- MS Lync - Exchange - IntegrationDocument29 paginiMS Lync - Exchange - IntegrationCristhian HaroÎncă nu există evaluări

- 1500 Series: Pull Force Range: 10-12 Lbs (44-53 N) Hold Force Range: 19-28 Lbs (85-125 N)Document2 pagini1500 Series: Pull Force Range: 10-12 Lbs (44-53 N) Hold Force Range: 19-28 Lbs (85-125 N)Mario FloresÎncă nu există evaluări

- Pedagogy MCQS 03Document54 paginiPedagogy MCQS 03Nawab Ali MalikÎncă nu există evaluări