Documente Academic

Documente Profesional

Documente Cultură

Calculation Code For Erosion Corrosion Induced Wall Thinning PDF

Încărcat de

Habibie RahmanDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Calculation Code For Erosion Corrosion Induced Wall Thinning PDF

Încărcat de

Habibie RahmanDrepturi de autor:

Formate disponibile

Nuclear Engineering and Design 119 (1990) 431-438 North-Holland

431

CALCULATION CODE FOR EROSION CORROSION INDUCED WALL THINNING IN PIPING SYSTEMS W. K A S T N E R , M. E R V E , N. H E N Z E L a n d B. S T E L L W A G

Siemens AG/KWU Group, Erlangen, Fed Rep. Germany

Received: first version October 1988, revised version 21 July 1989

Extensive experimental and theoretical investigations have been performed to develop a calculation code for wail thinning due to erosion corrosion in power plant piping systems. The so-called WATHEC code can be applied to single-pha~ water flow as well as to two-phase water/steam flow. Only input data which are available to the design engineer or the operator of a plant are taken into consideration. Together with a continuously updated erosion corrosion data base containing results from experimental investigations and aetuai damage in power plants the calculation exxle forms one element of a weak point analysis for power plant piping systems which can be applied to minimize material loss due to erosion corrosion, reduce non-destructive testing and curtail monitoring programs for piping systems, recommend life-extending measures.

-

1. Introduction The severe damage at the Surry 2 PWR nuclear power plant in December 1986 and the Trojan PWR in June 1987 has attracted broad attention - including that of the licensing authorities - to the phenomenon of erosion corrosion in water systems, that is in single-phase flow. As is known, the incident at Surry 2 was a rupture in a section of a carbon steel feedwater pump suction line containing a T-junction/elbow combination due to a high degree of material loss not expected by the operator (fig. 1 a-c). At Trojan, non-destructive examinations showed evidence of a reduction in wall thickness in carbon steel piping in the feedwater system. These results led to the prophylactic replacement of the components (but not to a change of material). At Trojan, erosion corrosion occurred not only at pipe elbows but, on the face of it surprisingly, in straight sections of the piping as well. It will be demonstrated in the following that a plausible explanation for the occurrence of erosion corrosion in both of these cases can be found by detailed analyses and consideration of the boundary conditions. Due to the large number of factors influencing the degree of material loss due to erosion corrosion, the analysis of such damage is possible only with the aid of a computer code. The main application of the WATHEC PC code developed by Siemens/KWU, however lies not

in obtaining confirmation of damage which has already occurred but in performing diagnostic analyses aimed at the development of measures to prevent further damage to the piping systems.

24" WCPO.Zl.301I

Flowdimetio~ I~

Fig. la. Erosion corrosion damage in 18"-feed pump suction pipe at Surry-2 - Prineipai schematic of damage location.

0 0 2 9 - 5 4 9 3 / 9 0 / $ 0 3 . 5 0 1990 - Elsevier Science Publishers B.V. ( N o r t h - H o l l a n d )

432

W. Kastner et al. / Calculation codefor erosion corrosion induced wall thinning

/ ...... \

Fig. lb. Erosion corrosion damage in 18"-feed pump suction pipe at Surry-2 - Damage configuration in 90 o elbow (top view). The present report describes the development of the WATHEC computer code and its application to weak point analyses for power plant piping systems.

Fig. 2. Mechanism of erosion corrosion.

abrasive corrosion (caused by particles in water) and droplet impingement erosion (caused by water droplets in steam) on the one hand and cavitation (caused by imploding gas bubbles) on the other. It also indicates that erosion corrosion is a mass transport phenomenon

2. Description of the erosion corrosion phenomenon The term erosion corrosion is defined in [1] as follows: "Erosion corrosion is a flow-induced process of material degradation. This phenomenon can affect metallic materials which owe their corrosion resistance to the formation of oxide films. Wearing away of the oxide films by turbulent water or wet steam flow is followed by dissolution corrosion of the unprotected metal." The metal surface is kept in a permanent state of enhanced reactivity. This clearly distinguishes erosion corrosion from purely mechanical processes such as

Fig. lc. Erosion corrosion damage in 18"-feed pump suction pipe at Surry-2 - Ruptured pipe section (top view),

Fig. 3. Appearance of erosion corrosion in a steam extraction fine with two-phase steam/water flow.

W. Kastner et al.

Calculation code for erosion corrosion induced wall thinning

433

(fig. 2), which can occur under both single-phase (water) flow and two-phase (steam/water) flow conditions; in the latter case erosion corrosion and droplet impingement erosion often occur in conjunction. The characteristic surface appearance of erosion corrosion caused by wet steam has long been known as the tiger skin or stripe pattern (fig. 3). Erosion corrosion under singlephase flow conditions had been experienced in the past as well, but it is only since the damage at Surry 2 that major interest has been shown in the effects of this phenomenon on water pipes.

3. Important factors affecting erosion corrosion The parameters affecting material loss from steel surfaces due to erosion corrosion were established in extensive laboratory experiments carried out by Siem e n s / K W U over the past several years (since 1973) as part of a research program [2]. Comparable investigations were performed by EdF [12,13], CEGB [14,15], MIT [16,17], etc. As fig. 4 shows other important factors besides the geometry conditions, which will be dealt with more closely in the following, are the material composition - principally the chromium a~a.d molybdenum, and, according to literature, also the copper content - and the flow velocity of the water.

Of major impact are the temperature, pH and oxygen content of the water (fig. 5). The strong dependency of material loss on pH emphasizes that the AVT chemistry characterized by pH values above 9.8 in feedwater, as practiced in almost all PWR plants built by Siemens/KWU, has a favourable impact on erosion corrosion. In BWR plants, highly pure de-ionized water is used as the fluid of the steam-water cycle. It contains oxygen and has a pH close to neutral. The presence of an adequate amount of oxygen in the feedwater (optimum around 50 ppb) results in good water chemistry protection against erosion corrosion. In most cases the fluid temperature is given. The water chemistry can be adjusted only within a limited range as dictated by other parameters. For this reason the following items are of great practical importance: - M a t e r i a l selection: here it should be mentioned that austeuitic stainless steels are not susceptible to erosion corrosion, the resistance of carbon and low-alloy steels increases with chromium, molybdenum and copper content, coatings rich in chromium, applied by flamesprayhag, may be highly advantageous, especially for local repairs [3,4]. - Flow velocity: this can be limited for a given mass flow by selecting suitable line cross sections, and

Wall thinning

T.=

200

I I

~iii~i~i:iiii ~ii}~iii~iii{ii!i!iii ~ii~![i~i~iii[!i[

10

!~ii~iN/ii~iii~iiii

~i~l,~ii~i

p - SSO psi T -356F w - 66 ftls ~';~i~ -pH7 ~!!!ii!i~!!!i~iii!ii 2 < Sp~ - 2 0 0 + 500 h C~bon r e e l 0.3 % Mo ~ , , ~

0.5

0.2

0.1

0.05 0 .2

_ __ ~_~ - - - \ \

~iiiiii~ii:iiiiiii

:~iii!ii~i!iii iiii~ilili!iii!iiiii!

~i~iii~iiiiiiiii!

.4

p = 580 T = 356 F w = 66 ftls ~7 02 ~ S p ~ t -200h I~e q~imm

__

p - S80 ma T =356F pH7 02 <_ 5 p ~ t -200h Plate m ~ m s Cmbon st,.iL 0.3% Mo

.6

.8

1.0

10

I. Geomatff factor k c

15 % 20 Cr and Mo content

50 ......

100

his IS0 Flow velocity

Fig. 4. Parameters of influence on erosion corrosion (1).

434

W. Kastner et aL Wd ,~ri~

Calculation code for erosion corrosion induced wall thinning

L

50+

2OO Mils/| tO0

I :

C u ~ Im~l m

2 _~O~ _~505 ppb

2O 10 5 2

1 .

I

I

I I I

p T w O+ t

"5801Bi " 356F -128fl/s <_ 5ppb - 200 + 400 h

"'-'" l i

1

p T w pH t

-580psi - 248F -115fl/s - 7 -2005

0.5.

p w pH O, t

-580psi " 115 i l l , - 7 _< 40ppb -200h

0.2. 0.1 0.05

Cadam a a l , 0.3% Mo

Cadam atad. 0.3 % Mo

Cmboa aI~L 0.3% Mo

100

Fig. 5. Parameters of influence on erosion corrosion (2).

P i p e geometry: this can be optimized to improve flow

conditions by selecting sufficiently large elbow radii, replacing T-fittings with laterals, etc.

Type of exposure

Reflmmce vMocity w

kc 1.00

-~..~

at pipes

Fig. 6 shows the effect of pipe geometry in detail. The figure includes the Keller factors kc [5] (here without units) for various flow configurations. These factors range from 0.04 for an ideal straight pipe unaffected by additional turbulence sources, to a maximum of 1.0 for stagnation point flow which represents the worst possible flow condition.

-(

...

4. Calculation of material loss using the WATHEC program

--~v

~ ' PJD - 0,5

0.60 0.52

in ro4nds lllld outlet

|!

~-.~'~

R/D- 1,5

+_

O.3O

h

"]/r

I~ ~ '~

'

Flow velocity

o

0.16

(slwp-edOed) FlowwlocNy i t aM IIiltlml kbllctlons

Ifl BlbrllOlllplNI

'

0.16

~

i

Flow{

~ c<Mro4gondMg to I o a l u l tokM b u d

In leaky jMots In ladlydnthl

It Inllllllr Wl~lIllpll

0,04 o.ae 0.06

- - -

IiI110~I~O~l~llp

--+

0.20

Fig. 6. Geometry factors according to Keller.

Laboratory experiments were carried out to develop an empirical relationship for the calculation of material loss due to erosion corrosion, which links the factors presented in figs. 4 to 6 and also the parameter of the exposure time of the components involved, (fig. 7). This relationship applies in the first instance to single-phase flow only. It can, however, fotlowing slight modification, be applied to two-phase flow, but only provided the metal wall is wetted by a continuously moving, coherent film of water (see fig. 7). This condition exists, for example, in the case of annular flow of a steam and water mixture with a continuous film of water along the wall and the steam in the center of the flow. The flow velocity in such a case is taken to be the mean velocity of the water film along the pipe wall, which is dependent on the mass flow rate, on the

W. Kastner et al.

/ Calculation code for erosion corrosion induced wall thinning

435

[~

(u~) now

I Two.plum (wutm'/Mmm) flow

1

Flow v.ioaty Water temperature

Ivbtabl let, Mo, etc.)

~// % // //

,A

Wmr cbemtry (pH, 02) Opuh~t~e

W,a _Z M~m velo~, of the we~w ~m at the wall of the compo~ cak:ulat~l to Rouhmi/11/ leom flow rata. stum quality and void fraction

I Emp~k~ bmmd on r~k~L parmele~l known to 1

the d~ge ~ or opwator

Empidcal model to calculate:

wa~us~Uv

WATHEC

_~,m crone

in wator and wnw/guan Ilow

Fig. 7. Development of the model to calculate wall thinning due to erosion corrosion. density of the water under saturation conditions, on the steam quality and the void fraction. At the same time, the pH and oxygen content parameters input into the calculation must take into account the temperature- and pressure-dependent distribution coefficients for alkalizing agents and for oxygen. The calculation procedure described here (see also [6]) now exists in the form of a computer code, the PC version of which is named WATHEC ( = WAll THinping due to Erosion Corrosion). Similar computer programs for erosion corrosion analysis of steam-water cycles in power plants were developed e.g. by EPRI, see [18]. Common to these codes is that they are based on functional relationships established in laboratory tests under well defined flow and water chemistry conditions. Prediction accuracy depends on the quality of the input data. During development of these codes they had to be tested extensively and calibrated to plant data in order to ensure conservative prediction on the one hand and to avoid overestimation of in-plant erosion corrosion material losses on the other. These requirements were taken into account during development of the WATHEC code by comparing the calculated material losses with measured values taken from other laboratory experiments and with data gathered during power plant oper-

ation. These data are stored in a data bank (containing approximately 2000 sets of data), set up and continuously updated by KWU. One particular problem recognlsed during the extensive testing of the W A T H E C computer code is described in more detail in the following: In piping systems, components which disrupt normal flow and thus create turbulence are often located only short distances apart. The piping geometry at the point of rupture at Surry 2, where an elbow followed a T-fitting, is an example of this. In such cases, the turbulence created by an upstream component A with geometry factor k~,A has not yet completely subsided when the water flowing in the pipe reaches component B with geometry factor kc,B. For reliable and conservative prediction of erosion corrosion material loss a portion of geometry factor k~,A must thus be taken into account in determining the geometry factor for component B. A relation for the declining effects of the geometry factor downstream of a component which disrupts flow was developed on the basis of analyses of the subsiding of turbulences carried out by Albring [7]. The portion of the geometry factor from component A remaining can be described by means of an exponential function [8]: Akc, A = kc, A exp( - C z / D ) ,

(1)

where: D = pipe diameter z = distance from component A, C ffi constant = 0.231, see [8]. The validity of this relation is demonstrated by the following example: Material loss due to erosion corrosion on a test setup consisting of a sharp elbow followed by straight piping of the same diameter was investigated in an experiment conducted in our laboratories [2]. Wall thinning due to erosion corrosion enlarges the pipe diameter. Fig. 8 plots this enlargement along the length of the test setup. The decrease in material loss due to erosion corrosion in the region 0 < z / D < 10 shows essentially the same pattern as the curve obtained with eq. (1) for the respective geometry factors. The geometry factor for a component B a short distance downstream of component A is now calculated using the equation: (k~.a)to t --- kc.B + Akc.a.

(2)

It should be borne in mind that the geometry factor for a combination of components cannot exceed the value

436

W. Kostner et al. / Calculation code for erosion corrosion induced wall thinning

GeometryfKt~.

l 'l

0.61 ' ~ " /

Kwu.s.~,,, : I

W~ vqdooly 18.6m/s Wet wmpwmm180C 7

O~ ~ 0.85pp~

0.8

0.6 -- 0.4 0.2

" T

~ Expmwe time

St37.2 51,1 h

a! ]_."

0

I

10 ,5

-,-t-20

I

I

~ . 1

~'Zl z/D

25

F- - T !

*

. . . .

l

I

t t

~ - ' ----'--- -i

IT 7

0/D~ 0.5

16mm~

480m

-"I

Fig. 8. Wall thinning due to erosion corrosion measured as pipe diameter increase and calculated decrease of the geometry factor in a pipe behind a sharp bend.

for stagnation point flow, that is to say (k,B)to , < 1.0. (3)

The considerations presented here related to singlephase flow in which, according to [9] the extent of

turbulent effects is limited to z = 10 D. In two-phase (steam/water) flow this extent might be much larger, depending on the steam quality (see [10]). The conservative and reliable application of the W A T H E C computer code to the conditions existing in

K15115Mo3 (not machined Intemally)

Water velocity 18.6 m/s Pmuure 40 bar Water temperature 180 C

K111RSt 37.2

/

I,

RIO/St37.2 RB/15Mo3

pH.V~

Oxygen cone. Expo~uR time I

0.85 ppb 513 h

R12/13CrMo44

Connecting

piece 1.4550 I L 480

K1/RSt37.2 ! -- ZT/St37.2

Connecting piece 1.4550

K13/13CrM044 R6/15Mo3 48c

~]

R2/St37.2- -

T

nn ___~[ R4115M03 480 ~ 2280-

K5/15Mo3 ~

K9115Mo3

Fig. 9. Arrangement of the 6 ID 16-elbows and 7 ID 16-piping sections within the KWU-piping-test-geometry.

W. Kastner et al. / Calculation code for erosion corrosion induced wall thinning

437

Loud (wan thi,~M~)

- --

Avmgl (mm~ht)

ning was calculated and between 0.6 and 4.4 mm thinning was measured.

5. Weak point analysis

10"

1000

2~

3000 t e ~ h of p i p ~ ~ M

in ~,u

Fig. 10. Comparison of wall thinning calculation and measurements for the KWU-piping-test-geometry(ID 16 mm= 5/8").

a complex piping system was to be demonstrated on a test setup consisting of straight pipes and elbows (see fig. 9) made of different materials. The experiment was carried out in the Siemens/KWU laboratories using water as the flow medium [2]. The results calculated with the WATHEC code can be output in either list or graphic form (see fig. 10). The presentation of material loss over the length of the piping system also includes the local (obtained by wall thickness measurement) and average (by weighing) material losses determined as part of the experiment. In addition to a quite good agreement between calculated and measured values, the comparison also shows that the computer code is adequately capable of calculating the flow disturbances caused by turbulence-inducing components. The code's capabilities also become clear when the code is used to perform re-calculations of the Surry 2 and Trojan damage within the limits allowed by the design and operational data available on the two plants. The exact initial wall thickness of piping is often unknown. Residual wall thickness measurements can thus be correlated only with nominal wall thicknesses. As a result, the wall thinning data thus obtained also include the initial within-tolerance deviations from nominal wall thickness which, in the case of Trojan, are as much as + 12.5%. Nevertheless a comparison of the calculated and measured values is convincing: in Surry 2, a measured material removal of max. 11.5 nun is to be compared with a calculated thinning of 7.7 mm; in the case of Trojan, thinning by 5 nun in 90 elbows was calculated, as compared to measured thinning values which, in keeping with the nominal tolerances, may lie between 3.2 and 7.1 ram, while in straight piping 1.3 mm thin-

As mentioned earlier, the WATHEC program was developed for the determination of the material removal to be expected in a power plant component or a piping system a n d / o r to predict the remaining life expectancy of a component under the given loading conditions. This application is best pursued as part of a "weak point analysis", the sequence of which is as follows: On the basis of the data available at the plant, those plant systems are first selected which lie within the crucial range of relevant parameters within which erosion corrosion on a significant scale is possible at all. Within these systems, the points comparatively most susceptible to damage are identified on the basis of the pertaining geometry and flow conditions. The material loss to be expected at these potential weak points is then calculated with the aid of the prediction model. The results of these calculations are subjected to a critical analysis including, for instance, an appraisal on the basis of the measurement data available in the data base.

L. . . . . . .

I . . . .

I

Fig. 11. Erosion corrosion management program.

438

W. Kastner et al. / Calculation code for erosion corrosion reduced wall throning

The advantage of this procedure is clear: the scope of inspection and non-destructive examination, and of remedial work in response to the findings thereof, can be significantly reduced and concentrated on the plant components most susceptible to erosion corrosion. Fig. 11 gives an impression of potential actions to combat erosion corrosion. The present work discusses only the use of ultrasonic techniques to measure component wall thickness. The results of these measurements are important to the verification of the calculation output generated by the W A T H E C program. In this context it should be mentioned that the accuracy of the input (plant operating) data is important to the reliability of the calculation results. Due to the large number of measurement data obtained from ultrasonic examinations, a " D a t a Management System" compatible with W A T H E C has recently been developed to store and process these data for comparison with the results of calculation.

[3]

[4] [5] [6]

[7] [8]

[9]

6. Conclusions In response to the events in Surry 2 and Trojan, analyses using the prediction m o d e l described ( W A T H E C ) were performed in a number of nuclear power plants and the results thereof verified by means of non-destructive examination. The findings confirmed both the reliability of the computer program and also the low susceptibility of the piping systems in plants built by S i e m e n s / K W U to erosion corrosion. This low susceptibility can be attributed to the continuous feedback gained from design, construction and operation: at no point were significant material losses detected. The prediction model is of broader benefit for two reasons: particularly in plants in which the crucial aspects identified have not been fully taken into account, for instance in terms of flow conditions or of p H levels, the model can give an indication of the current component condition. Application of the model is also particularly interesting whether a thought is being given to reducing m e a s u r e m e n t and monitoring effort and to extending the life expectancy of components of whole piping systems.

[10]

[11] [12]

[13]

[14]

[15]

[16]

[17] References [18] [1] H.-G. Heitmann, Praxis der Kraftwerk-Chemie (VulkanVerlag, Essen, 1986). [2] W. Kastner, K. Riedle, H. Tratz, Experimentelle Un-

tersuchungen zum Materialabtrag durch Erosionskorrosion, VGB-Kraftwerkstechnik 64, 5 (1984) 452-465. G. Faber, A. H~usermann, R. Svoboda, Ten years of experience with erosion corrosion in a PWR and a BWR power plant, ASME Joint Power Generation Conference '82, 8 2 - J ~ - P w r - 4 6 (1982). J. Tavast, Flamespraying combats erosion-corrosion in wet steam, Nucl. Engrg. Int. (March 1988) 44. H. Keller, Erosionskorrosion an Nassdampfturbinen, VGB-Kraftwerkstechnik 54, 5 (1974) 292-295. W. Kastner, K. Riedle, Empirisches Modell zur Berechnung yon Materialabtr~gen durch Erosionskorrosion, VGB-Kraftwerkstechnik 66, 12 (1986) 1171-1178. W. Albring, Elementarvorg~lnge fluider Wirbelbewegungen (Akademieverlag, Berlin, 1981). N. Henzel, W. Kastner, B. Stellwag, Erosion corrosion in power plants under single- and two-phase flow conditions - Updated experience and proven counteractions, American Power Conference, 50th Annual Meeting, Chicago, April 17-20, 1988. VDI - Gesellschaft Verfahrenstechnik und Chemieingenieurwesen (GVC), VDI -Wiirmeatlas, Blatt Lc 5&6 (VDI - Verlag GmbH, Diisseldorf, 4. Auflage, 1984). W. Kastner, M. Erve, N. Henzel, B. Stellwag, Erosion corrosion in power plant piping systems - Calculation code for predicting wall thinning, IAEA Specialist Meeting on "Corrosion and Erosion Aspects in Pressure Boundary Components in LWR", Vienna, Sept. 12-14, 1988. Z. Rouhani, Modified correlations for void and two-phase pressure drop, AE-RTV-841 (1969). J. Ducreux, The influence of flow velocity on the corrosion-erosion of carbon steel in pressurized water, Proc. 3rd BNES, London, 1983, pp. 227-233. Pfi. Berge, J. Ducreux, P. Saint-Paul, Effects of chemistry on corrosion-erosion of steels in water and wet steam, Proc. 2nd BNES, London, 1981, pp. 19-23. G.J. Bignold, C.H. de Whalley, K. Garbett, I.S. Woolsey, Mechanistic aspects of erosion-corrosion under boiler feedwater conditions, Proc. 3rd BNES, London, 1983, pp. 219-226. I.S. Woolsey, G.J. Bignold, C.H. de Whalley, K. Garbett, The Influence of oxygen and hydrazine on the erosioncorrosion behaviour and electrochemical potentials of carbon steel under boiler feedwater conditions, Proc. 4th BNES, Vol. 1, London, 1986, pp. 337-346. L.E. Sanchez-Caldera, The mechanism of corrosion-erosion in steam extraction fines of power stations, Ph.D. Thesis, MIT (1984). R.G. Keek, Prediction and mitigation of erosive-corrosive wear in steam extraction piping systems, Ph.D. Thesis, MIT (1987). B. Cfiexal, J. Horowitz, Flow assisted corrosion in carbon steel piping - parameters and influences, presented at 4th Syrup. on Env. Deg. of Mat. in Nucl. Power Systems Water Reactors, Jekyll Island, Georgia, USA, Aug. 1989.

S-ar putea să vă placă și

- Thermite Welding MetallurgyDocument3 paginiThermite Welding MetallurgyDarryl007Încă nu există evaluări

- HP40 NBDocument13 paginiHP40 NBTarun ChandraÎncă nu există evaluări

- Synloop Waste Heat Boiler in Ammonia Plants: Borsig Process Heat Exchanger GMBHDocument20 paginiSynloop Waste Heat Boiler in Ammonia Plants: Borsig Process Heat Exchanger GMBHArif AhmedÎncă nu există evaluări

- Feed Water Pipe FailureDocument9 paginiFeed Water Pipe Failuredafteri11Încă nu există evaluări

- Elimination of Bowing Distortion in Welded StiffenersDocument8 paginiElimination of Bowing Distortion in Welded StiffenersHaris HartantoÎncă nu există evaluări

- Otc18895 Flow Induced Pulsations in RisersDocument5 paginiOtc18895 Flow Induced Pulsations in Risershamadani100% (1)

- Mitigate Corrosion in CondensateDocument27 paginiMitigate Corrosion in CondensateGeorge MarkasÎncă nu există evaluări

- Limits and State of The Art of The New Creep Resistant SteelsDocument64 paginiLimits and State of The Art of The New Creep Resistant SteelsRené Galbraith BerraÎncă nu există evaluări

- Section I 2015Document33 paginiSection I 2015ferds2599Încă nu există evaluări

- Flow Accelerated Corrosion of Pressure Vessels in Fossil Plants - DooleyDocument6 paginiFlow Accelerated Corrosion of Pressure Vessels in Fossil Plants - Dooleyvandrake10Încă nu există evaluări

- 545Document11 pagini545hiyeonÎncă nu există evaluări

- Measurements in A Pulsating FlowDocument13 paginiMeasurements in A Pulsating Flowusebio64Încă nu există evaluări

- HCL, CL Corrosion DataDocument8 paginiHCL, CL Corrosion DataShah RajendraÎncă nu există evaluări

- Understanding Vibration-Induced Pipework FailureDocument3 paginiUnderstanding Vibration-Induced Pipework Failureأصلان أصلانÎncă nu există evaluări

- Effect of Alloying Elements On Metal PropertiesDocument5 paginiEffect of Alloying Elements On Metal PropertiesJim GrayÎncă nu există evaluări

- Astm C795Document4 paginiAstm C795Nacer KisyÎncă nu există evaluări

- Duplex Stainless Steel DetailDocument12 paginiDuplex Stainless Steel DetailessnelsonÎncă nu există evaluări

- Understanding The Environmental Limits in NACE MR0175-2003Document30 paginiUnderstanding The Environmental Limits in NACE MR0175-2003sain65100% (1)

- 32 Samss 019Document17 pagini32 Samss 019Moustafa BayoumiÎncă nu există evaluări

- Improvements in Design and Fitness Evaluation of Above Ground Steel Storage TanksDocument284 paginiImprovements in Design and Fitness Evaluation of Above Ground Steel Storage TanksrodrigoperezsimoneÎncă nu există evaluări

- Engineering Failure Analysis: H. Kazempour-Liacy, M. Mehdizadeh, M. Akbari-Garakani, S. AboualiDocument10 paginiEngineering Failure Analysis: H. Kazempour-Liacy, M. Mehdizadeh, M. Akbari-Garakani, S. AboualiAndrie MaulanaÎncă nu există evaluări

- Valve and Pipeline Design Notes - Part 1Document29 paginiValve and Pipeline Design Notes - Part 1vikky123100% (1)

- Notes For Material Selection Philosophy (Methodology)Document2 paginiNotes For Material Selection Philosophy (Methodology)SMAHMADI100% (1)

- FAC ChemistryDocument6 paginiFAC ChemistrymarydaughterÎncă nu există evaluări

- Scope ASME Section Requirements For Boiler ASME StampDocument3 paginiScope ASME Section Requirements For Boiler ASME StampThineshraaj Naidu JayaramanÎncă nu există evaluări

- Pge Sa 000 PD SP 0015 02Document30 paginiPge Sa 000 PD SP 0015 02sajadranjbaranÎncă nu există evaluări

- Dhawi - Reclassification of SRU Equipment To ASME Section VIIIDivision 1 PDFDocument8 paginiDhawi - Reclassification of SRU Equipment To ASME Section VIIIDivision 1 PDFRenan Gustavo PazÎncă nu există evaluări

- SB 111-SB 111MDocument14 paginiSB 111-SB 111MRoberto Faustino FaustinoÎncă nu există evaluări

- P-91 Power Piping and Pressure VesselsDocument10 paginiP-91 Power Piping and Pressure VesselsOliver ArauzÎncă nu există evaluări

- Nozzle Details SRWNRFDocument1 paginăNozzle Details SRWNRFshazanÎncă nu există evaluări

- Woc Hse Manual Standards: Woc LP EP DepartmentDocument12 paginiWoc Hse Manual Standards: Woc LP EP DepartmentAkram AlhaddadÎncă nu există evaluări

- Tube To Header JointsDocument4 paginiTube To Header Jointsshabbir626Încă nu există evaluări

- REQUIREMENTS FOR LOW ALLOY STEEL PIPING ATTACHMENT WELDS-Final PROOFED (FINAL)Document15 paginiREQUIREMENTS FOR LOW ALLOY STEEL PIPING ATTACHMENT WELDS-Final PROOFED (FINAL)MubeenÎncă nu există evaluări

- U-Tube Heat ExchangerDocument9 paginiU-Tube Heat Exchangerhirenpatel_62Încă nu există evaluări

- Material Selection For Flare TipsDocument200 paginiMaterial Selection For Flare Tipscanakyuz100% (2)

- Pipe Stress Engineering (PDFDrive) 5Document1 paginăPipe Stress Engineering (PDFDrive) 5Darshan PanchalÎncă nu există evaluări

- In-Service Condition Monitoring of Piping Systems in Power Plants Requirements and Advanced TechniquesDocument13 paginiIn-Service Condition Monitoring of Piping Systems in Power Plants Requirements and Advanced Techniquesamirreza_eng3411Încă nu există evaluări

- Integrated Approach RLA of Reformer Tubes NDT (ARTiS) PDFDocument8 paginiIntegrated Approach RLA of Reformer Tubes NDT (ARTiS) PDFSatya RaoÎncă nu există evaluări

- Titanium Erosion in Urea Strippers & Emerging TechnologiesDocument19 paginiTitanium Erosion in Urea Strippers & Emerging Technologiesalimirpur100% (1)

- (Tech Insp) Inspection Techniques in Reformer FurnacesDocument10 pagini(Tech Insp) Inspection Techniques in Reformer FurnacesruchiniranjanÎncă nu există evaluări

- 7413 001 Standard Support UopDocument76 pagini7413 001 Standard Support UopPierre RamirezÎncă nu există evaluări

- Linings For Sulphur Storage TanksDocument3 paginiLinings For Sulphur Storage TanksGuru Raja Ragavendran NagarajanÎncă nu există evaluări

- How To Identify Water Side Corrosion Problems in HRSG'S - CCJDocument7 paginiHow To Identify Water Side Corrosion Problems in HRSG'S - CCJShameer MajeedÎncă nu există evaluări

- Boiler Materials For USC Plants IJPGC 2000Document22 paginiBoiler Materials For USC Plants IJPGC 2000pawanumarji1100% (1)

- Interpretations ASME B31.3Document338 paginiInterpretations ASME B31.3Claudenir AlvesÎncă nu există evaluări

- Status of Advanced Ultra-Supercritical Pulverised Coal Technology - ccc229Document57 paginiStatus of Advanced Ultra-Supercritical Pulverised Coal Technology - ccc229sarangss100% (1)

- Epilux - HB - MIO - Coating-Grey PDFDocument2 paginiEpilux - HB - MIO - Coating-Grey PDFRanjan Kumar SahuÎncă nu există evaluări

- Description of Damage: 5.1.1.1 Amine Corrosion 5.1.1.1.1Document5 paginiDescription of Damage: 5.1.1.1 Amine Corrosion 5.1.1.1.1Ajmi HmidaÎncă nu există evaluări

- Lecture 9 Erosion-CorrosionDocument27 paginiLecture 9 Erosion-Corrosionprakush01975225403Încă nu există evaluări

- Integral Low Fin TubeDocument16 paginiIntegral Low Fin TubePeter_Phee_341Încă nu există evaluări

- Uk Finned Technic HeatingspaceDocument18 paginiUk Finned Technic HeatingspacetuzlucayirÎncă nu există evaluări

- BD0425A-57A1 - Bolt Up Procedure For Critical FlangesDocument22 paginiBD0425A-57A1 - Bolt Up Procedure For Critical Flangesvpkaranam1100% (1)

- Plate Heat Exchangers FoulingDocument3 paginiPlate Heat Exchangers Foulingamilcarsoares100% (1)

- Combined Cycle Water Chemistry - POWERDocument9 paginiCombined Cycle Water Chemistry - POWERShameer MajeedÎncă nu există evaluări

- Paper No.: Pitting Corrosion Problems of Stainless Steels in A Pta PlantDocument12 paginiPaper No.: Pitting Corrosion Problems of Stainless Steels in A Pta PlantAdrian Galvis100% (1)

- Piping - Nozzle LoadingDocument2 paginiPiping - Nozzle Loadingaap1100% (1)

- Ing 4 - 01 - 03Document45 paginiIng 4 - 01 - 03awhk2006Încă nu există evaluări

- Flow Accelerated CorrosionDocument9 paginiFlow Accelerated Corrosioncoolguy12345Încă nu există evaluări

- Sweet Corrosion in PipelineDocument8 paginiSweet Corrosion in PipelinedgkmurtiÎncă nu există evaluări

- Mcsa PDFDocument12 paginiMcsa PDFdurgaprasad reganiÎncă nu există evaluări

- Vibration Analysis Training Program PDFDocument1 paginăVibration Analysis Training Program PDFHabibie RahmanÎncă nu există evaluări

- SOP Pengujian MCSADocument3 paginiSOP Pengujian MCSAHabibie Rahman0% (1)

- Bearing Mounting Basics PDFDocument4 paginiBearing Mounting Basics PDFssoares1989Încă nu există evaluări

- Direct Cooler Pump ADocument9 paginiDirect Cooler Pump AHabibie RahmanÎncă nu există evaluări

- VIbration Monitoring of PumpsDocument26 paginiVIbration Monitoring of Pumpsnabil160874Încă nu există evaluări

- 5313 PDFDocument177 pagini5313 PDFHabibie RahmanÎncă nu există evaluări

- Pengaruh Pemberian Diet Tinggi Karbohidrat Dibandingkan Diet Tingg PDFDocument10 paginiPengaruh Pemberian Diet Tinggi Karbohidrat Dibandingkan Diet Tingg PDFHabibie RahmanÎncă nu există evaluări

- Failure Analysis of Natural Gas PipesDocument20 paginiFailure Analysis of Natural Gas PipesHeru BerianÎncă nu există evaluări

- 1Document85 pagini1Habibie RahmanÎncă nu există evaluări

- Tutorial Guide Gambit 2.2Document630 paginiTutorial Guide Gambit 2.2diegop8706Încă nu există evaluări

- 07 PDFDocument13 pagini07 PDFHabibie RahmanÎncă nu există evaluări

- 118 Zavadinka PDFDocument13 pagini118 Zavadinka PDFHabibie Rahman100% (1)

- Astm E974 PDFDocument5 paginiAstm E974 PDFHabibie RahmanÎncă nu există evaluări

- LL Dimcompstat PDFDocument11 paginiLL Dimcompstat PDFHabibie RahmanÎncă nu există evaluări

- A Review 2004 Literature PDFDocument54 paginiA Review 2004 Literature PDFHabibie RahmanÎncă nu există evaluări

- Comments On 'Performance Evaluation of Single-Flash Geothermal Power Plant in Denizli, Turkey' PDFDocument5 paginiComments On 'Performance Evaluation of Single-Flash Geothermal Power Plant in Denizli, Turkey' PDFHabibie RahmanÎncă nu există evaluări

- A Strategy For The Risk-Based Inspection of Pressure Safety Valves (2009) PDFDocument9 paginiA Strategy For The Risk-Based Inspection of Pressure Safety Valves (2009) PDFHabibie RahmanÎncă nu există evaluări

- Risk-Based Prioritization and Its Application To Inspect Ion of Valves (2012) PDFDocument8 paginiRisk-Based Prioritization and Its Application To Inspect Ion of Valves (2012) PDFHabibie RahmanÎncă nu există evaluări

- 1 s2.0 S0017931096003110 Main - 2 PDFDocument14 pagini1 s2.0 S0017931096003110 Main - 2 PDFHabibie RahmanÎncă nu există evaluări

- Ultrasonic Monitoring of Erosioncorrosion Thinning Rates (2013) PDFDocument8 paginiUltrasonic Monitoring of Erosioncorrosion Thinning Rates (2013) PDFHabibie RahmanÎncă nu există evaluări

- Predicting The Wall Thinning Engendered by Erosion-Corrosion Using CFD (2010) PDFDocument6 paginiPredicting The Wall Thinning Engendered by Erosion-Corrosion Using CFD (2010) PDFHabibie RahmanÎncă nu există evaluări

- Nondestructive Assessment of Elbow Wall-Thinning (2011) PDFDocument6 paginiNondestructive Assessment of Elbow Wall-Thinning (2011) PDFHabibie RahmanÎncă nu există evaluări

- 1 s2.0 0042207X66928053 Main PDFDocument1 pagină1 s2.0 0042207X66928053 Main PDFHabibie RahmanÎncă nu există evaluări

- Autocad 3D and 2D Practice ActivitiesDocument19 paginiAutocad 3D and 2D Practice ActivitiesJed Tedor88% (33)

- 1 s2.0 0029549389901611 Main PDFDocument15 pagini1 s2.0 0029549389901611 Main PDFHabibie RahmanÎncă nu există evaluări

- 1 s2.0 S1877705811051113 Main PDFDocument8 pagini1 s2.0 S1877705811051113 Main PDFHabibie RahmanÎncă nu există evaluări

- A Review 2004 Literature PDFDocument54 paginiA Review 2004 Literature PDFHabibie RahmanÎncă nu există evaluări

- Mil STD 792fDocument13 paginiMil STD 792fdoradoanÎncă nu există evaluări

- Thanks For Visiting Our Page!: Hi Doc!Document15 paginiThanks For Visiting Our Page!: Hi Doc!bey luÎncă nu există evaluări

- Heart Sounds: Presented by Group 2A & 3ADocument13 paginiHeart Sounds: Presented by Group 2A & 3AMeow Catto100% (1)

- DyslexiaDocument19 paginiDyslexiaKeren HapkhÎncă nu există evaluări

- Indian Standard (First Revision) : Method of Chemical Analysis of Hydraulic CementDocument44 paginiIndian Standard (First Revision) : Method of Chemical Analysis of Hydraulic CementArijit dasguptaÎncă nu există evaluări

- Weld Metal Overlay & CladdingDocument2 paginiWeld Metal Overlay & CladdingbobyÎncă nu există evaluări

- QA-QC TPL of Ecube LabDocument1 paginăQA-QC TPL of Ecube LabManash Protim GogoiÎncă nu există evaluări

- HVAC (Heating, Ventilation and Air Conditioning) : SRS PrecautionsDocument1 paginăHVAC (Heating, Ventilation and Air Conditioning) : SRS PrecautionssoftallÎncă nu există evaluări

- CXC - Past - Paper - 2022 Solutions PDFDocument17 paginiCXC - Past - Paper - 2022 Solutions PDFDarren Fraser100% (1)

- EV Hammer Impact Crusher - ENDocument8 paginiEV Hammer Impact Crusher - ENKeshav NandaÎncă nu există evaluări

- Feeder BrochureDocument12 paginiFeeder BrochureThupten Gedun Kelvin OngÎncă nu există evaluări

- ALL102-Walker Shirley-Unemployed at Last-The Monkeys Mask and The Poetics of Excision-Pp72-85Document15 paginiALL102-Walker Shirley-Unemployed at Last-The Monkeys Mask and The Poetics of Excision-Pp72-85PÎncă nu există evaluări

- Lab Manual PDFDocument68 paginiLab Manual PDFSantino AwetÎncă nu există evaluări

- ATI Respiratory PowerpointDocument90 paginiATI Respiratory PowerpointAnn KelseaÎncă nu există evaluări

- 2019 06 28 PDFDocument47 pagini2019 06 28 PDFTes BabasaÎncă nu există evaluări

- Fast FashionDocument9 paginiFast FashionTeresa GonzalezÎncă nu există evaluări

- Demages Goods RecordDocument22 paginiDemages Goods Recordtariq malikÎncă nu există evaluări

- Impact of Employee Motivation in The Banking SectorDocument48 paginiImpact of Employee Motivation in The Banking Sectormohd talalÎncă nu există evaluări

- Rules For State Competitions and Iabf Approved TournamentsDocument56 paginiRules For State Competitions and Iabf Approved TournamentsQuality management systems documentsÎncă nu există evaluări

- Comprehensive Safe Hospital FrameworkDocument12 paginiComprehensive Safe Hospital FrameworkEbby OktaviaÎncă nu există evaluări

- Present Continuous Exercises Test 1 - Positive Statements ExerciseDocument2 paginiPresent Continuous Exercises Test 1 - Positive Statements Exerciseangel omar peraltaÎncă nu există evaluări

- Model Probabilistik: "Variable Demand and Variable Lead Time" & Konsep Service LevelDocument30 paginiModel Probabilistik: "Variable Demand and Variable Lead Time" & Konsep Service LevelVladimir Hery WijannarkoÎncă nu există evaluări

- EIL Document On Motor, PanelDocument62 paginiEIL Document On Motor, PanelArindam Samanta100% (1)

- Pe 3 Syllabus - GymnasticsDocument7 paginiPe 3 Syllabus - GymnasticsLOUISE DOROTHY PARAISO100% (1)

- Ventricular Septal DefectDocument8 paginiVentricular Septal DefectWidelmark FarrelÎncă nu există evaluări

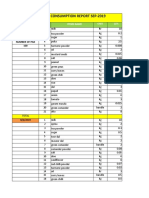

- Daily Staff Food Consumption Reports Sep-2019Document4 paginiDaily Staff Food Consumption Reports Sep-2019Manjit RawatÎncă nu există evaluări

- OPSS1213 Mar98Document3 paginiOPSS1213 Mar98Tony ParkÎncă nu există evaluări

- High Speed DoorsDocument64 paginiHigh Speed DoorsVadimMedooffÎncă nu există evaluări

- انظمة انذار الحريقDocument78 paginiانظمة انذار الحريقAhmed AliÎncă nu există evaluări

- Dr. Sajjad Hussain Sumrra Isomerism (CHEM-305) Inorganic Chemistry-IIDocument48 paginiDr. Sajjad Hussain Sumrra Isomerism (CHEM-305) Inorganic Chemistry-IITanya DilshadÎncă nu există evaluări