Documente Academic

Documente Profesional

Documente Cultură

BOQ and Rates Oil Gas

Încărcat de

nirdoshkumarDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

BOQ and Rates Oil Gas

Încărcat de

nirdoshkumarDrepturi de autor:

Formate disponibile

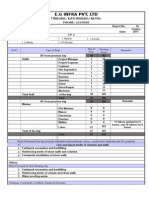

Tender Inviting Authority: Chief Manager (Contracts),IOCL(AOD),Digboi

Name of Work: FABRICATION & LAYING OF ONE 4", ONE 6" & ONE 8" N PERMANENT CATHODIC PROTECTION IN THE ABOVE LINES INCLUD

Contract No: DRC1125306 Bidder Name:

Sl. No.

Signature of Tenderer with seal

Tender Inviting Authority: Chief Manager (Contracts),IOCL(AOD),Digboi

Name of Work: FABRICATION & LAYING OF ONE 4", ONE 6" & ONE 8" N PERMANENT CATHODIC PROTECTION IN THE ABOVE LINES INCLUD

Contract No: DRC1125306 Bidder Name:

Sl. No. 1

Signature of Tenderer with seal

Tender Inviting Authority: Chief Manager (Contracts),IOCL(AOD),Digboi

Name of Work: FABRICATION & LAYING OF ONE 4", ONE 6" & ONE 8" N PERMANENT CATHODIC PROTECTION IN THE ABOVE LINES INCLUD

Contract No: DRC1125306 Bidder Name:

Sl. No. 2

Signature of Tenderer with seal

Tender Inviting Authority: Chief Manager (Contracts),IOCL(AOD),Digboi

Name of Work: FABRICATION & LAYING OF ONE 4", ONE 6" & ONE 8" N PERMANENT CATHODIC PROTECTION IN THE ABOVE LINES INCLUD

Contract No: DRC1125306 Bidder Name:

Sl. No. 3

Signature of Tenderer with seal

Tender Inviting Authority: Chief Manager (Contracts),IOCL(AOD),Digboi

Name of Work: FABRICATION & LAYING OF ONE 4", ONE 6" & ONE 8" N PERMANENT CATHODIC PROTECTION IN THE ABOVE LINES INCLUD

Contract No: DRC1125306 Bidder Name:

Sl. No. 4

4.1

Signature of Tenderer with seal

Tender Inviting Authority: Chief Manager (Contracts),IOCL(AOD),Digboi

Name of Work: FABRICATION & LAYING OF ONE 4", ONE 6" & ONE 8" N PERMANENT CATHODIC PROTECTION IN THE ABOVE LINES INCLUD

Contract No: DRC1125306 Bidder Name:

Sl. No. 4.2

4.3

Signature of Tenderer with seal

Tender Inviting Authority: Chief Manager (Contracts),IOCL(AOD),Digboi

Name of Work: FABRICATION & LAYING OF ONE 4", ONE 6" & ONE 8" N PERMANENT CATHODIC PROTECTION IN THE ABOVE LINES INCLUD

Contract No: DRC1125306 Bidder Name:

Sl. No. 5.1

5.2

5.3

Signature of Tenderer with seal

Tender Inviting Authority: Chief Manager (Contracts),IOCL(AOD),Digboi

Name of Work: FABRICATION & LAYING OF ONE 4", ONE 6" & ONE 8" N PERMANENT CATHODIC PROTECTION IN THE ABOVE LINES INCLUD

Contract No: DRC1125306 Bidder Name:

Sl. No. 6

Signature of Tenderer with seal

Tender Inviting Authority: Chief Manager (Contracts),IOCL(AOD),Digboi

Name of Work: FABRICATION & LAYING OF ONE 4", ONE 6" & ONE 8" N PERMANENT CATHODIC PROTECTION IN THE ABOVE LINES INCLUD

Contract No: DRC1125306 Bidder Name:

Sl. No. 8

8.1

8.2

Signature of Tenderer with seal

Tender Inviting Authority: Chief Manager (Contracts),IOCL(AOD),Digboi

Name of Work: FABRICATION & LAYING OF ONE 4", ONE 6" & ONE 8" N PERMANENT CATHODIC PROTECTION IN THE ABOVE LINES INCLUD

Contract No: DRC1125306 Bidder Name:

Sl. No. 8.3

8.4

8.5

Signature of Tenderer with seal

Tender Inviting Authority: Chief Manager (Contracts),IOCL(AOD),Digboi

Name of Work: FABRICATION & LAYING OF ONE 4", ONE 6" & ONE 8" N PERMANENT CATHODIC PROTECTION IN THE ABOVE LINES INCLUD

Contract No: DRC1125306 Bidder Name:

Sl. No. 8.6

8.7

8.8

8.9

Signature of Tenderer with seal

Tender Inviting Authority: Chief Manager (Contracts),IOCL(AOD),Digboi

Name of Work: FABRICATION & LAYING OF ONE 4", ONE 6" & ONE 8" N PERMANENT CATHODIC PROTECTION IN THE ABOVE LINES INCLUD

Contract No: DRC1125306 Bidder Name:

Sl. No. 8.10

9.1

9.2

Signature of Tenderer with seal

Tender Inviting Authority: Chief Manager (Contracts),IOCL(AOD),Digboi

Name of Work: FABRICATION & LAYING OF ONE 4", ONE 6" & ONE 8" N PERMANENT CATHODIC PROTECTION IN THE ABOVE LINES INCLUD

Contract No: DRC1125306 Bidder Name:

Sl. No. 9.3

9.4

9.5

Signature of Tenderer with seal

Tender Inviting Authority: Chief Manager (Contracts),IOCL(AOD),Digboi

Name of Work: FABRICATION & LAYING OF ONE 4", ONE 6" & ONE 8" N PERMANENT CATHODIC PROTECTION IN THE ABOVE LINES INCLUD

Contract No: DRC1125306 Bidder Name:

Sl. No. 9.6

9.7

Signature of Tenderer with seal

Tender Inviting Authority: Chief Manager (Contracts),IOCL(AOD),Digboi

Name of Work: FABRICATION & LAYING OF ONE 4", ONE 6" & ONE 8" N PERMANENT CATHODIC PROTECTION IN THE ABOVE LINES INCLUD

Contract No: DRC1125306 Bidder Name:

Sl. No. 9.8

9.9

Signature of Tenderer with seal

Tender Inviting Authority: Chief Manager (Contracts),IOCL(AOD),Digboi

Name of Work: FABRICATION & LAYING OF ONE 4", ONE 6" & ONE 8" N PERMANENT CATHODIC PROTECTION IN THE ABOVE LINES INCLUD

Contract No: DRC1125306 Bidder Name:

Sl. No. 9.10

9.11

Signature of Tenderer with seal

Tender Inviting Authority: Chief Manager (Contracts),IOCL(AOD),Digboi

Name of Work: FABRICATION & LAYING OF ONE 4", ONE 6" & ONE 8" N PERMANENT CATHODIC PROTECTION IN THE ABOVE LINES INCLUD

Contract No: DRC1125306 Bidder Name:

Sl. No. 9.12

9.13

Signature of Tenderer with seal

Tender Inviting Authority: Chief Manager (Contracts),IOCL(AOD),Digboi

Name of Work: FABRICATION & LAYING OF ONE 4", ONE 6" & ONE 8" N PERMANENT CATHODIC PROTECTION IN THE ABOVE LINES INCLUD

Contract No: DRC1125306 Bidder Name:

Sl. No. 9.14

9.15

Signature of Tenderer with seal

Tender Inviting Authority: Chief Manager (Contracts),IOCL(AOD),Digboi

Name of Work: FABRICATION & LAYING OF ONE 4", ONE 6" & ONE 8" N PERMANENT CATHODIC PROTECTION IN THE ABOVE LINES INCLUD

Contract No: DRC1125306 Bidder Name:

Sl. No. 9.16

9.17

Signature of Tenderer with seal

Tender Inviting Authority: Chief Manager (Contracts),IOCL(AOD),Digboi

Name of Work: FABRICATION & LAYING OF ONE 4", ONE 6" & ONE 8" N PERMANENT CATHODIC PROTECTION IN THE ABOVE LINES INCLUD

Contract No: DRC1125306 Bidder Name:

Sl. No. 10

Signature of Tenderer with seal

Tender Inviting Authority: Chief Manager (Contracts),IOCL(AOD),Digboi

Name of Work: FABRICATION & LAYING OF ONE 4", ONE 6" & ONE 8" N PERMANENT CATHODIC PROTECTION IN THE ABOVE LINES INCLUD

Contract No: DRC1125306 Bidder Name:

Sl. No. 10.1

Signature of Tenderer with seal

Tender Inviting Authority: Chief Manager (Contracts),IOCL(AOD),Digboi

Name of Work: FABRICATION & LAYING OF ONE 4", ONE 6" & ONE 8" N PERMANENT CATHODIC PROTECTION IN THE ABOVE LINES INCLUD

Contract No: DRC1125306 Bidder Name:

Sl. No. 10.2 10.3

10.4 10.5 10.6

Signature of Tenderer with seal

Tender Inviting Authority: Chief Manager (Contracts),IOCL(AOD),Digboi

Name of Work: FABRICATION & LAYING OF ONE 4", ONE 6" & ONE 8" N PERMANENT CATHODIC PROTECTION IN THE ABOVE LINES INCLUD

Contract No: DRC1125306 Bidder Name:

Sl. No. 10.7

10.8

10.9

Signature of Tenderer with seal

Tender Inviting Authority: Chief Manager (Contracts),IOCL(AOD),Digboi

Name of Work: FABRICATION & LAYING OF ONE 4", ONE 6" & ONE 8" N PERMANENT CATHODIC PROTECTION IN THE ABOVE LINES INCLUD

Contract No: DRC1125306 Bidder Name:

Sl. No. 10.10

10.11

11 11.1

Signature of Tenderer with seal

Tender Inviting Authority: Chief Manager (Contracts),IOCL(AOD),Digboi

Name of Work: FABRICATION & LAYING OF ONE 4", ONE 6" & ONE 8" N PERMANENT CATHODIC PROTECTION IN THE ABOVE LINES INCLUD

Contract No: DRC1125306 Bidder Name:

Sl. No. 11.2 11.3 11.4

11.5

Signature of Tenderer with seal

Tender Inviting Authority: Chief Manager (Contracts),IOCL(AOD),Digboi

Name of Work: FABRICATION & LAYING OF ONE 4", ONE 6" & ONE 8" N PERMANENT CATHODIC PROTECTION IN THE ABOVE LINES INCLUD

Contract No: DRC1125306 Bidder Name:

Sl. No. 11.6

11.7

11.8 11.9

Signature of Tenderer with seal

Tender Inviting Authority: Chief Manager (Contracts),IOCL(AOD),Digboi

Name of Work: FABRICATION & LAYING OF ONE 4", ONE 6" & ONE 8" N PERMANENT CATHODIC PROTECTION IN THE ABOVE LINES INCLUD

Contract No: DRC1125306 Bidder Name:

Sl. No. 11.10

11.11 11.12

11.13

11.14

Signature of Tenderer with seal

Tender Inviting Authority: Chief Manager (Contracts),IOCL(AOD),Digboi

Name of Work: FABRICATION & LAYING OF ONE 4", ONE 6" & ONE 8" N PERMANENT CATHODIC PROTECTION IN THE ABOVE LINES INCLUD

Contract No: DRC1125306 Bidder Name:

Sl. No. 11.15

11.16

11.17

11.18 Total estimated cost in Figures

Signature of Tenderer with seal

Tender Inviting Authority: Chief Manager (Contracts),IOCL(AOD),Digboi

Name of Work: FABRICATION & LAYING OF ONE 4", ONE 6" & ONE 8" N PERMANENT CATHODIC PROTECTION IN THE ABOVE LINES INCLUD

Contract No: DRC1125306 Bidder Name:

Sl. No. Quoted Amount Quoted rate in Words

Signature of Tenderer with seal

viting Authority: Chief Manager (Contracts),IOCL(AOD),Digboi

Work: FABRICATION & LAYING OF ONE 4", ONE 6" & ONE 8" NB 3LPE COATED SEAMLESS PRODUCT PIPELINES FROM NTF TO NENT CATHODIC PROTECTION IN THE ABOVE LINES INCLUDING LAYING OF 40 mm OD HDPE PIPE AS OFC CONDUIT, OFC BL

No: DRC1125306

SCHEDULE OF WORKS Description of work

Signature of Tenderer with seal

viting Authority: Chief Manager (Contracts),IOCL(AOD),Digboi

Work: FABRICATION & LAYING OF ONE 4", ONE 6" & ONE 8" NB 3LPE COATED SEAMLESS PRODUCT PIPELINES FROM NTF TO NENT CATHODIC PROTECTION IN THE ABOVE LINES INCLUDING LAYING OF 40 mm OD HDPE PIPE AS OFC CONDUIT, OFC BL

No: DRC1125306

SCHEDULE OF WORKS Description of work

MAIN LINE LAYING : Laying of Owner-supplied pre-coated mild steel/ CS line pipe, including arranging all additional land required for Contractor's storage, fabrication, access for construction site, movement of construction equipment etc., receiving and taking over Owner-supplied materials, handling, transportation etc. from Owner issue point to work site, stringing along Right of Way (ROW), providing labour, equipment and supply of other inputs & materials/ consumables necessary to perform and complete the work in all respects in accordance with the contract including, but not limited to, the following works: - Taking delivery of coated pipe from the stockpile location - Clearing and grading of ROW / additional land arranged for construction purpose including dewatering etc., - Trenching to all depths to maintain clear earth cover as per specification and to fit minimum bend radius, by excavation in all kinds of terrain & soil. - Carrying out repair of pipe defects, replacement in the case of non-repairable defects and repairing damages to pipe coating including defects/ damages occurring during transportation & handling. - Aligning, bending, lining up, cutting and bevelling (as required) of pipes for field adjustments, welding (manual / semi-automatic / automatic), physical inspection of all weld joints by qualified welding engineer/ inspector, carrying out repair of weld-joints found defective. - Carrying out 100% radiographic inspection of all field weld joints for initial 1 km (for 8" NB, 6" NB & 4" NB pipeline section only) and crossings & other specific locations as per specification and Special Conditions of Contract and 20% radiographic inspection for the balance portion (excluding crossings & other specific locations), and destructive testing of one weld joint in Spread as per specification and direction of Site Engineer including providing crawler type automatic XRay machine/ external X-Ray machine and all other requisite equipment, labour, supervision, materials, films, consumables, all facilities and personnel to process, develop, examine and interpret radiographs (by qualified and experienced Radiography Inspector) and other tests as required, carrying out repair of weld-joints found defective, carrying out re-radiography and other tests as required on repaired joints, etc. - Carrying out coating of all field joints by qualified coating insulators, including supply of approved joint coating materials, providing all equipment, materials and consumables necessary to carry out the job as per manufacturer recommendation. - Carrying out holiday detection and repair of coating, if any. -Laying pipeline by open cut method at crossings viz. cart track, metalled/ un-metalled road, minor watercourses, nalas, drains, etc. (except cased and submerged crossings / marshy areas) using carrier pipe and restoration of the site to original condition including performance of additional works for strengthening of banks of watercourses, stabilisation of slopes in hillocks, etc. - Lowering the pipeline in trench, tieing-in, backfilling with excavated earth and/or other suitable soft soil. - Carrying out air cleaning, gauge pigging and hydrostatic testing (to specified pressure) of the complete pipeline including providing "pre-testing" of designated sections as approved by Engineer-in-Charge, providing all equipment, pumps, fittings, instruments, dead weight tester etc. and services, supervision, labour, consumables, testing of water, supply & injection of corrosion inhibitor, locating leaks, if any, and rectification of defects attributable to Contractor, re-testing after rectification etc. and cleaning the pipeline section after successful hydrotesting.- All tie-ins -Installing all inline fittings including but not limited to all SW fittings, flanged Valves / MOVs etc as directed by the OWNER. - Final clean-up and restoration of ROW and disposal of debris and surplus material to designated disposal areas, as directed. - Supply of all materials (other than those specifically undertaken to be supplied by the Owner under the contract) necessary for performance of work or for temporary or permanent incorporation in the works, and all other acts, deeds, matters and things necessary to make the pipeline ready for commissioning including completing the works in all respects as per drawings, specifications and instructions of Engineer-in-Charge. - Laying of the pipeline sections (individually) at both sides of cased crossing locations (in order to negotiate the distance between common trench to individual cased crossing locations) Laying 1 No. 8" NB 40-Sch ASTM A106 Grade B, 1 No. 6" NB 40-Sch ASTM A106 Grade B and 1 No. 4" NB 40-Sch ASTM A106 Grade B externally coated with 3LPE coating and laying 40mm OD HDPE pipe and accessories(in the same trench). Signature of Tenderer with seal NOTE : I) Laying all the above 8"NB, 6"NB, 4" NB steel pipes & 40mm OD HDPE pipe shall be considered as ONE unit for payment purpose.

viting Authority: Chief Manager (Contracts),IOCL(AOD),Digboi

Work: FABRICATION & LAYING OF ONE 4", ONE 6" & ONE 8" NB 3LPE COATED SEAMLESS PRODUCT PIPELINES FROM NTF TO NENT CATHODIC PROTECTION IN THE ABOVE LINES INCLUDING LAYING OF 40 mm OD HDPE PIPE AS OFC CONDUIT, OFC BL

No: DRC1125306

SCHEDULE OF WORKS Description of work

CASED CROSSINGS: Laying cased crossings using casing pipes and externally 3LPE coated and internally epoxy coated carrier pipes of various sizes, according to drawings/ specification(s) and providing all works, labour, inputs and materials/ consumables necessary to perform and complete the works in all respect in accordance with the contract, including collecting the pipes and other Owner-supplied materials from Owner issue point and loading, transporting them to site, setting out the works, aligning and welding the casing and carrier pipes, 100% radiography of weld joints of carrier pipes, field joint coating, holiday detection & repair of coating, applying atleast two coats of bitumastic paint over coat of suitable primer to external surface of casing pipe, excavating/ trenching and boring/directional drilling in all kinds of soil including rocky strata,if any, inserting the casing pipe into the bore, pre-hydrostatic testing of the carrier pipe and replacement / rectification of defects / pipes, suppy & installation of inter-locking type HDPE casing insulators (without metallic nuts & bolts) on carrier pipe, sealing the ends of casing pipe, as per procedure given in specifications, with heat shrinkable wraparound type end seal of approved make, fixing of vent pipes at the ends of the casing pipe, priming and applying two coats of coal tar based epoxy paint on underground portion of vent pipes, measuring final resistance between carrier pipe and casing, and doing preparation work necessary to produce correct resistance, applying one coat of primer and two coats of epoxy paint to all exposed and overground fittings & piping, proper compaction of backfill below carrier pipe at either ends and strengthening with sand bags to prevent settlement of carrier pipe and damage to insulators, final clean-up and restoration of the site and disposal of wastes and surplus in accordance with the contract and supply of all materials (other than those specifically undertaken to be supplied by the Owner under contract) necessary for or in the performance of the work or for temporary or permanent incorporation in the works, and all other acts, matters and things necessary Signature of Tenderer with seal to make the pipeline ready for commissioning in all respects. NOTE :

viting Authority: Chief Manager (Contracts),IOCL(AOD),Digboi

Work: FABRICATION & LAYING OF ONE 4", ONE 6" & ONE 8" NB 3LPE COATED SEAMLESS PRODUCT PIPELINES FROM NTF TO NENT CATHODIC PROTECTION IN THE ABOVE LINES INCLUDING LAYING OF 40 mm OD HDPE PIPE AS OFC CONDUIT, OFC BL

No: DRC1125306

SCHEDULE OF WORKS Description of work

SUBMERGED CROSSINGS:Laying submerged crossings using pipes with or without concrete sheathing across major rivers, canals, lakes, ponds, etc. and providing all works, labour, inputs & materials/ consumables necessary to perform and complete the work in all respects in accordance with the contract, arranging the required additional land for construction purpose, transportation of owner supplied material, preparation of site, aligning, bending, lining up and welding the pipe, 100% radiography of weld joints, coating of field joints, holiday detection and repair of coating, hydrostatic testing (both pre & post installation) and replacement of pipes/ defects, excavation of the trench to required depth in all kinds of soil and conditions including rock trenching and maintenance of trench in all kind of soil including rocky strata, if any and laying of the pipeline in approved trench, backfilling and final clean-up, stabilisation of the excavated banks by additional means, disposal of waste and surplus in accordance with the contract, and supply of materials (other than those specifically undertaken to be supplied by the Owner under the contract) necessary for or in the performance of the work or for temporary or permanent incorporation in the works and all other acts, matters and things necessary to complete the pipeline/ crossings in all respects according to the contract. Using 1 No. 8" NB , 1 No. 6" NB& 1 No. 4" NB, ASTM A106 Grade-B (externally coated with 3LPE coating) and 40mm OD HDPE pipe ( in a single trench width). NOTE : I) Laying all these 8"NB, 6"NB , 4" NB pipes and 40mm OD HDPE pipe shall be considered as ONE unit for payment purpose.

Signature of Tenderer with seal

viting Authority: Chief Manager (Contracts),IOCL(AOD),Digboi

Work: FABRICATION & LAYING OF ONE 4", ONE 6" & ONE 8" NB 3LPE COATED SEAMLESS PRODUCT PIPELINES FROM NTF TO NENT CATHODIC PROTECTION IN THE ABOVE LINES INCLUDING LAYING OF 40 mm OD HDPE PIPE AS OFC CONDUIT, OFC BL

No: DRC1125306

SCHEDULE OF WORKS Description of work

CONCRETE COATING (50MM): Providing and laying concrete sheathing on the carrier pipe i.e. continuous concrete coating (1:1.5:3) using specified (approved) wire mesh reinforcement as shown in the standard drawing, including supply of cement, steel wire mesh, aggregate, sand, shuttering and all other materials, consumables and inputs etc. required to complete the job and as per direction of Engineer-in-Charge. 50mm thick concrete coating over 8" NB, 6" NB & 4" NB pipes (For each pipeline sections separately) NOTE : I)Payment shall be made for the actual length of pipe coated with concrete. II)The rates shall include compensation for additional hardship caused in handling and/or lowering the pipe with concrete coating. The above shall be executed at the discretion of Engineer-in-Charge. For 8" Item dia pipes

Signature of Tenderer with seal

viting Authority: Chief Manager (Contracts),IOCL(AOD),Digboi

Work: FABRICATION & LAYING OF ONE 4", ONE 6" & ONE 8" NB 3LPE COATED SEAMLESS PRODUCT PIPELINES FROM NTF TO NENT CATHODIC PROTECTION IN THE ABOVE LINES INCLUDING LAYING OF 40 mm OD HDPE PIPE AS OFC CONDUIT, OFC BL

No: DRC1125306

SCHEDULE OF WORKS Description of work

For 6" dia pipes

For 4 dia pipes

PIPE LINE MARKERS: Supply of all materials necessary for fabrication and installation of kilometre posts, direction markers and warning signs at the locations as per specifications, excavating & grouting in cement concrete 1:4:8, and all other works necessary for fabrication & installation of the markers including cleaning, priming & applying two coats of coal tar based epoxy paint on underground portions, supply and application of one coat of primer and two coats of epoxy paint of approved colour and quality on overground portion, stencil letter cutting for number, direction, chainage etc. and restoration of site to original condition and all other acts, deeds, matters and things and work, labour, inputs and materials/ consumables necessary to perform and complete the work in all respects as per exhibit

Signature of Tenderer with seal

viting Authority: Chief Manager (Contracts),IOCL(AOD),Digboi

Work: FABRICATION & LAYING OF ONE 4", ONE 6" & ONE 8" NB 3LPE COATED SEAMLESS PRODUCT PIPELINES FROM NTF TO NENT CATHODIC PROTECTION IN THE ABOVE LINES INCLUDING LAYING OF 40 mm OD HDPE PIPE AS OFC CONDUIT, OFC BL

No: DRC1125306

SCHEDULE OF WORKS Description of work

KM Post

Direction markers

Warning Signs

Signature of Tenderer with seal

viting Authority: Chief Manager (Contracts),IOCL(AOD),Digboi

Work: FABRICATION & LAYING OF ONE 4", ONE 6" & ONE 8" NB 3LPE COATED SEAMLESS PRODUCT PIPELINES FROM NTF TO NENT CATHODIC PROTECTION IN THE ABOVE LINES INCLUDING LAYING OF 40 mm OD HDPE PIPE AS OFC CONDUIT, OFC BL

No: DRC1125306

SCHEDULE OF WORKS Description of work

CALLIPER SURVEY: Preparation and cleaning of the pipeline/ pipeline sections by running series of pigs for cleaning the line from debris, water & making it dry for launching calliper pigs, launching and receiving the electronic & standard calliper pigs, data retrieval, interpretation of data and submission of reports in the form acceptable to the Owner, including rectification of defects observed from calliper survey, including supply of all labour, materials, equipment & instruments, calliper pigs, fabrication of launching & receiving barrels, all complete for ascertaining the geometry of the pipeline. 8" NB Pipeline (1 No.), 6" NB Pipeline (1 No.) & 4" NB Pipeline (1 No.)(Item rate shall be for each pipeline sections separately) PRESERVATION OF PIPELINE(OPTIONAL): Preservation of entire pipeline / pipeline sections by using inhibited water (with uniform inhibitor concentration adequate for 6 (six) months preservation period as per manufacturer's recommendation), including arranging water, laboratory testing of water, supply of approved inhibitors, all equipment, manpower, consumables etc. complete as per specifications and direction of Site Engineer / Engineerin-Charge 8" NB Pipeline (1 No.), 6" NB Pipeline (1 No.) & 4" NB Pipeline (1 No.)(Item rate shall be for each pipeline sections separately)

Signature of Tenderer with seal

viting Authority: Chief Manager (Contracts),IOCL(AOD),Digboi

Work: FABRICATION & LAYING OF ONE 4", ONE 6" & ONE 8" NB 3LPE COATED SEAMLESS PRODUCT PIPELINES FROM NTF TO NENT CATHODIC PROTECTION IN THE ABOVE LINES INCLUDING LAYING OF 40 mm OD HDPE PIPE AS OFC CONDUIT, OFC BL

No: DRC1125306

SCHEDULE OF WORKS Description of work

CATHODIC PROTECTION SYSTEM:(SUPPLY )

SUPPLY MAINLINE CATHODIC PROTECTION SYSTEM : Supply of materials as given below complete in all respects, as per the specification as detailed in the tender document including transportation to site and storing : Supply of polarisation cells (including its backfill material packed in cannister) of approved make & as per specification for protection of MOVs and at HT line crossing locations.

Signature of Tenderer with seal

viting Authority: Chief Manager (Contracts),IOCL(AOD),Digboi

Work: FABRICATION & LAYING OF ONE 4", ONE 6" & ONE 8" NB 3LPE COATED SEAMLESS PRODUCT PIPELINES FROM NTF TO NENT CATHODIC PROTECTION IN THE ABOVE LINES INCLUDING LAYING OF 40 mm OD HDPE PIPE AS OFC CONDUIT, OFC BL

No: DRC1125306

SCHEDULE OF WORKS Description of work

Supply of Grounding cells ( including its backfill material packed in cannister) of approved make & as per specification for protection of insulating couplings & surges .

CATHODIC PROTECTION UNIT : Supply of Cathodic Protection Transformer Rectifier (CPTR) unit with integrated Electronic Control Unit complete in all respects, as per the specification as detailed in the tender document including transportation to site and storing with all its accessories to ensure trouble free operation with SCADA linkage facility : 25 V, 25 A DC . Supply of Flame proof, weather proof Junction box of IP:55 Degree of protection of approved make conforming to relevent drg as in the technical documents in the tender. (including but not limited to 9200-99900-404-606-00) as per specification detailed in the tender document complete with all connecting terminal & shunts, other fittings, DC bus, MS plate box, bakelite terminal board, cable termination bolts, painting , resistors etc. as per specifications (Cathode Junction Box & Anode Junction Box) .

Signature of Tenderer with seal

viting Authority: Chief Manager (Contracts),IOCL(AOD),Digboi

Work: FABRICATION & LAYING OF ONE 4", ONE 6" & ONE 8" NB 3LPE COATED SEAMLESS PRODUCT PIPELINES FROM NTF TO NENT CATHODIC PROTECTION IN THE ABOVE LINES INCLUDING LAYING OF 40 mm OD HDPE PIPE AS OFC CONDUIT, OFC BL

No: DRC1125306

SCHEDULE OF WORKS Description of work

Supply of 1C x 35 sq.mm. XLPE insulated , PVC sheathed, armoured copper conductor cable, 1100 v grade conforming to IS: 7098 (P1) , Anode header cable & Cathode header cable as per specifications and approved make. Supply of 1C x 25 sq.mm. XLPE insulated, PVC sheathed, armoured copper conductor cable, 1100 v grade conforming to IS:7098 (P1)for bonding purpose as per specifications and approved make Supply of 2C x 6 sq.mm. XLPE insulated, armoured copper conductor cable, 1100 v grade conforming to IS: 7098 (P-1) for Reference cell feedback to TRU, as per specifications and approved make Supply of Cu-Cuso4 permanent Half cell, as per specifications of approved make .

Signature of Tenderer with seal

viting Authority: Chief Manager (Contracts),IOCL(AOD),Digboi

Work: FABRICATION & LAYING OF ONE 4", ONE 6" & ONE 8" NB 3LPE COATED SEAMLESS PRODUCT PIPELINES FROM NTF TO NENT CATHODIC PROTECTION IN THE ABOVE LINES INCLUDING LAYING OF 40 mm OD HDPE PIPE AS OFC CONDUIT, OFC BL

No: DRC1125306

SCHEDULE OF WORKS Description of work

Supply of Cu- Cuso4 portable Half cell, as per specifications of approved make .

Composite Work:

Installation of polarisation cells as per specifications including connecting the cable to the pipe, repair of coat & wrap, terminating the cables in the TLP box with cable lugs, sealing material, laying of cable, testing & commissioning of grounding cell etc. all complete with required material, excavation, backfilling etc. as per specification and directions of Site Engineer. Installation of grounding cells including connecting the cable to the pipe/MOV, repair of coat & wrap, terminating the cables in the TLP box with cable lugs, sealing material, laying of cable, testing & commissioning of grounding cell etc. all complete with required material, excavation, backfilling etc. as per specification and directions of Site Engineer.

Signature of Tenderer with seal

viting Authority: Chief Manager (Contracts),IOCL(AOD),Digboi

Work: FABRICATION & LAYING OF ONE 4", ONE 6" & ONE 8" NB 3LPE COATED SEAMLESS PRODUCT PIPELINES FROM NTF TO NENT CATHODIC PROTECTION IN THE ABOVE LINES INCLUDING LAYING OF 40 mm OD HDPE PIPE AS OFC CONDUIT, OFC BL

No: DRC1125306

SCHEDULE OF WORKS Description of work

Installation of permanent half cells including connecting the cable in the TLP etc. with cable lugs, sealing material, laying of cable, testing & commissioning of cell etc. all complete with required material, excavation, backfilling etc. as per specifications, recommendation of cell supplier and directions of Site Engineer. Conducting " Coating-Resistance Survey" for calculation of effective coating resistance of the new pipelines in ohms-sq.m. along the entire pipeline route and plotting on SEMILOG or X-Y GRAPH & submitting the report in graphical form as per Specification / approved procedure.(For all four Pipelines) Conducting Close Interval ON/OFF Potential Logging Survey at an interval of 1 m over the buried line in the right of way including the cost of all expert manpower, transportation and camping facilities etc. to their employees, materials, test instruments, equipments, consumables etc., required for the survey as per the standard specifications, identification of areas/locations where coating repair is required alongwith suggestion for remedial measures etc. including the submission of draft reports in 2 sets and incorporation of owner's comments in the draft report and final reports in 6 sets including one soft copy containing the survey results in the graphical as well as tabular forms computerised colour print and complete in all respects.

Signature of Tenderer with seal

viting Authority: Chief Manager (Contracts),IOCL(AOD),Digboi

Work: FABRICATION & LAYING OF ONE 4", ONE 6" & ONE 8" NB 3LPE COATED SEAMLESS PRODUCT PIPELINES FROM NTF TO NENT CATHODIC PROTECTION IN THE ABOVE LINES INCLUDING LAYING OF 40 mm OD HDPE PIPE AS OFC CONDUIT, OFC BL

No: DRC1125306

SCHEDULE OF WORKS Description of work

Conducting "Soil Resistivity Survey" at anode bed location after ascertaining its suitablity with respect to the existing system , for installation of Anode Bed (deep / shallow), as per the specification and instructions of Engineer-in-Charge. Conducting Direct Current Voltage Gradient Survey over the buried line to identify / pin point the coating defects in the right of way including the cost of all expert manpower, transportation and camping facilities etc. to their employees, materials, test instruments, equipments, consumables etc., required for the survey as per the standard specifications, identification of areas/locations where coating repair is required alongwith suggestion for remedial measures etc. including the submission of draft reports in 2 sets and incorporation of owner's comments in the draft report and final reports in 6 sets including one soft copy containing the survey results in the graphical as well as tabular forms computerised colour print and complete in all respects. Note : The item includes establishing the coating defect at specified locations (maximum 5% of overall coating defects) by excavation in

Signature of Tenderer with seal

viting Authority: Chief Manager (Contracts),IOCL(AOD),Digboi

Work: FABRICATION & LAYING OF ONE 4", ONE 6" & ONE 8" NB 3LPE COATED SEAMLESS PRODUCT PIPELINES FROM NTF TO NENT CATHODIC PROTECTION IN THE ABOVE LINES INCLUDING LAYING OF 40 mm OD HDPE PIPE AS OFC CONDUIT, OFC BL

No: DRC1125306

SCHEDULE OF WORKS Description of work

Conducting AC interference survey, to detect presence of any AC voltage(induced owing to proximity of any HT transmission line (66 KV and above) crossing or running parallel within a distance of 20 M from the pipeline alignment as per approved procedure. The work shall be completed along with installation, commissioning of polarisation cells (covered under separate item of SOR) & with supply of any other equipments required for mitigation of AC influence on the pipelines. The work includes all tools, tackles, consumables etc. all complete, required for survey / test as deemed necessary and as per the directions of the site engineer. (For all the pipelines). Conducting Mututal Interference Survey among the new and existing pipelines (foreign) by taking PSP survey of all the pipelines as per approved procedure to determine level of interference at different places along the pipleine and at point of crossing in common ROW including identifying points and providing the data/ record in graphical form and carrying out all necessary work for mitigating the interference observed among the pipelines , including retesting the same to ensure efficacy of the remedial measures undertaken.The contractor shall submit a full final report with detail PSP readings at all TLPs along with graphs in six sets.The item should be complete

Signature of Tenderer with seal

viting Authority: Chief Manager (Contracts),IOCL(AOD),Digboi

Work: FABRICATION & LAYING OF ONE 4", ONE 6" & ONE 8" NB 3LPE COATED SEAMLESS PRODUCT PIPELINES FROM NTF TO NENT CATHODIC PROTECTION IN THE ABOVE LINES INCLUDING LAYING OF 40 mm OD HDPE PIPE AS OFC CONDUIT, OFC BL

No: DRC1125306

SCHEDULE OF WORKS Description of work

Erection, testing and commissioning of CPTR unit integrated with ECU; including supply and installation of all facilities, materials etc., : including fuses, all supporting structures, supply, laying and connecting the 1100 V Grade power cable (4Cx16 sqmm Cu. conductor XLPE insulated UnArmoured Cable from PMCC to CPTR), laying & connection of feedback cable from permanent half cells (2C x 6 sqmm cable supply & laying covered as separate item elsewhere in the SOR) providing the earthing arrangement, wiring and making anode & cathode cable connections to the CP rectifier, and obtaining necessary certificates from the statutory authorities for the installation. All related foundation works required shall be in the scope of this contractor. The work includes furnishing the test results by conducting all the NO LOAD and ON LOAD tests on the rectifier and adjusting its tappings as required and of testing the pipeline section Laying of anode header cable connection for the Cathodic Protection station; including installation & laying the cable in all types of strata and soil (including rock) by making the trench, back filling the trench, connecting the end of cable to cathodic protection station and providing the required PVC sleeve and copper end lug to the header cable, terminating in the Anode Junction Box & CP station, work complete in all respects including cost of all labour, material, tools etc. as per specification and instruction of Engineer-In-Charge and approved drawings.

Signature of Tenderer with seal

viting Authority: Chief Manager (Contracts),IOCL(AOD),Digboi

Work: FABRICATION & LAYING OF ONE 4", ONE 6" & ONE 8" NB 3LPE COATED SEAMLESS PRODUCT PIPELINES FROM NTF TO NENT CATHODIC PROTECTION IN THE ABOVE LINES INCLUDING LAYING OF 40 mm OD HDPE PIPE AS OFC CONDUIT, OFC BL

No: DRC1125306

SCHEDULE OF WORKS Description of work

Laying of Cathode cable and connection to the pipeline at locations of installations of C.P.station; including supply of all the required materials, including cad welding / pin brazing and sealing materials, PVC sleeve copper cable and lug etc., laying of the cable as per specified procedure in trenches in all types of strata and soil (including rock), exposing and cleaning the pipe and making the coating with repair matreial as specified in the document, backfilling the excavations, etc. providing the PVC sleeve and copper end lug to the cable, etc. complete in all respects, including the cost of all labour, materials tools etc., complete as per specification and instructions of Laying of 2Cx 6.0 sq.mm PE/PVC insulated armoured copper cable from the three locations of installation (at 3 permanent reference cells) along the pipeline to CP unit of each cathodic protection stations, and cad welding the cable with pipe end, connecting the cable to copper-copper sulphate permanent half cell, installing the permanent half cell including supplying all materials such as sealing materials, PVC sleeve, copper cable end lugs, laying the cable in trench of 1 meter depth (in all types of strata and soil (including rock) along with cathode header cable, connecting the cable with CP unit, zero centre voltmeter, desired control point of closed loop control system, complete in all respects including cost of all labour, tools, materials etc. as per specification and instructions of Site Engineer.

Signature of Tenderer with seal

viting Authority: Chief Manager (Contracts),IOCL(AOD),Digboi

Work: FABRICATION & LAYING OF ONE 4", ONE 6" & ONE 8" NB 3LPE COATED SEAMLESS PRODUCT PIPELINES FROM NTF TO NENT CATHODIC PROTECTION IN THE ABOVE LINES INCLUDING LAYING OF 40 mm OD HDPE PIPE AS OFC CONDUIT, OFC BL

No: DRC1125306

SCHEDULE OF WORKS Description of work

Laying of 1 core, 25 sq.mm. bond cable and making connection to the pipeline at location of installations of C.P.station in Common ROW as per requirement based on Mutual Interference Survey recommendations and or approved design ; including supply of all the required materials, including but not limited to cad welding / pin brazing and sealing materials, PVC sleeve copper cable and lug etc., laying of the cable as per specified procedure in trenches in all types of strata and soil (including rock), exposing and cleaning the pipe and making the necessary cable connection to the pipe, using cad- welding techniques as specified, repairing the coating with repair material as specified in the document, backfilling the excavations, etc., terminating the cable in the Type -C test stations, providing the PVC sleeve recording and copper end lug to thethe cable, etc. complete in readings all respects, including thepipeline cost of all materials toolsof etc., as Measuring, and submitting cathodic protection along the entire by labour, repeated adjustments the complete settings of the owners TRUs/ECUs etc as per specifications for achieving full/maximum protection of all the stretches as per the criteria of protection mentioned in the specifications. Measuring the relevant readings at the cathodic protection stations and "pipe to soil potential" readings at all the test lead locations along the pipeline including the CP station parameters like current(AC/DC), voltage(AC/DC),circuit resistance,battery voltage/current etc.,preparing and submitting pipe to soil potential profile, graphs and other data pertaining to the cathodic protection of the pipeline,job complete in all respects as per specification and instructions of Site Engineer, including cost of all

Signature of Tenderer with seal

viting Authority: Chief Manager (Contracts),IOCL(AOD),Digboi

Work: FABRICATION & LAYING OF ONE 4", ONE 6" & ONE 8" NB 3LPE COATED SEAMLESS PRODUCT PIPELINES FROM NTF TO NENT CATHODIC PROTECTION IN THE ABOVE LINES INCLUDING LAYING OF 40 mm OD HDPE PIPE AS OFC CONDUIT, OFC BL

No: DRC1125306

SCHEDULE OF WORKS Description of work

Commisioning of CP system: Final Commissioning of the impressed current cathodic protection system for the mainline for achieving full protection as per protection criteria as mentioned in the specifictions through repeated adjustments of the CP units after installation of galvanic anodes for hot spot protection and mitigation of AC/ DC interference, if any and submission of the resultant data to the owner and testing, measuring, recording and submitting all these data once again after the lapse of a period as per specifications / directions of the Site engineer, including the cost ofrecording all labourand tools and materials as required, complete in all respect. Testing, measuring, submitting the temporary cathodic protection readings along the entire pipeline by connecting or disconnecting the Mg anodes, for optimal protection through test lead box, (in Nos.) measuring the relevant reading at the cathodic protection stations and "pipe to soil potential" readings at all the test lead locations along the pipeline and at stations, preparing and submiting relative pipe to soil potential profile and other data and as specifications and submitting all the relevant data pertaining to the temporary cathodic protection of the pipeline, job complete in all respects as per the specifications and instructions of site engineer / EIC, including cost of all labour, instruments and services rendered. The readings shall be furnished as per the specifications. Also, prepare & submit technical report including detail engineering & drawings for TCP system and other documentations as mentioned in the

Signature of Tenderer with seal

viting Authority: Chief Manager (Contracts),IOCL(AOD),Digboi

Work: FABRICATION & LAYING OF ONE 4", ONE 6" & ONE 8" NB 3LPE COATED SEAMLESS PRODUCT PIPELINES FROM NTF TO NENT CATHODIC PROTECTION IN THE ABOVE LINES INCLUDING LAYING OF 40 mm OD HDPE PIPE AS OFC CONDUIT, OFC BL

No: DRC1125306

SCHEDULE OF WORKS Description of work

ELECTRICAL :

Signature of Tenderer with seal

viting Authority: Chief Manager (Contracts),IOCL(AOD),Digboi

Work: FABRICATION & LAYING OF ONE 4", ONE 6" & ONE 8" NB 3LPE COATED SEAMLESS PRODUCT PIPELINES FROM NTF TO NENT CATHODIC PROTECTION IN THE ABOVE LINES INCLUDING LAYING OF 40 mm OD HDPE PIPE AS OFC CONDUIT, OFC BL

No: DRC1125306

SCHEDULE OF WORKS Description of work

Supply, Installation, testing and commissioning of Tests Lead posts (at locations, as directed); and including supply of weather proof test lead box with bakelite strip and brass bolt terminals, 4 inch MS pipe welded at one end with a separate MS plate to fit with the test lead box with a base plate welded at bottom , providing of PVC hard pipe for providing cable entry through foundation, erection of the Test Lead point over concrete foundation, supply and connection of cable to pipe & to the brass terminal bolt/bolts inside the test lead box, jointing the cables to pipe (using cad welding/ pin brazing technique), as specified, repairing the damage to coat & wrap (with coating repair etc, back filling the trenches, cleaning the site, applying 2 coats of aluminium paint over a coat of zinc chromate primer on the test lead box and MS pipe, installation of corrosion coupons (as described below) etc. The item also includes supply, installation / laying & termination of all XLPE, Cu cables of required length (as per site conditions) and size as mentioned in the standard drawings, cable glands and lugs etc. complete in all respect. The work shall include supply and fixing of a non-corrosive name plate containing the details like KM location, identification, TLP No., direction of flow, connection scheme, type etc. on the side of the TLP box, etc. complete in the all respect (including the cost of all labour, materials, tools and tackles etc.), as per the specification, drawing and instructions of the site Engineer. Installation of corrosion coupons, as described above, includes the preparation of corrosion coupon from owner supplied coated pipe. which involves preparation of sample of size 2"x4", dipping the coupon in coal tar enamel, soldering 6 sq. mm. cable with coupon, sealing the soldered joint with epoxy, positioning the coupon at the pipe line depth and with in a distance of 0.5 M from the pipeline inclusive of cable & terminating the

Signature of Tenderer with seal

viting Authority: Chief Manager (Contracts),IOCL(AOD),Digboi

Work: FABRICATION & LAYING OF ONE 4", ONE 6" & ONE 8" NB 3LPE COATED SEAMLESS PRODUCT PIPELINES FROM NTF TO NENT CATHODIC PROTECTION IN THE ABOVE LINES INCLUDING LAYING OF 40 mm OD HDPE PIPE AS OFC CONDUIT, OFC BL

No: DRC1125306

SCHEDULE OF WORKS Description of work

TLP Type A TLP Type B

TLP Type C TLP Type D TLP Type E

Signature of Tenderer with seal

viting Authority: Chief Manager (Contracts),IOCL(AOD),Digboi

Work: FABRICATION & LAYING OF ONE 4", ONE 6" & ONE 8" NB 3LPE COATED SEAMLESS PRODUCT PIPELINES FROM NTF TO NENT CATHODIC PROTECTION IN THE ABOVE LINES INCLUDING LAYING OF 40 mm OD HDPE PIPE AS OFC CONDUIT, OFC BL

No: DRC1125306

SCHEDULE OF WORKS Description of work

TLP Type DAC

TLP Type DMV

TEMPORARY CATHODIC PROTECTION / Hot spot protection Supply, Installation , testing and commisioning of 7.6 kgs each Magnesium anodes including its tail cable of size of 1c x 6 sq.mm. PE/ PVC insulated stranded copper cable of total length 10 meter including PVC cap, special back-fill material ( filled in cotton sack) with sealing compound complete in all respect including its excavations, back filling etc. as per specifications and drawings for Temporary cathodic protection of mainline. The work complete in all respect shall include supply of all labour , tools etc. and shall be carried out as per the directions of the Site Engineer.

Signature of Tenderer with seal

viting Authority: Chief Manager (Contracts),IOCL(AOD),Digboi

Work: FABRICATION & LAYING OF ONE 4", ONE 6" & ONE 8" NB 3LPE COATED SEAMLESS PRODUCT PIPELINES FROM NTF TO NENT CATHODIC PROTECTION IN THE ABOVE LINES INCLUDING LAYING OF 40 mm OD HDPE PIPE AS OFC CONDUIT, OFC BL

No: DRC1125306

SCHEDULE OF WORKS Description of work

Supply & installation of Anode bed ( shallow type ) as per the approved configuration for 'Impressed Current Cathodic Protection' system with Hi-Si-Cr/MMO type canistered Anodes including supply of all anode tail cable (XLPE insulated copper conductor) suitable with length for connecting upto Anode junction box without any joints in between including laying of PVC sleeve / trunk pipe & drawing all the lead wires through the pipe and connecting the same with Anode bus in Anode junction box including erection on foundations and inside chain link fencing as per specifications inlcuding supply of back fill material, excavation, backfill of earth and filling the sand with requisite back fill material as per specification & also compacting the same with soil for restoring it to normal finished ground level all Cable Marker: Supply, erection and installation of MS cable markers; including excavation,installation of the markers,cement concrete grouting, backfilling etc. required as per drawings, specifications and directions of the Site Engineer,including the cost of all materials, labour,tools etc. complete in all of respects. All the below works and supply materials are as per data & guidelines mentioned in and governed by Special Conditions of Contract, Techincal Specifications laying of transfer pipelines, SCC and Technical Specifications of HDPE laying and OFC blowing jobs. NETWORKING HARDWARE-SUPPLIES :

Signature of Tenderer with seal

viting Authority: Chief Manager (Contracts),IOCL(AOD),Digboi

Work: FABRICATION & LAYING OF ONE 4", ONE 6" & ONE 8" NB 3LPE COATED SEAMLESS PRODUCT PIPELINES FROM NTF TO NENT CATHODIC PROTECTION IN THE ABOVE LINES INCLUDING LAYING OF 40 mm OD HDPE PIPE AS OFC CONDUIT, OFC BL

No: DRC1125306

SCHEDULE OF WORKS Description of work

Fibre Management System NETWORKING HARDWARE-SERVICE Erection, installation, testing & commissioning

MAINLINE RELATED WORKS - SUPPLIES

Signature of Tenderer with seal

viting Authority: Chief Manager (Contracts),IOCL(AOD),Digboi

Work: FABRICATION & LAYING OF ONE 4", ONE 6" & ONE 8" NB 3LPE COATED SEAMLESS PRODUCT PIPELINES FROM NTF TO NENT CATHODIC PROTECTION IN THE ABOVE LINES INCLUDING LAYING OF 40 mm OD HDPE PIPE AS OFC CONDUIT, OFC BL

No: DRC1125306

SCHEDULE OF WORKS Description of work

Supply 40 mm OD HDPE pipe

Supply of jointing kits

Supply of pre-fabricated printed markers Supply of pre-fabricated RCC(1:1.5:3) pull box

Signature of Tenderer with seal

viting Authority: Chief Manager (Contracts),IOCL(AOD),Digboi

Work: FABRICATION & LAYING OF ONE 4", ONE 6" & ONE 8" NB 3LPE COATED SEAMLESS PRODUCT PIPELINES FROM NTF TO NENT CATHODIC PROTECTION IN THE ABOVE LINES INCLUDING LAYING OF 40 mm OD HDPE PIPE AS OFC CONDUIT, OFC BL

No: DRC1125306

SCHEDULE OF WORKS Description of work

Supply of transition pit

MAINLINE RELATED WORKS - SERVICES Blowing of OFC through HDPC pipe including, jointing, splicing etc.

Installation of jointing kits

Installation of pre-fabricated printed markers

Signature of Tenderer with seal

viting Authority: Chief Manager (Contracts),IOCL(AOD),Digboi

Work: FABRICATION & LAYING OF ONE 4", ONE 6" & ONE 8" NB 3LPE COATED SEAMLESS PRODUCT PIPELINES FROM NTF TO NENT CATHODIC PROTECTION IN THE ABOVE LINES INCLUDING LAYING OF 40 mm OD HDPE PIPE AS OFC CONDUIT, OFC BL

No: DRC1125306

SCHEDULE OF WORKS Description of work

Installation of RCC box

Installation of Transition pit

Supply & installation of 80 mm GI pipe for Railway Cased Crossings.

Supply & installation of 100 mm GI pipe

mated cost in Figures

Signature of Tenderer with seal

viting Authority: Chief Manager (Contracts),IOCL(AOD),Digboi

Work: FABRICATION & LAYING OF ONE 4", ONE 6" & ONE 8" NB 3LPE COATED SEAMLESS PRODUCT PIPELINES FROM NTF TO NENT CATHODIC PROTECTION IN THE ABOVE LINES INCLUDING LAYING OF 40 mm OD HDPE PIPE AS OFC CONDUIT, OFC BL

No: DRC1125306

SCHEDULE OF WORKS Description of work

mount

e in Words

Signature of Tenderer with seal

UCT PIPELINES FROM NTF TO DIGBOI MARKETING TERMINAL, PROVIDING TEMPORARY AND PE AS OFC CONDUIT, OFC BLOWING JOB UNDER DIGBOI TERMINAL PROJECT.

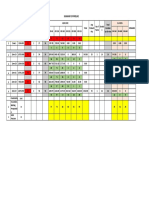

Excess ( + ) No.or Qty. Unit Figure Estimated Rate Words

0.00 % AMOUNT Rs. P

F WORKS

Signature of Tenderer with seal

UCT PIPELINES FROM NTF TO DIGBOI MARKETING TERMINAL, PROVIDING TEMPORARY AND PE AS OFC CONDUIT, OFC BLOWING JOB UNDER DIGBOI TERMINAL PROJECT.

Excess ( + ) No.or Qty. 5575.00 Unit Figure 2,078.54 Estimated Rate

0.00 % AMOUNT Rs. P 11587860.50

F WORKS

Words Rupees Two Thousand Seventy Eight And Fifty Four Paise Only

Signature of Tenderer with seal

UCT PIPELINES FROM NTF TO DIGBOI MARKETING TERMINAL, PROVIDING TEMPORARY AND PE AS OFC CONDUIT, OFC BLOWING JOB UNDER DIGBOI TERMINAL PROJECT.

Excess ( + ) No.or Qty. 500.00 Unit Figure 10220.18 Estimated Rate

0.00 % AMOUNT Rs. P 5110090.00

F WORKS

Words Rupees Ten Thousand Two Hundred Twenty And Eighteen Paise Only

Signature of Tenderer with seal

UCT PIPELINES FROM NTF TO DIGBOI MARKETING TERMINAL, PROVIDING TEMPORARY AND PE AS OFC CONDUIT, OFC BLOWING JOB UNDER DIGBOI TERMINAL PROJECT.

Excess ( + ) No.or Qty. 300.00 Unit Figure 11190.38 Estimated Rate

0.00 % AMOUNT Rs. P 3357114.00

F WORKS

Words Rupees Eleven Thousand One Hundred Ninety And Thirty Eight Paise Only

Signature of Tenderer with seal

UCT PIPELINES FROM NTF TO DIGBOI MARKETING TERMINAL, PROVIDING TEMPORARY AND PE AS OFC CONDUIT, OFC BLOWING JOB UNDER DIGBOI TERMINAL PROJECT.

Excess ( + ) No.or Qty. Unit Figure Estimated Rate Words

0.00 % AMOUNT Rs. P

F WORKS

366.67

3836.70

Rupees Three Thousand Eight Hundred Thirty Six And Seventy Paise Only

1406802.79

Signature of Tenderer with seal

UCT PIPELINES FROM NTF TO DIGBOI MARKETING TERMINAL, PROVIDING TEMPORARY AND PE AS OFC CONDUIT, OFC BLOWING JOB UNDER DIGBOI TERMINAL PROJECT.

Excess ( + ) No.or Qty. 366.67 Unit Figure 2877.53 Estimated Rate

0.00 % AMOUNT Rs. P 1055103.93

F WORKS

366.67

1918.35

Words Rupees Two Thousand Eight Hundred Seventy Seven And Fifty Three Paise Only Rupees One Thousand Nine Hundred Eighteen And Thirty Five Paise Only

703401.39

Signature of Tenderer with seal

UCT PIPELINES FROM NTF TO DIGBOI MARKETING TERMINAL, PROVIDING TEMPORARY AND PE AS OFC CONDUIT, OFC BLOWING JOB UNDER DIGBOI TERMINAL PROJECT.

Excess ( + ) No.or Qty. 10.00 Unit Figure 2431.01 Estimated Rate

0.00 % AMOUNT Rs. P 24310.10

F WORKS

EA

100.00

EA

2431.01

15.00

EA

2431.01

Words Rupees Two Thousand Four Hundred Thirty One And One Paise Only Rupees Two Thousand Four Hundred Thirty One And One Paise Only Rupees Two Thousand Four Hundred Thirty One And One Paise Only

243101.00

36465.15

Signature of Tenderer with seal

UCT PIPELINES FROM NTF TO DIGBOI MARKETING TERMINAL, PROVIDING TEMPORARY AND PE AS OFC CONDUIT, OFC BLOWING JOB UNDER DIGBOI TERMINAL PROJECT.

Excess ( + ) No.or Qty. 3.00 Unit Figure 385875.00 Estimated Rate

0.00 % AMOUNT Rs. P 1157625.00

F WORKS

LS

Words Rupees Three Lakhs Eighty Five Thousand Eight Hundred Seventy Five Only

3.00

LS

44100.00

Rupees Forty Four Thousand One Hundred Only

132300.00

Signature of Tenderer with seal

UCT PIPELINES FROM NTF TO DIGBOI MARKETING TERMINAL, PROVIDING TEMPORARY AND PE AS OFC CONDUIT, OFC BLOWING JOB UNDER DIGBOI TERMINAL PROJECT.

Excess ( + ) No.or Qty. Unit Figure Estimated Rate Words

0.00 % AMOUNT Rs. P

F WORKS

8.00

EA

100782.60

Rupees One Lakh Thousand Seven Hundred Eighty Two And Sixty Paise Only

806260.80

Signature of Tenderer with seal

UCT PIPELINES FROM NTF TO DIGBOI MARKETING TERMINAL, PROVIDING TEMPORARY AND PE AS OFC CONDUIT, OFC BLOWING JOB UNDER DIGBOI TERMINAL PROJECT.

Excess ( + ) No.or Qty. 8.00 Unit Figure 18812.75 Estimated Rate

0.00 % AMOUNT Rs. P 150502.00

F WORKS

EA

Words Rupees Eighteen Thousand Eight Hundred Twelve And Seventy Five Paise Only Rupees Seventy Three Thousand Nine Hundred Seven And Twenty Four Paise Only Rupees Twenty Four Thousand One Hundred Eighty Seven And Eighty Two Paise Only

1.00

EA

73907.24

73907.24

2.00

EA

24187.82

48375.64

Signature of Tenderer with seal

UCT PIPELINES FROM NTF TO DIGBOI MARKETING TERMINAL, PROVIDING TEMPORARY AND PE AS OFC CONDUIT, OFC BLOWING JOB UNDER DIGBOI TERMINAL PROJECT.

Excess ( + ) No.or Qty. 1,500.00 Unit Figure 571.10 Estimated Rate

0.00 % AMOUNT Rs. P 856650.00

F WORKS

Words Rupees Five Hundred Seventy One And Ten Paise Only Rupees Four Hundred Thirty Six And Seventy Two Paise Only Rupees One Hundred Forty Seven And Eighty One Paise Only Rupees Two Thousand Two Hundred Eighty Four And Forty One Paise Only

200.00

436.72

87344.00

500.00

147.81

73905.00

3.00

EA

2284.41

6853.23

Signature of Tenderer with seal

UCT PIPELINES FROM NTF TO DIGBOI MARKETING TERMINAL, PROVIDING TEMPORARY AND PE AS OFC CONDUIT, OFC BLOWING JOB UNDER DIGBOI TERMINAL PROJECT.

Excess ( + ) No.or Qty. 2.00 Unit Figure 12093.91 Estimated Rate

0.00 % AMOUNT Rs. P 24187.82

F WORKS

EA

Words Rupees Twelve Thousand Ninety Three And Ninety One Paise Only

8.00

EA

9922.50

8.00

EA

4961.25

Rupees Nine Thousand Nine Hundred Twenty Two And Fifty Paise Only Rupees Four Thousand Nine Hundred Sixty One And Twenty Five Paise Only

79380.00

39690.00

Signature of Tenderer with seal

UCT PIPELINES FROM NTF TO DIGBOI MARKETING TERMINAL, PROVIDING TEMPORARY AND PE AS OFC CONDUIT, OFC BLOWING JOB UNDER DIGBOI TERMINAL PROJECT.

Excess ( + ) No.or Qty. 3.00 Unit Figure 4961.25 Estimated Rate

0.00 % AMOUNT Rs. P 14883.75

F WORKS

EA

6.00

KM

1212.75

Words Rupees Four Thousand Nine Hundred Sixty One And Twenty Five Paise Only Rupees One Thousand Two Hundred Twelve And Seventy Five Paise Only Rupees One Thousand Eight Hundred Seventy Four And Twenty Five Paise Only

7276.50

6.00

KM

1874.25

11245.50

Signature of Tenderer with seal

UCT PIPELINES FROM NTF TO DIGBOI MARKETING TERMINAL, PROVIDING TEMPORARY AND PE AS OFC CONDUIT, OFC BLOWING JOB UNDER DIGBOI TERMINAL PROJECT.

Excess ( + ) No.or Qty. 1.00 Unit Figure 24806.25 Estimated Rate

0.00 % AMOUNT Rs. P 24806.25

F WORKS

EA

Words Rupees Twenty Four Thousand Eight Hundred Six And Twenty Five Paise Only Rupees Four Thousand Nine Hundred Sixty One And Twenty Five Paise Only

6.00

KM

4961.25

29767.50

Signature of Tenderer with seal

UCT PIPELINES FROM NTF TO DIGBOI MARKETING TERMINAL, PROVIDING TEMPORARY AND PE AS OFC CONDUIT, OFC BLOWING JOB UNDER DIGBOI TERMINAL PROJECT.

Excess ( + ) No.or Qty. 1.00 Unit Figure 9922.50 Estimated Rate Words Rupees Nine Thousand Nine Hundred Twenty Two And Fifty Paise Only Rupees Nine Thousand Nine Hundred Twenty Two And Fifty Paise Only

0.00 % AMOUNT Rs. P 9922.50

F WORKS

EA

1.00

KM

9922.50

9922.50

Signature of Tenderer with seal

UCT PIPELINES FROM NTF TO DIGBOI MARKETING TERMINAL, PROVIDING TEMPORARY AND PE AS OFC CONDUIT, OFC BLOWING JOB UNDER DIGBOI TERMINAL PROJECT.

Excess ( + ) No.or Qty. 1.00 Unit Figure 40792.50 Estimated Rate Words Rupees Forty Thousand Seven Hundred Ninety Two And Fifty Paise Only

0.00 % AMOUNT Rs. P 40792.50

F WORKS

EA

800.00

176.40

Rupees One Hundred Seventy Six And Forty Paise Only

141120.00

Signature of Tenderer with seal

UCT PIPELINES FROM NTF TO DIGBOI MARKETING TERMINAL, PROVIDING TEMPORARY AND PE AS OFC CONDUIT, OFC BLOWING JOB UNDER DIGBOI TERMINAL PROJECT.

Excess ( + ) No.or Qty. 700.00 Unit Figure 176.40 Estimated Rate

0.00 % AMOUNT Rs. P 123480.00

F WORKS

Words Rupees One Hundred Seventy Six And Forty Paise Only

500.00

176.40

Rupees One Hundred Seventy Six And Forty Paise Only

88200.00

Signature of Tenderer with seal

UCT PIPELINES FROM NTF TO DIGBOI MARKETING TERMINAL, PROVIDING TEMPORARY AND PE AS OFC CONDUIT, OFC BLOWING JOB UNDER DIGBOI TERMINAL PROJECT.

Excess ( + ) No.or Qty. 200.00 Unit Figure 176.40 Estimated Rate

0.00 % AMOUNT Rs. P 35280.00

F WORKS

Words Rupees One Hundred Seventy Six And Forty Paise Only

6.00

KM

496.13

Rupees Four Hundred Ninety Six And Thirteen Paise Only

2976.78

Signature of Tenderer with seal

UCT PIPELINES FROM NTF TO DIGBOI MARKETING TERMINAL, PROVIDING TEMPORARY AND PE AS OFC CONDUIT, OFC BLOWING JOB UNDER DIGBOI TERMINAL PROJECT.

Excess ( + ) No.or Qty. 1.00 Unit Figure 220500.00 Estimated Rate Words Rupees Two Lakhs Twenty Thousand Five Hundred Only

0.00 % AMOUNT Rs. P 220500.00

F WORKS

LS

6.00

KM

496.13

Rupees Four Hundred Ninety Six And Thirteen Paise Only

2976.78

Signature of Tenderer with seal

UCT PIPELINES FROM NTF TO DIGBOI MARKETING TERMINAL, PROVIDING TEMPORARY AND PE AS OFC CONDUIT, OFC BLOWING JOB UNDER DIGBOI TERMINAL PROJECT.

Excess ( + ) No.or Qty. Unit Figure Estimated Rate Words

0.00 % AMOUNT Rs. P

F WORKS

Signature of Tenderer with seal

UCT PIPELINES FROM NTF TO DIGBOI MARKETING TERMINAL, PROVIDING TEMPORARY AND PE AS OFC CONDUIT, OFC BLOWING JOB UNDER DIGBOI TERMINAL PROJECT.

Excess ( + ) No.or Qty. Unit Figure Estimated Rate Words

0.00 % AMOUNT Rs. P

F WORKS

Signature of Tenderer with seal

UCT PIPELINES FROM NTF TO DIGBOI MARKETING TERMINAL, PROVIDING TEMPORARY AND PE AS OFC CONDUIT, OFC BLOWING JOB UNDER DIGBOI TERMINAL PROJECT.

Excess ( + ) No.or Qty. 16.00 8.00 Unit Figure 17640.00 41343.75 Estimated Rate

0.00 % AMOUNT Rs. P 282240.00 330750.00

F WORKS

EA EA

Words Rupees Seventeen Thousand Six Hundred Forty Only Rupees Forty One Thousand Three Hundred Forty Three And Seventy Five Paise Only Rupees Thirty Four Thousand One Hundred Seventy Seven And Fifty Paise Only Rupees Twenty Three Thousand One Hundred Fifty Two And Fifty Paise Only Rupees Twenty Three Thousand One Hundred Fifty Two And Fifty Paise Only

4.00 8.00 8.00

EA EA EA

34177.50 23152.50 23152.50

136710.00 185220.00 185220.00

Signature of Tenderer with seal

UCT PIPELINES FROM NTF TO DIGBOI MARKETING TERMINAL, PROVIDING TEMPORARY AND PE AS OFC CONDUIT, OFC BLOWING JOB UNDER DIGBOI TERMINAL PROJECT.

Excess ( + ) No.or Qty. 2.00 Unit Figure 23152.50 Estimated Rate

0.00 % AMOUNT Rs. P 46305.00

F WORKS

EA

8.00

EA

23703.75

12.00

EA

11025.00

Words Rupees Twenty Three Thousand One Hundred Fifty Two And Fifty Paise Only Rupees Twenty Three Thousand Seven Hundred Three And Seventy Five Paise Only Rupees Eleven Thousand Twenty Five Only

189630.00

132300.00

Signature of Tenderer with seal

UCT PIPELINES FROM NTF TO DIGBOI MARKETING TERMINAL, PROVIDING TEMPORARY AND PE AS OFC CONDUIT, OFC BLOWING JOB UNDER DIGBOI TERMINAL PROJECT.

Excess ( + ) No.or Qty. 1.00 Unit Figure 248062.50 Estimated Rate Words Rupees Two Lakhs Forty Eight Thousand Sixty Two And Fifty Paise Only

0.00 % AMOUNT Rs. P 248062.50

F WORKS

EA

5.00

EA

1488.38

Rupees One Thousand Four Hundred Eighty Eight And Thirty Eight Paise Only

7441.90

Signature of Tenderer with seal

UCT PIPELINES FROM NTF TO DIGBOI MARKETING TERMINAL, PROVIDING TEMPORARY AND PE AS OFC CONDUIT, OFC BLOWING JOB UNDER DIGBOI TERMINAL PROJECT.

Excess ( + ) No.or Qty. Unit Figure 41985.88 Estimated Rate

0.00 % AMOUNT Rs. P 83971.76

F WORKS

2.00 SET

Words Rupees Forty One Thousand Nine Hundred Eighty Five And Eighty Eight Paise Only Rupees Twenty Eight Thousand Seven Hundred Six And Twenty Four Paise Only

2.00 SET

28706.24

57412.48

Signature of Tenderer with seal

UCT PIPELINES FROM NTF TO DIGBOI MARKETING TERMINAL, PROVIDING TEMPORARY AND PE AS OFC CONDUIT, OFC BLOWING JOB UNDER DIGBOI TERMINAL PROJECT.

Excess ( + ) No.or Qty. 6.00 Unit Figure 52479.41 Estimated Rate

0.00 % AMOUNT Rs. P 314876.46

F WORKS

KM

Words Rupees Fifty Two Thousand Four Hundred Seventy Nine And Forty One Paise Only Rupees Nine Thousand Seven Hundred Forty Six And Thirty Paise Only Rupees Three Thousand Thirty Six And Twenty Paise Only Rupees Eighteen Thousand Seven Hundred Forty Two And Twenty Six Paise Only

2.00

EA

9746.30

19492.60

20.00 2.00

EA EA

3036.20 18742.26

60724.00 37484.52

Signature of Tenderer with seal

UCT PIPELINES FROM NTF TO DIGBOI MARKETING TERMINAL, PROVIDING TEMPORARY AND PE AS OFC CONDUIT, OFC BLOWING JOB UNDER DIGBOI TERMINAL PROJECT.

Excess ( + ) No.or Qty. 2.00 Unit Figure 7497.26 Estimated Rate

0.00 % AMOUNT Rs. P 14994.52

F WORKS

EA

Words Rupees Seven Thousand Four Hundred Ninety Seven And Twenty Six Paise Only

6.00

KM

22143.92

2.00

EA

6766.60

20.00

EA

922.62

Rupees Twenty Two Thousand One Hundred Forty Three And Ninety Two Paise Only Rupees Six Thousand Seven Hundred Sixty Six And Sixty Paise Only Rupees Nine Hundred Twenty Two And Sixty Two Paise Only

132863.52

13533.20

18452.40

Signature of Tenderer with seal

UCT PIPELINES FROM NTF TO DIGBOI MARKETING TERMINAL, PROVIDING TEMPORARY AND PE AS OFC CONDUIT, OFC BLOWING JOB UNDER DIGBOI TERMINAL PROJECT.

Excess ( + ) No.or Qty. 2.00 Unit Figure 1845.23 Estimated Rate

0.00 % AMOUNT Rs. P 3690.46

F WORKS

EA

2.00

EA

13839.25

Words Rupees One Thousand Eight Hundred Forty Five And Twenty Three Paise Only Rupees Thirteen Thousand Eight Hundred Thirty Nine And Twenty Five Paise Only Rupees Three Thousand Five Hundred Five And Ninety Four Paise Only Rupees One Thousand Forty Five And Twenty Six Paise Only

27678.50

50.00

3505.94

175297.00

80.00

1045.26

83620.80 30612351.77

Signature of Tenderer with seal

UCT PIPELINES FROM NTF TO DIGBOI MARKETING TERMINAL, PROVIDING TEMPORARY AND PE AS OFC CONDUIT, OFC BLOWING JOB UNDER DIGBOI TERMINAL PROJECT.

Excess ( + ) No.or Qty. Unit Figure Estimated Rate Words

0.00 % AMOUNT Rs. P 30612351.77 30612352.00

F WORKS

Rupees Three Crores Six Lakhs Twelve Thousand Three Hundred Fifty Two Only

Signature of Tenderer with seal

S-ar putea să vă placă și

- Construction NormsDocument18 paginiConstruction Normston100% (1)

- B Estimate & Check ListDocument122 paginiB Estimate & Check Listmani0214Încă nu există evaluări

- Pt. Duta Utama Tehnik Abadi: Daily ReportDocument45 paginiPt. Duta Utama Tehnik Abadi: Daily ReportMa'rifatullahÎncă nu există evaluări

- Monthly Commercial Report:: Emmar Properties (PJSC)Document9 paginiMonthly Commercial Report:: Emmar Properties (PJSC)Yasser Elsalhy100% (1)

- Mobilization Checklist 1Document3 paginiMobilization Checklist 1MuslimkarimjeeÎncă nu există evaluări

- Project Management Plan TemplateDocument9 paginiProject Management Plan TemplateAsmaaÎncă nu există evaluări

- Value Of Work Done A Complete Guide - 2020 EditionDe la EverandValue Of Work Done A Complete Guide - 2020 EditionÎncă nu există evaluări

- BOQ For Batching Plant Area1Document10 paginiBOQ For Batching Plant Area1sh2705_877839042Încă nu există evaluări

- SOR 8th Ed 2013Document467 paginiSOR 8th Ed 2013Durgesh Govil100% (3)

- Productivity of Plant and MachineryDocument65 paginiProductivity of Plant and Machinerynebiyu100% (1)

- Standard Productivity - NaumanDocument2 paginiStandard Productivity - NaumanEngineer Usama100% (1)

- Daily Progress Report - 12.6.14Document13 paginiDaily Progress Report - 12.6.14bulzae100% (1)

- 374 Provisional Extension of Time (EOT) For Completion Under Article 10 Clause 10.5 of EPC Agriment 22-06-17 Executed Between The AuthorityDocument9 pagini374 Provisional Extension of Time (EOT) For Completion Under Article 10 Clause 10.5 of EPC Agriment 22-06-17 Executed Between The AuthorityAjay GuptaÎncă nu există evaluări

- Generalprocedure Export PDFDocument20 paginiGeneralprocedure Export PDFUTTAL RAYÎncă nu există evaluări

- Mason: SL# Vehicle/Equipment Act - No Commodities UOM Norm / M.day Remarks 1Document1 paginăMason: SL# Vehicle/Equipment Act - No Commodities UOM Norm / M.day Remarks 1John Mark EvangelistaÎncă nu există evaluări

- Productivity Rate (Road Works)Document32 paginiProductivity Rate (Road Works)Ahmed Essam TimonÎncă nu există evaluări

- Temporary Facilities and ControlsDocument4 paginiTemporary Facilities and ControlsSaud PathiranaÎncă nu există evaluări

- Unit Cost AnalysisDocument24 paginiUnit Cost Analysisedla3710Încă nu există evaluări

- Productivity NormsDocument2 paginiProductivity NormsMartin Buniag100% (1)

- Equipment Productivity DetailsDocument3 paginiEquipment Productivity DetailsRana Muhammad TalhaÎncă nu există evaluări

- Legal Cases of Importance To Quantity SurveyorsDocument3 paginiLegal Cases of Importance To Quantity SurveyorsRoshan de Silva100% (2)

- Clearing and Grubbing 201.1. ScopeDocument5 paginiClearing and Grubbing 201.1. Scopenandi_scrÎncă nu există evaluări

- U Shape DRAINDocument13 paginiU Shape DRAINjitenderÎncă nu există evaluări

- Wooden Wall Cladding 1st Fix Wooden Wall Cladding 2 ND FixDocument3 paginiWooden Wall Cladding 1st Fix Wooden Wall Cladding 2 ND Fixsayr0sÎncă nu există evaluări

- Dia Inch PipingDocument77 paginiDia Inch PipingmyDJAPA myDJAPAÎncă nu există evaluări

- Cyberzon Budget 1Document223 paginiCyberzon Budget 1vijay2528Încă nu există evaluări

- PDFDocument14 paginiPDFAlexander RichardsonÎncă nu există evaluări

- S-Curve Rev.2 Due To Eot No. 1Document1 paginăS-Curve Rev.2 Due To Eot No. 1Budi DermawanÎncă nu există evaluări

- BASELINESCHEDULENARRATIVEDocument24 paginiBASELINESCHEDULENARRATIVEJose RibeiroÎncă nu există evaluări

- Productivity Rate by Tengku HafizDocument121 paginiProductivity Rate by Tengku HafizTengku Hafiz83% (6)

- JNV Moran Letter For HinderanceDocument2 paginiJNV Moran Letter For Hinderancesumanjit dasÎncă nu există evaluări

- Productivity Output For PreliminariesDocument2 paginiProductivity Output For PreliminariesAmalina YaniÎncă nu există evaluări

- Site Visit ReportDocument20 paginiSite Visit ReportWayneÎncă nu există evaluări

- PWD Schedule-Schedule of Rates of PWD (W.B) 2015 For Road Bridge Work (Vol-III) Wef 30.08.2018 PDFDocument367 paginiPWD Schedule-Schedule of Rates of PWD (W.B) 2015 For Road Bridge Work (Vol-III) Wef 30.08.2018 PDFAlipurÎncă nu există evaluări

- MWPS Daily Activity Report 28 August2011Document1 paginăMWPS Daily Activity Report 28 August2011Peni M. SaptoargoÎncă nu există evaluări

- E.G Infra Pvt. LTD: Tinkune, Kathmandu NepalDocument2 paginiE.G Infra Pvt. LTD: Tinkune, Kathmandu Nepaldipesh_dmdÎncă nu există evaluări

- 151591149-Productivity-Rate-Labor-Eqpt (4) .Xls - LABOR PRODUCTION TABLE ITEM NO A WORK DESCRIPTION M.H UNIT MANHOURS PER QUANTITY (MDocument9 pagini151591149-Productivity-Rate-Labor-Eqpt (4) .Xls - LABOR PRODUCTION TABLE ITEM NO A WORK DESCRIPTION M.H UNIT MANHOURS PER QUANTITY (MZelalem MengistuÎncă nu există evaluări

- CP 300 (A) - QCP-002 Laying of Vitrified Clay Pipes Rev. 01Document6 paginiCP 300 (A) - QCP-002 Laying of Vitrified Clay Pipes Rev. 01tarekÎncă nu există evaluări

- Attachment 4 Scope of WorkDocument5 paginiAttachment 4 Scope of WorkMathias OnosemuodeÎncă nu există evaluări

- PROJECT STANDARD and SPECIFICATIONS Progress Measurement Procedure Rev01 WebDocument6 paginiPROJECT STANDARD and SPECIFICATIONS Progress Measurement Procedure Rev01 WebAkangAtetÎncă nu există evaluări

- Work Done ReportDocument443 paginiWork Done ReportNagarajÎncă nu există evaluări

- A - Substructure 1. Excavation & EarthworksDocument4 paginiA - Substructure 1. Excavation & Earthworkstofikkemal100% (1)

- Unit Cost Analysis As of April 2003: Sub Total (Materials)Document15 paginiUnit Cost Analysis As of April 2003: Sub Total (Materials)Abdul Q HannanÎncă nu există evaluări

- Physical & Financial Progress Work Carried Out by NMR/PRW/LCDocument5 paginiPhysical & Financial Progress Work Carried Out by NMR/PRW/LCyashas sÎncă nu există evaluări

- CFLHD Production RatesDocument7 paginiCFLHD Production RatesabhiazadÎncă nu există evaluări

- Form K - Item 2 - Nigerian Content RequirementDocument21 paginiForm K - Item 2 - Nigerian Content RequirementBALARISI ENGINEERÎncă nu există evaluări

- Labor Requirements For Construction M Aterials: Par T Il-Concrete Masonry UnitsDocument22 paginiLabor Requirements For Construction M Aterials: Par T Il-Concrete Masonry UnitsMohammed AffrozeÎncă nu există evaluări

- Excess (+) %: ValidateDocument22 paginiExcess (+) %: ValidateNEMI CHAND SOODÎncă nu există evaluări

- Productivity PipelineDocument1 paginăProductivity PipelineDilip Kumar100% (1)

- Productivity of ExcavatorDocument4 paginiProductivity of Excavatorpawan paudel100% (1)

- 1-Diversion Project SssDocument14 pagini1-Diversion Project Sssilyas AhmadÎncă nu există evaluări

- Productivity in Concrete Masonry ConstructionDocument7 paginiProductivity in Concrete Masonry ConstructionTanveerAhmed NiaziÎncă nu există evaluări

- Construction Civil Works Productivity RatesDocument5 paginiConstruction Civil Works Productivity Rateschinna_p_123Încă nu există evaluări

- PGIDM-Highway Project ManagementDocument40 paginiPGIDM-Highway Project ManagementSaurabh Kumar Sharma100% (1)

- Comparison of Scaffolds. Rental RatesDocument2 paginiComparison of Scaffolds. Rental RatesSujani MaarasingheÎncă nu există evaluări

- 002 R2. Material Submittal For SheduleDocument1 pagină002 R2. Material Submittal For SheduleJoe PsÎncă nu există evaluări

- Construction Methodology - Maholiya ProjectDocument6 paginiConstruction Methodology - Maholiya ProjectPrateek DasÎncă nu există evaluări

- Rate Analysis Report - Concrete Block MachineAMEX (Version 1)Document21 paginiRate Analysis Report - Concrete Block MachineAMEX (Version 1)Jayaraman KamarajÎncă nu există evaluări

- BOQ and Rates Oil GasDocument93 paginiBOQ and Rates Oil GasAnsaf AskyÎncă nu există evaluări

- DCS 006 29.03.10 Perforation of UPVC PipesDocument4 paginiDCS 006 29.03.10 Perforation of UPVC Pipesmirza057Încă nu există evaluări

- Tendernotice - 1 - 2022-09-05T153458.722Document5 paginiTendernotice - 1 - 2022-09-05T153458.722nirdoshkumarÎncă nu există evaluări

- Tendernotice - 1 - 2022-09-05T154535.632Document6 paginiTendernotice - 1 - 2022-09-05T154535.632nirdoshkumarÎncă nu există evaluări

- Tendernotice - 1 - 2022-09-05T154137.515Document10 paginiTendernotice - 1 - 2022-09-05T154137.515nirdoshkumarÎncă nu există evaluări

- Tendernotice - 1 - 2022-09-05T153634.075Document7 paginiTendernotice - 1 - 2022-09-05T153634.075nirdoshkumarÎncă nu există evaluări

- Tendernotice 1Document48 paginiTendernotice 1nirdoshkumarÎncă nu există evaluări

- Tendernotice - 1 - 2022-09-05T154407.020Document9 paginiTendernotice - 1 - 2022-09-05T154407.020nirdoshkumarÎncă nu există evaluări

- G&J Contractors Profile 20082018 Reliance VadodaraDocument16 paginiG&J Contractors Profile 20082018 Reliance VadodaranirdoshkumarÎncă nu există evaluări

- Urdu Meter A Practical HandbookDocument110 paginiUrdu Meter A Practical HandbooknirdoshkumarÎncă nu există evaluări

- G&J ContractorsDocument14 paginiG&J ContractorsnirdoshkumarÎncă nu există evaluări

- Bhel Hydra 12 Ton TenderDocument12 paginiBhel Hydra 12 Ton TendernirdoshkumarÎncă nu există evaluări

- GJ Profile (11-Jan-2015)Document15 paginiGJ Profile (11-Jan-2015)nirdoshkumarÎncă nu există evaluări

- Coal Tar Tape & Synthetic Prmer-15337Document2 paginiCoal Tar Tape & Synthetic Prmer-15337nirdoshkumar100% (2)

- A Tale of Two CitiesDocument537 paginiA Tale of Two Citiessilver999Încă nu există evaluări

- VOI-I-A BhelDocument95 paginiVOI-I-A BhelnirdoshkumarÎncă nu există evaluări

- Coal Fired Thermal Power PlantDocument33 paginiCoal Fired Thermal Power Plantflorece33% (3)

- FinalresultprepDocument7 paginiFinalresultprepnirdoshkumar0% (1)

- S CurveDocument3 paginiS CurvenirdoshkumarÎncă nu există evaluări

- ModelRule FlaresDocument17 paginiModelRule FlaresM Ahmed LatifÎncă nu există evaluări

- A Guide To Refinery ProcessDocument35 paginiA Guide To Refinery ProcessBalamurugan100% (3)

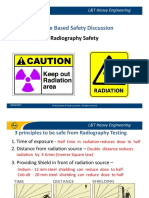

- RT Finalpresenatation08 161118104713Document56 paginiRT Finalpresenatation08 161118104713sajay2010Încă nu există evaluări

- Appendix 1 Part 4 Radiographic Interpreter 5th Edition February 2016 PDFDocument6 paginiAppendix 1 Part 4 Radiographic Interpreter 5th Edition February 2016 PDFRizwan NazirÎncă nu există evaluări

- Non - Destructive TestDocument22 paginiNon - Destructive TestAlsonChinÎncă nu există evaluări

- Lion KingsDocument32 paginiLion KingsFahad AhmadÎncă nu există evaluări

- Non Destructive Testing and EvaluationDocument24 paginiNon Destructive Testing and EvaluationVignesh kumar GÎncă nu există evaluări

- Small Diameter Tube and Pipe Inspection With Phased Array PDFDocument7 paginiSmall Diameter Tube and Pipe Inspection With Phased Array PDFAlanka PrasadÎncă nu există evaluări

- NDT Testing University of MauritiusDocument12 paginiNDT Testing University of MauritiusAadil Bo SpitzmausÎncă nu există evaluări

- RT ProcedureDocument10 paginiRT ProcedureSandeep SundriyalÎncă nu există evaluări

- TOP 3-2-807 1985 Nondestructive Testing of MaterialsDocument19 paginiTOP 3-2-807 1985 Nondestructive Testing of MaterialsDaoudÎncă nu există evaluări

- ASME VIII-2-Service Restrictions, Joint Efficiencies, RadiographyDocument34 paginiASME VIII-2-Service Restrictions, Joint Efficiencies, RadiographyMohammed AnshafÎncă nu există evaluări

- RT 02Document91 paginiRT 02HAKANÎncă nu există evaluări

- 2 PDFDocument51 pagini2 PDFSalah JallaliÎncă nu există evaluări

- R1 Part 1Document56 paginiR1 Part 1OLiver Robert100% (1)

- HIA Mid-Field Fuel Farm Expansion - Welding of Steel StructuresDocument18 paginiHIA Mid-Field Fuel Farm Expansion - Welding of Steel Structuressrp. mohammedÎncă nu există evaluări

- Saep 1141Document71 paginiSaep 1141omar santos100% (3)

- IAEA Jakarta Seminar Report Dec 09 r6Document54 paginiIAEA Jakarta Seminar Report Dec 09 r6Manzur AbdulÎncă nu există evaluări

- 7.2 Radiaographic Testing ProcedureDocument14 pagini7.2 Radiaographic Testing ProcedureMd Anamul HoqueÎncă nu există evaluări

- Radiographic and Ultrasonic Testing of WeldsDocument3 paginiRadiographic and Ultrasonic Testing of WeldscinthyaÎncă nu există evaluări

- Radiography 50 Question QuizDocument9 paginiRadiography 50 Question QuizMukund2288100% (7)

- A660Document4 paginiA660Amreusit SaschimbnumeleÎncă nu există evaluări

- Lessons Learned From Accidents in Industrial RadiographyDocument70 paginiLessons Learned From Accidents in Industrial RadiographyMohammed Al-leswasÎncă nu există evaluări

- ASNT Inspection Procedures - 08 - Industrial Radiography PDFDocument88 paginiASNT Inspection Procedures - 08 - Industrial Radiography PDFBasil KuriakoseÎncă nu există evaluări

- Sicc-Rt-01 Asme Rev 01Document29 paginiSicc-Rt-01 Asme Rev 01Enrique Campos Cannavaro100% (1)

- System Testing: (E.g. Pressure Testing, Electrical Testing, Radiography)Document3 paginiSystem Testing: (E.g. Pressure Testing, Electrical Testing, Radiography)Muhammad Saqib AsifÎncă nu există evaluări

- Revision Questions For Cswip ExamsDocument65 paginiRevision Questions For Cswip Examshandsomeforever91% (11)

- TBTDocument14 paginiTBTMr. XÎncă nu există evaluări