Documente Academic

Documente Profesional

Documente Cultură

Ymt 1

Încărcat de

Prof Dr Md Saifur RahmanDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Ymt 1

Încărcat de

Prof Dr Md Saifur RahmanDrepturi de autor:

Formate disponibile

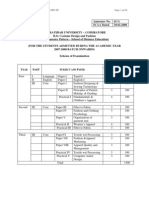

CITY UNIVERSITY Department of Textile Engineering Course Outline Course ID : Tex 201 Course Title : Yarn Manufacturing Technology

I Course Hours : 3 Contact class per week Class Hours : Sunday & Tuesday, 9.00 to 10.30 AM, Room-503 Course Description

Characteristics of fibers required to spun into yarn. Process involved in yarn manufacturing Technology. Fundamentals of mixing and blending of fibers. Brief description of blow room, carding and Drawing process. Production procedure of long staple fibers and brief study of Jute fiber processing.

Course necessity

After successful completion of this course the students will learn the procedure of making yarns from fibers and that knowledge will help them understanding the subsequent process involved in Yarn manufacturing Process.

Topics Included

1. Short Staple Fibers: Characteristics of fibers considered by a spinner. Process flow chart of carded and combed yarns. Importance of mixing and blending of various types. Blow Room: Principles of opening and cleaning. Study of blow room machines for blending , opening, cleaning and control of waste, settings for waste, blow room lines for different purposes, use of suitable sequences of machines, advantages and disadvantages of chute feeding to cards, safety, air flowing method, calendaring procedure, containing cotton and man made fiber. Carding: Principles and objects of carding, detailed study of the revolving flat card, types of wire, stripping and grinding, doffing, draft distribution mechanism. Extraction and control of waste and dust, can coiling. Speeds, production, settings, cleaning efficiency, control of neps and fiber damage, variation in sliver mass per unit length. Draw Frame: Principles of roller drafting, drafting force, drafting determination method, fiber control, drafting wave and effect of short fibers and fibers with hoocked ends created in carding. Mechanical faults causing periodic variations. Effects of doubling and drafting study of draw frame, drafting system, stop mechanisms, can coiling, roller setting, production, introduction to auto levelers.

2. Long StapleFibers: Flow charts for production of yarns from bast fibers, woolen and worsted and silk. Brief study of acrylic, woolen, and silk spinning process. Processing of Jute fibers. Emulsion preparation and application, softening technique and selection. Carding: Principles and objects of jute carding, detailed study of carding systems and machinery, finisher cards, pinning. Control of opening and waste, cleaning efficiency, settings, speeds and procedures.

Reference Books

1. Textile Yarns ----- E. R. Trotman 2. Spun Yarn Technology ----- Dr. V. A. Shenai

Course Schedule

Topics Introduction of fibers Mixing and Blending of fibers Study of Blow room process Study of Carding process Study of Drawing process Study of Long staple fibers Study of Jute Carding process No. of classes to be taken 2 3 5 5 5 5 3

Marks Allotment

Attendance and Class Performance ------------------------------ 10 Marks Assignment Class Test Mid-Term Final Examination ----------------------------- 05 Marks ----------------------------- 20 Marks ----------------------------- 25 Marks ----------------------------- 40 Marks _____________________ Total =100 Marks

Standard Grading Scale of city University

Class Interval Above 90 85-89 80-84 75-79 70-74 65-69 60-64 55-59 50-54 Less 50 Letter Grade A(Simple) A-(Minus) B+(Plus) B(Simple) B-(Minus) C+(Plus) C(Simple) C-(Minus) D(Simple) F Grade Point 4.00 3.67 3.33 3.00 2.67 2.33 2.00 1.67 1.00 0.00 Remarks Excellent Good Average Poor Fail

Rules and Advices

1. The students must have to be submitted at least one assignment of given topics before the semester final begins and after that no excuse will be considered. The assignment must be hand written and in A4 size papers. 2. The individual response of every student in the classroom and sincerity will be considered as class performance. 3. Three class tests will be taken and among them best two will be counted. After completion of the 3 tests no further test will be taken. The entire class test will be held in the class room. 4. Mid-term and Final exam are full of short and essay type question. All students are suggested to study carefully, take notes during class and contact to the course instructor in the office hours when any kinds of problem arise.

Course Instructor

Md. Koushic Uddin Office: 703 Office Hours: Sunday 10.30 - 13.30, Monday 10.30 15.00 Tuesday 10.30 16.30, Wednesday 10.30 15.00 Thursday 15.00 17.00 Contact Number: 0188252577

S-ar putea să vă placă și

- Project On Knitted Fabric ParametreDocument47 paginiProject On Knitted Fabric Parametresaifsabid82% (22)

- Carding BookletDocument46 paginiCarding Bookletsitu_tex859480% (5)

- Project On Knitted Fabric ParametreDocument58 paginiProject On Knitted Fabric ParametreMozzammal Hossain Shaown100% (3)

- Complete Book of Sewing Techniques, New 2nd Edition: More Than 30 Essential Sewing Techniques for You to MasterDe la EverandComplete Book of Sewing Techniques, New 2nd Edition: More Than 30 Essential Sewing Techniques for You to MasterEvaluare: 4 din 5 stele4/5 (3)

- Garmentdyeingtechniques 120621040800 Phpapp01Document28 paginiGarmentdyeingtechniques 120621040800 Phpapp01Monjur MorshedÎncă nu există evaluări

- Complete Book of Sewing Techniques: More Than 30 Essential Sewing Techniques for You to MasterDe la EverandComplete Book of Sewing Techniques: More Than 30 Essential Sewing Techniques for You to MasterÎncă nu există evaluări

- Study On Denim and Gabardine Twill Fabric Cover FactorDocument47 paginiStudy On Denim and Gabardine Twill Fabric Cover FactorAtik U Bhuiyan71% (7)

- QC in WeavingDocument42 paginiQC in WeavingFarrukh Jamil100% (3)

- Yarn Clearing SystemsDocument11 paginiYarn Clearing SystemsLohit MohapatraÎncă nu există evaluări

- Classimate Fualt DescriptionDocument16 paginiClassimate Fualt DescriptionSaad Naseem100% (2)

- ,loom TimingDocument23 pagini,loom TimingDipesh Jain67% (3)

- KNT 305Document113 paginiKNT 305Farhad Rana100% (2)

- 2 Carding LONGDocument118 pagini2 Carding LONGzohaab AhmadÎncă nu există evaluări

- Yarn Faults and ClearingDocument8 paginiYarn Faults and Clearingsitu_tex8594100% (7)

- SyllabusDocument6 paginiSyllabusHasmukh ShahÎncă nu există evaluări

- Modified Btech Tex 6th Semester SyllabusDocument11 paginiModified Btech Tex 6th Semester SyllabusPulak DebnathÎncă nu există evaluări

- Course Outline 1Document2 paginiCourse Outline 1kkkgn007Încă nu există evaluări

- M.SC Fashion DesigningDocument27 paginiM.SC Fashion DesigningAIM INSTITUTEÎncă nu există evaluări

- M Tech (Part Time) SyllabusDocument21 paginiM Tech (Part Time) SyllabusKrishna PrasadÎncă nu există evaluări

- Wrinkle Seam ProblemDocument8 paginiWrinkle Seam Problemdokumen terkontrolÎncă nu există evaluări

- Fabric InspectionDocument5 paginiFabric InspectionpravinthombreÎncă nu există evaluări

- Instructions For Students Following TTX3255 Woven Fabric Technology IDocument6 paginiInstructions For Students Following TTX3255 Woven Fabric Technology IKalyan Ray GuptaÎncă nu există evaluări

- Modified Btech Tex 5th Semester SyllabusDocument10 paginiModified Btech Tex 5th Semester SyllabusPulak DebnathÎncă nu există evaluări

- KNT2101 Knitwear Design For TriDocument40 paginiKNT2101 Knitwear Design For TriNoshin TabassumÎncă nu există evaluări

- Exam Mid Term Woven 2022 DecDocument4 paginiExam Mid Term Woven 2022 DecMinidu PabasaraÎncă nu există evaluări

- Course Outline 3403Document2 paginiCourse Outline 3403Delwar HossainÎncă nu există evaluări

- Study On Weft Knitted Fabric Faults and Remedies-1Document75 paginiStudy On Weft Knitted Fabric Faults and Remedies-1asmkhanrahat50% (4)

- Study of The Garments & Apparel Seam Quality Characterization PerformanceDocument9 paginiStudy of The Garments & Apparel Seam Quality Characterization PerformanceSanjeev singlaÎncă nu există evaluări

- Winding 1Document16 paginiWinding 1Siddhesh Pradhan67% (3)

- M - SC Garment Manufacturing Technology (GMT) (Scheme & Syllabus 1st To 4th Sem)Document105 paginiM - SC Garment Manufacturing Technology (GMT) (Scheme & Syllabus 1st To 4th Sem)Mohammad Zahirul IslamÎncă nu există evaluări

- Six SigmaDocument6 paginiSix Sigmasayeef khanÎncă nu există evaluări

- Measurement of Seam Puckering and Influence of Its Causes: Sandun Fernando Tss JayawardenaDocument7 paginiMeasurement of Seam Puckering and Influence of Its Causes: Sandun Fernando Tss JayawardenaIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalÎncă nu există evaluări

- Textile Engineering and Fibre ScienceDocument3 paginiTextile Engineering and Fibre ScienceNikhil TakbhateÎncă nu există evaluări

- Yarn Manufacturing - IDocument1 paginăYarn Manufacturing - ISiva Jagadish Kumar M100% (2)

- Btech Syllabus Textile EngineeringDocument68 paginiBtech Syllabus Textile EngineeringShubham BansalÎncă nu există evaluări

- BAT KEY 2022-2026 BatchDocument4 paginiBAT KEY 2022-2026 BatchvimalÎncă nu există evaluări

- To Study The Impact On Process Parameter of Knitted Fabric: April 2011Document20 paginiTo Study The Impact On Process Parameter of Knitted Fabric: April 2011Fahad AshfaqÎncă nu există evaluări

- Bgmea University of Fashion and Technology: Final SubmissionDocument34 paginiBgmea University of Fashion and Technology: Final Submissionmortuza hasanÎncă nu există evaluări

- Selection of Suitable Machine Gauge by Considering The GSM, Shrinkage and Spirality of Single Jersey Knit FabricDocument6 paginiSelection of Suitable Machine Gauge by Considering The GSM, Shrinkage and Spirality of Single Jersey Knit FabricOptimisticPersonÎncă nu există evaluări

- Uster Technologies Regularly Publishes Standards Such As USTERDocument12 paginiUster Technologies Regularly Publishes Standards Such As USTERHeba AlaaÎncă nu există evaluări

- Gate 2014 Syllabus Textile Engineering and Fibre Science TFDocument3 paginiGate 2014 Syllabus Textile Engineering and Fibre Science TFapi-287058159Încă nu există evaluări

- Stenter Machine Operator CurriculumDocument5 paginiStenter Machine Operator CurriculumMohon KhanÎncă nu există evaluări

- Full Book TPSPDocument120 paginiFull Book TPSPDeenaÎncă nu există evaluări

- Introductory LectureDocument13 paginiIntroductory LecturePawan GuptaÎncă nu există evaluări

- Syllabus For Textile Engineering and Fibre Science (TF) : Linear AlgebraDocument4 paginiSyllabus For Textile Engineering and Fibre Science (TF) : Linear AlgebrakamalkantmbbsÎncă nu există evaluări

- Shanto - Mariam University of Creative TechnologyDocument49 paginiShanto - Mariam University of Creative Technologylablu_ahammadÎncă nu există evaluări

- BGMEA University of Fashion & Technology (BUFT) : Assignment. (k-3)Document19 paginiBGMEA University of Fashion & Technology (BUFT) : Assignment. (k-3)NeFariOus ArYan AraFat AnikÎncă nu există evaluări

- Materi PTT NewDocument25 paginiMateri PTT NewMark Riha JrÎncă nu există evaluări

- Textile Training-Maintannance+knittingDocument60 paginiTextile Training-Maintannance+knittingAlamin KhanÎncă nu există evaluări

- Woven Fabrics Are FlexibleDocument7 paginiWoven Fabrics Are FlexibleDessilu NegesseÎncă nu există evaluări

- Common For The Subjects/Streams Mentioned Below: Textile Engineering and Fibre Science (Max. Marks: 70)Document4 paginiCommon For The Subjects/Streams Mentioned Below: Textile Engineering and Fibre Science (Max. Marks: 70)Ambika RajawatÎncă nu există evaluări

- Tt423 Apparel Production Technology: Course OutcomesDocument2 paginiTt423 Apparel Production Technology: Course OutcomesVenkatesh GogineniÎncă nu există evaluări

- B.SC SubjectsDocument24 paginiB.SC Subjectsranju93Încă nu există evaluări

- Fabric Stiffness TestingDocument13 paginiFabric Stiffness TestingFahima RashidÎncă nu există evaluări

- S 44Document1 paginăS 44Prof Dr Md Saifur RahmanÎncă nu există evaluări

- S 44Document1 paginăS 44Prof Dr Md Saifur RahmanÎncă nu există evaluări

- S 44Document1 paginăS 44Prof Dr Md Saifur RahmanÎncă nu există evaluări

- S 44Document1 paginăS 44Prof Dr Md Saifur RahmanÎncă nu există evaluări

- S 45Document1 paginăS 45Prof Dr Md Saifur RahmanÎncă nu există evaluări

- S 43Document1 paginăS 43Prof Dr Md Saifur RahmanÎncă nu există evaluări

- S 44Document1 paginăS 44Prof Dr Md Saifur RahmanÎncă nu există evaluări

- S 44Document1 paginăS 44Prof Dr Md Saifur RahmanÎncă nu există evaluări

- S 36Document1 paginăS 36Prof Dr Md Saifur RahmanÎncă nu există evaluări

- S 39Document1 paginăS 39Prof Dr Md Saifur RahmanÎncă nu există evaluări

- S 40Document1 paginăS 40Prof Dr Md Saifur RahmanÎncă nu există evaluări

- S 42Document1 paginăS 42Prof Dr Md Saifur RahmanÎncă nu există evaluări

- S 36Document1 paginăS 36Prof Dr Md Saifur RahmanÎncă nu există evaluări

- S 36Document1 paginăS 36Prof Dr Md Saifur RahmanÎncă nu există evaluări

- S 31Document1 paginăS 31Prof Dr Md Saifur RahmanÎncă nu există evaluări

- S 30Document1 paginăS 30Prof Dr Md Saifur RahmanÎncă nu există evaluări

- S 33Document1 paginăS 33Prof Dr Md Saifur RahmanÎncă nu există evaluări

- S 35Document1 paginăS 35Prof Dr Md Saifur RahmanÎncă nu există evaluări

- S 34Document1 paginăS 34Prof Dr Md Saifur RahmanÎncă nu există evaluări

- S 32Document1 paginăS 32Prof Dr Md Saifur RahmanÎncă nu există evaluări

- S 26Document1 paginăS 26Prof Dr Md Saifur RahmanÎncă nu există evaluări

- S 29Document1 paginăS 29Prof Dr Md Saifur RahmanÎncă nu există evaluări

- S 28Document1 paginăS 28Prof Dr Md Saifur RahmanÎncă nu există evaluări

- S 25Document1 paginăS 25Prof Dr Md Saifur RahmanÎncă nu există evaluări

- S 22Document1 paginăS 22Prof Dr Md Saifur RahmanÎncă nu există evaluări

- S 27Document1 paginăS 27Prof Dr Md Saifur RahmanÎncă nu există evaluări

- S 23Document1 paginăS 23Prof Dr Md Saifur RahmanÎncă nu există evaluări

- S 24Document1 paginăS 24Prof Dr Md Saifur RahmanÎncă nu există evaluări

- S 21Document1 paginăS 21Prof Dr Md Saifur RahmanÎncă nu există evaluări

- S 20Document1 paginăS 20Prof Dr Md Saifur RahmanÎncă nu există evaluări