Documente Academic

Documente Profesional

Documente Cultură

Manual PQM II

Încărcat de

Luis Eugenio Hernandez QuijaiteDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Manual PQM II

Încărcat de

Luis Eugenio Hernandez QuijaiteDrepturi de autor:

Formate disponibile

PQM II

power quality meter Power Quality and Energy Cost Management

Digital Metering

Key Benefits

Power quality metering with waveform capture and historical data logging Easy to program and use with keypad and large illuminated 40 character display Multiple communication ports for integration with DCS and SCADA systems Supports DNP 3.0 and Modbus protocols Digital and analog I/Os for control and alarms Voltage disturbance recording capability for electrical sag and swell events.

Applications

Metering of distribution feeders, transformers, generators, capacitor banks and motors Medium and low voltage systems Commercial, industrial, utility Flexible control for demand load shedding, power factor, etc.

Features Features

Monitoring and Metering

Ia Ib Ic In Va Vb Vc Vab Vbc Vca V I unbalance True PF crest and K factor Hz W var VA Wh varh VAh W cost Demand: A W var VA Harmonic analysis through 63rd with THD and TIF Event recorder - 150 events Waveform capture Data logger -98,000 events Voltage Disturbance Recorder (VDR) -500 events

Communications

Front RS232 serial port (1,200 to 19,200 bps) Two rear RS485 serial ports with ModBus and DNP 3.0 protocol Ethernet connectivity provided by MultiNet EnerVistaTM software is provided for setup and monitoring functions External dial-in modem capabilities

Protection & Control

Load shedding Power factor control Pulse input totalizing

Energy

581

PQM II Power Quality Meter

Introduction

GE Multilin has set a new standard in metering technology with the introduction of the PQM II. This meter, designed on the latest industry specifications, provides accurate and reliable three-phase power metering with an optional Ethernet and fiber communications module in a small and modern package. The PQM II can be used for a variety of applications including metering of distribution feeders, transformers, generators and motors.

Ethernet capability

With the optional Multinet module, users can add Ethernet capability to their meter. Multinet is an Ethernet communications module that allows connection of up to 30 ModBus devices, providing ModBus TCP/IP communications for these devices over Ethernet. This allows connection to Fiber Optic LAN and WAN systems for remote access to data on the PQM II.

Hz W var VA Wh varh VAh W cost Demand: A W var VA

Keypad and illuminated 40 character dis play provides local setpoint settings and monitoring of values and status.

Mounting Versatility

PQM II panel mount with display, offers an easy local interface. Standard models have RS485 communications for programming and monitoring. Users can replace expensive additional devices byadding the CONTROL, TRANS DUCER and POWER analysis options to the PQM II as required.

Standard Features

The PQM II provides continuous monitoring of a three-phase system. It provides metering of current, voltage, real and reactive power, energy use, cost of power, power factor and frequency. Ethernet communications are available through the optional Multinet module.

Robust Metering and Power Quality Capabilities in One Package

The PQM II is an ideal choice when continuous monitoring of a three phase system is required. It provides metering for current, voltage, real and reactive power, energy use, cost of power, power factor and frequency. Waveform capture and Voltage Disturbance Recorder continuously monitors power quality. Programmable setpoints and 4 assignable output relays allow control functions to be added for specific applications.

Alarms

Any of the assignable outputs may be used to trigger an alarm for specific applications. Simple alarm messages provide easy notification.

Metering

PQM II is a true RMS meter with 0.2% accuracy for voltage and currents. The PQM II provides advanced features for monitoring and metering which include:

Ia Ib Ic In Va Vb Vc Vab Vbc Vca V I unbalance True PF crest and K factor

Digital Metering

CONDITION

overcurrent undercurrent neutral current current unbalance overvoltage undervoltage phase sequence overfrequency underfrequency power factor switch input

APPLICATION

motors/transformers pumps/compressors leakage/unbalance motors equipment protection motors/load transfer pumps/equipment generators load shedding capacitor banks process control

Communications Made Easy

Integrate process, instrumentation and electrical requirements in a plant automation system by connecting PQM II meters to a DCS or SCADA system. Meter provides multiple communication ports that can provide data simultaneously to multiple masters such as SCADA, DCS, BMS etc. Meter supports both ModBus and DNP 3.0 protocol. A computer running EnerVistaTM software can change system setpoints, monitor values, status and alarms. Continuous monitoring minimizes process downtime by immediately identifying potential problems due to faults or changes.

Industry leading software makes setup simple

The PQM II comes complete with EnerVistaTM GE Multilin's suite of software tools for managing the entire lifecycle implementation of the PQM II. EnerVistaTM contains all of the tools for setting up and configuring your PQM II in minutes via RS232, RS485, external modem or Ethernet LAN.

Connect up to 32 ModBus devices to your Ethernet network

582

www.GEDigitalEnergy.com

PQM II Power Quality Meter

Communications

Integrate process, instrumentation and electrical requirements in a plant automation system by connecting PQM II meters to a DCS or SCADA system. Initially PQM II meters can be used as stand-alone units. Open architecture allows connection to other ModBus compatible devices on the same communication link. At a later stage PQM II can be integrated in a complete plant wide system for overall process monitoring and control. The standard PQM II comes complete with a rear RS485 and front RS232 port. RS232 port can be used for data collection, printing reports or problem analysis without disturbing the main RS485 communication interface at rear. The standard meter provides:

RS485 ModBus 1,200 to 19,200bps DNP 3.0 Level 2 Protocol Mini RTU SCADA system component Measure actual values Read status Issue control commands Load all setpoints from a file Change individual setpoints

STATUS

STATUS

ALARM PROGRAM

1a=100 1b=102 11c 0b0 A2M P S 1a= 0= 0 11 =10 1c=100 AMPS

COMMUNICATE RELAYS

ALARM AUX1 MESSAGE AUX2 AUX3

ESCAPE

COMMUNICATE RELAYS ALARM TX1

TX1 ALARM

PROGRAM RX1

RX1 TX2 RX2

AUX1 AUX2 AUX3

MESSAGE ENTER VALUE

VALUE

ENTER

SIMULATION TX2 SIMULATION SELF TEST

MENU

MENU

SELF TEST

RX2

e e

ESCAPE

Power Quality Meter

RESET

Power Quality Meter

RESET

Connect two 4 to 20 mA transducers for process variable measurement and control.

Future Expansion

The PQM II uses non-volatile flash memory for firmware storage. This allows future product upgrades to be loaded via the serial port. Upgrades can also be downloaded from the GE Multilin website.

Communications

Second Rear Comm Port: An additional rear RS485 comm port is provided for simultaneous monitoring by process, instrument, electrical or maintenance personnel.

Options

There are a variety of options available to the user, allowing a range of custom configurations:

Control

Three output relays and four inputs allow measured parameters from the standard PQM II to be combined with setpoints and I/Os for control applications. With the control option, three output relays and four switch inputs are added along with programmable set points to make a mini RTU. Output relays can also be controlled via the communication port or assigned to different setpoints for custom programming to accommodate many applications such as: Undercurrent alarm for pumps Over and undervoltage for generators Unbalance alarm for rotating machines Dual level power factor for capacitor bank switching Underfrequency/demand output for load shedding resulting in power cost savings kWh, kvarh and kVAh pulse output for PLC interface

Transducer

Four Analog Outputs: Four isolated analog outputs can be used to replace eight analog transducers. Output signals can be selected from any of the measured parameters for direct interface to a PLC or other devices. Analog Input: PQM II meter can accept two analog inputs from external devices. Meter can be programmed to activate a control relay based on analog input from transducers (temperature, level etc.)

A computer running EnerVistaTM software can change system setpoints, monitor values, status and alarms. Continuous monitoring minimizes process downtime by immediately identifying potential problems due to faults or changes.

COM 1 RS485

PLANT CONTROL SYSTEM

COM 2 RS485

Power Analysis

Data Logger (Trending): Trending is useful as a trouble shooting aid when a problem is detected. Measured values can be selected and plotted with a programmable sampling rate to suit the time interval of interest. The generated chart recorder screen can be printed or

VALUE

1a=100 1b=102 1c=100 AMPS

STATUS

ALARM PROGRAM SIMULATION SELF TEST

1a=100 1b=102 1c=100 AMPS

STATUS

ALARM

MESSAGE VALUE

ENTER

1a=100 1b=102 1c=100 AMPS

STATUS

ALARM

MESSAGE VALUE

ENTER

COMMUNICATE RELAYS

TX1 RX1 TX2 RX2 ALARM AUX1 AUX2 AUX3

ESCAPE

COMMUNICATE RELAYS

TX1 RX1 TX2 RX2 ALARM AUX1 AUX2 AUX3

ESCAPE

COMMUNICATE RELAYS

TX1 RX1 TX2 RX2 ALARM AUX1 AUX2 AUX3

ESCAPE

PROGRAM

MENU

PROGRAM

MENU

MESSAGE

ENTER

SIMULATION SELF TEST

SIMULATION SELF TEST

MENU

Power Quality Meter

RESET

Power Quality Meter

RESET

Power Quality Meter

RESET

Redundancy in high security systems is provided by the 2nd RS485 comm port.

www.GEDigitalEnergy.com

583

Digital Metering

PQM II Power Quality Meter

exported to other programs for report writing. Harmonic Analysis: Non linear loads such as variable speed drives, computers and electronic ballasts can cause harmonics which may lead to problems such as nuisance breaker tripping, telephone interference, transformer, capacitor or motor overheating. Harmonic analysis can be used for fault diagnosis such as detecting undersized neutral wiring, need for a harmonic rated transformer, or effectiveness of harmonic filters. Details of the harmonic spectrum are useful and available with the power analysis option. Voltage Disturbance Recorder (VDR) The Voltage Disturbance Recorder (VDR) function adds to the PQM II the ability to monitor and record Sag and Swell disturbances. It can record up to 500 sag/swell events for all voltages simultaneously.

Digital Metering

Waveform Capture: Voltage and current waveforms can be captured and displayed on a PC using the EnerVistaTM program supplied with the PQM II or using third party software. Distorted peaks or notches from SCR switching provide clues for taking corrective action. Event Recorder: Alarms, setpoint triggers, input and output events can be stored in a 150 event record and time and date stamped by the internal clock. This is useful for diagnosing problems and system activity. Minimum and maximum values are also continuously updated and time stamped. Trace Memory: The PQM II can be configured to record a maximum of 36 cycles of data on all voltage and current inputs based on overvoltage, undervoltage, overcurrent or switch input state change.

EnerVistaTM Software

EnerVistaTM Launchpad

EnerVistaTM Launchpad is a powerful software package that provides users with all of the setup and support tools needed for configuring and maintaining GE Multilin Products. Launchpad allows configuration of devices in real-time by communicating using RS232, RS485, Ethernet, or modem connections. The intuitive user interface makes it simple to enter setpoints, read metered values, monitor status and evaluate power quality. Powerful troubleshooting features make it easy to retrieve and view voltage & current waveshapes and harmonic analysis. This vital information can help provide early warning of problems and prevent equipment damage or nuisance breaker tripping.

EnerVista Launchpad PQM II Setup and Analysis

PQM II setup program contains many tools and reports that simplify device configuration and allows viewing of power system events.

Simplified IED Setup

Record trends of measured parameters over time

Voltage and current waveforms provide valuable insights into system problems

584

www.GEDigitalEnergy.com

PQM II Power Quality Meter

Included in Launchpad is a document archiving and management system that ensures critical documentation is up-to-date and available when needed by automatically checking for and downloading new versions of manuals, applications notes, specifications, and service bulletins.

Annunciator Alarm Screens Trending Reports Automatic Event Retrieval Automatic Waveform Retrieval

EnerVistaTM Integrator

EnerVistaTM Integrator is a toolkit that allows seamless integration of GE Multilin devices into new or existing automation systems by sending GE device data to HMI, DCS, and SCADA systems. Included in EnerVista Integrator is: OPC/DDE Server GE Multilin Drivers Automatic Event Retrieval Automatic Waveform Retrieval

Viewpoint Monitoring

Viewpoint Monitoring is a simple-touse, full-featured monitoring and data recording software package for small systems. Viewpoint Monitoring provides a complete HMI package that instantly puts critical real-time device data on your PC through pre-configured graphical screens with the following functionality. Plug-&-Play Device Monitoring System Single-Line Monitoring & Control

EnerVista Viewpoint Monitoring Plug-and-Play Screens

Viewpoint Monitoring PQM II analysis screen for detailed power quality information

Viewpoint Monitoring PQM II real-time overview screen for detailed device status

www.GEDigitalEnergy.com

585

Digital Metering

PQM II Power Quality Meter

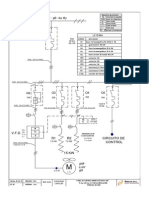

Typical Wiring

ALTERNATIVE CT/VT CONNECTIONS

4 WIRE WYE/120 VOLTAGE 3 VTs PHASE A CT PHASE B CT PHASE C CT OPTIONAL NEUTRAL CT ANY VOLTAGE LOAD A B C N

4 WIRE WYE/120 VOLTAGE 3 VTs A B LINE C N PHASE A CT PHASE B CT PHASE C CT

ANY VOLTAGE A B C OPTIONAL NEUTRAL CT N LOAD

LINE A B C N

VT an

VT bn

VT cn

1 V1

9

5A

10

1A

11 12

COM 5A

13 14 15 16

1A COM 5A 1A

17

COM

18 19 20

5A 1A COM

V2 V3 VN VOLTAGE INPUTS

PHASE A

PHASE B

PHASE C

NEUTRAL

CURRENT INPUTS

Perferrred 4 wire configuration

4 WIRE WYE DIRECT/120 VOLTAGE NO VT LINE A B C N PHASE A CT PHASE B CT PHASE C CT OPTIONAL NEUTRAL CT 600V MAX LOAD A B C N

OBSERVE CT & VT POLARITY

VT an

VT bn

VT cn

1 V1

CONTROL POWER 90-300 VDC 70-265 VAC 50/60 Hz

9

5A

10

1A

11 12 13 14 15 16 17

COM 5A 1A COM 5A 1A COM

18 19 20

5A 1A COM

V 2 V3 VN VOLTAGE INPUTS

PHASE A

1 V1

9

5A

10

1A

11 12

COM 5A

13 14 15 16

1A COM 5A 1A

17

COM

18 19 20

5A 1A COM

PHASE C PHASE B CURRENT INPUTS

NEUTRAL

V2 V3 VN VOLTAGE INPUTS

PHASE A

PHASE B

PHASE C

NEUTRAL

Digital Metering

CURRENT INPUTS ANY VOLTAGE LOAD A PHASE B CT PHASE C CT OPTIONAL NEUTRAL CT B C N

8 7

USE HEAVY GAUGE WIRE

4 WIRE WYE/60 VOLTAGE 2 VTs (2-1/2 ELEMENTS) LINE A B C N PHASE A CT

+ N _

6 5

SAFETY GROUND FILTER GROUND

g

ALARM

COM 1

VT an

VT cn

SWITCHGEAR GROUND BUS 45 NO

RS 485 S ERIAL

COM 2

CONTROL POWER

Multilin PQM II Power Quality Metering System

+ _ COM + _ COM 48 47 46 51 50 49

USE SHIELDED TWISTED PAIR WIRE COM1 RS485 TO/FROM DEVICE COM2 RS485 TO/FROM DEVICE

1 V1

9

5A

10

1A

11 12

COM 5A

13 14 15 16

1A COM 5A 1A

17

COM

18 19 20

5A 1A COM

44 COM 43 NC

V2 V3 VN VOLTAGE INPUTS

PHASE A

PHASE B

PHASE C

NEUTRAL

CURRENT INPUTS

*Note: Accurate only with balanced phase voltages

3 WIRE DELTA/60 VOLTAGE 2 VTs 2 PHASE CTs ANY VOLTAGE LOAD A B PHASE C CT C

42 NO 41 COM 40 NC 39 NO 38 COM 37 NC 36 NO AUX2 AUX1

OUTPUT RELAYS

ANALOG IN

+ _

SHIELD

23 22 21 4-20mA TRANSDUCER

LINE A B C

VT ab VT cb

1+

ANALOG OUT 4-20m A

28 27 26 25 24 TO PLC OR SCADA SYSTEM

2+ 3+ 4+ COM

2 or 3 CTs see below

35 COM 34 NC DRY CONTACT SWITCH INPUTS

AUX3

1 V1

9

5A

10

1A

11 12

COM 5A

13 14

1A COM

15 16

5A 1A

17 18 19

COM 5A 1A

20

COM

V2 V3 VN VOLTAGE INPUTS

PHASE A

PHASE B

PHASE C

NEUTRAL

CURRENT INPUTS

PROGRAMMABLE SWITCH INPUTS

Preferred 3 wire configuration

3 WIRE DIRECT/120 VOLTAGE NO VTs LINE A B C PHASE A CT PHASE B CT PHASE C CT 2 or 3 CTs see above 600V MAX LOAD L N

32 31 30 29

SW1 SW2 SW3 SW4

COM3 RS232 (FRONT)

RS232 INTERFACE

PQM 1 2 3 4 SGND 5 6 7 8 9 TXD RXD 9 PIN CONNECTOR 25 PIN CONNECTOR COMPUTER 1 2 3 4 5 6 7 8 9 8 3 RXD 2 TXD 20 7 SGND 6 4 5 22

1 V1

9

5A

10

1A

11 12

COM 5A

13 14

1A COM

15 16

5A 1A

17 18 19

COM 5A 1A

20

COM

V2 V3 VN VOLTAGE INPUTS

PHASE A

PHASE B

PHASE C

NEUTRAL

NOTES: 1) Relay contact state shown with control power not applied.

CURRENT INPUTS 600V MAX LOAD L N

SINGLE PHASE DIRECT NO VTs LINE L N PHASE CT

PERSONAL COMPUTER

CAUTION: USE HRC FUSES FOR VT PRIMARY TO ENSURE ADEQUATE INTERRUPTING CAPACITY.

1 V1

9

5A

10

1A

11 12

COM 5A

13 14 15 16

1A COM 5A 1A

17

COM

18 19 20

5A 1A COM

Transducer Option Control Option

V2 V3 VN VOLTAGE INPUTS

PHASE A

PHASE B

PHASE C

NEUTRAL

CURRENT INPUTS

586

www.GEDigitalEnergy.com

9 WIRE RS 232

33 +24VDC

RS232

PQM II Power Quality Meter

Technical Specifications

monitoring undervoltage monitoring Required voltage: 20 V applied Pickup level: 0.50 0.99 in steps of 0.01 x VT Dropout level: 103% of pickup Time delay: 0.5 600.0 in steps of 0.5 sec Phases: Any one/any two/all three (programmable) phases have to go below pickup to operate Level accuracy: Per voltage input Timing accuracy: -0/+1 sec Overvoltage monitoring Pickup level: 1.01 1.25 in steps of 0.01 x VT Dropout level: 97% of pickup Time delay: 0.5 600.0 in steps of 0.5 sec Phases: Any one/any two/all three (programmable) phases have to exceed pickup to operate Level accuracy: Per voltage input Timing accuracy: -0/+1 sec Underfrequency monitoring Required voltage: 20 V applied Pickup level: 20 70.00 in steps of 0.01 Hz Dropout level: Pickup +0.03 Hz Time delay: 0.1 10.0 in steps of 0.1 sec Level accuracy: 0.02 Hz Timing accuracy: 3 cycles Overfrequency monitoring Required voltage: 20 V applied Pickup level: 20 70.00 in steps of 0.01 Hz Dropout level: Pickup -0.03 Hz Time delay: 0.1 10.0 in steps of 0.1 sec Level accuracy: 0.02 Hz Timing accuracy: 3 cycles Power factor monitoring Required voltage: 20 V applied Pickup level: 0.50 lag 0.50 lead in steps of 0.01 Dropout level: 0.50 lag 0.50 lead in steps of 0.01 Time delay: 0.5 600.0 in steps of 0.5 sec Timing accuracy: -0/+1 sec SAMPLING MODES SAMPLES/ INPUTS SAMPLED DURATION

CYCLE AT A TIME

INPUTs AC CURRENT Conversion: True RMS, 64 samples/cycle 1 A and 5 A secondary CT input: 0.2 VA Burden: Overload: 20 x CT for 1 sec 100 x CT for 0.2 sec Full scale: 150% of CT Frequency: up to 32nd harmonic Accuracy: 0.2% of full scale, true RMS AC voltage Conversion: True RMS, 64 samples/cycle VT pri/sec: Direct or 120 72,000 : 69 240 Input range: 20 600 VAC Full scale: 150/600 VAC autoscaled Burden: <0.1 VA Frequency: up to 32nd harmonic Accuracy: 0.2% of full scale, true RMS switch inputs Type: Dry contact Resistance: 1,000 max ON resistance Voltage: 24 VDC @ 2 mA Duration: 100 ms minimum analog input Range: 4 20 mA Accuracy: 1% of full scale Relay output: Programmable 4 20 mA Internal burden resistance: 250 pulse INPUT Max inputs: 4 Min pulse width: 150 ms Min off time: 200 ms communications COM1/COM2 type: RS485 2-wire, half duplex, isolated COM3 type: RS232, 9PIN Baud rate: 1,200 19,200 bps Protocol: ModBus RTU and DNP 3.0 level 2 Functions: Read/write setpoints Read actual values Execute commands POWER SUPPLY control power Input: Power: Holdup:

OUTPUTs analog outputs Accuracy: 1% of full scale reading OUTPUT 0 1 mA (T1 Option) 4 20 mA (T20 Option) Max load 2400 600 Max output 1.1 mA 21 mA Isolation: 36 VDC isolated, active source output relays Voltage Make/Carry Make/Carry Continuous 0.2 SEC Break 30 Vdc 5 30 5 Resistive 125 Vdc 5 30 0.5 250 Vdc 5 30 0.3 30 Vdc 5 30 5 Inductive 125 Vdc 5 30 0.25 (Vr = 7ms) 250 Vdc 5 30 0.15 120 Vac 5 30 5 Resistive 250 Vac 5 30 5 Inductive 120 Vac 5 30 5 PF = 0.4 250 Vac 5 30 5 Configuration FORM C NO/NC Contact material SILVER ALLOY pulse output +ve kWh, ve kWh, +ve kvarh, Parameters: ve kvarh, kVAh Interval: 1 65000 in steps of 1 Pulse width: 100 2000 ms in steps of 10 ms Min pulse interval:500 ms TYPE TESTS Dielectric voltage withstand: Impulse voltage withstand: Insulation resistance: Damped Oscillatory: Electrostatic Discharge: RF immunity:

EN60255-5 EN60255-5 EN60255-5 IEC61000-4-18 / IEC6025522-1 EN61000-4-2 / IEC6025522-2 EN61000-4-3 / IEC6025522-3 EN61000-4-4 / IEC6025522-4 EN61000-4-5 / IEC6025522-5 EN61000-4-6 / IEC6025522-6 CISPR11 / CISPR22 / IEC60255-25 IEC60255-21-1 IEC60255-21-2 IEC61000-4-8 IEC61000-4-9 IEC61000-4-11 IEC60529 IEC60068-2-1 IEC60068-2-2 IEC60068-2-30 IEEE / ANSI C37.90.1

Metered values Trace memory

64 16 Harmonic spectrum 256

ALL ALL 1

2 continuous 1

(CYCLES)

90 300 VDC 70 265 VAC 50/60 Hz 10 VA nominal, 20 VA maximum 100 ms typical @ 120 VAC/VDC -10C to +60C operating up to 95% (non condensing) @ 55C 2 IP40 (front), IP20 (back)

Fast Transient Disturbance: Surge Immunity: Conducted RF Immunity: Radiated & Conducted Emissions: Sinusoidal Vibration: Shock & Bump: Power magnetic Immunity: Pulse Magnetic Immunity: Voltage Dip & interruption: Ingress Protection: Environmental (Cold): Environmental (Dry heat): Relative Humidity Cyclic: EFT: Approvals ISO: cULus e83849 NKCR/7: CE:

Demand Monitoring Measured values: Phase A/B/C/N current (A) 3f real power (kW) 3f reactive power (kvar) 3f apparent power (kVA) Measurement type:Thermal exponential 90% response time (programmable): 5 60 min, steps of 1 min Block interval/rolling demand time in interval (programmable): 5 60 min, steps of 1 min Pickup level: A: 10 7,500 in steps of 1 kW: 0.1 6,500.0 in steps of 0.1 kvar: 0.1 6,500.0 in steps of 0.1 kVA: 0.1 6,500.0 in steps of 0.1 METERING measured values ACCURACY

PARAMETER Voltage Current Voltage unbalance Current unbalance kW kvar kVA kWh kvarh kVAh Power factor Frequency kw demand kvar demand kva demand Amps demand Amps THD Volts THD Crest factor

Environmental Operating Temperature: Humidity: Pollution Degree: Ingress Protection:

Packaging Shipping box: 8 1/2" L x 6" H x 6" D (215 mm x 152 mm x 152 mm) Ship weight: 5 lbs (2.3 kg) Note: LCD contrast impaired below -20 C

(% of full scale) RESOLUTION RANGE 0.2% 1 VOLT 20% of VT 100% of VT 0.2% 1 A 1% of CT 150% of CT 1% 0.1% 0 100.0% 1% 0.1% 0 100.0% 0.4% 0.01 kW 0 999,999.99 kW 0.4% 0.01 kvar 0 999,999.99 kvar 0.4% 0.01 kVA 0 999,999.99 kVA 0.4% 1 kWh 232 kWh 0.4% 1 kvarh 232 kvarh 0.4% 1 kVAh 232 kVAh 1% 0.01 0.0 1.0 0.02 Hz 0.01 Hz 20.00 70.00 Hz 0.4% 0.1 kw 999,999.99 kw 0.4% 0.1 kvar 999,999.99 kvar 0.4% 0.1 kva 999,999.99 kva 0.2% 1 A 0 7,500 A 2.0% 0.1% 0.0 100.0% 2.0% 0.1% 0.0 100.0% 0.4% 1 9.99

Manufactured to an ISO9001 registered program UL508, UL1053, C22.2.No 14 EN60255-5, EN61000-6-2

Please refer to the Multilin PQMII Power Quality Meter Instruction Manual for complete technical specifications

www.GEDigitalEnergy.com

587

Digital Metering

PQM II Power Quality Meter

PQM II Dimensions

A B

1.73" (44)

Digital Metering

(6) - 0.218" Dia. HOLES (6.00) 7 . 24" (184)

3.47" (88)

Ordering

PQM II

PQM I I Basic unit with display, all current/voltage/power measurements, T20 Transducer option; 4 isolated analog outputs 0 20 mA and 4 20 mA,

1RS485 comm port, 1 RS232 comm port

746750A1.dwg

Description

assignable to all measured parameters, 4 20 mA analog input, 2nd RS485 comm port T1 Transducer option; 4 isolated analog outputs 0 1 mA, assignable to all measured parameters, 4 20 mA analog input, 2nd RS485 comm port C Control option; 3 additional programmable output relays (total of 4), 4programmable switch inputs Power analysis option; harmonic analysis, triggered trace memory A waveform capture, event record, data logger, voltage disturbance recorder (VDR) Modifications:

MOD 501: MOD 504: MOD 525:

Control Power:

90 300 VDC/70 265 VAC standard 20 60 VDC/20 48 VAC 20 60 VDC/20 48 VAC (MOD 501) control power Removable terminal blocks Harsh Environments Conformal Coating

Accessories for the PQM II:

Multilink Ethernet Switch Multinet Viewpoint Monitoring ML1600-HI-A2-A2 Multinet-FE VP-1

Visit www.GEMultilin.com/PQM II to:

View Guideform Specifications Download the instruction manual Review applications notes and support documents Buy a PQM II online

588

www.GEDigitalEnergy.com

110825-v12

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Planos Del Giramatic Del PLCDocument88 paginiPlanos Del Giramatic Del PLCLuis Eugenio Hernandez QuijaiteÎncă nu există evaluări

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- 015 Arquitectura APACS1Document12 pagini015 Arquitectura APACS1Luis Eugenio Hernandez QuijaiteÎncă nu există evaluări

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Hardware PLC Pt2Document1 paginăHardware PLC Pt2Luis Eugenio Hernandez QuijaiteÎncă nu există evaluări

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Cat785c D TruckDocument28 paginiCat785c D Truckbanksy875% (4)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Plano PLC Pt2Document11 paginiPlano PLC Pt2Luis Eugenio Hernandez QuijaiteÎncă nu există evaluări

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Plano PLC Dry CobbingDocument7 paginiPlano PLC Dry CobbingLuis Eugenio Hernandez QuijaiteÎncă nu există evaluări

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Diagram ADocument1 paginăDiagram ALuis Eugenio Hernandez QuijaiteÎncă nu există evaluări

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Plano de Ecavadora de MartilloDocument2 paginiPlano de Ecavadora de MartilloLuis Eugenio Hernandez Quijaite100% (1)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Excavadora de MartilloDocument2 paginiExcavadora de MartilloLuis Eugenio Hernandez QuijaiteÎncă nu există evaluări

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Cat785c D TruckDocument28 paginiCat785c D Truckbanksy875% (4)

- Guidelines For Maintaining Motor Efficiency During RebuildingDocument0 paginiGuidelines For Maintaining Motor Efficiency During RebuildingLuis Eugenio Hernandez QuijaiteÎncă nu există evaluări

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Rodaje SKF Nu 310 Ecp - c3Document1 paginăRodaje SKF Nu 310 Ecp - c3Luis Eugenio Hernandez QuijaiteÎncă nu există evaluări

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- Rodaje SKF 7314 BegajDocument1 paginăRodaje SKF 7314 BegajLuis Eugenio Hernandez QuijaiteÎncă nu există evaluări

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Unifilar ConveyorDocument1 paginăUnifilar ConveyorLuis Eugenio Hernandez QuijaiteÎncă nu există evaluări

- Produced by An Autodesk Educational Product: PoleaDocument1 paginăProduced by An Autodesk Educational Product: PoleaLuis Eugenio Hernandez QuijaiteÎncă nu există evaluări

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Tablero Marco (2) ModelDocument1 paginăTablero Marco (2) ModelLuis Eugenio Hernandez QuijaiteÎncă nu există evaluări

- Circuito de Control R1 R2 V.F.D.: 63A 85 KA NS 100Document1 paginăCircuito de Control R1 R2 V.F.D.: 63A 85 KA NS 100Luis Eugenio Hernandez QuijaiteÎncă nu există evaluări

- Tablero Marco ModelDocument1 paginăTablero Marco ModelLuis Eugenio Hernandez QuijaiteÎncă nu există evaluări

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- Wound RotorDocument4 paginiWound Rotormareymorsy2822Încă nu există evaluări

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- MaintenanceDocument55 paginiMaintenanceAshraf EnjoyingÎncă nu există evaluări

- Rotor Winding1Document7 paginiRotor Winding1Luis Eugenio Hernandez QuijaiteÎncă nu există evaluări

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Catalogo de Maquina de Soldar Marca Miller XMT 304 CC CV MA410427ADocument36 paginiCatalogo de Maquina de Soldar Marca Miller XMT 304 CC CV MA410427ALuis Eugenio Hernandez QuijaiteÎncă nu există evaluări

- S e R I e S: Motortroni CSDocument4 paginiS e R I e S: Motortroni CSLuis Eugenio Hernandez QuijaiteÎncă nu există evaluări

- Sample Codal ComplianceDocument1 paginăSample Codal Complianceshangz1511Încă nu există evaluări

- Collusion-Resistant Group Key Management Using Attribute-Based EncryptionDocument15 paginiCollusion-Resistant Group Key Management Using Attribute-Based Encryptionsomebody314Încă nu există evaluări

- Summative Test English 8Document2 paginiSummative Test English 8Cristina SarmientoÎncă nu există evaluări

- Part 1 General EducationDocument8 paginiPart 1 General EducationGrimReaper20Încă nu există evaluări

- FIRO Element B InterpretationDocument8 paginiFIRO Element B InterpretationchinadavehkÎncă nu există evaluări

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- EN GB SPIKE Prime Python ProgramsDocument31 paginiEN GB SPIKE Prime Python ProgramsAMINE BOURASSÎncă nu există evaluări

- Working With DatabaseDocument105 paginiWorking With DatabaseTara Marie Robinson WhiteÎncă nu există evaluări

- Lecture15 Analysis of Single PilesDocument32 paginiLecture15 Analysis of Single PilesJulius Ceasar SanorjoÎncă nu există evaluări

- Free W3 Blog TemplateDocument4 paginiFree W3 Blog TemplateMaseko CharuzuÎncă nu există evaluări

- Servomotor PptsDocument26 paginiServomotor Pptsjasdeep_kour236066Încă nu există evaluări

- 160W002GB Brochure ColormixDocument40 pagini160W002GB Brochure ColormixPaky PakicÎncă nu există evaluări

- Gold Exp C1 U4 Lang Test BDocument2 paginiGold Exp C1 U4 Lang Test Bmaituti1Încă nu există evaluări

- Block 7Document15 paginiBlock 7api-3703652Încă nu există evaluări

- What Are You Going To Do Today?: Learning ObjectivesDocument10 paginiWhat Are You Going To Do Today?: Learning ObjectivesMaryantiÎncă nu există evaluări

- How GE Is Disrupting ItselfDocument2 paginiHow GE Is Disrupting ItselfAdithya PrabuÎncă nu există evaluări

- Advances Chemical Engineering PDFDocument248 paginiAdvances Chemical Engineering PDFDaiane SantanaÎncă nu există evaluări

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Math - MAA Problem Series List PDFDocument2 paginiMath - MAA Problem Series List PDFadasdÎncă nu există evaluări

- PEI-QHSE-002-Hazards Identification and Risk Management ProcedureDocument16 paginiPEI-QHSE-002-Hazards Identification and Risk Management ProcedureJacob Keemink100% (1)

- IBPS IT Officer Model Questions Computer MIcroprocessor and Assembly Language MCQ Question BankDocument146 paginiIBPS IT Officer Model Questions Computer MIcroprocessor and Assembly Language MCQ Question BankNaveen KrishnanÎncă nu există evaluări

- Thiết bị hiệu chuẩn BeamexDocument116 paginiThiết bị hiệu chuẩn BeamexLe Thanh DuyÎncă nu există evaluări

- Edimax Print Server PS 1210MFn ManualDocument144 paginiEdimax Print Server PS 1210MFn ManualCODYBOSS1969Încă nu există evaluări

- A Disease, Disorder, Illness or Condition: How To Label Epilepsy?Document5 paginiA Disease, Disorder, Illness or Condition: How To Label Epilepsy?HaniÎncă nu există evaluări

- Asl Ga75 PDFDocument76 paginiAsl Ga75 PDFMarco Soto100% (1)

- Chapter One 1.1. Background of The Study: Iloilo City's Heritage Tourist Destinations Are Worth Keeping ForDocument2 paginiChapter One 1.1. Background of The Study: Iloilo City's Heritage Tourist Destinations Are Worth Keeping ForCrisÎncă nu există evaluări

- Anth 1020 Natural Selection Lab ReportDocument4 paginiAnth 1020 Natural Selection Lab Reportapi-272845435Încă nu există evaluări

- Feasibility Study OutlineDocument4 paginiFeasibility Study OutlineKim GosengÎncă nu există evaluări

- Identification of The Challenges 2. Analysis 3. Possible Solutions 4. Final RecommendationDocument10 paginiIdentification of The Challenges 2. Analysis 3. Possible Solutions 4. Final RecommendationAvinash VenkatÎncă nu există evaluări

- Intermediate Statistics Test Sample 2Document19 paginiIntermediate Statistics Test Sample 2muralidharan0% (1)

- International Baccalaureate ProgrammeDocument5 paginiInternational Baccalaureate Programmeapi-280508830Încă nu există evaluări

- Raj Yoga ReportDocument17 paginiRaj Yoga ReportSweaty Sunny50% (2)