Documente Academic

Documente Profesional

Documente Cultură

Leds in Automotive Lighting: Dr. Karsten Eichhorn, Hella Kgaa Hueck & Co., Lippstadt, Germany

Încărcat de

Travis WoodTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Leds in Automotive Lighting: Dr. Karsten Eichhorn, Hella Kgaa Hueck & Co., Lippstadt, Germany

Încărcat de

Travis WoodDrepturi de autor:

Formate disponibile

Invited Paper

LEDs in Automotive Lighting

Dr. Karsten Eichhorn, Hella KGaA Hueck & Co., Lippstadt, Germany

Abstract

Light emitting diodes (LED) are becoming more and more significant in interior and exterior automotive lighting. The long service life, energy and space savings, shock and vibration resistance and new styling potential are the main advantages of using LEDs in automotive applications. Today, most central high mounted stop lamps use LEDs. In rear combination lamps the number of LEDs in amber and red is increasing rapidly. This year, a first rear combination lamp using LEDs for all functionalities including the back-up lamp function was realized. In addition, first signal functions in headlamps using white High Power LEDs were launched onto the market. The long service life characteristic makes LEDs especially predestined for the DRL function combined with the position/parking light. Exterior automotive applications, including requirements and performance will be discussed and an outlook will be given on future scenarios. Keywords : LED, Optics, Front Lighting, Rear Lighting, Headlamp, Signal function

1. Introduction

The revolutionary triumph of LEDs in automotive lighting started at the end of the 1980s/beginning of the 1990s with the first central high mounted stop lamps (CHMSL). The fact that today, more than 95 % of these lamp functions are already being generated with the aid of LEDs, underlines the dynamic advanced development and penetration of this technology. The implementation of LEDs in rear combination lamps (RCL) began a decade later. At first, individual tail lamp, stop lamp and direction indicator functions were developed on an LED basis to supplement conventional filament bulb technology. In 2005 the first "full LED" rear combination slamp was launched on the market. All the functionalities including the reverse lamp are realized on the basis of LEDs. They clearly demonstrate the unique combination of advantages of a complete LED lamp solution: vehicle service life, reduced design space thanks to extremely low-profile design and top-level energy saving. The drastic increase in performance of white LEDs in particular in the past few years has made LED technology interesting for headlamp applications, too. As early as 2002, the first position light to use white high-power LEDs and be integrated in the headlamp was presented to the market. Only a year later, daytime running light (DRL) followed in a standard series vehicle. The combination position / daytime running light in particular results in a functional solution predestined for LED technology. Here, the advantages of LEDs in terms of efficiency, ability to be dimmed and service life can be exploited to the full. LED manufacturers predict that the first main lighting functions such as fog light, low beam and high beam will be able to be realized in the next few years, thus completing the application range for LEDs in exterior automotive lighting. This development is underlined by the wide range of prototypes for headlamp main lighting functions currently on display at motor shows all over the world. Figure 1 documents the use of LEDs for various exterior applications on the time line.

Light-Emitting Diodes: Research, Manufacturing, and Applications X, edited by Klaus P. Streubel, H. Walter Yao, E. Fred Schubert, Proc. of SPIE Vol. 6134, 613405, (2006) 0277-786X/06/$15 doi: 10.1117/12.660145 Proc. of SPIE Vol. 6134 613405-1

headlamp

position light

stop light

RCL

tail light

::tion indicator]

Fig. 1 Roadmap for LEDs in exterior automotive lighting

2. Advantages of LEDs in automotive lighting

LEDs have many advantages over the light sources conventionally used in automotive applications. Thus, for example, the very principle of the LED leads to a longer service life and increased reliability. The working principle means that the lamp can be used for 10,000 hours and more, depending on operating temperature and definition. The service life of filament and halogen bulbs is typically a few hundred hours, whereas the gas discharge lamps also used in automotive lighting manage a service life of several thousand hours. In addition, the LED has significant advantages in resisting mechanical stress of the kind which occurs in vehicles. Its compact design is another advantage. LEDs can be used to realize lamp systems optimized in terms of design space, reducing component height and thus saving space. This is supported by the high efficiency of the LEDs, which significantly reduces the heat produced by the complete lighting system, particularly in the case of colored functionalities such as the tail lamp and direction indicator. Not forgetting the innovative styling options which result from the use of several light sources and new, LEDspecific optic concepts. They provide vehicle manufacturers with new possibilities of distinguishing between makes and models.

Proc. of SPIE Vol. 6134 613405-2

Fig. 2 Advantages of LEDs in comparison to conventional light sources in vehicles

3. Structure of an automotive LED system

In order to realize lighting equipment in the vehicle on the basis of LEDs, components other than the light source itself are of major importance for securing the function.

Fig. 3 Components of an automotive LED system

Proc. of SPIE Vol. 6134 613405-3

I.

Suitable thermal management keeps the LED within the component-specific temperature range. At the same time, it ensures that the cover lenses of the headlamp systems do not freeze up in winter. Typically, specially designed heat sinks are used, which can optionally be supplemented by fans. The electronic control depends to a large extent on the functional requirements. Simple individual functional solutions begin with low-cost resistor solutions, whereas more complex circuits are usually based on pulse width modulation. The various structural and connection technologies used to link the light source with the other components are relevant for manufacturing processes and thus pertinent to the question of costs. Last but not least, optical components are also required. Typically, both reflective and transmissive optics can be used. Since the special characteristics of LEDs means that no IR radiation is emitted in the light output direction, solid optics are particularly well suited for this application. These capture the LED light directly at the emitter and guide and shape it extremely efficiently, in particular using the technique of total internal reflection. Combinations, such as classical projectors for example, can also be used as so-called hybrid systems. Figure 4 shows a selection of possible LED optics.

t t.

reflective

transmissive

hybrid

Fig. 4 Examples of reflective, transmissive and hybrid optics

4. LEDs in use

Automotive lighting equipment is generally divided into interior and exterior applications. In the case of exterior applications, a distinction is made between signal functions and main lighting functions. Signal functions are primarily used for vehicle marking as well as to indicate changes in direction. They are located on the front, rear and side of the vehicle. LEDs of all colors, capacities and shapes are already being used for such applications. Figure 5 shows various application examples. In these cases, the higher costs of the LED in comparison with conventional bulbs will determine further market penetration.

Proc. of SPIE Vol. 6134 613405-4

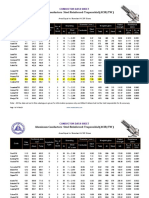

Fig. 5 Examples of LED lamps in series applications The task of main lighting functions in the headlamp is to illuminate the road for the driver in the dark. This makes significantly higher engineering demands on the LED light source. Low luminances and luminous flux per LED in particular have so far made series applications in vehicles impossible. A comparison of the photometric parameters of LEDs with light sources conventionally used (Figure 6) clearly illustrates this fact.

W5W

5O

27OO

Halogen H7

-32OO

-3O

Xenon

D2S

-32OO

-9O

-4OOO

-9O

LED

-65 (2004) -110 (2006)

-30 (2004) -45 (2006)

-650D

-1O (2004)

-20 (2006)

Fig. 6 Comparison of photometric parameters of various light sources used in automotive headlamps

Proc. of SPIE Vol. 6134 613405-5

Yet the steadily increasing performance of LEDs and their further development in the field of automotive applications has put first applications for main lighting functions within grasp. First prototypes have already proved principle feasibility with acceptable light output and design spaces. A handful of multi-chip LEDs is used to produce a luminous flux of several hundred lumen, and specially designed free-form reflectors realize all headlamp lighting functions. Figure 7 shows a demonstrator which realizes the main lighting functions low beam, high beam and sequential bend lighting alongside LED signal functions such as position lamp, direction indicator and daytime running light.

Fig. 7 Prototype of a full LED headlamp

LEDs offer special potential for adaptive-dynamic lighting functions such as bend lighting or future "active" lighting functions. With these, the freely controllable LED provides innovative flexibility in switching and modulating light. In future in particular, this aspect will distinguish LEDs from the light sources currently used.

5. Summary and outlook

The triumph of LEDs in automotive lighting began at the end of the 1980s. Its numerous advantages in comparison with conventional light sources support its continuous market penetration. Starting from the high mounted stop lamp and spreading to signal functions at the rear and front of the vehicle, the realization of a first full LED headlamp including the main lighting functions with white high-power LEDs is expected in the next few years. The time scale for the general replacement of conventional automotive light sources by LEDs mainly depends on the development of the costs per unit of luminous flux generated. Here, automotive applications and white LEDs in particular will benefit from the predicted market penetration of LEDs in the field of general lighting applications.

Proc. of SPIE Vol. 6134 613405-6

S-ar putea să vă placă și

- Logcat CSC Compare LogDocument2.491 paginiLogcat CSC Compare LogCosmin TironÎncă nu există evaluări

- Hitachi L26 L32A01ADocument68 paginiHitachi L26 L32A01ACarlos A. TorresÎncă nu există evaluări

- PowerMaxOS 5978.711.711 Release NotesDocument14 paginiPowerMaxOS 5978.711.711 Release NotesPavan NavÎncă nu există evaluări

- SUBHIKSHADocument12 paginiSUBHIKSHAAkshat ChaturvediÎncă nu există evaluări

- Technical Note: Software Device Drivers For Micron MT29F NAND Flash MemoryDocument12 paginiTechnical Note: Software Device Drivers For Micron MT29F NAND Flash MemorygogiÎncă nu există evaluări

- Mitsubishi 380Document8 paginiMitsubishi 380robertoÎncă nu există evaluări

- KnownIssues ExternalDocument10 paginiKnownIssues ExternalTolulope AbiodunÎncă nu există evaluări

- Ola s1 BrochureDocument6 paginiOla s1 BrochureSajeev S Chadayamangalam SajÎncă nu există evaluări

- F. 5D (Francesca Chu (8) ) - Science Park Vs Cyber PortDocument15 paginiF. 5D (Francesca Chu (8) ) - Science Park Vs Cyber Portapi-19582615Încă nu există evaluări

- Logcat Prev CSC LogDocument1.630 paginiLogcat Prev CSC LogRuth GonzálezÎncă nu există evaluări

- ZYGO Translating From American MIL Drawings To ISO 10110 PDFDocument1 paginăZYGO Translating From American MIL Drawings To ISO 10110 PDFNashraat BukhoryÎncă nu există evaluări

- Complete Business Plan JhanelleDocument18 paginiComplete Business Plan JhanelleCASTOR Z CMNHSÎncă nu există evaluări

- Preparation of Ultrafine Rhenium Powders by CVD Hydrogen Reduction of Volatile Rhenium OxidesDocument5 paginiPreparation of Ultrafine Rhenium Powders by CVD Hydrogen Reduction of Volatile Rhenium OxidesMario Flores SalazarÎncă nu există evaluări

- LV Motors: IE2 Safe Area: Reliable - Long Las NGDocument16 paginiLV Motors: IE2 Safe Area: Reliable - Long Las NGAvish ShahÎncă nu există evaluări

- Status of Secondary Sector in Nabarangpur, OdishaDocument10 paginiStatus of Secondary Sector in Nabarangpur, OdishaEditor IJTSRDÎncă nu există evaluări

- Receipt SummaryDocument1 paginăReceipt SummaryKamna VaidÎncă nu există evaluări

- MGT 7-Annual ReturnDocument14 paginiMGT 7-Annual Returnkalaiselvi venugopalÎncă nu există evaluări

- AcronymsDocument4 paginiAcronymsAnastasia ZaitsevÎncă nu există evaluări

- PMW-160 PMW-150 PMW-EX260: Solid-State Memory CamcorderDocument25 paginiPMW-160 PMW-150 PMW-EX260: Solid-State Memory CamcordersilictronicÎncă nu există evaluări

- Exemplu CVDocument2 paginiExemplu CVAdrian CapatinaÎncă nu există evaluări

- 00217055Document15 pagini00217055api-3834272Încă nu există evaluări

- Basic Understanding Cloud ComputingDocument7 paginiBasic Understanding Cloud ComputingInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- Recen RC A11 Pro Catalog - OptDocument7 paginiRecen RC A11 Pro Catalog - OptINFO TOP SKYÎncă nu există evaluări

- Enphase - Solar Survival Guide - CH 1 Back OfficeDocument19 paginiEnphase - Solar Survival Guide - CH 1 Back OfficeEdson CustodioÎncă nu există evaluări

- KALRE ESE Lightning Protection System CatalogDocument20 paginiKALRE ESE Lightning Protection System CatalogEd Macusi AsuncionÎncă nu există evaluări

- Schneider Preisliste 2012 NLDocument13 paginiSchneider Preisliste 2012 NLalfredopagÎncă nu există evaluări

- Preview ASHRAE+Guideline+23-2016Document4 paginiPreview ASHRAE+Guideline+23-2016Cad TutorÎncă nu există evaluări

- Risk and Return in Practice - ProblemsDocument6 paginiRisk and Return in Practice - ProblemsKinÎncă nu există evaluări

- Rdms Chapter 5Document26 paginiRdms Chapter 5vibhav thakurÎncă nu există evaluări

- Dividend Policy of VEDANTA LTDDocument14 paginiDividend Policy of VEDANTA LTDVivek rathodÎncă nu există evaluări

- SUN2000-50KTL-M3 EN50549-1 Cert - Intertek - 20221018Document2 paginiSUN2000-50KTL-M3 EN50549-1 Cert - Intertek - 20221018Stefan BusoiÎncă nu există evaluări

- Company Profile of Ncell Pvt. Ltd.Document22 paginiCompany Profile of Ncell Pvt. Ltd.Ayush Man Tamrakar100% (1)

- Airteltigo Sms Bundle Code - Google SearchDocument1 paginăAirteltigo Sms Bundle Code - Google SearchAbigail BrownÎncă nu există evaluări

- Sri VadDocument10 paginiSri VadSunyOraÎncă nu există evaluări

- U5L07 - Activity Guide - Will It CrashDocument6 paginiU5L07 - Activity Guide - Will It CrashShatha AlyazoriÎncă nu există evaluări

- Cuadernillo 5toDocument31 paginiCuadernillo 5toNELLY ARIZBETH SERNA VALLEJOÎncă nu există evaluări

- Organic Gaseous FuelsDocument108 paginiOrganic Gaseous FuelsDHANUSH KARTHIK 20BME1003Încă nu există evaluări

- JACC 2017 - 2017 ACC Expert Consensus Decision Pathway On Management of Bleeding in Patients On Oral AnticoagulantsDocument26 paginiJACC 2017 - 2017 ACC Expert Consensus Decision Pathway On Management of Bleeding in Patients On Oral AnticoagulantsMara TorrealbaÎncă nu există evaluări

- Apollo DCF Cards Guide Dispersion Compensation FibersDocument8 paginiApollo DCF Cards Guide Dispersion Compensation FibersmexybabyÎncă nu există evaluări

- GF Ar Complete NotesDocument35 paginiGF Ar Complete Notesviraj007001Încă nu există evaluări

- Ultraconductor ReportDocument25 paginiUltraconductor Reportamit patilÎncă nu există evaluări

- Testing Paytm App for QualityDocument3 paginiTesting Paytm App for Quality04 Omkar BodkeÎncă nu există evaluări

- Assignment#10 Global Strategy and The Multinational CorporationDocument1 paginăAssignment#10 Global Strategy and The Multinational CorporationAnjaneth A. VillegasÎncă nu există evaluări

- Ecology Energy Corporation Company ProfileDocument6 paginiEcology Energy Corporation Company ProfileCrissa Mae Haduca MaritoriaÎncă nu există evaluări

- Strategic ManagementDocument6 paginiStrategic ManagementPramila PaudelÎncă nu există evaluări

- Glucose EstimationDocument6 paginiGlucose EstimationUsman GhaniÎncă nu există evaluări

- Sharad Finial 6Document67 paginiSharad Finial 6diptanshu gaikwadÎncă nu există evaluări

- It Industry in IndiaDocument28 paginiIt Industry in IndiaNjanum NjanumÎncă nu există evaluări

- DT Stock and ETF Report 1-9-2015Document20 paginiDT Stock and ETF Report 1-9-2015chr_maxmannÎncă nu există evaluări

- BK7252, 1 Data SheetDocument25 paginiBK7252, 1 Data SheetRizky SyahÎncă nu există evaluări

- JCZ Marine Axial Fan: Safety - High Quality - Professional - Fast Delivery - Reliable PartnerDocument9 paginiJCZ Marine Axial Fan: Safety - High Quality - Professional - Fast Delivery - Reliable PartnerSea Man MktÎncă nu există evaluări

- NRCEP Announcement of CPD Requirement For Competent PersonsDocument3 paginiNRCEP Announcement of CPD Requirement For Competent PersonsAku Lah100% (2)

- 150w BoostDocument1 pagină150w BoostKunal Kundanam100% (1)

- Antika Raya Malang Offers Aluminum Boxes Starting from Rp18,000,000Document2 paginiAntika Raya Malang Offers Aluminum Boxes Starting from Rp18,000,000AntoproboÎncă nu există evaluări

- Solar Power Industrial Capacity Enhancement in IndiaDocument23 paginiSolar Power Industrial Capacity Enhancement in IndiaSnehal NivsarkarÎncă nu există evaluări

- Aug21 15ec62tDocument25 paginiAug21 15ec62tNAVEENÎncă nu există evaluări

- SIR - Existing Conditions - P10Document396 paginiSIR - Existing Conditions - P10Remington Veritas PraevalebitÎncă nu există evaluări

- The Change in Automobiles Led LightingsDocument39 paginiThe Change in Automobiles Led LightingsShubham BhatnagarÎncă nu există evaluări

- LuminotecniaDocument64 paginiLuminotecniahenlopÎncă nu există evaluări

- DIY Guide: Repairing PAR Lights, 12V SMPS, 5V SMPS, and Pixel LEDDe la EverandDIY Guide: Repairing PAR Lights, 12V SMPS, 5V SMPS, and Pixel LEDÎncă nu există evaluări

- Re Voltage StabilityDocument27 paginiRe Voltage StabilityTravis WoodÎncă nu există evaluări

- Anandaram BaruaDocument1 paginăAnandaram BaruaTravis WoodÎncă nu există evaluări

- Aluminum Conductors Steel Reinforced-Trapezoidal (ACSR/TW)Document4 paginiAluminum Conductors Steel Reinforced-Trapezoidal (ACSR/TW)Travis WoodÎncă nu există evaluări

- Enhanced Performance of Zinc Oxide Arrester by Simple Modification in Processing and Design 2169 0022.1000135Document6 paginiEnhanced Performance of Zinc Oxide Arrester by Simple Modification in Processing and Design 2169 0022.1000135Travis WoodÎncă nu există evaluări

- Unidirectional Corona RingDocument2 paginiUnidirectional Corona RingTravis WoodÎncă nu există evaluări

- April Is The Cruellest MonthDocument1 paginăApril Is The Cruellest MonthTravis WoodÎncă nu există evaluări

- KSEB Technical SPec PDFDocument279 paginiKSEB Technical SPec PDFTravis WoodÎncă nu există evaluări

- Overhead Conductor Installation Guide: Recommended PracticesDocument20 paginiOverhead Conductor Installation Guide: Recommended Practicesvjs270385Încă nu există evaluări

- Gear Design For Quiet Reduction GearDocument8 paginiGear Design For Quiet Reduction GearTravis WoodÎncă nu există evaluări

- Analysis of Grading Ring and Heat Sink Impact on Surge Arrester PerformanceDocument7 paginiAnalysis of Grading Ring and Heat Sink Impact on Surge Arrester PerformanceTravis WoodÎncă nu există evaluări

- 1363 Bolts and Nut Standard PDFDocument7 pagini1363 Bolts and Nut Standard PDFTravis WoodÎncă nu există evaluări

- Ceramic Manufacturing PDFDocument41 paginiCeramic Manufacturing PDFTravis WoodÎncă nu există evaluări

- 3 Sec-III-Hardware Fittings & AccessoriesDocument49 pagini3 Sec-III-Hardware Fittings & AccessoriesTravis WoodÎncă nu există evaluări

- Ehv Disconnectors For Smart GridDocument2 paginiEhv Disconnectors For Smart GridTravis WoodÎncă nu există evaluări

- Double Sampling-Wha It Means PDFDocument17 paginiDouble Sampling-Wha It Means PDFTravis WoodÎncă nu există evaluări

- Anil Agarwal: Research: Mud As A Traditional Building MaterialDocument10 paginiAnil Agarwal: Research: Mud As A Traditional Building MaterialTravis WoodÎncă nu există evaluări

- Study of Single and Double Sampling PlansDocument14 paginiStudy of Single and Double Sampling PlansTravis WoodÎncă nu există evaluări

- En 10204-2004 Metallic Products - Types of Inspection DocumentsDocument10 paginiEn 10204-2004 Metallic Products - Types of Inspection DocumentsDalamagas KwnstantinosÎncă nu există evaluări

- Spacer Damper IssuesDocument5 paginiSpacer Damper IssuesTravis WoodÎncă nu există evaluări

- CT Grounding To Avoid Nuisance TrippingDocument2 paginiCT Grounding To Avoid Nuisance TrippingTravis WoodÎncă nu există evaluări

- Innovative Adhesive For Sandwich SystemsDocument20 paginiInnovative Adhesive For Sandwich SystemsTravis WoodÎncă nu există evaluări

- Transformer Factory Assembly Area LayoutDocument55 paginiTransformer Factory Assembly Area LayoutTravis Wood100% (2)

- Fretting Fatigue in Overhead ConductorsDocument16 paginiFretting Fatigue in Overhead ConductorsTravis WoodÎncă nu există evaluări

- SPEED Continuous Panels Plants Design IssuesDocument18 paginiSPEED Continuous Panels Plants Design IssuesTravis WoodÎncă nu există evaluări

- SPEED Continuous Panels Plants Design IssuesDocument18 paginiSPEED Continuous Panels Plants Design IssuesTravis WoodÎncă nu există evaluări

- An Introduction To Conway's Games and NumbersDocument30 paginiAn Introduction To Conway's Games and NumbersSilentSparrow98Încă nu există evaluări

- ElectricalDocument34 paginiElectricalTravis WoodÎncă nu există evaluări

- Bolt InterlocksDocument5 paginiBolt InterlocksTravis WoodÎncă nu există evaluări

- Mud Architecture: I J I R S E TDocument6 paginiMud Architecture: I J I R S E TJazzÎncă nu există evaluări

- CB Spec SvenskaDocument44 paginiCB Spec SvenskaTravis WoodÎncă nu există evaluări

- Method Report for GPT- GISAN AssayDocument1 paginăMethod Report for GPT- GISAN AssayHussein N. FarhatÎncă nu există evaluări

- Cot 1Document24 paginiCot 1Ronalyn Dechopo BejoÎncă nu există evaluări

- IDRA - NistDocument3 paginiIDRA - NistVolca CmmÎncă nu există evaluări

- Ruide RT-2 User Manual 1908 (A5)Document14 paginiRuide RT-2 User Manual 1908 (A5)Karya Perdana MandiriÎncă nu există evaluări

- Optical Systems Final Exam 2012Document6 paginiOptical Systems Final Exam 2012drhammoudaÎncă nu există evaluări

- Ford replacement headlight and taillight catalogDocument45 paginiFord replacement headlight and taillight catalogLuis Manuel Eduardo ContrerasÎncă nu există evaluări

- Eeer16 PDFDocument143 paginiEeer16 PDFRayapati Devi PrasadÎncă nu există evaluări

- Eumig Projector P8 Automatic Novo User ManualDocument23 paginiEumig Projector P8 Automatic Novo User Manualalmimotiempo71% (7)

- Bicycle Touring Photography GuideDocument52 paginiBicycle Touring Photography GuideBudhiYo100% (1)

- Actividad 3 Images Computer Vision - Ipynb - ColaboratoryDocument8 paginiActividad 3 Images Computer Vision - Ipynb - ColaboratoryAna VelezÎncă nu există evaluări

- An Introduction To Macro PhotographyDocument68 paginiAn Introduction To Macro Photographyb mÎncă nu există evaluări

- Bio Medical Engineering PDFDocument127 paginiBio Medical Engineering PDFRaviChandraReddy100% (1)

- FISA DE LUCRU-Reflexie Totala Si Refractie-ExperimenteDocument4 paginiFISA DE LUCRU-Reflexie Totala Si Refractie-ExperimenteEma BoicuÎncă nu există evaluări

- Gem Identification and Testing Equipment From YourGemologistDocument4 paginiGem Identification and Testing Equipment From YourGemologistDeepak Singh RaghuvansheÎncă nu există evaluări

- Panasonic TC-P50ST30 CNET Review Calibration ResultsDocument7 paginiPanasonic TC-P50ST30 CNET Review Calibration ResultsDavid KatzmaierÎncă nu există evaluări

- Antenna & Wave PropagationDocument3 paginiAntenna & Wave PropagationShakshi AgarwalÎncă nu există evaluări

- Emerging screenless display technologyDocument33 paginiEmerging screenless display technologyAnuÎncă nu există evaluări

- Essential Parameters For The Visibility of Iqis and Small Indications in Digital RadiographyDocument14 paginiEssential Parameters For The Visibility of Iqis and Small Indications in Digital RadiographyAzadeh AliabadiÎncă nu există evaluări

- History of PhotographyDocument11 paginiHistory of Photographyapi-250842033Încă nu există evaluări

- Government of Maharashtra’s Ismail Yusuf College Chemistry MCQDocument6 paginiGovernment of Maharashtra’s Ismail Yusuf College Chemistry MCQFarhadz Sailama BarahamaÎncă nu există evaluări

- JNTU ONLINE EXAMINATIONS for Optoelectronics and Fiber Optic CommunicationDocument22 paginiJNTU ONLINE EXAMINATIONS for Optoelectronics and Fiber Optic CommunicationswarnasugandhÎncă nu există evaluări

- Seismic Reflection Module 3: Properties, Resolution, and AmplitudesDocument53 paginiSeismic Reflection Module 3: Properties, Resolution, and AmplitudesRoy Bryanson SihombingÎncă nu există evaluări

- Save My Exams! GCSE Physics Light RevisionDocument11 paginiSave My Exams! GCSE Physics Light RevisionKim Sanghoo 8AÎncă nu există evaluări

- SPIRE HandbookDocument113 paginiSPIRE HandbookvthiseasÎncă nu există evaluări

- 5 - Light EnergyDocument22 pagini5 - Light EnergyJessa YaunÎncă nu există evaluări

- Epson EH-TW6600 / EH-TW6600W: Brilliant 2D & 3D Entertainment With Wireless HDMIDocument2 paginiEpson EH-TW6600 / EH-TW6600W: Brilliant 2D & 3D Entertainment With Wireless HDMIsangram jadhavÎncă nu există evaluări

- 1st Grade Science Unit: Color and Light: Composed By: David KnappDocument38 pagini1st Grade Science Unit: Color and Light: Composed By: David Knappapi-300868069Încă nu există evaluări

- United States Patent (19) : Patent Number: Date of PatentDocument36 paginiUnited States Patent (19) : Patent Number: Date of PatentGretel HanselÎncă nu există evaluări

- Investigating Light PropertiesDocument11 paginiInvestigating Light PropertiesFrit ZieÎncă nu există evaluări