Documente Academic

Documente Profesional

Documente Cultură

NR-L3-CIV-140-201N (Issue 2) - Section 201 Subgrade and Formation Works - Notes To Specifier (Sept 2009)

Încărcat de

sandycastleTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

NR-L3-CIV-140-201N (Issue 2) - Section 201 Subgrade and Formation Works - Notes To Specifier (Sept 2009)

Încărcat de

sandycastleDrepturi de autor:

Formate disponibile

Reference Issue Publication date Compliance date

NR/L3/CIV/140/201N 2 5th September 2009 5th December 2009

MODEL CLAUSES FOR CIVIL ENGINEERING WORKS

SECTION 201 SUBGRADE AND FORMATION WORKS NOTES TO SPECIFIER: These notes do not form part of the Specification. Frost protection 201.1 In nearly all situations pavement materials within 450 mm of the finished road surface should be non-frost susceptible as required by Specification for Highway Works series 700 clauses. This requirement need not apply for footways. The pavement foundation should be designed for construction traffic loading using the advice contained in the Highways Agency Design Manual for Roads and Bridges (DMRB) Volume 7, Section 2, Part 2. Failure to provide adequate foundations can lead to early pavement failure. Weak areas of formation should be replaced by sub-base or capping, designed in accordance with DMRB Volume 7, Section 2, Part 2. A weak subgrade can be improved and protected by placing a capping layer of relatively cheap material between it and subbase. A capping layer with a laboratory CBR value of at least 15% should provide an adequate platform for constructing the sub-base although the Specification for Highway Works does not require a minimum CBR for the capping or sub-formation. Capping is detailed in Section 201: Subgrade and Formation Works which, in turn, refers to the Specification for Highway Works Series 600 clauses. Two materials for capping are specified: 6F1 - a fine graded material and 6F2 - a coarser graded material. 6F2 is relatively free-draining and is thus more suitable for sites where there is a shallow water table. When a sub-grade has a CBR below 2% it is unsuitable as a pavement foundation. In such cases the material, or as a minimum the top layer down to a level of between half to one metre, should be removed and replaced by more suitable material; but if the soil is cohesive, lime treatment might be an economic option. In either case, the Highways Agency requires that the improved subgrade is overlain by 600 mm of capping. Another method for improving the upper layers of a reasonably permeable subgrade is to install a deeper than normal drainage system.

Pavement design foundations

201.2

Page 1 of 2

Reference Issue Publication date Compliance date

NR/L3/CIV/140/201N 2 5th September 2009 5th December 2009

Further details of subgrade improvement works can be found in DMRB Volume 7, Section 2, Part 2. To minimise the risk of water penetrating slab joints and cracks (which will lead to erosion and weakening of the sub-base) the Highways Agency recommends that cemented sub-bases are only used for rigid and rigid composite pavements. Both granular and cemented sub-bases are permitted for flexible and flexible composite pavements. Sub-formation and capping 201.3 Clause 201.001 may be omitted if there is no requirement for capping. Any restriction in the choice of capping should be explicitly specified. The requirements for capping are described in the DMRB Volume 7. When specifying lime stabilisation, the type of lime (i.e. quicklime, hydrated lime or other form of lime) and the rate of spread should be specified where it differs from that stated in clause 615.

REFERENCES This is a list of publications referred to only within the Notes to Specifier. Publication TSO Title Highways Agency Design Manual for Roads and Bridges Volume 7. Pavement Design and Maintenance. Issue date Latest version available online

Page 2 of 2

S-ar putea să vă placă și

- BS 594.2-92 - Hot Rolled Asphalt For Roads and Other Paved Areas (Spec For Transport, Laying and Compaction of Rolled Asphalt)Document8 paginiBS 594.2-92 - Hot Rolled Asphalt For Roads and Other Paved Areas (Spec For Transport, Laying and Compaction of Rolled Asphalt)Michael VeneerÎncă nu există evaluări

- BD 30 - 87Document14 paginiBD 30 - 87tpop1707Încă nu există evaluări

- Pavement and Materials Design Manual 1999 - CHAPTER 8Document12 paginiPavement and Materials Design Manual 1999 - CHAPTER 8Kisali Sarakikya100% (2)

- Structural Design of Concrete Block PavementsDocument11 paginiStructural Design of Concrete Block PavementsOso OsoÎncă nu există evaluări

- Pipe Bedding 6pp - 231015 Low ResDocument6 paginiPipe Bedding 6pp - 231015 Low ResHoang An TranÎncă nu există evaluări

- GN018 Minor Works Specification For Bituminous Pavement ConstructionDocument8 paginiGN018 Minor Works Specification For Bituminous Pavement Constructionahtin618Încă nu există evaluări

- NR-L3-CIV-140-202C (Issue 2) - Section 202 Road Pavements (Sept 2009)Document5 paginiNR-L3-CIV-140-202C (Issue 2) - Section 202 Road Pavements (Sept 2009)sandycastleÎncă nu există evaluări

- Standard Specification For Precast Reinforced Concrete Box Sections For Culverts, Storm Drains, and SewersDocument28 paginiStandard Specification For Precast Reinforced Concrete Box Sections For Culverts, Storm Drains, and Sewersjun flores100% (1)

- HD 39-01 Footway DesignDocument34 paginiHD 39-01 Footway DesignMelissa GrahamÎncă nu există evaluări

- BD 30-87 Backfilled Retaining Walls and Bridge AbutmentsDocument14 paginiBD 30-87 Backfilled Retaining Walls and Bridge AbutmentsDavid Shanks 1100% (1)

- 456 - Ammendment No. 3 Aug07Document3 pagini456 - Ammendment No. 3 Aug07Ravi Singh0% (1)

- c64 Chapter101Document36 paginic64 Chapter101Geeta RamsinghÎncă nu există evaluări

- FAA Eng Brief 66 RubilizationDocument16 paginiFAA Eng Brief 66 Rubilizationjscurrie6614Încă nu există evaluări

- 150 5320 6eDocument9 pagini150 5320 6eomidziaÎncă nu există evaluări

- Highways Department: Guidance Notes 014D Permanent Trench ReinstatementDocument43 paginiHighways Department: Guidance Notes 014D Permanent Trench ReinstatementMing WuÎncă nu există evaluări

- JUN 20tlj: Department of Public Works and HighwaysDocument10 paginiJUN 20tlj: Department of Public Works and HighwaysSimeon James Defeo VillacrusisÎncă nu există evaluări

- IS 456 Comparison of 1978 Vs 2000Document9 paginiIS 456 Comparison of 1978 Vs 2000man.drakeÎncă nu există evaluări

- Salient Changes in IRC 37 2012 and BitumDocument10 paginiSalient Changes in IRC 37 2012 and BitumNatarajan SaravananÎncă nu există evaluări

- Salient Changes in IRC 37 2012 and BitumDocument10 paginiSalient Changes in IRC 37 2012 and Bitumsuman subediÎncă nu există evaluări

- Bs 4987 2Document15 paginiBs 4987 2Hamid Naveed100% (1)

- Sp-s-04 - Rev - 3 - Roads & PavingsDocument9 paginiSp-s-04 - Rev - 3 - Roads & PavingsJahanzeb MaharÎncă nu există evaluări

- 11-Gravel Wearing Course DesignDocument10 pagini11-Gravel Wearing Course DesignHaftamu TekleÎncă nu există evaluări

- Subgrades and Base Courses: Design ConsiderationsDocument19 paginiSubgrades and Base Courses: Design Considerationsipman99Încă nu există evaluări

- DPWH Concrete SPECIFICATIONSDocument6 paginiDPWH Concrete SPECIFICATIONSShe Timbancaya100% (1)

- RN5Document9 paginiRN5anjanaÎncă nu există evaluări

- Chapter 5 - Flexible and Composite Pavements Final (Individual Narrative Reports)Document30 paginiChapter 5 - Flexible and Composite Pavements Final (Individual Narrative Reports)Frederick AgliamÎncă nu există evaluări

- 11-Gravel Wearing Course Design PDFDocument10 pagini11-Gravel Wearing Course Design PDFjohn_d_thirdÎncă nu există evaluări

- Pavement Design: 1) Pavement Condition and Field InvestigationDocument5 paginiPavement Design: 1) Pavement Condition and Field InvestigationSumit BhatiÎncă nu există evaluări

- Bridge Technical Note 2023 - 023 AS5100 Part 3 v20 July 2023Document11 paginiBridge Technical Note 2023 - 023 AS5100 Part 3 v20 July 2023roshansm1978Încă nu există evaluări

- AC1504Document30 paginiAC1504Alysson Santos0% (1)

- Volume 2 Section 3 Detailing, Construction and Workmanship BA 36/90Document4 paginiVolume 2 Section 3 Detailing, Construction and Workmanship BA 36/90chatxxnoirÎncă nu există evaluări

- Subsoil DrainageDocument11 paginiSubsoil DrainageRachel IngramÎncă nu există evaluări

- Periodic Wearing Coat & OverlayDocument2 paginiPeriodic Wearing Coat & OverlayA PrasannakumarÎncă nu există evaluări

- C BituminousshouldersDocument7 paginiC BituminousshouldersJulián Tiburcio GonzálezÎncă nu există evaluări

- SDCS-02-16 Rev. 0 MANHOLEDocument12 paginiSDCS-02-16 Rev. 0 MANHOLEHappy HeartÎncă nu există evaluări

- Asphalt Applications - Construction and Surfacing of Parking Areas PDFDocument9 paginiAsphalt Applications - Construction and Surfacing of Parking Areas PDFfa_fa67Încă nu există evaluări

- Highwaycp 2 ADocument58 paginiHighwaycp 2 AAbuÎncă nu există evaluări

- 3550-8310-SP-0006 Rev D2.pdf MARKED-c.vanDocument8 pagini3550-8310-SP-0006 Rev D2.pdf MARKED-c.vanPhuong ThaoÎncă nu există evaluări

- Subsoil Drainage Detailed DesignDocument4 paginiSubsoil Drainage Detailed Designbirajr78Încă nu există evaluări

- Manual - Lining - Irrigation - Canals - West BengalDocument22 paginiManual - Lining - Irrigation - Canals - West Bengalsudheer7320_58503644Încă nu există evaluări

- Bridge Design Memorandum - Dm0111: SCDOT Geotechnical Design ManualDocument3 paginiBridge Design Memorandum - Dm0111: SCDOT Geotechnical Design ManualkingdbmÎncă nu există evaluări

- Chapter-10 - Gravel Road DesignDocument13 paginiChapter-10 - Gravel Road DesignAbuye HDÎncă nu există evaluări

- F Cpa Design Construction SpecificationsDocument12 paginiF Cpa Design Construction SpecificationsFCOJCOGOLLOÎncă nu există evaluări

- Department of Public Works and Highways: Republic of The PhilippinesDocument7 paginiDepartment of Public Works and Highways: Republic of The PhilippinesRyan FelipeÎncă nu există evaluări

- Construction % Surfacing of Parking Areas 2Document8 paginiConstruction % Surfacing of Parking Areas 2John DoughÎncă nu există evaluări

- Design Guide of Slab On GradeDocument20 paginiDesign Guide of Slab On GradePriyanka100% (2)

- Annexure-III: Compliance of General Provisions (Technical) During Construction Phase (To Be Ensured by TL)Document4 paginiAnnexure-III: Compliance of General Provisions (Technical) During Construction Phase (To Be Ensured by TL)sriÎncă nu există evaluări

- Engineering Standards Manual: Code of Practice For City Infrastructure & Land DevelopmentDocument13 paginiEngineering Standards Manual: Code of Practice For City Infrastructure & Land DevelopmentAther Hussain MoverÎncă nu există evaluări

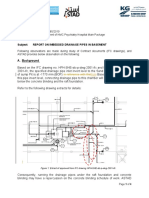

- A. Background: in Reference With ThefromDocument4 paginiA. Background: in Reference With Thefromyaseen457Încă nu există evaluări

- Volume 2 Section 3 Design BA 36/90: Crack Width Calculated at Lowest in Situ Concrete SurfaceDocument6 paginiVolume 2 Section 3 Design BA 36/90: Crack Width Calculated at Lowest in Situ Concrete SurfacechatxxnoirÎncă nu există evaluări

- Permanent FormworkDocument13 paginiPermanent FormworkjimmydomingojrÎncă nu există evaluări

- Naroda NHDocument4 paginiNaroda NHAnkit DhimanÎncă nu există evaluări

- IS218.02B - Suggested Specification For Concrete Parking AreasDocument2 paginiIS218.02B - Suggested Specification For Concrete Parking AreasfarhanÎncă nu există evaluări

- Stone Masonry SpecsDocument5 paginiStone Masonry SpecsAJothamChristianÎncă nu există evaluări

- Ba3690 3Document11 paginiBa3690 3chatxxnoirÎncă nu există evaluări

- Concrete in Highway Engineering: International Series of Monographs in Civil EngineeringDe la EverandConcrete in Highway Engineering: International Series of Monographs in Civil EngineeringEvaluare: 4 din 5 stele4/5 (5)

- 2010 ADA Standards for Accessible DesignDe la Everand2010 ADA Standards for Accessible DesignEvaluare: 3 din 5 stele3/5 (1)

- Ground Improvement Case Histories: Compaction, Grouting and GeosyntheticsDe la EverandGround Improvement Case Histories: Compaction, Grouting and GeosyntheticsEvaluare: 3.5 din 5 stele3.5/5 (3)

- A Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsDe la EverandA Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsÎncă nu există evaluări

- The Fabrication of Materials: Materials TechnologyDe la EverandThe Fabrication of Materials: Materials TechnologyEvaluare: 5 din 5 stele5/5 (1)

- Cementation Skanska Data Sheet For Large Diameter Bored Piles (UK)Document2 paginiCementation Skanska Data Sheet For Large Diameter Bored Piles (UK)sandycastleÎncă nu există evaluări

- Cementation Skanska Piling Rig Data Sheet - Rig Sizes, Pile Diameters and Pile Lengths (Jan 2017)Document2 paginiCementation Skanska Piling Rig Data Sheet - Rig Sizes, Pile Diameters and Pile Lengths (Jan 2017)sandycastleÎncă nu există evaluări

- Case History Regarding Use of Continuous Helical Displacement (CHD) Piles For Golden Jubilee Hospital, GlasgowDocument2 paginiCase History Regarding Use of Continuous Helical Displacement (CHD) Piles For Golden Jubilee Hospital, GlasgowsandycastleÎncă nu există evaluări

- SHW Series NG 1700 Structural Concrete (Dec 2014)Document52 paginiSHW Series NG 1700 Structural Concrete (Dec 2014)sandycastleÎncă nu există evaluări

- BBA Certificate 14-H218 Securegrid HS Geogrid For Basal Reinforcement (BBA, First Issue, Oct 2018)Document14 paginiBBA Certificate 14-H218 Securegrid HS Geogrid For Basal Reinforcement (BBA, First Issue, Oct 2018)sandycastleÎncă nu există evaluări

- Soil Compaction Handbook (Short Booklet) (Multiqip)Document16 paginiSoil Compaction Handbook (Short Booklet) (Multiqip)sandycastle100% (1)

- NR-CIV-SD-FORMA-690 (ISSUE A01, 2013) - Form A Generic Foundation Design For OLE Support Structures PDFDocument82 paginiNR-CIV-SD-FORMA-690 (ISSUE A01, 2013) - Form A Generic Foundation Design For OLE Support Structures PDFsandycastleÎncă nu există evaluări

- Case History For Use of Maccaferri Paralink, MacRes and ParawebDocument4 paginiCase History For Use of Maccaferri Paralink, MacRes and ParawebsandycastleÎncă nu există evaluări

- Counterfort Drains - Design, Installation and Long-Term Performance in Soils of Greater AucklandDocument8 paginiCounterfort Drains - Design, Installation and Long-Term Performance in Soils of Greater AucklandsandycastleÎncă nu există evaluări

- Case History For Use of Maccaferri Paralink High Strength GeogridDocument2 paginiCase History For Use of Maccaferri Paralink High Strength Geogridsandycastle100% (1)

- Piled Embankments - Recent Irish Experience (Orsmond, Geotechnical Society of Ireland Conf, Oct 2012)Document9 paginiPiled Embankments - Recent Irish Experience (Orsmond, Geotechnical Society of Ireland Conf, Oct 2012)sandycastle100% (1)

- Foundations For Tall Buildings On Alluvial Deposits - Geotechnical Aspects (Sundaram Et Al, Indian Geotechnical Conf, Dec 2018)Document23 paginiFoundations For Tall Buildings On Alluvial Deposits - Geotechnical Aspects (Sundaram Et Al, Indian Geotechnical Conf, Dec 2018)sandycastleÎncă nu există evaluări

- Earthworks in Europe (2nd International Seminar On Earthworks in Europe, GSL, 2012)Document3 paginiEarthworks in Europe (2nd International Seminar On Earthworks in Europe, GSL, 2012)sandycastleÎncă nu există evaluări

- Tensar Basetex Technical Info (April 2003)Document4 paginiTensar Basetex Technical Info (April 2003)sandycastleÎncă nu există evaluări

- Balfour Beatty's Pencol 'Alternative' To Controlled Modulus Columns (From BB Website, March 2019)Document4 paginiBalfour Beatty's Pencol 'Alternative' To Controlled Modulus Columns (From BB Website, March 2019)sandycastleÎncă nu există evaluări

- Case History For Fortrac MP Basal Reinforced Piled EmbankmentDocument2 paginiCase History For Fortrac MP Basal Reinforced Piled EmbankmentsandycastleÎncă nu există evaluări

- Case History For Basal Reinforced Platform On A40 Carmarthen Eastern Bypass, Wales (Constucted Sept 1998) (Maccaferri, Rev 02, Nov 2008)Document2 paginiCase History For Basal Reinforced Platform On A40 Carmarthen Eastern Bypass, Wales (Constucted Sept 1998) (Maccaferri, Rev 02, Nov 2008)sandycastleÎncă nu există evaluări

- BBA Certificate 08-4609 ACEGrid Geogrids For Basal Reinforcement (BBA, Third Issue, Nov 2013)Document13 paginiBBA Certificate 08-4609 ACEGrid Geogrids For Basal Reinforcement (BBA, Third Issue, Nov 2013)sandycastleÎncă nu există evaluări

- Soilmec SR-125 HIT Hydraulic Rotary Rig (April 2016)Document12 paginiSoilmec SR-125 HIT Hydraulic Rotary Rig (April 2016)sandycastleÎncă nu există evaluări

- Investment in Stations - A Guide For Promoters and Developers (Network Rail)Document30 paginiInvestment in Stations - A Guide For Promoters and Developers (Network Rail)sandycastleÎncă nu există evaluări

- Performance of Bored Piles Constructed Using Polymer Fluids: Lessons From European ExperienceDocument9 paginiPerformance of Bored Piles Constructed Using Polymer Fluids: Lessons From European ExperiencesandycastleÎncă nu există evaluări

- Link Middle East (Lme) Earth Retention and Protection Systems Lme Welded Mesh Gabion Boxes and MattressesDocument12 paginiLink Middle East (Lme) Earth Retention and Protection Systems Lme Welded Mesh Gabion Boxes and MattressessandycastleÎncă nu există evaluări

- Safety in Design For Pile Foundations and Embedded Retaining Walls (FPS Guidance On CDM 2007, June 2009)Document3 paginiSafety in Design For Pile Foundations and Embedded Retaining Walls (FPS Guidance On CDM 2007, June 2009)sandycastleÎncă nu există evaluări

- User Manual Jamicon 3vaav eDocument15 paginiUser Manual Jamicon 3vaav ematwan29Încă nu există evaluări

- CiscoTrouble Shooting Guide For Attendant ConsoleDocument42 paginiCiscoTrouble Shooting Guide For Attendant ConsoleAravindan ThambusamyÎncă nu există evaluări

- Slab Design Calculations: Definitions of TermsDocument28 paginiSlab Design Calculations: Definitions of TermsAlbasir Tiang Sedik REEÎncă nu există evaluări

- Method Statement For Temporary OpeningDocument1 paginăMethod Statement For Temporary Openingvaibhav_sparshÎncă nu există evaluări

- IStructE CM Exam Report 2012Document17 paginiIStructE CM Exam Report 2012aÎncă nu există evaluări

- ACreferencias BibliográficasDocument3 paginiACreferencias BibliográficasSenialsell Lains GuillenÎncă nu există evaluări

- Chapter 15 Django Based Web Application Part IDocument24 paginiChapter 15 Django Based Web Application Part IPranav Pratap SinghÎncă nu există evaluări

- Exhibitor ListDocument4 paginiExhibitor ListRajiv ShahÎncă nu există evaluări

- Chapter 12 BennetDocument29 paginiChapter 12 BennetpapipapiiÎncă nu există evaluări

- Form + Words: Glenn Murcutt: Magney House (1984)Document4 paginiForm + Words: Glenn Murcutt: Magney House (1984)Andrea CucchiÎncă nu există evaluări

- Diffusion ChameleonDocument8 paginiDiffusion ChameleonAdnan KhanÎncă nu există evaluări

- ThesisDocument95 paginiThesisAper ZavaÎncă nu există evaluări

- Pipe Rack Sizing and Loading DataDocument5 paginiPipe Rack Sizing and Loading DataAnand.5Încă nu există evaluări

- Chapter4 Problems BSME V-ADocument26 paginiChapter4 Problems BSME V-AAldren Arnaiz0% (1)

- Synchronization Techniques PDFDocument11 paginiSynchronization Techniques PDFDemarco Dayanghirang FormalejoÎncă nu există evaluări

- d36978010 S5000vsa Tps r1 9Document71 paginid36978010 S5000vsa Tps r1 9t111938Încă nu există evaluări

- Variable Speed Drives: Smart Ideas For Your BusinessDocument2 paginiVariable Speed Drives: Smart Ideas For Your BusinessSamiYousifÎncă nu există evaluări

- Material HeritageDocument5 paginiMaterial HeritageAxx A AlÎncă nu există evaluări

- Reference Design Guide For PAS and PKS With NSX-TDocument81 paginiReference Design Guide For PAS and PKS With NSX-TPete RobertsonÎncă nu există evaluări

- Manual HLB 860 EnglishDocument14 paginiManual HLB 860 EnglishAlexandra UrruelaÎncă nu există evaluări

- Problem Set 8Document5 paginiProblem Set 8xxvvÎncă nu există evaluări

- Interoperability of Juniper and Cisco DevicesDocument11 paginiInteroperability of Juniper and Cisco DevicesvasanthmeÎncă nu există evaluări

- Rawl Bolts and CapacityDocument2 paginiRawl Bolts and Capacitykevinisonline0% (1)

- Client Server Architecture: by Vijay TM Mba-It PRN-060341022Document31 paginiClient Server Architecture: by Vijay TM Mba-It PRN-060341022narendraidealÎncă nu există evaluări

- Indian Council of Architecture - Practice of ArchitectureDocument17 paginiIndian Council of Architecture - Practice of ArchitectureRoshni Santosh100% (1)

- QB Som He306 2015 2016Document23 paginiQB Som He306 2015 2016etayhailuÎncă nu există evaluări

- Guiadmingles PDFDocument68 paginiGuiadmingles PDFeddie2166Încă nu există evaluări

- District Rate - Morang 075 76 Final PDFDocument78 paginiDistrict Rate - Morang 075 76 Final PDFDinesh PoudelÎncă nu există evaluări

- CiscoDataCenterCertificatione Guide 2017Document40 paginiCiscoDataCenterCertificatione Guide 2017Fayyaz AhmedÎncă nu există evaluări

- Set Up An Encrypted NAS On Odroid-C2 or Rasbperry 3 With OpenMediaVaultDocument18 paginiSet Up An Encrypted NAS On Odroid-C2 or Rasbperry 3 With OpenMediaVaultrsaÎncă nu există evaluări