Documente Academic

Documente Profesional

Documente Cultură

Simulation of Orbital Forming Process Using 3D Fem and Inverse Analysis For Determination of Reliable Flow Stress

Încărcat de

Eldori1988Descriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Simulation of Orbital Forming Process Using 3D Fem and Inverse Analysis For Determination of Reliable Flow Stress

Încărcat de

Eldori1988Drepturi de autor:

Formate disponibile

SIMULATION OF ORBITAL FORMING PROCESS

USING 3D FEM AND INVERSE ANALYSIS FOR

DETERMINATION OF RELIABLE FLOW STRESS

H. Cho

(1)

, N. Kim

(2)

, and T. Altan

(1)

(1)

ERC for Net Shape Manufacturing, The Ohio State University

339 Bakers Systems Building, 1971 Neil Avenue, Columbus OH, 43210 USA

(2)

Dept. of Mechanical Engineering, Sogang University

Shinsoo-dong, Mapo-gu 1, Seoul, 121-742 Korea

Summary

In this study the feasibility of 3D FEM simulation of the orbital forming process was investigated

by evaluating the simulation time. Commercial FEA software DEFORM

TM

3D v4.0 that has an

efficient computation algorithm for simulating incremental forming process was used for the

simulations and the savings in computation time was determined. In order to provide reliable flow

stress for the simulation, a finite element based inverse analysis technique has been introduced.

Results show that developed inverse analysis technique is efficient and accurate for use in 3D FEM

simulation for process optimization.

1. Introduction

The finite element simulation technique is a

popular and powerful tool to improve the

forging sequences and the quality of forgings at

industry. The applications of 2D FEM to

practical industrial problems began in the late

1980s. By using FEM simulation, the influence

of individual design parameters involved in

forming operations on forged part could be

investigated easily. Recently, thanks to increase

in computing speed, efforts on combining FEM

simulation with optimization algorithm are being

made in order to optimize the manufacturing

operations [1,2]. Also, the use of 3D FEM

simulation keeps growing rapidly. However, in

spite of improvement of computing speed, the

associated cost of 3D FEM simulation is still

expensive. Further reducing computation time is

still a key to make 3D FEM simulation practical,

efficient, and robust for industrial applications.

In using user-friendly commercial FEA

software it is necessary to assign reliable input

data since the results of process simulation are

extremely sensitive to the accuracy of flow

stress and interface friction that are input to

FEM programs. It is essential that these input

values are determined using appropriate material

tests and the evaluation of the test results should

be able to overcome difficulties frequently

introduced by inhomogeneous deformation.

Even in the simple cylinder compression,

interface friction leads to an inevitable bulging

of the sample and affects flow stress

determination. Thus, it is better to consider the

unavoidable friction at the tool/workpiece

interface in the test and to identify it together

with flow stress using the inverse analysis. In the

inverse analysis, the unknown parameters are

determined by minimizing a least-square

functional consisting of experimental data and

FEM simulated data. The FEM is used to

analyze the behavior of the material during the

test, whereas the optimization technique allows

for automatic adjustment of parameters until the

calculated response matches the measured one

within a specified tolerance [3].

In this study, based on rigid-plastic finite

element formulation, a new inverse analysis

algorithm has been developed. This analysis

identifies the material strength constant and

strain hardening exponent of the flow stress

equation by minimizing a least-square functional

consisting of experimental load and predictions

made by FEM simulation. Furthermore, a

methodology for simultaneous determination of

flow stress and interface friction has been

introduced. Also, in order to investigate a

feasibility of application to 3D FEM simulation,

as an example, 3D FEM simulations of orbital

forming process were performed.

2. Reliable flow stress determination

2.1 Inverse analysis algorithm

The basic concept of an inverse analysis for

parameter identification is to compute a set of

unknown material parameters , which

represents the flow stress curve. The unknown

parameters are determined by minimizing an

objective function, , representing the

difference between the experimental and

corresponding computed loads in a least-square

sense:

p

) ( p E

=

|

|

.

|

\

|

=

N

i

i

i i

F

f F

N

E

1

2

) ( 1

) (

p

p (1)

where F is the experimentally measured load

and is the computed load. is the number of

data sampling points in a load vs. stroke curve

used to construct the objective function. For a

given set of material parameters, the objective

function will be minimum at:

f N

0

) (

k

=

p

E p

for (2) m k ,..., 1 =

where is the number of parameters to be

identified.

m

The equation (2) is solved with respect to the

parameters using Newton-Raphson iterative

method.

k

p

k

j

j k

p

E

p

p p

E

2

for (3) m j k ,..., 1 , =

The first and second derivatives of the objective

function with respect to the parameters are

evaluated by taking the derivatives of Equation

(1) with respect to material parameters :

k

p

k

p

( )

=

)

`

N

i

k

i

i

i i

k

p

f

F

f F

N p

E

1

2

(4)

( )

=

)

N

i

j k

i

i i

j

i

k

i

j k

p p

f

f F

p

f

p

F

N p p

E

1

2 2

2

(5)

where the computed force is defined in rigid-

plastic FEM as follows [4]:

i

f

2

3

e e

T

e e

V V

dV G dV = +

&

T T

i

f

B DB v B cc B (6)

is the effective stress, which is equal to the

flow stress of material during the plastic

deformation,

&

is the effective strain rate, is

the strain rate-nodal velocity matrix, and G is the

penalty constant respectively. and are a

matrix and a vector of constant components.

Thus, ,

B

D c

i

f

k

i

p

f

, and

j k

i

p p

f

2

are calculated using

Equations (6)-(8) only for tool-contacting

elements.

2 1

3

e e

V

dV

| |

=

|

|

\ .

&

T i

k k

f

p p

B DB v (7)

2 2

2 1

3

e e

V

dV

| |

| =

|

\ .

&

T i

k j k j

f

p p p p

B DB v (8)

For a strain hardening material, the flow stress

equation may be given by

n

K = . The first and

second derivatives of the flow stress equation

with respect to material strength constant K and

strain hardening exponent

are expressed by

Equation (9).

n

) ln (

1

K

p

k

,

(

(

(

2

2

) (ln

ln

ln

0

K

K

p p

j k

(9)

The optimal amount of adjustments for material

parameters

k

p is found after solving Equation

(3). Then material parameters are improved

iteratively until Equation (2) is satisfied using

the following equation.

( )

k k k

p p p + =

+ (i) 1 i

(10)

At the next optimization step a new FEM

simulation is conducted with improved material

parameters and this procedure is repeated until

the deviation of material parameters becomes

within tolerance. The flow chart of this

algorithm is shown in Figure 1.

Figure 1: Flow chart of inverse analysis.

2.2 Inverse analysis of non-homogeneous

cylinder compression.

The developed inverse analysis algorithm has

been tested by using the real experimental data

obtained from the cylinder compression test of

AISI 1022. Cylinder with 0.4 inch height x

0.265 inch diameter was compressed at the

reduction of 45%. During the compression, a

barreling was observed due to the existing

frictional force at the die/specimen interface. In

order to determine reliable flow stress, the effect

of existing frictional force has to be taken into

account in the inverse analysis. For this purpose,

two experimental quantities: (1) the load-stroke

curve and (2) the barreling shape (bulge

diameter) of the cylinder specimen at the end of

stroke were measured and flow stress and

interface friction are determined simultaneously.

As explained as the flow chart in Figure 2, flow

stress is first determined by minimizing the

difference in the load-stroke curves. Then, the

unknown friction factor is identified by

comparing the measured bulge diameter and its

corresponding computed diameter.

Figure 2: Flow chart for determination of flow

stress and friction factor by the inverse analysis.

Table 1: Predicted inverse analysis results.

Friction

f

m

Bulge diameter

[in], (Error %)

K-value

(Mpa)

n-value

0.1 0.363 (- 0.7) 113.5 0.138

0.15 0.366 (- 0.11) 113.1 0.138

0.2 0.368 (+ 0.56) 112.9 0.139

The results of identified parameters (K-value

and n-value) in the flow stress equation and

friction factor by the inverse analysis are

summarized in Table 1. Three inverse analyses

were conducted by varying the friction factor

from 0.1 to 0.2. As initial guesses of material

parameters 130 = K and n were used for

every case. When the friction factor 0.15 was

assumed, the inverse analysis prediction

produced only 0.11% underestimation in bulge

diameter comparison. Thus, a combination of

friction factor

2 . 0 =

15 . 0 =

f

m and flow stress

) (

138

Mpa 113

. 0

= gives the best matches both

in load-stroke curve and bulge diameter

comparisons. As shown in Figure 3, after four

optimization iterations, the computed and

experimental loads are nearly identical.

Newton-

Raphson

Iteration

{ } n K p

k

, =

n K,

k

p

k

p

( ) ( )

2

1

<

+ s

k

s

k

p p

1

<

k

p

E

( ) 1 + s

k

p

1 + = s s

1 + = i i

Initial guess + measured load-stroke { } p =

Improve

Yes

Yes

No

No

Determined

Extract simulation results

Calculate the derivative

Find

Converge ?

Run FEM simulation

Eqs. (4) and (5)

Eq. (10) Update

Eq. (3)

Converge ?

Optimization

iteration

< d D

Identified

Yes

No

Modify

Friction

Run FEM Simulation

Determination of flow stress

Identified k

p

f

m

Is it good ?

Measured

geometry

Computed

geometry

as shown in Figure 1

0

2000

4000

6000

8000

10000

12000

14000

0 0.05 0.1 0.15 0.2

Stroke (in.)

L

o

a

d

(

l

b

f

)

Experiment

1st optimization itr.

4th optimization itr.

Figure 3: Comparison of computed and

experimental load stroke curves.

In Figure 4, the measured bulge diameter from

the test and the computed bulge diameter from

the simulation were compared at the same stroke

position. When friction factor was 0.15, they

showed a good match.

Figure 4: Comparison of measured (top) and

computed (bottom) bulge diameters at the end of

stroke with ) ( 113

138 . 0

Mpa = and 15 . 0 =

f

m .

The convergence behaviours of the material

parameters { } n , K P

k

= during optimization

iteration were shown in Figure 5 and Figure 6,

respectively. In both cases, monotonously

converging behaviors were observed.

110

115

120

125

130

0 1 2 3 4

Iteration

S

t

r

e

n

g

t

h

c

o

e

f

.

K

(

k

s

i

)

Figure 5: Convergence of material strength

coefficient, K.

0.00

0.05

0.10

0.15

0.20

0 1 2 3 4

Iteration

S

t

r

a

i

n

h

a

r

d

e

n

i

n

g

e

x

p

o

n

e

n

t

,

n

Figure 6: Convergence of strain hardening

exponent, n.

3. Simulation of orbital forming

3.1 Orbital forming of wheel spindle bearing

Orbital forming is an incremental forming

process in which the conventional overall

compression of the billet is replaced by localized

incremental deformation of the billet until the

final shape is formed. The tool is tilted at small

angle with respect to the axis of the lower die

and the tool rotates and moves axially as it

completes its stroke. When orbital forming is

used for assembly of automotive wheel spindle

bearings, the orbiting tool deforms the forged

spindle material gradually so as to create an axial

clamping force, Figure 7. This axial force acts

through the inner ring and keeps the bearing pre-

loaded and retained.

Bulge diameter

= 0.365 (in.)

Since the orbital forming is an incremental

forming process, it requires a number of

revolutions to form a part. For FEM simulation,

a relatively large number of simulation steps are

required to minimize the errors in solution

accuracy. Also, a full 3D modeling is required

due to an asymmetric rotational tool movement.

Figure 7: Principle of orbital forming of wheel

spindle bearing.

3.2 Simulation conditions

The FE model of spindle was generated with

9875 nodes and 43231 tetrahedral elements. The

finer mesh system was created near the tab

region to have an accurate prediction of metal

flow. The spindle material is assumed to show

rigid-plastic deformation behavior and flow

stress of ) ( 113

138 . 0

Mpa = determined by

inverse analysis was used in the simulation. The

tool and the inner ring were regarded as rigid

objects and shear friction factor of 0.15 was used

in the simulations, assuming lubricated

conditions. From a given movement of the

orbital tool, 500 simulation steps are assigned

and time step size was determined as 0.0025

(sec/step). In the simulation, this time step size

provides 48 incremental steps for simulating one

revolution of the orbit tool. Figure 8 shows

generated finite element models for the 3D

simulation. In order to evaluate how efficient the

new computation method of DEFORM

TM

3D

v4.0 for simulating orbital forming process, one

simulation was conducted using the new

efficient solution method and the other

simulation was carried out by inactivating the

new solution method. As a default, new solution

method is automatically activated in

DEFORM

TM

3D v4.0.

Tool

Inner

ring

Spindle

Figure 8: 3D Finite element model for orbital

forming simulation.

3.3 Simulation results

In Table 1, the results of two simulations are

summarized. When the simulation was made in

DEFORM

TM

3D v4.0, 8 hrs. 12 min. CPU time

was required to complete the stroke. However,

when the new solution method was inactivated

the CPU time was dramatically increased up to

98 hrs. Therefore, around 91% saving of

computation time was achieved. The difference

between the predicted maximum forming forces

is about 2.5 % and between the predicted tab

outer diameters is about 0.5 %, respectively.

This comparison indicates that the simulation

results made with the enhanced solution method

are nearly identical to the results obtained with

conventional solution method.

Table 2: Comparison of consumed CPU time.

Activating

new method

Inactivating

new method

Overall CPU time 8 hrs. 12 min. 98 hrs.

CPU Time / Itr. 0.5~1.0 sec. 30~40 sec.

(Machine: HP J6000 w/2GB Memory)

In Figure 9, the predicted metal flow at

different punch strokes near the tab of the

spindle are shown. The predicted outer tab

diameter is defined in Figure 9 (c).

(a) After 40% punch stroke

(a) After 80% punch stroke

(c) At the end of punch stroke

Figure 9: Predicted metal flow of spindle at

intermediate stages.

4. Conclusions and discussion

In this study, simulation of orbital forming for

assembly of wheel spindle bearing was

conducted using commercial FE software

DEFORM

TM

3D v4.0, which recently introduced

an efficient computation numerical algorithm for

simulating incremental forming processes. It is

concluded that the computation time required for

simulating an incremental forming process has

been significantly reduced by 91 % in spite of

the nature of incremental forming process where

a large number of simulation steps are needed

with a full 3D finite element modeling. Solution

accuracy was verified by comparing the

predicted forces and tab outer diameters and they

showed good agreements. Therefore, the use of

3D FEM in simulating and optimizing the orbital

forming seems to be a reasonably reliable tool

for process and tool design in this process.

Also, in order to provide reliable flow stress

for the simulation, finite element based inverse

analysis technique was developed to identify the

material strength constant and strain hardening

exponent of the flow stress equation. The results

indicated that with this method it was possible to

predict the flow stress and friction

simultaneously with acceptable accuracy.

References

[1] L. Fourment and J. L. Chenot, Optimal

Design For Non-Steady-State Metal

Forming Processes-I. Shape Optimization

Method, Int. J. Numerical Methods in Eng.,

Vol. 39, pp. 33-50, 1996.

Tab outer diameter

[2] G. Zhao, E. Wright, and R. V. Grandhi,

Sensitivity Analysis Based Preform Die

Shape Design For Net-Shape Forging, Int. J.

Mach. Tools Manufact., Vol. 37, No. 9, pp.

1251-1271, 1997.

[3] J. L. Chenot, E. Massoni, and L. Fourment,

Inverse Problems in Finite Element

Simulation of Metal Forming Processes,

Engineering Computations, Vol. 13, No.

2/3/4, p. 190-225, 1996.

[4] S. Kobayashi, S.-I. Oh, and T. Altan, Metal

Forming and Finite Element Method,

Oxford University Press, NY, 1989

S-ar putea să vă placă și

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionDe la EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionÎncă nu există evaluări

- Neuber FEADocument12 paginiNeuber FEAPrashantha RajuÎncă nu există evaluări

- Applied RVE Reconstruction and Homogenization of Heterogeneous MaterialsDe la EverandApplied RVE Reconstruction and Homogenization of Heterogeneous MaterialsÎncă nu există evaluări

- Sheet - Ansys, SpringbackDocument9 paginiSheet - Ansys, Springbacksupersonny007Încă nu există evaluări

- 124 TMT09 061Document4 pagini124 TMT09 061vovancuong8Încă nu există evaluări

- Asme - Stress Classification Lines Straight Through SingularitiesDocument10 paginiAsme - Stress Classification Lines Straight Through SingularitiesRay FaiersÎncă nu există evaluări

- Comparative Analysis of Experimental and Numerical Evaluation of Strength of A Boom of The Underground LoaderDocument8 paginiComparative Analysis of Experimental and Numerical Evaluation of Strength of A Boom of The Underground LoaderEric CÎncă nu există evaluări

- Effect of Friction Coefficient On Finite Element Modeling of The Deep - Cold Rolling ProcessDocument5 paginiEffect of Friction Coefficient On Finite Element Modeling of The Deep - Cold Rolling ProcessAdnen LaamouriÎncă nu există evaluări

- Effect of Friction Coefficient On Finite Element Modeling of The Deep - Cold Rolling ProcessDocument5 paginiEffect of Friction Coefficient On Finite Element Modeling of The Deep - Cold Rolling ProcessAdnen LaamouriÎncă nu există evaluări

- FEA of PipeDocument11 paginiFEA of Pipedimos dimouÎncă nu există evaluări

- ACMSM23 083 CameraReadyDocument6 paginiACMSM23 083 CameraReadypiscesas45Încă nu există evaluări

- Strength of LugDocument8 paginiStrength of LugnareniviÎncă nu există evaluări

- Analysis of The Tightening Process of AnDocument8 paginiAnalysis of The Tightening Process of AnmirosekÎncă nu există evaluări

- Comparison of Different FE Calculation Methods For The Electromagnetic Torque of PM MachinesDocument8 paginiComparison of Different FE Calculation Methods For The Electromagnetic Torque of PM Machinesmlkz_01Încă nu există evaluări

- Determination of Blockage Correction in Open-Jet Wind TunnelDocument6 paginiDetermination of Blockage Correction in Open-Jet Wind Tunnelmoro1381100% (1)

- Theoretical Calculation of Strain Hardening ExponentDocument4 paginiTheoretical Calculation of Strain Hardening ExponentRavi TejaÎncă nu există evaluări

- 2 67 1644220454 Ijmperdfeb202206Document9 pagini2 67 1644220454 Ijmperdfeb202206TJPRC PublicationsÎncă nu există evaluări

- Optimization of Tube Hydroforming Process Using Simulated Annealing AlgorithmDocument8 paginiOptimization of Tube Hydroforming Process Using Simulated Annealing AlgorithmAhmad SaepuddinÎncă nu există evaluări

- ISTAM - Stress Concentration Factor Convergence Study of A Thin PlateDocument7 paginiISTAM - Stress Concentration Factor Convergence Study of A Thin PlateKanak_KalitaÎncă nu există evaluări

- Keywords Ključne Reči: Radetomic@ppt - Co.rsDocument6 paginiKeywords Ključne Reči: Radetomic@ppt - Co.rsmedica101Încă nu există evaluări

- Creeps Analysis of ThermoplasticsDocument7 paginiCreeps Analysis of ThermoplasticsIgor AlarcónÎncă nu există evaluări

- Reliability of Buried Pipelines With Corrosion Defects Under Varying Boundary ConditionsDocument8 paginiReliability of Buried Pipelines With Corrosion Defects Under Varying Boundary ConditionsMuhammad OmarÎncă nu există evaluări

- SEM XI Int Cong s025p01 T Stress Determination Using Digital Image CorrelationDocument7 paginiSEM XI Int Cong s025p01 T Stress Determination Using Digital Image CorrelationElizabeth SantiagoÎncă nu există evaluări

- FEA 2 CopyDocument13 paginiFEA 2 CopyJo JoÎncă nu există evaluări

- Example 11 - Tensile Test: Law Characterization Strain Rate EffectDocument33 paginiExample 11 - Tensile Test: Law Characterization Strain Rate EffectSanthosh LingappaÎncă nu există evaluări

- Technical AssesmentDocument7 paginiTechnical AssesmentbikramjitpodderÎncă nu există evaluări

- Paper Aimtdr SCLDocument6 paginiPaper Aimtdr SCLMohan Kumar Pradhan Associate ProfessorÎncă nu există evaluări

- 49ff PDFDocument4 pagini49ff PDFDele TedÎncă nu există evaluări

- Blank Optimization in Sheet Metal Forming Using An Evolutionary Algorithm-LibreDocument9 paginiBlank Optimization in Sheet Metal Forming Using An Evolutionary Algorithm-Libreicv.xaviÎncă nu există evaluări

- Integrated Design Optimization of Voltage Channel Distribution and Control Voltages For Tracking The Dynamic Shapes of Smart PlatesDocument9 paginiIntegrated Design Optimization of Voltage Channel Distribution and Control Voltages For Tracking The Dynamic Shapes of Smart PlateslinzqÎncă nu există evaluări

- Contact Stress Distribution of Deep Groove Ball Bearing Using AbaqusDocument13 paginiContact Stress Distribution of Deep Groove Ball Bearing Using AbaqusDr-Nouby Mahdy GhazalyÎncă nu există evaluări

- The Optimisation of Shot Peen Forming ProcessesDocument5 paginiThe Optimisation of Shot Peen Forming ProcessesbkhmohamedÎncă nu există evaluări

- Compensation of Friction and Backlash Effects in An Electrical Actuator by MerzoukiDocument10 paginiCompensation of Friction and Backlash Effects in An Electrical Actuator by MerzoukijacobwatsonÎncă nu există evaluări

- A Mixed Finite Element For Interlaminar Stress Computation: Yi-Bing ShiDocument10 paginiA Mixed Finite Element For Interlaminar Stress Computation: Yi-Bing ShiR Vignesh BabuÎncă nu există evaluări

- Wilson 1990Document13 paginiWilson 1990Sebastiao SilvaÎncă nu există evaluări

- AApplication of Artificial Neural Network and Taguchi Method To Preform Design in Metal Forming Considering WorkabilityDocument15 paginiAApplication of Artificial Neural Network and Taguchi Method To Preform Design in Metal Forming Considering WorkabilityHa Linh PhanÎncă nu există evaluări

- Dynamic Load Analysis and Optimization of Connecting Rod of Samand EngineDocument9 paginiDynamic Load Analysis and Optimization of Connecting Rod of Samand EnginecamiloromezÎncă nu există evaluări

- Numerical Simulation in Bulk Forming Process: Journal For Technology of Plasticity, Vol. 32 (2007), Number 1-2Document10 paginiNumerical Simulation in Bulk Forming Process: Journal For Technology of Plasticity, Vol. 32 (2007), Number 1-2Mujo Kukolj IIÎncă nu există evaluări

- Elastic-Plastic Fracture Mechanics Assessment of Test Data For Circumferential Cracked PipesDocument19 paginiElastic-Plastic Fracture Mechanics Assessment of Test Data For Circumferential Cracked Pipesjhon ortizÎncă nu există evaluări

- Perugia Stress EvaluationDocument20 paginiPerugia Stress Evaluationdf_campos3353Încă nu există evaluări

- Da DN Test5Document8 paginiDa DN Test5Anjan GhoshÎncă nu există evaluări

- Calibration of M-E PDG Rutting Model For Indian ConditionsDocument13 paginiCalibration of M-E PDG Rutting Model For Indian ConditionsSreeja SadanandanÎncă nu există evaluări

- Sborník Vědeckých Prací Vysoké Školy Báňské - Technické Univerzity OstravaDocument10 paginiSborník Vědeckých Prací Vysoké Školy Báňské - Technické Univerzity OstravaroccaÎncă nu există evaluări

- 1994 - 3D Finite Element Simulation of The Cold Forging of Helical GearsDocument13 pagini1994 - 3D Finite Element Simulation of The Cold Forging of Helical GearsNguyen Hoang DungÎncă nu există evaluări

- Pengaruh Ukuran Dan Jumlah Elemen Singular Terhadap Harga Faktor Intensitas Tegangan Untuk Kasus Retak Pojok Eliptik Dengan Metode Elemen HinggaDocument6 paginiPengaruh Ukuran Dan Jumlah Elemen Singular Terhadap Harga Faktor Intensitas Tegangan Untuk Kasus Retak Pojok Eliptik Dengan Metode Elemen HinggaPandu Wijaya KusumaÎncă nu există evaluări

- An Optimization Analysis On An Automotive Component With Fatigue Constraint Using Hyperworks Software For Environmental SustainabilityDocument5 paginiAn Optimization Analysis On An Automotive Component With Fatigue Constraint Using Hyperworks Software For Environmental SustainabilitySahaya GrinspanÎncă nu există evaluări

- Neuber Method For FatigueDocument12 paginiNeuber Method For FatigueKuan Tek SeangÎncă nu există evaluări

- Experimental and Numerical Studies To The Contact Stresses in AsymmetricDocument6 paginiExperimental and Numerical Studies To The Contact Stresses in AsymmetricHassan AlaaÎncă nu există evaluări

- An Improved 3d Adaptive EFG Method For Forging and Extrusion Analysis With Thermal Coupling in Ls-DynaDocument8 paginiAn Improved 3d Adaptive EFG Method For Forging and Extrusion Analysis With Thermal Coupling in Ls-DynausamaumerÎncă nu există evaluări

- W1D 1 AWinnicki CACDocument11 paginiW1D 1 AWinnicki CACTesfamichael AbathunÎncă nu există evaluări

- 06 1999fatigue BeijingDocument7 pagini06 1999fatigue BeijingTech MitÎncă nu există evaluări

- Hertz Contact Stress Analysis and Validation Using Finite Element AnalysisDocument8 paginiHertz Contact Stress Analysis and Validation Using Finite Element AnalysisPrabhakar Purushothaman100% (1)

- Finite Element Shot Peening Simulation For Residual Stress. Analysis and Comparison With Experimental ResultsDocument10 paginiFinite Element Shot Peening Simulation For Residual Stress. Analysis and Comparison With Experimental Resultsadhi.rohadhiÎncă nu există evaluări

- Buckled Beam Nonlinear VibrationDocument10 paginiBuckled Beam Nonlinear Vibrationhmsedighi459Încă nu există evaluări

- A Slope Stability Analysis Method Combined PDFDocument7 paginiA Slope Stability Analysis Method Combined PDFAnonymous 3XJRG5SIÎncă nu există evaluări

- Digital Image Correlation For Tensile TestDocument9 paginiDigital Image Correlation For Tensile TestAli AbbarÎncă nu există evaluări

- Dynamic Analysis of A Clamped BeamDocument9 paginiDynamic Analysis of A Clamped BeamFrancisco Lopez SantosÎncă nu există evaluări

- 20 SoicaDocument8 pagini20 SoicaVlad Alexandru FloreaÎncă nu există evaluări

- Fea For A 2D Metal Plate Using Matlab: March 2017Document17 paginiFea For A 2D Metal Plate Using Matlab: March 2017VivekÎncă nu există evaluări

- Bolt Grade Markings and Strength ChartDocument2 paginiBolt Grade Markings and Strength ChartEldori1988Încă nu există evaluări

- Demonstration For Certification (Participants Copy)Document2 paginiDemonstration For Certification (Participants Copy)Eldori1988Încă nu există evaluări

- SuspensiondfDocument3 paginiSuspensiondfAhmad UsamaÎncă nu există evaluări

- Sports Pictionary Poster 1 Vocabulary Worksheet PDFDocument2 paginiSports Pictionary Poster 1 Vocabulary Worksheet PDFSy Hafizah100% (1)

- ConfidenceDocument4 paginiConfidenceEldori1988Încă nu există evaluări

- Fishbone DiagramDocument2 paginiFishbone DiagramEldori1988Încă nu există evaluări

- Assembly in A BoxDocument2 paginiAssembly in A BoxEldori1988Încă nu există evaluări

- SIROLL Furnace Optimization enDocument0 paginiSIROLL Furnace Optimization enEldori1988Încă nu există evaluări

- Magna-Bulb Blind Fastener: Previous ScreenDocument3 paginiMagna-Bulb Blind Fastener: Previous ScreenEldori1988Încă nu există evaluări

- Onsert GB 0250 PDFDocument12 paginiOnsert GB 0250 PDFmazacotesÎncă nu există evaluări

- Rivset Gen2 GB 6705Document6 paginiRivset Gen2 GB 6705Eldori1988Încă nu există evaluări

- Toyota Business Practices and Academe - Industry Linkage - GasparDocument7 paginiToyota Business Practices and Academe - Industry Linkage - GasparEldori1988Încă nu există evaluări

- Huck Hucklok enDocument4 paginiHuck Hucklok enEldori1988Încă nu există evaluări

- HUCK Hucktainer enDocument8 paginiHUCK Hucktainer enEldori1988Încă nu există evaluări

- Böllhoff International With Companies In:: Partner of The Aerospace Industry Joining Together!Document3 paginiBöllhoff International With Companies In:: Partner of The Aerospace Industry Joining Together!Eldori1988Încă nu există evaluări

- Bolt Depot - Machinery Eye Bolt DimensionsDocument2 paginiBolt Depot - Machinery Eye Bolt DimensionsEldori1988Încă nu există evaluări

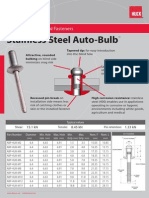

- HUCK Autobulb Stainless Steel enDocument1 paginăHUCK Autobulb Stainless Steel enEldori1988Încă nu există evaluări

- HUCK FloorTight enDocument8 paginiHUCK FloorTight enEldori1988Încă nu există evaluări

- Huck BOM: The Highest Strength Blind Fasteners in The WorldDocument5 paginiHuck BOM: The Highest Strength Blind Fasteners in The WorldEldori1988Încă nu există evaluări

- Lean Thinking For Flight: The Long View: Jim Womack, Senior Advisor, Lean Enterprise InstituteDocument18 paginiLean Thinking For Flight: The Long View: Jim Womack, Senior Advisor, Lean Enterprise InstituteEldori1988Încă nu există evaluări

- Bolt Depot - Metric Tap and Drill Size TableDocument1 paginăBolt Depot - Metric Tap and Drill Size TableEldori1988Încă nu există evaluări

- Bolt Depot - Metric Bolt Head, Wrench Size, and Diameter TableDocument2 paginiBolt Depot - Metric Bolt Head, Wrench Size, and Diameter TableEldori1988Încă nu există evaluări

- Lean For The Long Term: James P. Womack Chairman, Lean Enterprise InstituteDocument20 paginiLean For The Long Term: James P. Womack Chairman, Lean Enterprise InstituteEldori1988Încă nu există evaluări

- 561Document27 pagini561Eldori1988Încă nu există evaluări

- The Challenge of Lean Management: James P. Womack, Chairman, Lean Enterprise InstituteDocument27 paginiThe Challenge of Lean Management: James P. Womack, Chairman, Lean Enterprise InstituteEldori1988Încă nu există evaluări

- CPF PresentationDocument13 paginiCPF PresentationEldori1988Încă nu există evaluări

- Lean Counting: Jim Womack, Senior Advisor, Lean Enterprise InstituteDocument20 paginiLean Counting: Jim Womack, Senior Advisor, Lean Enterprise InstituteEldori1988Încă nu există evaluări

- German Presentation Feb 03Document8 paginiGerman Presentation Feb 03Eldori1988Încă nu există evaluări

- Simulation and Optimization of Metal Forming ProcessesDocument27 paginiSimulation and Optimization of Metal Forming ProcessesTamer HagasÎncă nu există evaluări

- STD Specification For Design and Integration of Fuel Energy Storage F3063Document7 paginiSTD Specification For Design and Integration of Fuel Energy Storage F3063Kobus PretoriusÎncă nu există evaluări

- Geopolitica y Medio Ambiente - Tarea 4 - Evaluacion FinalDocument7 paginiGeopolitica y Medio Ambiente - Tarea 4 - Evaluacion FinalKATERINEÎncă nu există evaluări

- Resolution: Owner/Operator, DocketedDocument4 paginiResolution: Owner/Operator, DocketedDonna Grace Guyo100% (1)

- 8. Nguyễn Tất Thành- Kon TumDocument17 pagini8. Nguyễn Tất Thành- Kon TumK60 TRẦN MINH QUANGÎncă nu există evaluări

- 30 de Thi Hoc Ky 2 Mon Tieng Anh Lop 9 Co Dap An 2023Document64 pagini30 de Thi Hoc Ky 2 Mon Tieng Anh Lop 9 Co Dap An 2023Trần MaiÎncă nu există evaluări

- Manuscript PDFDocument50 paginiManuscript PDFMartina Mae Benig GinoÎncă nu există evaluări

- Portfolio AdityaDocument26 paginiPortfolio AdityaAditya DisÎncă nu există evaluări

- Name: Mercado, Kath DATE: 01/15 Score: Activity Answer The Following Items On A Separate Sheet of Paper. Show Your Computations. (4 Items X 5 Points)Document2 paginiName: Mercado, Kath DATE: 01/15 Score: Activity Answer The Following Items On A Separate Sheet of Paper. Show Your Computations. (4 Items X 5 Points)Kathleen MercadoÎncă nu există evaluări

- Things You Can Do at Burnham ParkDocument2 paginiThings You Can Do at Burnham ParkBcpo TeuÎncă nu există evaluări

- Grade 10 Module 1 Performing Roughing in Activities For Communication and DistributDocument26 paginiGrade 10 Module 1 Performing Roughing in Activities For Communication and DistributNelshane JohnÎncă nu există evaluări

- CCNP SWITCH 300-115 - Outline of The Official Study GuideDocument31 paginiCCNP SWITCH 300-115 - Outline of The Official Study GuidehammiesinkÎncă nu există evaluări

- CLASS XI (COMPUTER SCIENCE) HALF YEARLY QP Bhopal Region Set-IIDocument4 paginiCLASS XI (COMPUTER SCIENCE) HALF YEARLY QP Bhopal Region Set-IIDeepika AggarwalÎncă nu există evaluări

- Airworthiness Directive: FAA Aviation SafetyDocument2 paginiAirworthiness Directive: FAA Aviation SafetyCarlos VarrentiÎncă nu există evaluări

- Advanced Methods For Complex Network AnalysisDocument2 paginiAdvanced Methods For Complex Network AnalysisCS & ITÎncă nu există evaluări

- SCC5-4000F Single ShaftDocument15 paginiSCC5-4000F Single ShaftudelmarkÎncă nu există evaluări

- Chapter 5 - Amino acids and Proteins: Trần Thị Minh ĐứcDocument59 paginiChapter 5 - Amino acids and Proteins: Trần Thị Minh ĐứcNguyễn SunÎncă nu există evaluări

- Advanced Statistical Approaches To Quality: INSE 6220 - Week 4Document44 paginiAdvanced Statistical Approaches To Quality: INSE 6220 - Week 4picalaÎncă nu există evaluări

- The Art of Street PhotographyDocument13 paginiThe Art of Street PhotographyDP ZarpaÎncă nu există evaluări

- Basic Knowledge About WDM Principle ADocument92 paginiBasic Knowledge About WDM Principle AJosé LópezÎncă nu există evaluări

- Letter of Acceptfor TDocument3 paginiLetter of Acceptfor TCCSÎncă nu există evaluări

- PDF Synopsis PDFDocument9 paginiPDF Synopsis PDFAllan D GrtÎncă nu există evaluări

- Geography NotesDocument2 paginiGeography NotesMinethegroundÎncă nu există evaluări

- Korea Times - Korean-EnglishDocument313 paginiKorea Times - Korean-EnglishgyeryongÎncă nu există evaluări

- 120 Câu Tìm Từ Đồng Nghĩa-Trái Nghĩa-Dap AnDocument9 pagini120 Câu Tìm Từ Đồng Nghĩa-Trái Nghĩa-Dap AnAlex TranÎncă nu există evaluări

- Retail Visibility Project of AircelDocument89 paginiRetail Visibility Project of Aircelabhishekkraj100% (1)

- Chanakya: For The Indian Television Series Based On His Life, SeeDocument11 paginiChanakya: For The Indian Television Series Based On His Life, SeeTrinadh CrazyguyÎncă nu există evaluări

- Elementary Electronics 1968-09-10Document108 paginiElementary Electronics 1968-09-10Jim ToewsÎncă nu există evaluări

- ERP22006Document1 paginăERP22006Ady Surya LesmanaÎncă nu există evaluări

- Online Shopping MallDocument17 paginiOnline Shopping MallMerin LawranceÎncă nu există evaluări

- Catalogo HydronixDocument68 paginiCatalogo HydronixNANCHO77Încă nu există evaluări

- Beginning AutoCAD® 2022 Exercise Workbook: For Windows®De la EverandBeginning AutoCAD® 2022 Exercise Workbook: For Windows®Încă nu există evaluări

- Certified Solidworks Professional Advanced Weldments Exam PreparationDe la EverandCertified Solidworks Professional Advanced Weldments Exam PreparationEvaluare: 5 din 5 stele5/5 (1)

- FreeCAD | Step by Step: Learn how to easily create 3D objects, assemblies, and technical drawingsDe la EverandFreeCAD | Step by Step: Learn how to easily create 3D objects, assemblies, and technical drawingsEvaluare: 5 din 5 stele5/5 (1)

- CATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchDe la EverandCATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchEvaluare: 4 din 5 stele4/5 (10)

- Beginning AutoCAD® 2020 Exercise WorkbookDe la EverandBeginning AutoCAD® 2020 Exercise WorkbookEvaluare: 2.5 din 5 stele2.5/5 (3)

- AutoCAD 2023 : Beginners And Intermediate user GuideDe la EverandAutoCAD 2023 : Beginners And Intermediate user GuideÎncă nu există evaluări

- Up and Running with AutoCAD 2020: 2D Drafting and DesignDe la EverandUp and Running with AutoCAD 2020: 2D Drafting and DesignÎncă nu există evaluări

- Design Research Through Practice: From the Lab, Field, and ShowroomDe la EverandDesign Research Through Practice: From the Lab, Field, and ShowroomEvaluare: 3 din 5 stele3/5 (7)