Documente Academic

Documente Profesional

Documente Cultură

Ocean Thermal Energy Conversion

Încărcat de

Rahul Kumar YadavTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Ocean Thermal Energy Conversion

Încărcat de

Rahul Kumar YadavDrepturi de autor:

Formate disponibile

A ON

PAPER

PRESENTATION

OCEAN ENERGY

THERMAL

CONVERSION

Document By SANTOSH BHARADWAJ REDDY Email: help@matlabcodes.com

Engineeringpapers.blogspot. com More Papers and Presentations available on above site

using the temperature difference of 20C (36F) or more that exists between warm tropical waters at the sun-warmed surface, and ABSTRACT Ocean Thermal Energy Conversion (OTEC) is a means of converting into useful energy the temperature difference colder waters drawn from depths of about 1000 m. To convert this thermal gradient into electrical energy, the warm water can be used to heat and vaporize a liquid (known as a working fluid). The working fluid develops pressure as it is caused to evaporate. This expanding vapor runs through a turbine generator and is then condensed back into a liquid by cold water brought up from depth, and the cycle is repeated. There are potentially three basic types of OTEC power plants: closed-cycle, open-cycle, and various blending of the two. All three types can be built on land, on offshore platforms fixed to the seafloor, on floating platforms anchored to the seafloor, or on ships that move from place to place A very important technical issue pertaining to the Claude cycle is the performance of direct contact heat exchangers operating at typical . OTEC generates electricity by OTEC boundary conditions. Many early Claude

between surface water of the oceans in tropical and sub-tropical water at a approximately the polar a areas, depth 1 and of 000 For is

meters which comes from regions. of 20oC OTEC difference temperature

adequate, which embraces very large ocean areas, and favors islands and many developing countries. The continuing increase in demand from this sector of the world (as indicated by World Energy Council figures) provides a major potential market

cycle designs used a surface condenser However condensers since direct offer their contact significant OCEAN THERMAL ENERGY CONVERSION Ocean Thermal Energy Conversion (OTEC) is a means of converting into useful energy the temperature difference between surface water of the oceans in tropical and sub-tropical areas, and water at 1 a depth 000 of approximately regions. For meters a performance is well understood.

disadvantages. As the warm sea water rises in the intake pipes, the pressure decreases to the point where gas begins to evolve. If a significant amount of gas comes out of the solution, designing a gas trap before the direct contact heat exchangers may be justified. Experiments simulating warm conditions intake in the pipe water

which comes from the polar OTEC temperature difference of 20oC is adequate, which embraces very large ocean areas, and favors islands and many developing countries. The continuing increase in demand from this sector of the world (as indicated by World Energy a Council major figures) provides

indicated about 30% of the dissolved gas evolve in the top 8.5 m of the tube. The tradeoff between pre-deaeration of the sea water and expulsion of all the non-condensable gases from the condenser is dependent on the gas evolution dynamics, deaerator efficiency, head loss, vent compressor efficiency and parasitic power. Experimental results vertical have indicated that spout condensers

potential market. Depending on the location of their cold and warm water supplies, OTEC plants can be land-based, floating, or - as a longer term development grazing. Floating plants have the advantage that the cold water pipe is shorter, reaching directly down to the cold resource, but

perform some 30% better than the falling jet types. INTRODUCTION

the power generated has to be brought ashore, and moorings are likely to be in water depths of, typically, 2 000 meters. The development of High Voltage DC transmission offers substantial advantage to floating OTEC, and the increasing depths for offshore oil and gas production over the last decade mean that mooring is no longer the problem which it once was - but still a significant cost item for floating power OTEC. transmission Land-based cable to plants have the advantage of no shore, and no mooring costs. However, the cold water pipe has to cross the surf zone and then follow the seabed until the depth reaches approximately 1 000 meters - resulting in a much longer pipe which has therefore greater friction losses, and greater warming of the cold water before it reaches the heat exchanger, both resulting in lower efficiency. The working cycle may be closed or open, the choice depending on circumstances. All these variants clearly develop their power in the tropical and sub-tropical

zones,

but

longer-term

development - a grazing plant allows OTEC energy use in highly which developed lie in the economies worlds

temperate zones. In this case the OTEC plant is free to drift in ocean areas with a high the temperature difference,

power being used to split sea water into liquid hydrogen and liquid oxygen. The hydrogen, and in some cases to where it is economic the oxygen too, is offloaded shuttle tankers which take the product to energyhungry countries. So, in time, the entire world can benefit from OTEC, not just tropical and subtropical areas. A further benefit of OTEC is that, unlike most renewable energies, it is base-load - the thermal resource of the ocean ensures the power source is available day or night, and with only modest to variation winter. benign, OTEC It from is and plants summer some

environmentally floating

would actually result in net CO2 absorption. A unique feature of OTEC is the additional products

which can readily be provided food (aquaculture and agriculture); potable water; air conditioning; etc. (see Figure 16.2). In large part these arise from the pathogen-free, nutrientrich, deep cold water. OTEC is therefore the basis for a whole family of Deep Ocean Water Applications generated water (DOWA), which Potable can can also benefit the cost of electricity. production alone

this

aspect,

the

technological

improvements - such as the much smaller heat exchangers now required - have contributed to significantly reduced capital expenditure. On top of these two factors the world-wide trend to whole-life costing benefits all renewable when compared with those energy systems which rely on conventional fuels (and their associated costs), even when the higher initial maintenance costs of early OTEC/DOWA plants are taken the into account. When compared with traditional fuels

reduce electrical generating costs by up to one third, and is itself in very considerable demand in most areas where OTEC can operate. The relevance of environmental impact was given a considerable boost by the Rio and Kyoto summits, and follow-up actions have included a much greater emphasis on this aspect by a number of energy companies. Calculations for generating costs now take increasing account of "downstream CO2 is factors" With for such example the costs associated with emissions. an criteria included, OTEC/DOWA becoming increasingly attractive option. Even without

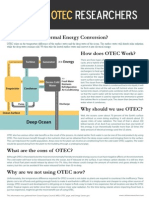

How it works OTEC generates electricity by using the temperature difference

of 20C (36F) or more that exists between warm tropical waters surface, at and the sun-warmed waters colder

drawn from depths of about 1000 m. To convert this thermal gradient into electrical energy, the warm water can be used to heat and vaporize a liquid The main components of the system are: Pumps and pipes for supplying the evaporator and the condenser respectively with warm and cold sea water; a working fluid which is vaporized to drive a steam turbine which generates mechanical mechanical energy. energy can This be (known as a working fluid). The working fluid develops pressure as it is caused to evaporate. This expanding vapor runs through a turbine generator and is then condensed back into a liquid by cold water brought up from depth, and the cycle is repeated. There are potentially three basic types of OTEC power plants: closed-cycle, open-cycle, and various blending of the two. All three types can be built on land, on offshore platforms fixed to the seafloor, on floating to the platforms anchored Cannot principle.

transformed in electric energy if the turbine is coupled to an alternator. A very simplified scheme The details of the process and the technology of the components for OTEC systems depend essentially on the choice of the working fluid. There are basically two types of OTEC processes: the

seafloor, or on ships that move from place to place The surface water and the deep water of tropical ocean can be used respectively as the heat source and the heat sink of a thermal engine ruled by the

closed-cycle and the open-cycle. of OTEC process is shown below.

The surface water and the deep water of tropical ocean can be used respectively as the heat source and the heat sink of a thermal engine ruled by the Carnot principle.

Depending on the cycle used

Open cycle Closed cycle Hybrid cycle

This cold seawater is an integral The main components of the system are: Pumps and pipes for supplying the evaporator and the condenser respectively with warm and cold sea water; a working fluid which is vaporized to drive a steam turbine which generates mechanical energy. This mechanical energy can be transformed in electric energy if the turbine is coupled to an alternator. A very simplified scheme of OTEC process is shown below Closed-cycle Diagram of a closed cycle OTEC plant Closed-cycle systems use fluid with a low boiling point, such as, The details of the process and the technology of the components for OTEC systems depend are essentially on the choice of the working fluid. There basically two types of OTEC processes: the closed-cycle and the open-cycle. to rotate a to generate electricity. Warm the surface is pumped fluid is through a heat exchanger where low-boiling-point vaporized. The expanding vapor turns the turbo-generator. Then, cold, deep seawaterpumped through a second heat exchanger condenses the vapor back into a liquid, which is then recycled through the system. part of each of the three types of OTEC systems: closed-cycle, open-cycle, and hybrid.

In,

the

Natural

Energy

Laboratory and several privatesector partners developed the mini OTEC experiment, which achieved the first successful atsea production net electrical power from closed-cycle OTEC. The mini OTEC vessel was moored 1.5 miles (2.4 km) off the Hawaiian coast and produced enough net electricity to illuminate the ship's light bulbs, and run its computers and televisions. Then, the Natural Energy Open-cycle Open-cycle OTEC uses the

tropical oceans' warm surface water to make electricity. When warm seawater is placed in a lowpressure container, it boils. The expanding steam drives a lowpressure turbine attached to an electrical generator. The steam, which has left its salt behind in the low-pressure container, is almost pure fresh water. It is condensed back into a liquid by exposure to cold temperatures from deep-ocean water In, the Solar Energy Research Institute now the developed a vertical-spout evaporator to convert warm seawater into lowpressure steam for open-cycle plants. Energy conversion efficiencies as high as 97% were achieved for the seawater to steam conversion process (note: the overall efficiency of an OTEC system using a vertical-spout evaporator would still only be a few per cent). In May, an opencycle OTEC plant at Keahole

Laboratory in tested a 250 kW pilot OTEC closed-cycle plant, the largest such plant ever put into operation. Since then, there have been no tests of OTEC technology in the United States, largely because the economics of energy production today have delayed the financing of a permanent, operating plant. Outside the United States, the government of has taken an active interest in OTEC technology. India has built and plans to test a 1 MW closedcycle, floating OTEC plant. continuously

Point, Hawaii, produced 50,000 watts of electricity during a net power-producing experiment. This broke the record of 40,000 watts set by a Japanese system in Hybrid Hybrid systems combine the features of both the closed-cycle and open-cycle systems. In a hybrid system, warm seawater enters a vacuum chamber where it is flash-evaporated into steam, similar vaporizes to a the open-cycle evaporation process. The steam low-boiling-point fluid (in a closed-cycle loop) that drives a turbine to produce electricity. Political Concerns Because OTEC facilities are more-or-less stationary surface platforms, their exact location and legal status may be affected by the treaty (UNCLOS). This treaty grants coastal nations 3-, 12-, and 200-mile zones of varying legal authority from land, creating potential conflicts and regulatory barriers to OTEC plant construction and ownership. OTEC plants and similar structures would be

considered

under

the

treaty,

giving them no legal authority of their own. OTEC plants could be perceived as either a threat or potential partner or to future seabed mining operations controlled by the. The has not ratified the treaty as of 2006 despite strong internal support. Cost and Economics For OTEC to be viable as a power source, it must either gain political favor (ie. favorable tax treatment types of and power, be widely of their subsidies) which or may become competitive with other themselves yet been subsidized. deployed, costs are

Because OTEC systems have not estimates uncertain. One study USD compared per with estimates power kilowatt-hour, $.07 for generation costs as low as $.07

subsidized wind systems Besides regulation and subsidies, other factors that should be taken into account include OTEC's status as a renewable resource (with no waste products or limited fuel supply), the limited geographical

area in which it is available the political effects of reliance on oil, the development of alternate forms of ocean power such as wave energy and the possibility of combining it with or filtration for trace minerals to obtain multiple uses from a single pump system. Technical difficulties Degradation of heat exchanger performance by dissolved gases A very important technical issue pertaining to the Claude cycle is the performance heat at of direct OTEC Many contact operating boundary exchangers typical

simulating

conditions

in

the

warm water intake pipe indicated about 30% of the dissolved gas evolve in the top 8.5 m of the tube. The tradeoff between preof the sea water and expulsion of all the non-condensable gases from the condenser is dependent on the gas evolution dynamics, deaerator efficiency, head loss, vent compressor efficiency and parasitic power. results vertical have spout Experimental that condensers indicated

perform some 30% better than the falling jet types. Improper sealing The evaporator, turbine, and condenser operate in partial vacuum ranging from 3 % to 1 % atmospheric pressure. This poses a number of practical concerns that must be addressed. First, the system must be carefully sealed to prevent in-leakage of atmospheric air that can severely degrade or shut down operation. Second, the specific volume of the low-pressure steam is very large compared to that of the pressurized working fluid used in the case of a closed cycle OTEC. This means that components

conditions.

early Claude cycle designs used a surface condenser since their performance is well understood. However condensers direct offer contact significant

disadvantages. As the warm sea water rises in the intake pipes, the pressure decreases to the point where gas begins to evolve. If a significant amount of gas comes out of the solution, designing a gas trap before the direct contact heat exchangers may be justified. Experiments

must have large flow areas to ensure that steam velocities do not attain excessively high values.

boost by the Rio and Kyoto summits, and follow-up actions have included a much greater emphasis on this aspect by a number of energy companies. Calculations for generating costs now take increasing account of "downstream factors" for example the costs associated with CO2 emissions. With such criteria included, becoming this aspect, OTEC/DOWA an the is increasingly technological

The working cycle may be closed or open, the choice depending on circumstances. All these variants clearly develop their power in the tropical and sub-tropical zones, but a longer-term development a grazing plant allows OTEC energy use in highly which developed lie in the economies worlds

attractive option. Even without improvements such as the much smaller heat exchangers now required have contributed to significantly reduced capital expenditure. On top of these two factors the world-wide trend to whole-life costing benefits all renewable when compared with those energy systems which rely on conventional fuels (and their associated costs), even when the higher initial maintenance costs of early OTEC/DOWA plants are taken the into account. When of compared with traditional fuels economic position OTEC/DOWA is now rapidly

temperate zones. In this case the OTEC plant is free to drift in ocean areas with a high the temperature difference,

power being used to split sea water into liquid hydrogen and liquid oxygen. The hydrogen, and in some cases where it is economic the oxygen too, is offloaded which to shuttle the tankers to take product

energy-hungry countries. So, in time, all the world can benefit from OTEC, not just tropical and sub-tropical areas. The relevance of environmental impact was given a considerable

approaching equality, and work in Hawaii at the Pacific has as International Center for High Technology contributed comparisons, Research to as well realistic

prepare overall ocean policies and recent years have seen a number of these introduced for example in Australia. Despite the existence of EEZs, the low costs of many "traditional" energy resources in the recent past had not encouraged venture capital investment in OTEC/DOWA, but the currently higher costs of oil, plus the growing recognition effects of noted environmental

component development.

above (and the associated costs) of some traditional fuels, are rapidly changing the economics of Nations which previously might not have contemplated activities have OTEC/DOWA these in relation and to other OTEC/DOWA

renewable. Technology transfer is a major factor in many maritime activities and OTEC/DOWA is no exception, in this case borrowing from the oil and gas industry again as already noted. It is all these factors which now place OTEC/DOWA within realistic reach of full economic commercialization early in the 21st century. But, whilst a number of the components plant for an are OTEC/DOWA

been given legal title over waters throughout the 200 nautical mile Exclusive Economic Zone (EEZ) associated with the UN Convention on the Law of the Sea (UNCLOS). Prior to that no investor private or public would seriously contemplate funding a new form of capital plant in such seas and oceans, but since UNCLOS a number of nations have worked steadily to

therefore either available, or nearly so, the inherent simplicity of a number of key elements of OTEC/DOWA refinement system, into this and still an require effective need will

allows OTEC energy use in highly which developed lie in the economies worlds

temperate zones. In this case the OTEC plant is free to drift in ocean areas with a high the temperature difference,

further R&D investment. Before OTEC/DOWA can be realized, this R&D must be completed to show clearly to potential investors, via a demonstrationscale plant, that the integrated system safely. operates effectively, and efficiently, economically,

power being used to split sea water into liquid hydrogen and liquid oxygen. The hydrogen, and in some cases to where it is economic the oxygen too, is offloaded shuttle tankers which take the product to energyhungry countries. So, in time, the entire world can benefit from OTEC, not just tropical and subtropical areas.

Document By SANTOSH BHARADWAJ REDDY Email: help@matlabcodes.com

The working cycle may be closed or open, the choice depending on circumstances. All these variants clearly develop their power in the tropical and sub-tropical zones, but a longer-term development a grazing plant

Engineeringpapers.blogspot. com More Papers and Presentations available on above site

S-ar putea să vă placă și

- Documenttopdf Trial Version, To Remove This Mark, Please Register This SoftwareDocument10 paginiDocumenttopdf Trial Version, To Remove This Mark, Please Register This Softwareranga247Încă nu există evaluări

- Otec Power Plant: NcercDocument22 paginiOtec Power Plant: NcercVimi WilsonÎncă nu există evaluări

- OTECDocument14 paginiOTECTALLURI LAKSHMI PRASANNAÎncă nu există evaluări

- Documenttopdf Trial Version, To Remove This Mark, Please Register This SoftwareDocument11 paginiDocumenttopdf Trial Version, To Remove This Mark, Please Register This Softwareranga247Încă nu există evaluări

- Chapter - 5 OTECDocument12 paginiChapter - 5 OTECsahitÎncă nu există evaluări

- Presentation ++Document15 paginiPresentation ++36.Praphull DesaleÎncă nu există evaluări

- CH 9 OTECDocument6 paginiCH 9 OTECscharichÎncă nu există evaluări

- Ocean Thermal Energy ConversionDocument15 paginiOcean Thermal Energy Conversion36.Praphull DesaleÎncă nu există evaluări

- Ocean Thermal Energy ConversionDocument20 paginiOcean Thermal Energy ConversionAthisayaraj RajÎncă nu există evaluări

- A Technical Paper Presentation On: Ocean Thermal Energy ConversionDocument20 paginiA Technical Paper Presentation On: Ocean Thermal Energy ConversionsaurabhÎncă nu există evaluări

- Case Study Report On: Pyre 202 - Wind Energy, Tidal Energy and OtecDocument15 paginiCase Study Report On: Pyre 202 - Wind Energy, Tidal Energy and OtecsundarÎncă nu există evaluări

- Ocean Thermal Energy ConversionDocument10 paginiOcean Thermal Energy ConversionRaviteja RokzÎncă nu există evaluări

- Seminar Report On Ocean Thermal Energy ConversionDocument21 paginiSeminar Report On Ocean Thermal Energy ConversionHARENDRA BHINCHARÎncă nu există evaluări

- Ocean Thermal Energy ConversionDocument13 paginiOcean Thermal Energy ConversionRandroxRÎncă nu există evaluări

- 16eemme023 Seminar ReportDocument9 pagini16eemme023 Seminar ReportShreya RathoreÎncă nu există evaluări

- Close&Hybrid OTECDocument26 paginiClose&Hybrid OTECJohn Jay AbinalÎncă nu există evaluări

- Module No 5a.ocean EnergyDocument15 paginiModule No 5a.ocean EnergyVaibhav Vithoba NaikÎncă nu există evaluări

- OTEC - Ocean Thermal Energy Conversion: by Maria Bechtel and Erik NetzDocument12 paginiOTEC - Ocean Thermal Energy Conversion: by Maria Bechtel and Erik NetzrodrigoflaÎncă nu există evaluări

- Presentation On Ocean Thermal Energy ConvertionDocument23 paginiPresentation On Ocean Thermal Energy ConvertionAtal SahaÎncă nu există evaluări

- Ocean Thermal Wave Energy ConversionsDocument12 paginiOcean Thermal Wave Energy ConversionsJoseph Gil SalcedoÎncă nu există evaluări

- Thermo OTECDocument15 paginiThermo OTECzikri annuurÎncă nu există evaluări

- Ocean Thermal EnergyDocument23 paginiOcean Thermal EnergyNAGMANI59Încă nu există evaluări

- RER Mod5@AzDOCUMENTS - inDocument13 paginiRER Mod5@AzDOCUMENTS - inMizan SalimÎncă nu există evaluări

- Ocean Energy Conversion Methods: Arshad Babu. U M7B Roll No: 7457 TKMCE KollamDocument32 paginiOcean Energy Conversion Methods: Arshad Babu. U M7B Roll No: 7457 TKMCE KollamgaviÎncă nu există evaluări

- Betck105e Mod4@Azdocuments - inDocument17 paginiBetck105e Mod4@Azdocuments - inswathiswathi7895467Încă nu există evaluări

- Ocean Thermal Energy ConversionDocument43 paginiOcean Thermal Energy ConversionMaitry DaveÎncă nu există evaluări

- OotecDocument12 paginiOotecLouie Jay Gitgitin SalvañaÎncă nu există evaluări

- Nes Module IIIDocument12 paginiNes Module IIIVenuÎncă nu există evaluări

- Otc 20340Document13 paginiOtc 20340Rasheed YusufÎncă nu există evaluări

- AGOJO - Ocean Thermal Energy ConversionDocument14 paginiAGOJO - Ocean Thermal Energy ConversionCarren MarquezÎncă nu există evaluări

- Ocean Thermal EnergyDocument14 paginiOcean Thermal EnergyRajat SinghÎncă nu există evaluări

- Energy From The Oceans: (OTEC, Tides, Waves, and Small Hydroelectric)Document55 paginiEnergy From The Oceans: (OTEC, Tides, Waves, and Small Hydroelectric)Patel NikhilÎncă nu există evaluări

- Ocean Thermal Energy Conversion: By-Snehanshu Das 7 Sem, B.TechDocument20 paginiOcean Thermal Energy Conversion: By-Snehanshu Das 7 Sem, B.TechJeanÎncă nu există evaluări

- OTEC Summary Aug 2012Document33 paginiOTEC Summary Aug 2012Robie TrieoÎncă nu există evaluări

- Ocean Thermal Energy: Submitted To DR - Harmeet KaurDocument19 paginiOcean Thermal Energy: Submitted To DR - Harmeet KaurAmitpal Singh CheemaÎncă nu există evaluări

- Vivek Chand OTECDocument20 paginiVivek Chand OTECvivek chand100% (1)

- Otec SeminarDocument21 paginiOtec SeminarAbhishekSuman80% (5)

- PCRES April2020 OTEC NotesDocument35 paginiPCRES April2020 OTEC NotesVISHAL MUKUNDANÎncă nu există evaluări

- HereDocument3 paginiHereBilly Joe BreakfastÎncă nu există evaluări

- OTECDocument18 paginiOTECkss_sachinvarma12100% (2)

- Rer Mod 5Document14 paginiRer Mod 5rahulÎncă nu există evaluări

- Research Paper Ocean Thermal Energy ConversionDocument4 paginiResearch Paper Ocean Thermal Energy ConversionfwuhlvgkfÎncă nu există evaluări

- Ocean Thermal Energy Conversion - PPTX Neelu OtecDocument17 paginiOcean Thermal Energy Conversion - PPTX Neelu OtecrahulÎncă nu există evaluări

- A Software To Evaluate Financial Viability of Geothermal ProjectsDocument18 paginiA Software To Evaluate Financial Viability of Geothermal ProjectsYetem FantuÎncă nu există evaluări

- Ocean Thermal Energy Conversion: International Journal of Energy and Power EngineeringDocument4 paginiOcean Thermal Energy Conversion: International Journal of Energy and Power EngineeringKemas Ganesha MahendraÎncă nu există evaluări

- Power Plant Engineering 160100082 - Assignment - 2Document12 paginiPower Plant Engineering 160100082 - Assignment - 2Vidushi VinodÎncă nu există evaluări

- Ocean Thermal Power Plant ReportDocument10 paginiOcean Thermal Power Plant ReportMahmud L. MusaÎncă nu există evaluări

- Unit - 4Document59 paginiUnit - 4aswinhacker28Încă nu există evaluări

- Electricity Generation Using Produced BR PDFDocument9 paginiElectricity Generation Using Produced BR PDFchariÎncă nu există evaluări

- Ocean Thermal Energy Conversion: HistoryDocument20 paginiOcean Thermal Energy Conversion: HistorySantosh PÎncă nu există evaluări

- Shakil2014 BangladeshDocument5 paginiShakil2014 BangladeshAbir Rashid, 170011004Încă nu există evaluări

- Ocean Thermal Energy Conversion (OTEC)Document28 paginiOcean Thermal Energy Conversion (OTEC)Sehati FisikaÎncă nu există evaluări

- OTEC Closed LoopDocument14 paginiOTEC Closed LoopAlexis CabigtingÎncă nu există evaluări

- Ocean Thermal Energy ConversionDocument17 paginiOcean Thermal Energy ConversionVamsi Pelluru100% (1)

- Renewable Sources of Energy: Unit 5 (A) Ocean EnergyDocument11 paginiRenewable Sources of Energy: Unit 5 (A) Ocean Energygeethu hanishaÎncă nu există evaluări

- JMI ESc OTECDocument16 paginiJMI ESc OTECAJKÎncă nu există evaluări

- Renewable Energy Sources For Caribbean Territories and SIDS: OTECDocument42 paginiRenewable Energy Sources For Caribbean Territories and SIDS: OTECVinay MaisuriyaÎncă nu există evaluări

- Cal Iot Ec ResearchersDocument1 paginăCal Iot Ec ResearchersShanaya GaharanaÎncă nu există evaluări

- Cooling Tower1Document66 paginiCooling Tower1Er Bali Pandhare100% (1)

- Rambilash Kumar CVDocument3 paginiRambilash Kumar CVRahul Kumar YadavÎncă nu există evaluări

- BPL Kit Indent 10.1.2019 THANDocument2 paginiBPL Kit Indent 10.1.2019 THANRahul Kumar YadavÎncă nu există evaluări

- Ajay Pratap Singh: Any Time Learning (ATL) Computer Concepts (CCC) - National Power Training Institute (NPTI)Document2 paginiAjay Pratap Singh: Any Time Learning (ATL) Computer Concepts (CCC) - National Power Training Institute (NPTI)Rahul Kumar YadavÎncă nu există evaluări

- RQM Report Midding Pasu Lower Subansiri Arunachal PradeshDocument24 paginiRQM Report Midding Pasu Lower Subansiri Arunachal PradeshRahul Kumar YadavÎncă nu există evaluări

- Jndal Power ResumeDocument2 paginiJndal Power ResumeRahul Kumar YadavÎncă nu există evaluări

- Salary Slip Aug 21Document1 paginăSalary Slip Aug 21Rahul Kumar YadavÎncă nu există evaluări

- Candaite Screening Inputs For CAD Drafts Person: AGS Consultting Engineers & Project ManagementDocument1 paginăCandaite Screening Inputs For CAD Drafts Person: AGS Consultting Engineers & Project ManagementRahul Kumar YadavÎncă nu există evaluări

- Salary Slip Aug 21Document1 paginăSalary Slip Aug 21Rahul Kumar YadavÎncă nu există evaluări

- RQM-Report-KHAHU-Lower Subansiri-Arunachal PradeshDocument22 paginiRQM-Report-KHAHU-Lower Subansiri-Arunachal PradeshRahul Kumar YadavÎncă nu există evaluări

- Design of 400 220 132 KV 1316 MW Power SubstationDocument117 paginiDesign of 400 220 132 KV 1316 MW Power SubstationAHMED YOUSEF100% (1)

- RQM-Report-UPPER LIYA DONCHA-EAST KAMENG-Arunachal PradeshDocument30 paginiRQM-Report-UPPER LIYA DONCHA-EAST KAMENG-Arunachal PradeshRahul Kumar YadavÎncă nu există evaluări

- RQM-Report-MiddingPasu-Lower Subansiri-Arunachal PradeshDocument22 paginiRQM-Report-MiddingPasu-Lower Subansiri-Arunachal PradeshRahul Kumar YadavÎncă nu există evaluări

- Maintenance Best Practices For Energy Efficient Facilities Course OutlineDocument3 paginiMaintenance Best Practices For Energy Efficient Facilities Course OutlineRahul Kumar YadavÎncă nu există evaluări

- Project Coordinator Personal Details Applica On Id:186000000214Document3 paginiProject Coordinator Personal Details Applica On Id:186000000214Rahul Kumar YadavÎncă nu există evaluări

- Report of Deposit Works Under ADP: Sl. No. Name of Work Department Est. Head Name of CircleDocument6 paginiReport of Deposit Works Under ADP: Sl. No. Name of Work Department Est. Head Name of CircleRahul Kumar YadavÎncă nu există evaluări

- 5S Strategy: A Workplace Improvement Lean Tool: January 2013Document9 pagini5S Strategy: A Workplace Improvement Lean Tool: January 2013Rahul Kumar YadavÎncă nu există evaluări

- Financial Analysis of Projects I - OutlineDocument2 paginiFinancial Analysis of Projects I - OutlineRochdi BahiriÎncă nu există evaluări

- HiiDocument1 paginăHiiRahul Kumar YadavÎncă nu există evaluări

- Ocean Thermal EnergyDocument23 paginiOcean Thermal EnergyNAGMANI59Încă nu există evaluări

- Measuring and Benchmarking OutlineDocument3 paginiMeasuring and Benchmarking OutlineRahul Kumar YadavÎncă nu există evaluări

- Letter of ConsentDocument1 paginăLetter of ConsentRahul Kumar YadavÎncă nu există evaluări

- Abhi CVDocument3 paginiAbhi CVRahul Kumar YadavÎncă nu există evaluări

- UGV ReviewDocument53 paginiUGV ReviewRahul Kumar YadavÎncă nu există evaluări

- Ocean Thermal Energy ConversionDocument14 paginiOcean Thermal Energy ConversionRahul Kumar YadavÎncă nu există evaluări

- Building Fire FightingDocument9 paginiBuilding Fire Fightingrmaffireschool100% (1)

- Unit Kimia Kolej Matrikulasi Kedah: SK 015, Chemistry Unit, KMK Pra PSPM Set 1Document7 paginiUnit Kimia Kolej Matrikulasi Kedah: SK 015, Chemistry Unit, KMK Pra PSPM Set 1aÎncă nu există evaluări

- Scaffolding and Solution in Iron Blast FurnaceDocument142 paginiScaffolding and Solution in Iron Blast Furnacesatya7960100% (2)

- JJ-THOMPSON - Conduction of Electricity Through GasesDocument572 paginiJJ-THOMPSON - Conduction of Electricity Through GasesgeorgeÎncă nu există evaluări

- Thermal Design of Economizer For Waste Heat Recovery Boiler WHRB IJERTV7IS100037Document7 paginiThermal Design of Economizer For Waste Heat Recovery Boiler WHRB IJERTV7IS100037Khushnood100% (1)

- Dehradun Public School ASSIGNMENT (2019 - 2020) Subject: Science (086) Class - IxDocument4 paginiDehradun Public School ASSIGNMENT (2019 - 2020) Subject: Science (086) Class - Ixbadnight4uÎncă nu există evaluări

- 2.thermal EngineeringDocument7 pagini2.thermal EngineeringVikram Rao100% (1)

- 8 - The Kinetic Model of MatterDocument21 pagini8 - The Kinetic Model of MatterEdgardo Leysa100% (1)

- Determination of Kinetics in Gas-Liquid Reaction Systems. An OverviewDocument22 paginiDetermination of Kinetics in Gas-Liquid Reaction Systems. An OverviewFauzi IhsanÎncă nu există evaluări

- Ansi Aga B109 1 2000Document43 paginiAnsi Aga B109 1 2000Ihab El-SaftawiÎncă nu există evaluări

- High Pressure Lift Ejector and Liquid Ejector Systems: Application GuideDocument28 paginiHigh Pressure Lift Ejector and Liquid Ejector Systems: Application Guidejvc hemitÎncă nu există evaluări

- CAT - 3516H Engine Shutdown OccurrenceDocument4 paginiCAT - 3516H Engine Shutdown Occurrencewagner_guimarães_1Încă nu există evaluări

- Simple Kinetic Molecular Model of Matter 5 QPDocument15 paginiSimple Kinetic Molecular Model of Matter 5 QPputri aÎncă nu există evaluări

- Enhanced Liquid Recovery SystemsDocument7 paginiEnhanced Liquid Recovery SystemsY.EbadiÎncă nu există evaluări

- Melting and Holding Furnaces For Die CastingDocument11 paginiMelting and Holding Furnaces For Die CastingVAP BOMBAYÎncă nu există evaluări

- Manual PerformDocument129 paginiManual PerformJosé TimanáÎncă nu există evaluări

- HA and Offline - Test Series - NEET - 2020 For XII - RMDocument4 paginiHA and Offline - Test Series - NEET - 2020 For XII - RMAmitesh TejaswiÎncă nu există evaluări

- Course: Cdi 601 - Fire Code, Protection and Arson Investigation Units: 3 Pre-Requisites: NoneDocument12 paginiCourse: Cdi 601 - Fire Code, Protection and Arson Investigation Units: 3 Pre-Requisites: Nonejohn martin urbinaÎncă nu există evaluări

- Solids Liquids and Gases Adapted Tests PDFDocument4 paginiSolids Liquids and Gases Adapted Tests PDFLaura HaniÎncă nu există evaluări

- Overpressure StudyDocument25 paginiOverpressure StudyBudiman -Încă nu există evaluări

- Kech106 PDFDocument32 paginiKech106 PDFPhantomAssaulterÎncă nu există evaluări

- Classical Mechanics FormulaDocument20 paginiClassical Mechanics FormulaMehdi KhouadriÎncă nu există evaluări

- EE Curs ScurtDocument325 paginiEE Curs ScurtAnca IonitzaÎncă nu există evaluări

- Lec 10Document6 paginiLec 10yeng botzÎncă nu există evaluări

- Science 10 4th QeDocument2 paginiScience 10 4th QeIris LeuterioÎncă nu există evaluări

- Grade 11 Term 2 Physical Sciences Study Notes: VectorsDocument41 paginiGrade 11 Term 2 Physical Sciences Study Notes: VectorssoopfaceÎncă nu există evaluări

- The Mole Concept: Prepared By: Pooran Appadu (Type The Company Name) 9/1/2009Document44 paginiThe Mole Concept: Prepared By: Pooran Appadu (Type The Company Name) 9/1/2009aldemairaÎncă nu există evaluări

- Oil and Gas Course Open Manual PDFDocument97 paginiOil and Gas Course Open Manual PDFWael_Barakat_3179Încă nu există evaluări

- Chapter 5Document22 paginiChapter 5FakhrulShahrilEzanieÎncă nu există evaluări

- Juan Pablo Physics Paper 1Document27 paginiJuan Pablo Physics Paper 1juanfogedaÎncă nu există evaluări

- House Rules: How to Decorate for Every Home, Style, and BudgetDe la EverandHouse Rules: How to Decorate for Every Home, Style, and BudgetÎncă nu există evaluări

- The Fitness Mindset: Eat for energy, Train for tension, Manage your mindset, Reap the resultsDe la EverandThe Fitness Mindset: Eat for energy, Train for tension, Manage your mindset, Reap the resultsEvaluare: 4.5 din 5 stele4.5/5 (31)

- 100 Micro Amigurumi: Crochet patterns and charts for tiny amigurumiDe la Everand100 Micro Amigurumi: Crochet patterns and charts for tiny amigurumiEvaluare: 5 din 5 stele5/5 (2)

- Clean Mama's Guide to a Healthy Home: The Simple, Room-by-Room Plan for a Natural HomeDe la EverandClean Mama's Guide to a Healthy Home: The Simple, Room-by-Room Plan for a Natural HomeEvaluare: 5 din 5 stele5/5 (2)

- The Encyclopedia of Spices & Herbs: An Essential Guide to the Flavors of the WorldDe la EverandThe Encyclopedia of Spices & Herbs: An Essential Guide to the Flavors of the WorldEvaluare: 3.5 din 5 stele3.5/5 (5)

- Eat That Frog!: 21 Great Ways to Stop Procrastinating and Get More Done in Less TimeDe la EverandEat That Frog!: 21 Great Ways to Stop Procrastinating and Get More Done in Less TimeEvaluare: 4.5 din 5 stele4.5/5 (3226)

- Success at Home with ADHD.: Practical Organization Strategies to Make Your Life Easier.De la EverandSuccess at Home with ADHD.: Practical Organization Strategies to Make Your Life Easier.Evaluare: 4 din 5 stele4/5 (17)

- Simplified Organization: Learn to Love What Must Be DoneDe la EverandSimplified Organization: Learn to Love What Must Be DoneÎncă nu există evaluări

- The Joy of Less: A Minimalist Guide to Declutter, Organize, and SimplifyDe la EverandThe Joy of Less: A Minimalist Guide to Declutter, Organize, and SimplifyEvaluare: 4 din 5 stele4/5 (277)

- Lightly: How to Live a Simple, Serene & Stress-free LifeDe la EverandLightly: How to Live a Simple, Serene & Stress-free LifeEvaluare: 4 din 5 stele4/5 (12)

- How to Keep House While Drowning: A Gentle Approach to Cleaning and OrganizingDe la EverandHow to Keep House While Drowning: A Gentle Approach to Cleaning and OrganizingEvaluare: 4.5 din 5 stele4.5/5 (845)

- How To Win Friends And Influence PeopleDe la EverandHow To Win Friends And Influence PeopleEvaluare: 4.5 din 5 stele4.5/5 (6513)

- The Hidden Life of Trees: What They Feel, How They CommunicateDe la EverandThe Hidden Life of Trees: What They Feel, How They CommunicateEvaluare: 4 din 5 stele4/5 (1002)

- Root to Leaf: A Southern Chef Cooks Through the SeasonsDe la EverandRoot to Leaf: A Southern Chef Cooks Through the SeasonsEvaluare: 4.5 din 5 stele4.5/5 (3)

- The Botanical Hand Lettering Workbook: Draw Whimsical & Decorative Styles & ScriptsDe la EverandThe Botanical Hand Lettering Workbook: Draw Whimsical & Decorative Styles & ScriptsEvaluare: 4.5 din 5 stele4.5/5 (2)

- Mini Farming: Self-Sufficiency on 1/4 AcreDe la EverandMini Farming: Self-Sufficiency on 1/4 AcreEvaluare: 4 din 5 stele4/5 (76)

- A Girl and Her Greens: Hearty Meals from the GardenDe la EverandA Girl and Her Greens: Hearty Meals from the GardenEvaluare: 3.5 din 5 stele3.5/5 (7)

- Aristotle and Dante Discover the Secrets of the UniverseDe la EverandAristotle and Dante Discover the Secrets of the UniverseEvaluare: 4.5 din 5 stele4.5/5 (2341)

- The Martha Manual: How to Do (Almost) EverythingDe la EverandThe Martha Manual: How to Do (Almost) EverythingEvaluare: 4 din 5 stele4/5 (11)

- The Gentle Art of Swedish Death Cleaning: How to Free Yourself and Your Family from a Lifetime of ClutterDe la EverandThe Gentle Art of Swedish Death Cleaning: How to Free Yourself and Your Family from a Lifetime of ClutterEvaluare: 4 din 5 stele4/5 (467)

- Crochet Zodiac Dolls: Stitch the horoscope with astrological amigurumiDe la EverandCrochet Zodiac Dolls: Stitch the horoscope with astrological amigurumiEvaluare: 4 din 5 stele4/5 (3)

- Crochet Impkins: Over a million possible combinations! Yes, really!De la EverandCrochet Impkins: Over a million possible combinations! Yes, really!Evaluare: 4.5 din 5 stele4.5/5 (10)

- Martha Stewart's Organizing: The Manual for Bringing Order to Your Life, Home & RoutinesDe la EverandMartha Stewart's Organizing: The Manual for Bringing Order to Your Life, Home & RoutinesEvaluare: 4 din 5 stele4/5 (11)

- Gardening Hacks: 300+ Time and Money Saving HacksDe la EverandGardening Hacks: 300+ Time and Money Saving HacksEvaluare: 5 din 5 stele5/5 (1)

- Crochet with London Kaye: Projects and Ideas to Yarn Bomb Your LifeDe la EverandCrochet with London Kaye: Projects and Ideas to Yarn Bomb Your LifeEvaluare: 5 din 5 stele5/5 (1)