Documente Academic

Documente Profesional

Documente Cultură

Composition and Properties of Bitumen

Încărcat de

Alex LeeTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Composition and Properties of Bitumen

Încărcat de

Alex LeeDrepturi de autor:

Formate disponibile

Composition and Properties of Bitumen

Composition of Bitumen Materials in bituminous family are: 1) Tar: Coal tar is a brown or dark black liquid of high viscosity, which smells of naphthalene and aromatic hdydrocarbons. Being flammable, coal tar is sometime used for heating or to fire boilers. It can be used in coal tar soap, and is used in medicated shampoo to kill and repel head lice, and as a treatment for dandruff. Depending upon its source of origin, TAR is classified as: 2) Coal Tar: It is the liquid by-product of the distillation of coal to make coke. The gaseous byproduct of this process is commonly known as town gas. It is used for coating of wooden poles and sleepers, iron poles. 3) Wood Tar: It is obtained by the distillation of resinous wood. Wood tar contains creosote and as such has strong preservative properties. Search for "resin" in the above search box. 4) Mineral Tar: It is obtained by the distillation of bituminous shale. 5) Coal Tar Pitch: It is the residue of the direct distillation of crude tar produced by the high temperature carbonization of coal. It is used as a water proofing compound in masonry, steel and timber structure. It is also used for water proofing concrete structures. Chemical Composition of Bitumen: Molecular weight wise, bitumen is a mixture of about 300 - 2000 chemical components, with an average of around 500 - 700. Elementally, it is around 95% carbon and hydrogen ( 87% carbon and 8% hydrogen), and up to 5% sulfur, 1% nitrogen, 1% oxygen and 2000ppm metals. Bitumens are composed mainly of highly condensed polycyclic aromatic hydrocarbons. They also contain several elements, a number of which are toxic. Chemical Components in bitumen are: 1. Asphaltenes

2. Resinous components (polar aromatics) 3. Non-polar aromatics (naphtene aromatics) and 4. Saturates Properties of Bitumen 1. Adhesion: Bitumen has the ability to adhere to a solid surface in a fluid state depending on the nature of the surface. The presence of water on the surface will prevent adhesion. 2. Resistance to Water: Bitumen is water resistant. Under some conditions water may be absorbed by minute quantities of inorganic salts in the bitumen or filler in it. 3. Hardness: To measure the hardness of bitumen, the penetration test is conducted, which measures the depth of penetration in tenths of mm. of a weighted needle in bitumen after a given time, at a known temperature. Commonly a weight of 100 gm is applied for 5 sec at a temperature of 77 F. The penetration is a measure of hardness. Typical results are 10 for hard coating asphalt, 15 to 40 for roofing asphalt and up to 100 or more for water proofing bitumen. 4. Viscosity and Flow: The viscous or flow properties of bitumen are of importance both at high temperature during processing and application and at low temperature to which bitumen is subjected during service. The flow properties of bitumens vary considerably with temperature and stress conditions. Deterioration, or loss of the desirable properties of bitumen, takes the form of hardening. Resultantly, decrease in adhesive and flow properties and an increase in the softening point temperature and coefficient of thermal expansion.

S-ar putea să vă placă și

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5795)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1091)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Frangible Roof To Shell JointDocument1 paginăFrangible Roof To Shell JointSAGARÎncă nu există evaluări

- Breaker KOM PDFDocument50 paginiBreaker KOM PDFnamduong368100% (5)

- TSE S.R.O. Karpatské Námestie 10A 831 06 Bratislava SlovakiaDocument2 paginiTSE S.R.O. Karpatské Námestie 10A 831 06 Bratislava SlovakiaIronko Pepe100% (1)

- Bulgaria - Bulgarians Know Which Atrocities and Oppression Islamo (-Arabs) Are Capable Of, When Invading A CountryDocument20 paginiBulgaria - Bulgarians Know Which Atrocities and Oppression Islamo (-Arabs) Are Capable Of, When Invading A CountryAlex LeeÎncă nu există evaluări

- RISER DIAGRAM ModelDocument1 paginăRISER DIAGRAM ModelMhel Cenidoza50% (2)

- 10.03.2015 HWD Feed Processing: ST ND RDDocument2 pagini10.03.2015 HWD Feed Processing: ST ND RDAlex LeeÎncă nu există evaluări

- The Assam MovementDocument12 paginiThe Assam MovementAlex LeeÎncă nu există evaluări

- Against The Sinister Move To Disinvest OngcDocument5 paginiAgainst The Sinister Move To Disinvest OngcAlex LeeÎncă nu există evaluări

- Tme 027Document1 paginăTme 027Alex LeeÎncă nu există evaluări

- An ADocument43 paginiAn AAlex LeeÎncă nu există evaluări

- Bsetrade InformationDocument1 paginăBsetrade InformationAlex LeeÎncă nu există evaluări

- To, Date: 09/03/2015 The Principal, Carmel School, Digboi: Yours' TrulyDocument1 paginăTo, Date: 09/03/2015 The Principal, Carmel School, Digboi: Yours' TrulyAlex LeeÎncă nu există evaluări

- Classification of Particles: Hadrons, Baryons, and MesonsDocument4 paginiClassification of Particles: Hadrons, Baryons, and MesonsAlex LeeÎncă nu există evaluări

- Incident: Information On The IncidentDocument3 paginiIncident: Information On The IncidentAlex LeeÎncă nu există evaluări

- Hdtu Shutdown - FG DisruptionDocument1 paginăHdtu Shutdown - FG DisruptionAlex LeeÎncă nu există evaluări

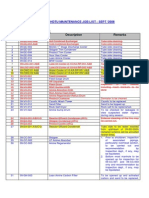

- HDT Job List For Sept '08Document3 paginiHDT Job List For Sept '08Alex LeeÎncă nu există evaluări

- #Squadno035 Anonghost-Team Third Eye Reporter Jennifer Hilapon Bahola Judylee Simbaya Connie Cabes 12 OthersDocument2 pagini#Squadno035 Anonghost-Team Third Eye Reporter Jennifer Hilapon Bahola Judylee Simbaya Connie Cabes 12 OthersAlex LeeÎncă nu există evaluări

- Hgu Feed GasDocument1 paginăHgu Feed GasAlex LeeÎncă nu există evaluări

- HDT Job List For AUG '08Document3 paginiHDT Job List For AUG '08Alex LeeÎncă nu există evaluări

- Hgu Job List For Sept '08Document3 paginiHgu Job List For Sept '08Alex LeeÎncă nu există evaluări

- Job ListDocument7 paginiJob ListAlex LeeÎncă nu există evaluări

- Acitivity Chart of Hgu Shutdown Due To Loss of NG: Disruption of Natural GasDocument4 paginiAcitivity Chart of Hgu Shutdown Due To Loss of NG: Disruption of Natural GasAlex LeeÎncă nu există evaluări

- HDTU Start UpDocument1 paginăHDTU Start UpAlex LeeÎncă nu există evaluări

- Hgu - Hdtu Shutdown HrsDocument1 paginăHgu - Hdtu Shutdown HrsAlex LeeÎncă nu există evaluări

- HSD To T - 62 - 63Document1 paginăHSD To T - 62 - 63Alex LeeÎncă nu există evaluări

- RE HDT HK RunDocument1 paginăRE HDT HK RunAlex LeeÎncă nu există evaluări

- SKO in T581Document1 paginăSKO in T581Alex LeeÎncă nu există evaluări

- Engine Crankshaft Deflection MeasurementDocument9 paginiEngine Crankshaft Deflection MeasurementVannex MensidorÎncă nu există evaluări

- Experiment:-1 (Role of Software) : ObjectiveDocument6 paginiExperiment:-1 (Role of Software) : ObjectiveRahul goume100% (1)

- EXER2Document12 paginiEXER2Angelus Vincent GuilalasÎncă nu există evaluări

- Van Der WallsDocument24 paginiVan Der WallsAnonymous oVRvsdWzfBÎncă nu există evaluări

- Study Properties of Concrete With Metakaolin As Partial Replacement of CementDocument5 paginiStudy Properties of Concrete With Metakaolin As Partial Replacement of CementLokesh MechÎncă nu există evaluări

- PythonDocument66 paginiPythoncredtechÎncă nu există evaluări

- Online Shopping Portal Project ReportDocument33 paginiOnline Shopping Portal Project ReportSagar Chauhan50% (2)

- Midterm JavaDocument4 paginiMidterm Javaمحمد سمورÎncă nu există evaluări

- Dynamic Prog Rod CuttingDocument10 paginiDynamic Prog Rod CuttingSreshtha KashyapÎncă nu există evaluări

- Low Power CMOS VLSI Design: Aditya Japa Assistant Professor (ECE) KL Hyderabad 12/07/2021Document14 paginiLow Power CMOS VLSI Design: Aditya Japa Assistant Professor (ECE) KL Hyderabad 12/07/2021karthikÎncă nu există evaluări

- IBM IVA White PaperDocument4 paginiIBM IVA White PaperTarek FahimÎncă nu există evaluări

- Unit-4 Refrigeration and Air ConditioningDocument11 paginiUnit-4 Refrigeration and Air ConditioningMatthew SmithÎncă nu există evaluări

- Guide For System Center Hyper-V Management Pack For Windows Server 2012 R2Document9 paginiGuide For System Center Hyper-V Management Pack For Windows Server 2012 R2George RaduÎncă nu există evaluări

- MDC CGK: Aji / Adnan Bayu MRDocument1 paginăMDC CGK: Aji / Adnan Bayu MRDivya NenaÎncă nu există evaluări

- LRB PS Inr18650b4 Rev7Document10 paginiLRB PS Inr18650b4 Rev7jeznerÎncă nu există evaluări

- The Great Eggscape: Corey Kelvin Group 73 Nizam Umayr PatriciaDocument7 paginiThe Great Eggscape: Corey Kelvin Group 73 Nizam Umayr PatriciaLegendaryNÎncă nu există evaluări

- Sustainable Development TriangleDocument5 paginiSustainable Development TriangleWhilteÎncă nu există evaluări

- Factors Affecting Career Track and Strand Choices of Grade 9 Students in The Division of Antipolo and Rizal, PhilippinesDocument3 paginiFactors Affecting Career Track and Strand Choices of Grade 9 Students in The Division of Antipolo and Rizal, PhilippinesJASH MATHEW100% (7)

- CableTies Technical Data PDFDocument1 paginăCableTies Technical Data PDFmohammed moussÎncă nu există evaluări

- SK100XHW-E24 AbmessungenDocument1 paginăSK100XHW-E24 AbmessungenKavabaÎncă nu există evaluări

- Modern Digital and Analog Communications Systems - B P Lathi Solutions Manual - F4VNDocument156 paginiModern Digital and Analog Communications Systems - B P Lathi Solutions Manual - F4VNAbdullah Khan LodhiÎncă nu există evaluări

- Eaton Low Voltage MCC Design Guide Dg043001en 1Document50 paginiEaton Low Voltage MCC Design Guide Dg043001en 1diegoÎncă nu există evaluări

- Admin JobsDocument4 paginiAdmin JobsLakshmann ChettiarÎncă nu există evaluări

- Cat Merkel PHDocument321 paginiCat Merkel PHEng. EmersonÎncă nu există evaluări

- TRZ 03 TRZ 03: Turbine Meter Turbine MeterDocument6 paginiTRZ 03 TRZ 03: Turbine Meter Turbine MeterLuigi PortugalÎncă nu există evaluări

- Lean Case Study Part IDocument6 paginiLean Case Study Part IAnonymous QI9xEjrbplÎncă nu există evaluări