Documente Academic

Documente Profesional

Documente Cultură

Quality Plan TPS 53-2013

Încărcat de

Akram FerchichiDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Quality Plan TPS 53-2013

Încărcat de

Akram FerchichiDrepturi de autor:

Formate disponibile

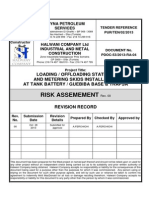

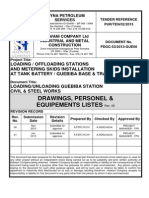

Client

THYNA PETROLEUM SERVICES

7 Avenue Abdelrahmen El Ghafiki BP 069 / 3069 Sfax-Hached Sfax (Tunisia) Phone: 216 74 229 999 - Fax: 216 74 299 916

TENDER REFERENCE PUR/TEN/02/2013

Constructor

HALWANI COMPANY Ltd INDUSTRIAL AND METAL CONSTRUCTION

Zone Industrielle Madagascar Prs Somatra CP 3000 Sfax (Tunisia) Phone: 216 74 497 166/010 - Fax: 216 74 497 795

DOCUMENT No. PDOC-53/2013-QC-03

Project Title:

LOADING / OFFLOADING STATIONS AND METERING SKIDS INSTALLATION AT TANK BATTERY / GUEBIBA BASE & TRAPSA

QUALITY PLAN Rev. 00

REVISION RECORD

Rev. No.

00

Submission Date

Oct 24 2013

Revision Details

Submitted for approval

Prepared By Checked By

A.FERCHICHI A.FERCHICHI

Approved by

This document has been prepared for the titled project or named part thereof and should not be relied upon or used for any other project without an independent check being carried out as to its suitability and prior written authority of Halwani Company being obtained. Halwani Company accepts no responsibility or liability for the consequences of this document being used for a purpose other than the purposes for which it was commissioned. Any person using or relying on the document for such other purpose agrees, and will by such use or reliance be taken to confirm his agreement to indemnify Mott MacDonald for all loss or damage resulting therefrom. Halwani Company accepts no responsibility or liability for this document to any party other than the person by whom it was commissioned.

HALWANI COMPANY Ltd AUTHOR: AKRAM FERCHICHI DOC.: QUALITY PLAN PROJECT: LOADING / OFFLOADING STATIONS

Job No : 53-2013 PDOC-53/2013-QP-03 Rev. : 00 Sheet : 2 of 12

TABLE OF CONTENTS

1. INTRODUCTION ................................................................................................................................. 4 2. PROJECT SCOPE .............................................................................................................................. 4 3. PROJECT QUALITY STATEMENT ................................................................................................... 4 4. REVISION STATUS/AMENDMENTS AND DISTRIBUTION ............................................................. 4 5. DEFINITION & THERMINOLOGY...................................................................................................... 5 6. QUALITY POLICY, QUALITY SYSTEM AND QUALITY STRATEGY ............................................. 7

6.1 Quality Policy Concept ............................................................................................................................. 7 6.1.1 Quality Policy: ........................................................................................................................................ 7 6.1.2 Quality System: ..................................................................................................................................... 7 6.1.3 Structure of Quality management System documentation: ................................................................... 8 6.1.4 Quality Management System Manual: .................................................................................................. 8 6.1.5 Quality Process and Procedure manual: ............................................................................................... 8 6.1.6 Project Quality Plan: .............................................................................................................................. 8 6.1.7 Other Quality Documents: ..................................................................................................................... 8 6.1.8 Quality Strategy: .................................................................................................................................... 8 6.2 Planning .................................................................................................................................................... 9 6.2 Verification ................................................................................................................................................ 9

7. QUALITY MANAGEMENT IN CONSTRUCTION AND REPORTING............................................... 9

7.1 Management Responsibilities: ................................................................................................................. 9 7.2 Responsibilities of Staff at Project Execution Team: .............................................................................. 10 7.2.1 Project Manager: ................................................................................................................................. 10 7.2.2 Team Leader Execution: .................................................................................................................. 10 7.2.3 QA & QC Manager: ............................................................................................................................. 10 7.2.4 Safety Responsible: ............................................................................................................................. 10 7.4.8 Surveyor: ............................................................................................................................................. 11 7.5 Functions of QA / QC System: ............................................................................................................... 11 7.6 Quality Management Reports: ................................................................................................................ 12 7.7 Management Reviews: ........................................................................................................................... 12 7.8 Monthly Progress Reports: ..................................................................................................................... 12

8. PROGRESS CONTROL ................................................................................................................... 12

Rev. : 00 Sheet : 2 of 12

HALWANI COMPANY Ltd AUTHOR: AKRAM FERCHICHI DOC.: QUALITY PLAN PROJECT: LOADING / OFFLOADING STATIONS

Job No : 53-2013 PDOC-53/2013-QP-03 Rev. : 00 Sheet : 3 of 12

Rev. : 00

Sheet : 3 of 12

HALWANI COMPANY Ltd AUTHOR: AKRAM FERCHICHI DOC.: QUALITY PLAN PROJECT: LOADING / OFFLOADING STATIONS

Job No : 53-2013 PDOC-53/2013-QP-03 Rev. : 00 Sheet : 4 of 12

1. INTRODUCTION

The Globalization and developing Technology in the Construction Industry is leading to High competition in the Current market. The best response to a competitive challenge in the Construction Industry is to become more competitive. The best means of achieving this is by improving the product quality and meeting the project schedule through a well-designed Quality Management system. The Quality Management system shall focus on providing improved control on processes and practices, thus enhancing customer satisfaction through its effective implementation

2. PROJECT SCOPE

Tender Reference QP Project Number Project Works Time Project location(s) : PUR/TEN/02/2013 : PDOC-53/2013-QP-03 : 120 days : Tank Battery / Guebiba base & Trapsa

Supply and Erection of Trucks loading and offloading steel stations at Tank Battery / Guebiba base & Trapsa, including procurement and pre-construction as well as this scope will covers all Civil & Steel activities.

Scope:

Terminal Shelter at Trapsa Skid Shelter at Trapsa Loading Shelter at Tank Battery Offloading Shelter at Tank Battery Loading/Offloading Shelter at Guebiba base

3. PROJECT QUALITY STATEMENT

To strive for Quality Excellence, in order to achieve Customer Satisfaction by Providing goods and services to the standards set by the Customer and to contribute to increasing the Companys competitiveness.

4. REVISION STATUS/AMENDMENTS AND DISTRIBUTION

The issue number, revision number and revision date are stated on each page of the Project Quality Manual. Should amendment of the Project Quality Manual be necessary during the life of the project, only the revised sub-section shall be reissued and its revision number and date changed accordingly? Amendments shall be approved by the Head Project Operations at Head Office. The Revision Status Sheet detailing the amendment, date and approval shall be issued with each amendment by the Project Manager. Each new revision shall be distributed as per the original with a request that the revised sub-sections be destroyed. After ten (10) revisions a new issue shall be introduced superseding all previous revisions.

Rev. : 00

Sheet : 4 of 12

HALWANI COMPANY Ltd AUTHOR: AKRAM FERCHICHI DOC.: QUALITY PLAN PROJECT: LOADING / OFFLOADING STATIONS

Job No : 53-2013 PDOC-53/2013-QP-03 Rev. : 00 Sheet : 5 of 12

5. DEFINITION & THERMINOLOGY

Calibration

All the operations for the purpose of determining the values of the errors of measuring instruments, material measures, and measurement standards.

Controlled Document

An original numbered copy of a document for which amendments will be automatically advised.

Corrective Action

An activity the intention of which is to return a non-conforming item or action to a stat or conformity. It also covers action taken to prevent further recurrences of Non-conformity.

Disposition

An action to be taken concerning material, components or products about which a Decision has been made.

Document

Any written or printed manual, procedure or form that is part of the quality system. The term includes documents and data that can be read by people or machines.

Inspection

The careful examination, measurement and testing of the characteristics of Products and services to ensure they meet regulatory and contractual requirements.

Inspection and test point

A location or stage in the manufacturing, production or construction cycle where inspection and testing are performed by personnel whose responsibility is to determine the acceptability of products or services and to record inspection and test data.

Non-conformance / Nonconformity

A deficiency in characteristic, documentation, or procedure which renders the quality of a product or service unacceptable or indeterminate or not according to specified requirements.

Procedure

A document that specifies, as applicable, the purpose and scope of an activity; what shall be done and by whom; when, where and how it shall be done; what materials, equipment, and documentations shall be used; and how it is all controlled.

Product

Material, part, item, component, assembly, sub-assembly structure, plant equipment, or finished project identified in or described in any standard or specification and production or obtained as a result of some manufacturing or construction operation or process.

Product Quality Audit

Inspection of the product at a lesser frequency than the inspection carried out for normal quality control

Rev. : 00 Sheet : 5 of 12

HALWANI COMPANY Ltd AUTHOR: AKRAM FERCHICHI DOC.: QUALITY PLAN PROJECT: LOADING / OFFLOADING STATIONS

Job No : 53-2013 PDOC-53/2013-QP-03 Rev. : 00 Sheet : 6 of 12

purposes as an aid to assessing the effectiveness of quality control.

Quality Assurance

All those planned and systematic actions necessary to provide confidence that products or services will satisfy given requirements.

Quality Audit

A systematic and independent examination to determine whether quality activities and related results comply with planned arrangements and whether these arrangements are implemented effectively and are suitable to achieve objective.

Quality System Audit

The independent examination of an organizations quality assurance system carried out by an auditing team from within or outside the organization.

Quality Control

Those actions which provide a means to measure and regulate the characteristics of a product or service to establish requirements. Operational techniques or activities (e.g. inspection or test) used to verify technical and quality requirements for services and or products.

Quality Policy

The overall quality intentions and directions of an organization as regards quality, as formally expressed by top management

Quality Plan

A document setting out the specific quality practices, resources, activities and responsibilities relevant to a particular contract or project.

Remedial Action

An action to be taken concerning material, components or products about which a decision has been made.

Repair The process of restoring a non-conforming characteristic to a condition such that the item conforms to the original specified requirements, where such a repair or restoration is acceptable. Verification Confirming that an activity or condition conforms to specified requirement

Rev. : 00

Sheet : 6 of 12

HALWANI COMPANY Ltd AUTHOR: AKRAM FERCHICHI DOC.: QUALITY PLAN PROJECT: LOADING / OFFLOADING STATIONS

Job No : 53-2013 PDOC-53/2013-QP-03 Rev. : 00 Sheet : 7 of 12

6. QUALITY POLICY, QUALITY SYSTEM AND QUALITY STRATEGY

6.1 Quality Policy Concept

The Quality Policy is communicated and made understood at all level of the organization through awareness program an display of the Quality Policy boards at all the Project sites/departments. The Quality Policy shall be reviewed annually for continual improvement and suitability to the purpose of the division. Taking Quality Policy as guide, the quality objectives are established in related functions and monitored in the monthly steering committee meetings and periodic Management Review meetings. Management review includes review of Quality objectives and specific policy statements with the view to achieve Quality objectives and meeting the requirements of the policy statement.

6.1.1 Quality Policy:

We aspire to fulfill the expectations of our customer by a dedicated and organized approach, which is amenable to skill and knowledge enhancement. We shall improve the competence of our Quality management System continually. Our focus to accomplish this aim shall be on: Effective design Effective Implementation of planning and Methodology Effective Supplier Management Proficient Management of Workforce. Training and development of Human Resource.

6.1.2 Quality System:

The Quality System has been designed to ensure that the Quality Policy, objectives and the requirements of ISO 9001:2008 are implemented. The system has been determined in terms of the following main processes. Estimation, Costing and Tendering Design and Engineering Quality planning and Control Planning, Monitoring and Control Plant and Machinery provision Project Operation Commercial, Contract and Procurement Personnel and training Finance Quality System

Rev. : 00

Sheet : 7 of 12

HALWANI COMPANY Ltd AUTHOR: AKRAM FERCHICHI DOC.: QUALITY PLAN PROJECT: LOADING / OFFLOADING STATIONS

Job No : 53-2013 PDOC-53/2013-QP-03 Rev. : 00 Sheet : 8 of 12

6.1.3 Structure of Quality management System documentation:

6.1.4 Quality Management System Manual:

This quality Management system manual describes the purpose and scope of the Quality management system. Interaction of functional process and establishment of documented to fulfil requirements of ISO 9001:2008 standard. The applicable causes of ISO 9001:2008 standard have been included in the chapters describing the systems as applicable.

6.1.5 Quality Process and Procedure manual:

The Procedures are established to meet the requirements of ISO 9001:2008 and are included in the quality process and procedure Manual. These procedures covers control of documents, control of records, internal quality audit, control of non-conforming products and corrective / preventative actions.

6.1.6 Project Quality Plan:

A definite quality plan for every project, detailing there in the activities, Acceptance criteria, Verifying documents, controlling agency (Organization/Customer) and the type of control and responsibility for implementing the activity and its control, including resource requirements are developed before start of the Project.

6.1.7 Other Quality Documents:

Quality records and formats from this level of documents. Other standards, check list and guidelines are also used for the supports of overall quality system structure.

6.1.8 Quality Strategy:

Implementation of the quality Management system and its effectiveness is ascertained by periodical monitoring as well as by structured internal quality audit and corrective and preventive action to ensure improvement in effectiveness of the Quality system in operation.

Rev. : 00 Sheet : 8 of 12

HALWANI COMPANY Ltd AUTHOR: AKRAM FERCHICHI DOC.: QUALITY PLAN PROJECT: LOADING / OFFLOADING STATIONS

Job No : 53-2013 PDOC-53/2013-QP-03 Rev. : 00 Sheet : 9 of 12

A continuous process of feasible Technology up gradation and value analysis is initially targeted at persisting unsolved non-conformities to be attended to as well as potential problems. Management review of the quality system is conducted periodically, to check for continued suitability for effectiveness, towards meeting the requirement of the organizations Quality Policy and objectives. The integrity of Quality Management System is ensured when changes are planned and implemented.

6.2 Planning

This Project Quality Manual is the document which details the Quality System to be planned, established, implemented and maintained as part of the contract for the road works for the project. The Quality Plan consists of the following: (i) The Project Quality Statement of the company (ii) Project Specific Details including Organization and System Element Description. (iii) Inspection and Test Plans (including Construction Process Flowcharts and Quality Verification Checklists). (iv) Project specific Procedures as required by the contract specification / concession agreement The Project Quality Manual describes the managerial and technical systems which shall be implemented to achieve conformance to specified requirements. The systems shall cover on site work under the contract. Where necessary the systems shall be extended to include offsite activities. The inspection and test plan shall identify necessary inspections and tests to verify conformance of the work during performance of the identified project tasks. It shall include acceptance criteria and details for performance of inspection and test activities, as applicable.

6.3 Verification

Verification processes shall be established to ensure that the planning and controls have been effective and the Quality System and constructed works conform to the specified requirements. The outcome of all verification activities shall be documented and maintained as quality records. Records of conformance shall be available for inspection by the Client / Clients Representative upon request to provide evidence of the outcome of activities undertaken to achieve conformance.

7. QUALITY MANAGEMENT IN CONSTRUCTION AND REPORTING

7.1 Management Responsibilities:

The Head Project Operations has the overall responsibility for construction of the project, ensuring Customer satisfaction. The Project Manager of Project will be in charge of this Project and will be reporting to the Head Project Operations. Project Quality Plan will be implemented by the Project Manager. The Project QA/QC team will interact with QA /QC team of Client / Clients Representative for review of material tests, mix designs and QA/QC procedures as per the Project Quality Plan and reports functionally to Head QA/QC H.O. The Head QA/QC H.O will report to the top management and act independently to implements QA policy of the Organization. He has the responsibility for formulating, implementing, reviewing, monitoring, verifying and assessing the effectiveness of Quality Assurance program. He has also been delegated the authority to take corrective measures in case of any significant quality related problems are noticed, with the intimation to the Project Manager.

Rev. : 00 Sheet : 9 of 12

HALWANI COMPANY Ltd AUTHOR: AKRAM FERCHICHI DOC.: QUALITY PLAN PROJECT: LOADING / OFFLOADING STATIONS

Job No : 53-2013 PDOC-53/2013-QP-03 Rev. : 00 Sheet : 10 of 12

7.2 Responsibilities of Staff at Project Execution Team: 7.2.1 Project Manager:

The Project Manager for the project has the following responsibilities Overall Management of this Project. He shall have the authority and responsibility for time, cost, and safety and quality aspects of the Project. Determining the policy with respect to the management of quality on the project. Issuing the Project Quality Plan including System Element Descriptions and Inspection and Test Plans. Approving the disposition of Non-conformance Reports issued by the authorized representative nominated by him. Communication and interface between CLIENT, Contractor, Subcontractors (if existed) and the Project team.

7.2.2 Team Leader Execution:

The Construction Manager for the project has the following responsibilities Responsibilities for the planning, implementation, control and maintenance of the Project Quality Plan. Issue all relevant documentation and amendments to the Project team. Guide and instruct others in the essential aspects of quality management. Verification of inspection and test activities. Liaise with the contractor in regard of Final Inspection and Acceptance of the work. Apply acceptance criteria and classify work as conforming or Non-conforming. Issue Non-conformance Reports where necessary. Recommend remedial action and re inspect to close out. Recommend corrective action in case of recurring non-conformance. Communication and interface between CLIENT, Contractor, Subcontractors (if existed) and the Project team

7.2.3 QA & QC Manager:

The QA & QC Manager for the project has the following responsibilities. Responsibilities for the planning, implementation, control and maintenance of the Project Quality Plan. Guide and instruct others in the essential aspects of quality management. Liaise that the quality of manufacture and construction satisfies the standards. Ensure that suitable measuring and testing equipment is available and calibration of same is monitored regularly. Verification of inspection and test activities. Recommend remedial action and re inspect to close out. Recommend corrective action in case of recurring non-conformance. Responsible for preparing Monthly Quality Management Report Interaction with CLIENTs representative, approval of all materials as per CA in day to day basis.

7.2.4 Safety Responsible:

The Safety Responsible of the project has the following responsibilities. Assist Project Manager in all aspect of Safety and Environment Management compliance as per Contract Agreement. Responsible for overall implementation of Safety and Environmental Compliance plan. Monitor, Inspect and Guide the project team in aspect of Safety, Environmental Compliance w.r.t

Rev. : 00 Sheet : 10 of 12

HALWANI COMPANY Ltd AUTHOR: AKRAM FERCHICHI DOC.: QUALITY PLAN PROJECT: LOADING / OFFLOADING STATIONS

Job No : 53-2013 PDOC-53/2013-QP-03 Rev. : 00 Sheet : 11 of 12

Contract agreement. Carry out regular inspection in line with the requirement of contract agreement and recommend corrective action in case of recurring non-conformance. Responsible for participating in preparation of Monthly Progress Report. Interaction with CLIENT regarding all aspect of Safety and Environmental Compliance plan.

7.4.8 Surveyor:

Report day to day basis to Construction Responsible in all aspects of Survey work. Responsible for organizing for detailed survey for the Pavement, checking alignment, Horizontal and vertical profile. Any difference shall be reported to Construction. Checking Lines and levels for the execution of works in accordance with drawing and Contract Agreement.

7.5 Functions of QA / QC System:

i) For each major activity of work, method statement will be prepared indicating the quality checks for incorporated materials and stage of construction. Detailed description shall be followed in later part of this section 10. ii) Ensure that equipment and testing instruments are calibrated properly and adjusted to maintain their accuracy within acceptable limits. iii) Provide day to day routine checks on materials and finished products. iv) Identify problems and initiate action, which results in solution. v) Verify implementation of solutions / corrections. vi) Report regularly on effectiveness of the system. vii) Tests to be performed jointly with Contractor and CLIENT at site before start of any activity and after review / approval of the same activity have to start. viii) All the test reports have to be certified by the Contractor and CLIENTs Representative. CLIENT has to nominate his representatives for joint testing during site working hours. In case of non-availability of CLIENTs Representative, tests will be carried out by Contractors QC Engineer under information in the interest of work. ix) All records of qualifying and routine tests / checks will be jointly maintained at the QA/QC Responsible office. x) Monthly Project QA report will be prepared by project QA/QC Responsible, summarizing the activities of QA department which is to be submitted to Management. xi) Head of QA from H.Q shall deploy his representative to carry out internal quality audit to ensure compliance of quality measures covered hereunder and to make necessary improvement, if required in quality system.

Rev. : 00 Sheet : 11 of 12

HALWANI COMPANY Ltd AUTHOR: AKRAM FERCHICHI DOC.: QUALITY PLAN PROJECT: LOADING / OFFLOADING STATIONS

Job No : 53-2013 PDOC-53/2013-QP-03 Rev. : 00 Sheet : 12 of 12

xii) Project Manager / QA & QC In-charge through his representative at site will point out the non-conformity of standards if any, to the contractors authorized representative in writing and a copy of the same to be sent to the General Manager for getting the work done as per quality standard required as specified in Contract Agreement, quality specifications or drawings. CLIENT, Material supplier and Manufacturer, each form a link of the quality chain. The strength of this chain is dependent on each and every link. The QA/QC Responsible is to keep a continuous watch on this chain and spot the weak link before it snapped.

7.6 Quality Management Reports:

The QA/QC in-charge at site shall prepare a Monthly Quality Management Report for review by the Project Manager / Construction Responsible. The Quality Report shall be subdivided into the following headings: Summary of Inspection and Test Activities. (Field & Laboratory) Registers of Non-conformance & Corrective Action. Status of Approvals of all Materials. Outstanding approvals by the CLIENTs Representative Items of specific concern.

7.7 Management Reviews:

The operation and effectiveness of the Project Quality Plan shall be regularly reviewed by Management Review meetings held once in One month for the duration of the project. The monthly Quality Management Report together with Audit Reports shall form the basis of the review.

7.8 Monthly Progress Reports:

The Monthly progress report (including daily reports) shall be prepared and submitted to the CLIENT as per requirement of Contractor agreement. The detailed format for the report, contained all the activities of the month, major achievements, miles stone achieved, progress, quality control reports, problems, issues etc.

8. PROGRESS CONTROL

This section of the Manual outlines requirements and procedures for construction scheduling and control of work progress.

8.1 Construction Work Program The Contractor is required to submit a detailed work program for execution of the works as per the QMS Process S00/PO/P/03 Project Planning & Budgeting process site. 8.2 Progress control

Rev. : 00

Sheet : 12 of 12

S-ar putea să vă placă și

- Asphalt Mix Design ProcedureDocument84 paginiAsphalt Mix Design ProcedureMujeeb Akhtar100% (6)

- Architectural Manifesto: Designing Software Architectures, Part 5Document6 paginiArchitectural Manifesto: Designing Software Architectures, Part 5Felix R50% (6)

- MAI 07 - Control of Insp Measuring and Testing Equipment - DJ - v1Document9 paginiMAI 07 - Control of Insp Measuring and Testing Equipment - DJ - v1IT Support - FernanÎncă nu există evaluări

- QAQCDocument15 paginiQAQCflawlessy2k100% (1)

- P M P Chapter 8Document17 paginiP M P Chapter 8Khaled KhanÎncă nu există evaluări

- Qa QC Plan Facility Site Work ConstructionDocument103 paginiQa QC Plan Facility Site Work Constructionmou777Încă nu există evaluări

- 45 Samss 006Document8 pagini45 Samss 006naruto256Încă nu există evaluări

- Field Inspection &test PlanDocument4 paginiField Inspection &test PlanSofda ImelaÎncă nu există evaluări

- Iso 9001:2000 Gap Checklist: 4.0 Quality Management System 4.1 General RequirementsDocument11 paginiIso 9001:2000 Gap Checklist: 4.0 Quality Management System 4.1 General Requirementscover filterÎncă nu există evaluări

- Lessons Learned PDFDocument1 paginăLessons Learned PDFYasir_Wafi_1101Încă nu există evaluări

- Air BlowerDocument5 paginiAir BlowerFishÎncă nu există evaluări

- Flange Asme ViiiDocument21 paginiFlange Asme Viiizahidwahla1Încă nu există evaluări

- Quality Process Map Shows Customer Requirements and Management SystemsDocument1 paginăQuality Process Map Shows Customer Requirements and Management SystemsDaniel PradityaÎncă nu există evaluări

- Water and Wastewater Calculation Spreadsheet InstructionsDocument10 paginiWater and Wastewater Calculation Spreadsheet InstructionsshahqazwsxÎncă nu există evaluări

- Quality policy objectives and QMS proceduresDocument1 paginăQuality policy objectives and QMS proceduresManInTheBush100% (1)

- Job & ResponsibilityDocument9 paginiJob & ResponsibilityKerri UnklebeachÎncă nu există evaluări

- Observation Training Report GCTDocument32 paginiObservation Training Report GCTAkram FerchichiÎncă nu există evaluări

- R As0007 Qa Proc 0744 - Fat Procedure Precoat - r0Document42 paginiR As0007 Qa Proc 0744 - Fat Procedure Precoat - r0phamthaituyen100% (1)

- Preparatory Inspection Checklist PaintingDocument5 paginiPreparatory Inspection Checklist PaintingHenry HermosuraÎncă nu există evaluări

- DNV Lifeboats and Rescue Boats 2007Document16 paginiDNV Lifeboats and Rescue Boats 2007Akram FerchichiÎncă nu există evaluări

- Quality Requirements For Subcontractor: Project ProcedureDocument15 paginiQuality Requirements For Subcontractor: Project ProcedureDindo QuintanÎncă nu există evaluări

- Quality Plan AuditDocument5 paginiQuality Plan AuditRajan100% (1)

- Quality Manual RS QMS 002Document11 paginiQuality Manual RS QMS 002WayneÎncă nu există evaluări

- Project Quality Plan (8.7.2012)Document27 paginiProject Quality Plan (8.7.2012)Vinodh Palanichamy75% (4)

- Saudi Aramco Inspection Checklist: Pre-Test Punch Listing of On-Plot Piping SAIC-A-2010 31-Aug-11 PipingDocument12 paginiSaudi Aramco Inspection Checklist: Pre-Test Punch Listing of On-Plot Piping SAIC-A-2010 31-Aug-11 PipingAnonymous 4e7GNjzGWÎncă nu există evaluări

- Teaching Students With Emojis, Emoticons, & Text SpeakDocument49 paginiTeaching Students With Emojis, Emoticons, & Text SpeakNastase Daniela EcaterinaÎncă nu există evaluări

- Internal QMS Audit Schedule: - Audit Area Department Auditor Auditee Audit Date RemaksDocument3 paginiInternal QMS Audit Schedule: - Audit Area Department Auditor Auditee Audit Date RemaksBihanChathurangaÎncă nu există evaluări

- Quality Assessment ProcedureDocument3 paginiQuality Assessment ProcedureAlina OnţaÎncă nu există evaluări

- 002-Quality PlanningDocument5 pagini002-Quality PlanningDanOtahÎncă nu există evaluări

- Quality Manual: M. Barbisotti & Sons LTDDocument20 paginiQuality Manual: M. Barbisotti & Sons LTDengsam777100% (1)

- Internal Quality AuditDocument8 paginiInternal Quality AuditElchin IsmayilovÎncă nu există evaluări

- Lesson 10 Project Quality PlanningDocument51 paginiLesson 10 Project Quality PlanningDevjit MandalÎncă nu există evaluări

- 04 - Human Resource PlanDocument10 pagini04 - Human Resource PlanMohammed AffrozeÎncă nu există evaluări

- HSE - 5.7 Procedure For Pre-Startup Safety Review ManagementDocument43 paginiHSE - 5.7 Procedure For Pre-Startup Safety Review Managementazimjoon67% (6)

- Standard Work For Leaders Daily Checklist SampleDocument2 paginiStandard Work For Leaders Daily Checklist SampleRanjeet DongreÎncă nu există evaluări

- Qualtiy Plan 1. Quality Objectives & Policies 1.1 Quality ObjectivesDocument7 paginiQualtiy Plan 1. Quality Objectives & Policies 1.1 Quality ObjectivesRHOWELLE TIBAYÎncă nu există evaluări

- Quality PlanDocument21 paginiQuality PlanQianlei ZhuÎncă nu există evaluări

- Quality InductionDocument15 paginiQuality InductionaleemmurtazaÎncă nu există evaluări

- ASTM A36-A36M-97ae1Document3 paginiASTM A36-A36M-97ae1NadhiraÎncă nu există evaluări

- DW143Document4 paginiDW143Greg Booysen0% (5)

- PCI Pulley Selection Guide 2014Document32 paginiPCI Pulley Selection Guide 2014Akram FerchichiÎncă nu există evaluări

- Quality Hold Points System Handbook: Produced by Jabatan Kerja Raya SarawakDocument47 paginiQuality Hold Points System Handbook: Produced by Jabatan Kerja Raya SarawakConnielya AdamÎncă nu există evaluări

- Design, Construction and Evaluation of An Experimental Ceramic Membrane Facility With Investigation Into Fouling ControlDocument157 paginiDesign, Construction and Evaluation of An Experimental Ceramic Membrane Facility With Investigation Into Fouling ControlAkram FerchichiÎncă nu există evaluări

- CIPS at a Shot: Sample Questions and AnswersDocument40 paginiCIPS at a Shot: Sample Questions and AnswersAtik Shaikh100% (1)

- SLPG Q 0000 24001 019 001 4 0Document15 paginiSLPG Q 0000 24001 019 001 4 0sivagnanamÎncă nu există evaluări

- ABS Part 4Document699 paginiABS Part 4Mariano Marcos100% (1)

- Quality Plan PresentationDocument16 paginiQuality Plan Presentationel1980Încă nu există evaluări

- TURCON Quality Assurance System Ensures Construction Project ComplianceDocument4 paginiTURCON Quality Assurance System Ensures Construction Project ComplianceAli IrvaliÎncă nu există evaluări

- 2017 11 22 Guidelines GMP For AtmpsDocument90 pagini2017 11 22 Guidelines GMP For Atmpserdo mandanaÎncă nu există evaluări

- 1-Quality Control PlanDocument3 pagini1-Quality Control PlanVeysel KoçÎncă nu există evaluări

- Quality Assurance (QA) StructureDocument10 paginiQuality Assurance (QA) Structureyuwantoni100% (1)

- Belt Conveyor PulleysDocument24 paginiBelt Conveyor PulleysPok Jak Salleh100% (2)

- Note de Calcul Mécanique Convoyeur OCPDocument11 paginiNote de Calcul Mécanique Convoyeur OCPAkram FerchichiÎncă nu există evaluări

- Project Rolling Stock Component FactoryDocument5 paginiProject Rolling Stock Component FactorySagar ParabÎncă nu există evaluări

- QMS & QA/QC OutlineDocument75 paginiQMS & QA/QC OutlineAbirham100% (1)

- ديدجلا رادصلا ISO DIS 9001:2015Document95 paginiديدجلا رادصلا ISO DIS 9001:2015Кари МедÎncă nu există evaluări

- Session-2 & 3 Quality - Evolution of QualityDocument20 paginiSession-2 & 3 Quality - Evolution of Qualitymatten yahyaÎncă nu există evaluări

- ECE LawsDocument4 paginiECE LawsMark JasonÎncă nu există evaluări

- QAP Plan For Biratnagar AirportDocument20 paginiQAP Plan For Biratnagar AirportNirmal bhandariÎncă nu există evaluări

- Project Quality Plan TemplateDocument5 paginiProject Quality Plan TemplateIja MirzaÎncă nu există evaluări

- QM Rev.02Document44 paginiQM Rev.02Romel MuldongÎncă nu există evaluări

- QUALITY CONTROL ASSURANCEDocument117 paginiQUALITY CONTROL ASSURANCENarendra100% (1)

- Asq What Is A Quality PlanDocument3 paginiAsq What Is A Quality PlanCloud RedfieldÎncă nu există evaluări

- Construction Quality Control PlanDocument10 paginiConstruction Quality Control PlanRawofi Abdul mateenÎncă nu există evaluări

- EMV v4.3 Book 4 Other Interfaces 20120607062305603Document154 paginiEMV v4.3 Book 4 Other Interfaces 20120607062305603Gregorio GazcaÎncă nu există evaluări

- Muhammad Javid Iqbal (Civil Engineer) Personal Information and ExperienceDocument4 paginiMuhammad Javid Iqbal (Civil Engineer) Personal Information and ExperienceJavid IqbalÎncă nu există evaluări

- Method Statement: Loading / Offloading Stations and Metering Skids Installation at Tank Battery / Guebiba Base & TrapsaDocument13 paginiMethod Statement: Loading / Offloading Stations and Metering Skids Installation at Tank Battery / Guebiba Base & TrapsaAkram FerchichiÎncă nu există evaluări

- 15need of SOP in Building Construction Managemenmanagementt PDFDocument4 pagini15need of SOP in Building Construction Managemenmanagementt PDFJannatul FirdousÎncă nu există evaluări

- As Per ISO 9001:2015 & IATF 16949:2016: Doc No CH-SMS-05 Rev No Rev DateDocument1 paginăAs Per ISO 9001:2015 & IATF 16949:2016: Doc No CH-SMS-05 Rev No Rev DaterohitÎncă nu există evaluări

- What Is Quality Management in Power DivisionDocument27 paginiWhat Is Quality Management in Power DivisionSiddhardha MsvÎncă nu există evaluări

- PQP Vs ISO 9001 Clauses List PDFDocument1 paginăPQP Vs ISO 9001 Clauses List PDFVpln Sarma100% (1)

- Quality Assurance Plan for ASARCO DemolitionDocument20 paginiQuality Assurance Plan for ASARCO DemolitionRen SalazarÎncă nu există evaluări

- Rehabilitation and Upgrading of Pakpattan Canal, Khadir Branch and Pakpattan Islam Link Contract: PCSBIP/ICB-01Document53 paginiRehabilitation and Upgrading of Pakpattan Canal, Khadir Branch and Pakpattan Islam Link Contract: PCSBIP/ICB-01yashas sÎncă nu există evaluări

- Civil Works Inspection - QA - QC-Construction LTDDocument1 paginăCivil Works Inspection - QA - QC-Construction LTDNashrul KarimÎncă nu există evaluări

- 02.method Statement Ver 2Document6 pagini02.method Statement Ver 2Peter ade TeacherÎncă nu există evaluări

- ENCOCORP QUALITY MANUAL ISO 9001-2015 - Updated On 5-Mar-2016 Webiste With ITP REV1Document29 paginiENCOCORP QUALITY MANUAL ISO 9001-2015 - Updated On 5-Mar-2016 Webiste With ITP REV1Sofia RegaladoÎncă nu există evaluări

- Qcs 2010 Section 5 Part 05 AdmixturesDocument7 paginiQcs 2010 Section 5 Part 05 AdmixturesRotsapNayrbÎncă nu există evaluări

- QCS-2010 Section 1 Part 11 Engineer's Site FacilitiesDocument8 paginiQCS-2010 Section 1 Part 11 Engineer's Site Facilitiesbryanpastor106Încă nu există evaluări

- Project Resource Planning TemplateDocument3 paginiProject Resource Planning TemplatehichemokokÎncă nu există evaluări

- PQP Flow ChartDocument1 paginăPQP Flow ChartFIRMANSYAHÎncă nu există evaluări

- Rev-2 Method Statement For Access Road Construction Works Puma Energy Daulatpur ProjectDocument11 paginiRev-2 Method Statement For Access Road Construction Works Puma Energy Daulatpur ProjectM Waqas HabibÎncă nu există evaluări

- Project Scope Statement: Tetra PakDocument5 paginiProject Scope Statement: Tetra PakDania KiyaniÎncă nu există evaluări

- DRP001 Puc Pro N 000 004 - 6Document58 paginiDRP001 Puc Pro N 000 004 - 6aasss100% (1)

- MST Installation of WEHOLITE Pipe - Stormwater - FinalDocument13 paginiMST Installation of WEHOLITE Pipe - Stormwater - FinalShahzaib ShahidÎncă nu există evaluări

- Structural Toolkit V3Document13 paginiStructural Toolkit V3Akram FerchichiÎncă nu există evaluări

- Allaboutailuminarylabsjanuary122017 170112151616Document28 paginiAllaboutailuminarylabsjanuary122017 170112151616pruebaprueba00Încă nu există evaluări

- Asia AIDocument17 paginiAsia AIhungbkpro90Încă nu există evaluări

- Note de Calcul Convoyeur MarocDocument10 paginiNote de Calcul Convoyeur MarocAkram FerchichiÎncă nu există evaluări

- 10 Ways Bad Bosses Destroy Employee MotivationDocument16 pagini10 Ways Bad Bosses Destroy Employee MotivationAkram FerchichiÎncă nu există evaluări

- UX Ethnography and PossibilitiesDocument80 paginiUX Ethnography and PossibilitiesAkram FerchichiÎncă nu există evaluări

- Note de Calcul Convoyeur MarocDocument10 paginiNote de Calcul Convoyeur MarocAkram FerchichiÎncă nu există evaluări

- Rapport Heli WinchDocument29 paginiRapport Heli WinchAkram FerchichiÎncă nu există evaluări

- Design Calculations Reboiler & Surge VesselDocument161 paginiDesign Calculations Reboiler & Surge VesselAkram Ferchichi100% (1)

- Pdoc 53 2013 Fi 06Document5 paginiPdoc 53 2013 Fi 06Akram FerchichiÎncă nu există evaluări

- E40000 Aquatherm Red Pipe 02Document74 paginiE40000 Aquatherm Red Pipe 02Akram FerchichiÎncă nu există evaluări

- Pdoc 53 2013 Gue General DrawingsDocument7 paginiPdoc 53 2013 Gue General DrawingsAkram FerchichiÎncă nu există evaluări

- Fire Safety Provision For LPG Storage Tank - Tawar MallDocument3 paginiFire Safety Provision For LPG Storage Tank - Tawar MallAkram FerchichiÎncă nu există evaluări

- Pdoc 53 2013 Ra 04Document11 paginiPdoc 53 2013 Ra 04Akram FerchichiÎncă nu există evaluări

- Pdoc 53 2013 Gue General DrawingsDocument10 paginiPdoc 53 2013 Gue General DrawingsAkram FerchichiÎncă nu există evaluări

- Pdoc 53 2013 Gue General DrawingsDocument10 paginiPdoc 53 2013 Gue General DrawingsAkram FerchichiÎncă nu există evaluări

- GRATINGS Gitterrost EngDocument72 paginiGRATINGS Gitterrost EngNajib KiwanÎncă nu există evaluări

- GUEBIBA Loading-Offloading StationDocument9 paginiGUEBIBA Loading-Offloading StationAkram FerchichiÎncă nu există evaluări

- PQR & WQ - Storage Tank TUNISAIR TECHNICS PDFDocument23 paginiPQR & WQ - Storage Tank TUNISAIR TECHNICS PDFAkram FerchichiÎncă nu există evaluări

- Steel Structure Design Report for Loading Station ShelterDocument35 paginiSteel Structure Design Report for Loading Station ShelterAkram FerchichiÎncă nu există evaluări

- Astm A240-16Document14 paginiAstm A240-16VIPAN RAIÎncă nu există evaluări

- DNIT01Document146 paginiDNIT01Anonymous wfgcPmJYÎncă nu există evaluări

- Recruitment and Selection Policy and ProcedureDocument18 paginiRecruitment and Selection Policy and ProcedureBobo SweÎncă nu există evaluări

- Unit-2-software-Requirement-engineering Ppt's PDFDocument45 paginiUnit-2-software-Requirement-engineering Ppt's PDFSuyog SabaleÎncă nu există evaluări

- Format For DST TSDPDocument24 paginiFormat For DST TSDPRajesh RishiÎncă nu există evaluări

- Java Software Developer Lead in Los Angeles CA Resume Prem SinghDocument4 paginiJava Software Developer Lead in Los Angeles CA Resume Prem SinghPremSinghÎncă nu există evaluări

- Enterprise® - Moveable WorkstationsDocument84 paginiEnterprise® - Moveable WorkstationsQuangThái NguyễnÎncă nu există evaluări

- Mimar Engineering Consultants RatesDocument16 paginiMimar Engineering Consultants RatesAmy FitzpatrickÎncă nu există evaluări

- Bus Ticket Reservation System: Software Requirements SpecificationDocument25 paginiBus Ticket Reservation System: Software Requirements SpecificationIshfaq BabarÎncă nu există evaluări

- PDF UG WBS MiniRule GetFromPricing TMRCRQ 11.1 119Document59 paginiPDF UG WBS MiniRule GetFromPricing TMRCRQ 11.1 119Abhijith RajuÎncă nu există evaluări

- Serwomotory Inovance Ms1 Instrukcja ObslugiDocument56 paginiSerwomotory Inovance Ms1 Instrukcja Obslugijuanete29Încă nu există evaluări

- Opss - Prov 410 Nov15 Construction Specification For Pipe Sewer Installation in Open CutDocument32 paginiOpss - Prov 410 Nov15 Construction Specification For Pipe Sewer Installation in Open Cutming_zhu10Încă nu există evaluări

- The Impact of Procurement On Domestic Contractors On Road PRDocument80 paginiThe Impact of Procurement On Domestic Contractors On Road PRBiruk100% (1)

- Refined Phenol: Standard Specification ForDocument1 paginăRefined Phenol: Standard Specification ForAhmed AbdullahÎncă nu există evaluări

- Astm B 237 - 01Document2 paginiAstm B 237 - 01kaminaljuyu100% (2)

- Raid-M SeriesDocument7 paginiRaid-M SeriesForum PompieriiÎncă nu există evaluări