Documente Academic

Documente Profesional

Documente Cultură

Overhead Lines PDF

Încărcat de

Salman FaisalTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Overhead Lines PDF

Încărcat de

Salman FaisalDrepturi de autor:

Formate disponibile

T&D PowerSkills Lineman Training Edition II

Page 1

Troubleshooting Overhead Lines

Edition II

Copyright MMVII

T&D PowerSkills, LLC

5501-A John Eskew Blvd.

Alexandria, LA 71303

866-880-1380

All rights reserved. This book or any part thereof

must not be reproduced in any form without the

written permission of T&D PowerSkills, LLC.

Printed in the United States of America

T&D PowerSkills Lineman Training Edition II

Page 2

T&D PowerSkills

General Guidelines for Students

This training unit is composed of a DVD and associated Student Manual. The DVD contains one

Course. The course is divided into Lessons, where each Lesson consists of a number of Topics.

The number of Lessons and Topics will vary with each course.

Recommended Sequence of Instruction

1. After the instructors introductory remarks, read the segment objectives found in the block at

the beginning of the first segment.

2. Briefly discuss the segment objectives with the instructor and other class members.

3. View the first segment of the DVD.

4. Read the text segment that corresponds to the first segment of the DVD.

5. Answer the questions at the end of the text segment. Check your answers with the correct

answers provided by the instructor.

6. Participate in a class discussion of the material just covered. Ask any questions you might

have concerning the material in the DVD and the text, and note any additional information

given by the instructor.

7. Before proceeding, be sure you understand the concepts presented in this segment.

8. Work through all segments in this manner.

9. A Course Test covering all the material will be administered by the instructor upon

completion of the unit.

10. Additional instruction and testing may be provided, at the instructors discretion.

OSHA Regulations Snap-Shot

OSHA Regulations, primarily in 1926.955, 1910.269 and 1910.268 will be used in conjunction

with this training unit. Where applicable, regulations will be highlighted and placed in a box like

this. Instructors and students are expected to review the current OSHA Regulations to

familiarize the student with the safety requirements expected by USDOL OSHA, specifically as

they relate to the topic being discussed. This information is an important part of this training

unit.

This Trouble Shooting Overhead Lines workbook is designed to be

used in conjunction with the associated training DVD/video.

T&D PowerSkills Lineman Training Edition II

Page 3

Field Performance Field Performance Field Performance Field Performance Requirements Requirements Requirements Requirements (FPR)

NAME: _____________________________

Complete

Incomplete

SECTION: Overhead Distribution - Energized

UNIT(S): Troubleshooting Overhead Lines

VG = Very Good

ACC = Acceptable

NI = Needs Improvement

NA = Not Able to Complete

on this Crew

REQUIREMENTS SUPERVISOR SIGN-OFF

VG ACC NI NA

SEGMENT 1 INTRODUCTION TO TROUBLESHOOTING

1.1 Given examples of problems, can apply logical troubleshooting

procedures to determine possible causes .

SEGMENT 2 PATROLLING

2.1 Can identify potential problems while patrolling a section of an

overhead distribution line

SEGMENT 3 TROUBLESHOOTING SAFETY

3.1 Can accurately report location to dispatcher or authorized person

3.2 Can follow approved procedures for obtaining and confirming a

clearance and work instructions ..

SEGMENT 4 SECTIONALIZING PRIMARY, PART 1

4.1 Can demonstrate approved procedures for closing in a line

SEGMENT 5 SECTIONALIZING PRIMARY, PART 2

5.1 Can describe the principles for locating problems on a primary line

by sectionalizing and energizing portions of the line safely ...

SEGMENT 6 TESTING SECONDARY, PART 1

6.1 Can demonstrate approved procedures for visually checking a

secondary circuit

6,2 Can safely test for voltage at a meter box ..

Continued:

T&D PowerSkills Lineman Training Edition II

Page 4

SEGMENT 7 TESTING SECONDARY, PART 2

7.1 Can demonstrate approved procedures for safely testing:

a. Transformer Output Voltage ...

b. Source Voltage .

______________________________ ______________________________ _______________

Employees Signature Supervisors Signature Date

PERFORMACE OTES: _____________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

1910.269(a)(2)(vii) as of July, 2006:

The employer shall certify that each employee has received the training required by paragraph

(a)(2) of this section. This certification shall be made when the employee demonstrates

proficiency in the work practices involved and shall be maintained for the duration of the

employees employment.

Note: Employment records that indicate that an employee has received the required training are

an acceptable means of meeting this requirement.

T&D PowerSkills Lineman Training Edition II

Page 5

TABLE OF COTETS

Section Title Page

1. Introduction to Troubleshooting 9

1.1 Purpose of Troubleshooting 9

1.2 Troubleshooting Steps 10

1.2.1 Gathering Information 10

1.2.2 Narrowing Down the Possible Causes or Locations of the

Problem

11

1.2.3 Locating the Problem 11

1.2.4 Isolating and Correcting the Problem 12

1.2.5 Documenting the Problem and the Action Taken 14

2. Patrolling 15

2.1 Purpose of Patrolling 15

2.2 Problems That May Be Encountered 18

3. Troubleshooting Safety 24

3.1 Reporting the Location 24

3.2 Obtaining Clearance or Work Instructions 25

3.3 Confirming Information or Instructions 26

3.4 Knowing the Consequences of Actions 26

4. Sectionalizing Primary 28

4.1 Closing In a Line 29

4.2 Sectionalizing a Line 31

5. Sectionalizing Primary 35

5.1 Sectionalizing a Primary by Sections 36

5.2 Sectionalizing a Primary at the Midpoint 40

T&D PowerSkills Lineman Training Edition II

Page 6

6. Testing Secondary 43

6.1 Visually Checking a Secondary Circuit 43

6.2 Testing for Voltage at a Meter Box 44

6.3 Additional Testing 47

7. Testing Secondary 49

7.1 Testing Voltage Output 49

7.2 Testing Source Voltage 51

7.3 Problem Solving 52

T&D PowerSkills Lineman Training Edition II

Page 7

LIST OF ILLUSTRATIOS

Figure Title Page

1-1. Broken Insulator Found by Patrolling Troubleman 11

1-2. Checking for Voltage with a Voltage Tester 12

1-3. Regulator and Bypass Switches 13

2-1. Branch on Power Lines 15

2-2. Erosion at the Base of a Pole 16

2-3. Downed Line on Guardrail 17

2-4. Broken Insulator and Line on Crossarm 18

2-5. Burned Pole and Crossarm 19

2-6. Leaking Transformer 20

2-7. Open Cutout 21

2-8. Broken Crossarm Brace 22

3-1. Pole Identification Number 25

4-1. Tree Branches Near Lines 29

4-2. Distribution Line Across a River 30

4-3. Line Opened 31

4-4. Cutout 32

4-5. Installing a Line Break 33

5-1. Primary Circuit 36

5-2. First Line Section Energized 37

5-3. Line Sections 1 and 2 Energized 38

5-4. Re-Energized Sections 1, 2, and 4 39

5-5. Half of Circuit Energized 40

T&D PowerSkills Lineman Training Edition II

Page 8

6-1. Part of a Typical Secondary Circuit 44

6-2. Typical Voltage Tester 46

6-3. Testing Phase-to-Phase Source Voltage to a Customer's Meter

Box

47

6-1. Testing Phase-to-Ground Transformer Output Voltage 49

6-2. Testing a Primary Line Using a Statiscope 52

6-3. Broken Jumper 53

OSHA Regulations Snap-Shot

1910.269 (c) (as of ovember, 2006)

Job Briefing.

The employer shall ensure that the employee in charge conducts a job briefing with employees involved

before they start each job. The briefing shall cover at least the following subjects: hazards associated

with the job, work procedures involved, special precautions, energy source controls, and personal

protective equipment requirements.

1. umber of briefings. If the work or operations to be performed during the work day or shift are

repetitive and similar, at least one job briefing shall be conducted before the start of the first job

of each day or shift. Additional job briefings shall be held if significant changes, which might

affect the safety of the employees, occur during the course of the work.

2. Extent of briefing. A brief discussion is satisfactory if the work involved is routine and if the

employee, by virtue of training and experience, can reasonably be expected to recognize and

avoid the hazards involved in the job. A more extensive discussion shall be conducted:

(i) if the work is complicated or particularly hazardous, or

(ii) if the employee cannot be expected to recognize and avoid the hazards involved in the

job.

T&D PowerSkills Lineman Training Edition II

Page 9

TROUBLESHOOTIG OVERHEAD LIES

Customers rely on overhead distribution systems as a source of uninterrupted power. When a

distribution system failure does occur, customers expect power to be restored quickly. In many

cases, troubleshooting is an important part of the power restoration process.

This training program is designed to provide basic information on troubleshooting overhead

electrical distribution systems. Among the topics covered are patrolling lines, following

common safety precautions, sectionalizing primary lines, and testing secondary systems.

1. Introduction to Troubleshooting

OBJECTIVES:

Describe the purpose of troubleshooting.

Describe logical steps for troubleshooting an overhead distribution system.

1.1 Purpose of Troubleshooting

The purpose of troubleshooting overhead distribution lines is to locate problems and restore

power to as many customers as possible as quickly as possible. When a problem occurs, the

troubleman uses the information that is available and his own experience to follow leads and

track down possible causes of the problem. He then eliminates possible causes until the source

of the problem is identified. Finally, the troubleman isolates and corrects the problem so that

customer service can be restored.

T&D PowerSkills Lineman Training Edition II

Page 10

TROUBLESHOOTIG OVERHEAD LIES

1. Introduction to Troubleshooting (continued)

1.2 Troubleshooting Steps

Specific troubleshooting procedures vary from company to company and from one situation to

another. The following steps represent a typical troubleshooting procedure for an overhead

distribution system problem such as a no-current/power outage situation.

Gathering information

Narrowing down the possible causes or locations of the problem

Locating the problem

Isolating and correcting the problem

Documenting the problem and the action taken

1.2.1 Gathering Information

The process of troubleshooting a problem on an overhead distribution line typically begins with

gathering information. A troubleman who has been sent to investigate a problem may have

several sources of information available to him. For example, a troubleman will typically learn

about a problem from a dispatcher. The troubleman may be able to get specific details from the

dispatcher by asking questions.

Customers may be another valuable source of information. Customers who phone in complaints

or reports of problems may have information that could save time. Eyewitnesses may be able to

direct the troubleman to the source of the problem.

Another important form of information is the troubleman's experience. For example,

remembering that a certain area of a power line is more likely to experience problems than

another area could save a lot of unnecessary work.

OSHA Regulations Snap-Shot

1910.333 (as of January, 2007)

Selection and use of work practices.

(a) General. Safety-related work practices shall be employed to prevent electric shock or other injuries resulting

from either direct or indirect electrical contacts, when work is performed near or on equipment or circuits which

are or may be energized. The specific safety-related work practices shall be consistent with the nature and extent

of the associated electrical hazards.

T&D PowerSkills Lineman Training Edition II

Page 11

TROUBLESHOOTIG OVERHEAD LIES

1. Introduction to Troubleshooting (continued)

1.2.2 arrowing Down the Possible Causes or Locations of the Problem

The information that a troubleman obtains can help him narrow down the possible causes or

locations of a problem. For example, if several customers serviced by the same lateral have

complained of a power outage, it would be logical to begin by checking that lateral. However, if

only one customer loses power, while other surrounding customers have normal service, it would

make sense to begin by checking the power at that customer's house.

1.2.3 Locating the Problem

After the cause or location of a problem has been narrowed down to a specific area, several

methods may be used to find the problem. These methods may include patrolling, sectionalizing,

and testing.

Patrolling means visually checking a line and equipment on the line for damage. The broken

insulator shown in Figure 1-1 was spotted by a patrolling troubleman. Extreme caution must be

used on all trouble jobs. You are there because something is wrong!

Figure 1-1. Broken Insulator Found by Patrolling Troubleman

Broken Insulator

T&D PowerSkills Lineman Training Edition II

Page 12

TROUBLESHOOTIG OVERHEAD LIES

1. Introduction to Troubleshooting (continued)

Sometimes it is necessary to sectionalize a circuit in order to locate a problem. Sectionalizing

means re-energizing the circuit a section at a time. A section that will not stay energized usually

indicates a problem.

Voltage testing may be necessary to find problems on secondary circuits. Figure 1-2 shows a

troubleman using a voltage tester to test for voltage at a customer's house. Perform a complete

facility check including visually inspecting the motor blocks.

Figure 1-2. Checking for Voltage with a Voltage Tester

Patrolling, sectionalizing, and testing are covered in more detail later in this program.

1.2.4 Isolating and Correcting the Problem

Once a problem has been located, decisions must be made on how to handle it. Some problems

are fairly easy to correct. For example, removing a tree branch from a power line may be a

relatively simple task.

T&D PowerSkills Lineman Training Edition II

Page 13

TROUBLESHOOTIG OVERHEAD LIES

1. Introduction to Troubleshooting (continued)

Other jobs, such as replacing a faulty regulator (Figure 1-3), may be more involved. Temporarily

bypassing the regulator may allow power to be restored quickly. The regulator can then be

repaired or replaced later without interfering with customer service.

Figure 1-3. Regulator and Bypass Switches

OSHA Regulations Snap-Shot

In this instance, do not

close by-pass into a

possibly faulted

regulator. Isolate the

regulator first.

1910.269(I) (as of January, 2007)

(6) Apparel.

(i) When work is performed within reaching distance of exposed energized parts of equipment, the employer

shall ensure that each employee removes or renders nonconductive all exposed conductive articles, such as key or

watch chains, rings, or wrist watches or bands, unless such articles do not increase the hazards associated with contact

with the energized parts.

(ii) The employer shall train each employee who is exposed to the hazards of flames or electric arcs in the

hazards involved.

(iii) The employer shall ensure that each employee who is exposed to the hazards of flames or electric arcs does

not wear clothing that, when exposed to flames or electric arcs, could increase the extent of injury that would be

sustained by the employee.

T&D PowerSkills Lineman Training Edition II

Page 14

TROUBLESHOOTIG OVERHEAD LIES

1. Introduction to Troubleshooting (continued)

1.2.5 Documenting the Problem and the Action Taken

Troubleshooting documentation requirements vary from company to company. Some companies

use a standard form such as an outage report form. This type of form is used for listing

information such as the cause of the problem, the location of the problem, and the nature of the

repair. Some companies only document temporary repairs that require additional work later.

Some companies require the completion of a route sheet listing each stop and repair made during

a shift. The route sheet generally includes information regarding times, places, and types of work

performed.

Questions

1-1. True or False. The purpose of troubleshooting overhead distribution lines is to locate

problems and restore power to as many customers as possible as quickly as possible.

1-2. Circle the correct answer.

Which of the following can be a valuable source of information during troubleshooting?

a. A dispatcher

b. Customers and eyewitnesses

c. The troubleman's experience

d. All of the above

1-3. True or False. If only one customer loses power, while other surrounding customers have

normal service, troubleshooting should begin by checking the main feeder.

1-4. Circle the correct answer.

Which of the following is NOT a method of locating a problem?

a. Patrolling

b. Sectionalizing

c. Documenting

d. Testing

1-5. True or False. Troubleshooting ends as soon as a problem is located.

T&D PowerSkills Lineman Training Edition II

Page 15

TROUBLESHOOTIG OVERHEAD LIES

2. Patrolling

OBJECTIVES:

Describe the purpose of patrolling overhead distribution lines.

Identify common problems to look for when patrolling overhead distribution lines.

2.1 Purpose of Patrolling

Patrolling means visually checking lines and equipment on the lines for damage. Generally,

overhead distribution lines are patrolled when there is a problem that must be located and

corrected. However, not all patrolling takes place as a result of a specific problem. Sometimes

patrolling is scheduled even though no problems have been reported. For example, lines in a

heavily wooded area may be patrolled after a storm to ensure that fallen tree branches (Figure 2-

1) will not cause problems.

Figure 2-1. Branch on Power Lines

T&D PowerSkills Lineman Training Edition II

Page 16

TROUBLESHOOTIG OVERHEAD LIES

2. Patrolling (continued)

Lines in areas that are susceptible to erosion may be patrolled from time to time to ensure that the

ground around poles (Figure 2-2) has not washed away.

Figure 2-2. Erosion at the Base of a Pole

Possible Erosion

T&D PowerSkills Lineman Training Edition II

Page 17

TROUBLESHOOTIG OVERHEAD LIES

2. Patrolling (continued)

Whether patrolling is done in response to a specific problem or as part of a scheduled routine,

there is always the potential for danger. A normally safe environment can quickly become a

potentially deadly one. For example, downed powerlines can contact objects on the ground, such

as a metal guardrail. As a result, the guardrail could become energized. Whenever patrolling is

done, it is a good practice to treat all lines and equipment as if they are energized.

Figure 2-3. Proper Troubleshooting PPE, After a Major Storm

The wearing of all Personal Protective Equipment (PPE) during troubleshooting, is critical for

personal safety.

OSHA Regulations Snap-Shot

1910.134 (as of January, 2007)

(f) Training.

(1) The employer shall provide training to each employee who is required by this section to use PPE. Each such

employee shall be trained to know at least the following:

(i) When PPE is necessary;

(ii) What PPE is necessary;

(iii) How to properly don, doff, adjust, and wear PPE;

(iv) The limitations of the PPE; and,

(v) The proper care, maintenance, useful life and disposal of the PPE.

1. Hard Hat

2. Safety Glasses

3. Insulated Sleeves

4. Insulated Gloves

5. Protective Work Gloves

6. Steel Toed Shoes with Insulated

Rubber Bootie

7. Fire Retardant work shirt

8. Linemans Climbing Belt and

Safety Strap

9. Insulated Hot Stick for testing

for voltage

10. ot Shown: Voltage Tester and

climbers

T&D PowerSkills Lineman Training Edition II

Page 18

TROUBLESHOOTIG OVERHEAD LIES

2. Patrolling (continued)

2.2 Problems That May Be Encountered

A wide variety of problems may be found while patrolling an overhead distribution line.

Problems can be related to wires, poles, hardware, and/or equipment. For example, in Figure 2-

4, a broken insulator has allowed a distribution line to fall on a crossarm, burning the crossarm.

A problem such as this could be easy to miss, especially when patrolling is done at night.

Figure 2-4. Broken Insulator and Line on Crossarm

Line on

Cross-

arm

Examples

of Broken

Insulators

T&D PowerSkills Lineman Training Edition II

Page 19

TROUBLESHOOTIG OVERHEAD LIES

2. Patrolling (continued)

Figure 2-5 shows a burned pole and crossarm. Current tracked across the insulator to the double

arm bolt and set the pole and crossarm on fire.

Figure 2-5. Burned Pole and Crossarm

Burned Pole and Crossarm

Double Arm Bolt

Insulators

T&D PowerSkills Lineman Training Edition II

Page 20

TROUBLESHOOTIG OVERHEAD LIES

2. Patrolling (continued)

The transformer shown in Figure 2-6 is leaking insulating oil. It is an example of an equipment

problem found by a troubleman while patrolling. Special care must be taken to determine if the

transformer contains oil laden with PCBs. If so, this must be treated as a hazardous chemical.

Other types of equipment problems include burned connections, burned or damaged insulators,

and ruptured or bulging equipment.

Figure 2-6. Leaking Transformer

T&D PowerSkills Lineman Training Edition II

Page 21

TROUBLESHOOTIG OVERHEAD LIES

2. Patrolling (continued)

Troublemen patrolling to find the cause of an outage often find that protective devices, such as

the cutout shown in Figure 2-7, have operated. Sometimes, a protective device may be the cause

of the problem. Usually, however, the protective device is triggered by other problems.

Figure 2-7. Open Cutout / Animal Caused Outages

Sometimes, squirrels or birds get into energized connectors and equipment and cause problems.

For example, a squirrel could bridge the gap between a phase and ground and cause an outage.

Animal caused outages are very common in urban and highly wooden areas.

T&D PowerSkills Lineman Training Edition II

Page 22

TROUBLESHOOTIG OVERHEAD LIE

2. Patrolling (continued)

Not all problems require immediate attention. Judgments often have to be made about the

severity of a problem. For example, the broken crossarm brace shown in Figure 2-8 may not

have to be replaced or repaired immediately if there are more severe problems on the line that

require attention.

Figure 2-8. Broken Crossarm

OSHA Regulations Snap-Shot

1910.269(q)(1)(i) as of July, 2006:

Before elevated structures, such as poles or towers, are subjected to such stresses as climbing or

the installation or removal of equipment my impose, the employer shall ascertain that the

structures are capable of sustaining the additional or unbalanced stresses. If the pole or other

structure cannot withstand the loads which will be imposed, it shall be braced or otherwise

supported so as to prevent failure.

Note: Appendix D to this section contains test methods that can be used in ascertaining whether

a wood pole is capable of sustaining the forces that would be imposed by an employee climbing

the pole. This paragraph also requires the employer to ascertain that the pole can sustain all other

forces that will be imposed by the work to be performed.

T&D PowerSkills Lineman Training Edition II

Page 23

TROUBLESHOOTIG OVERHEAD LIES

2. Patrolling (continued)

Questions

2-1. True or False. Patrolling an overhead distribution line means visually checking the line

and equipment on the line for damage.

2-2. True or False. Patrolling is scheduled only when specific problems have been reported on

a line.

2-3. A troubleman should always treat lines and equipment as if they are

_______________________.

(energized, de-energized)

2-4. Circle the correct answer.

Problems on overhead distribution lines can be related to

a. Wires

b. Poles

c. Hardware

d. Equipment

e. All of the above

f. Only a and b

OTES: _____________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

T&D PowerSkills Lineman Training Edition II

Page 24

TROUBLESHOOTIG OVERHEAD LIES (continued)

3. Troubleshooting Safety

Troubleshooting overhead distribution lines can take place in any kind of weather, and at any

time of the day or night. Since there may be unsuspected hazards, following safety precautions is

an important part of any troubleman's job. Specific safety procedures vary, depending on factors

such as the nature of the problem and company policies. This section examines some common

safety guidelines that apply in most situations.

OBJECTIVE:

Describe the following safety precautions to observe when troubleshooting

overhead distribution lines:

- Reporting the location

- Obtaining clearance or work instructions

- Confirming information and instructions

- Knowing the consequences of actions

3.1 Reporting the Location

One important safety practice that troublemen follow is accurately reporting their location. The

troubleman should work closely with the dispatcher. As long as the dispatcher knows where the

troubleman is, he can send help if there is a problem.

Battery Powered Radio Personal Voltage Sensor

T&D PowerSkills Lineman Training Edition II

Page 25

TROUBLESHOOTIG OVERHEAD LIES

3. Troubleshooting Safety (continued)

Locations can be established by several methods, depending on the situation and company policy.

For example, one method of establishing an accurate location is to use a street address. When

work is done in an area that is not near an identifiable street address, many companies use pole

identification numbers (Figure 3-1).

Figure 3-1. Pole Identification umber

Sometimes an accurate location can be established by describing landmarks. For example, an

area might be described as being on the west side of Fox Chase Road, five poles north of the

intersection at Clopper Road.

3.2 Obtaining Clearance or Work Instructions

Before a troubleman does any work on overhead lines or equipment, it is a good practice to

inform the dispatcher of the work that is to be performed. In some cases, the dispatcher must

give clearance for the work to be done. The dispatcher may also give the troubleman instructions

or other information that will help get the job done safely and efficiently.

T&D PowerSkills Lineman Training Edition II

Page 26

TROUBLESHOOTIG OVERHEAD LIES

3. Troubleshooting Safety (continued)

3.3 Confirming Information or Instructions

Some companies require or encourage troublemen to write down all instructions and read them

back to the dispatcher. This practice ensures that all information has been accurately

communicated and helps to ensure, for example, that a "B" was not mistaken for a "C" or that

"north" was not given as a direction when the direction should have been "south."

3.4 Knowing the Consequences of Actions

To avoid accidents, troublemen must consider the effects of their actions before doing work on a

line. For example, before energizing or de-energizing a line, a troubleman should contact the

dispatcher to clear the work. For each task, the troubleman should know what will happen as a

result of his actions.

OSHA Regulations Snap-Shot

1910.269 (a) (3) (as of ovember, 2006):

Existing Conditions.

Existing Conditions related to the safety of the work to be performed shall be determined before

work on or near electric line or equipment is started. Such conditions include, but are not

limited to, the nominal voltages of lines and equipment, the maximum switching transient

voltages, the presence of hazardous induced voltages, the presence and condition of protective

grounds and equipment grounding conductors, the condition of poles, environmental conditions

relative to safety, and the locations of circuits and equipment, including power and

communications lines and fire protective signaling circuits.

T&D PowerSkills Lineman Training Edition II

Page 27

TROUBLESHOOTIG OVERHEAD LIES

3. Troubleshooting Safety (continued)

Questions

3-1. True or False. Safety is an important part of troubleshooting.

3-2. Circle the correct answer.

Which of the following can be used by a troubleman to establish his location?

a. Street addresses

b. Pole identification numbers

c. Landmarks

d. All of the above

e. Only a and b

3-3. The _____________________ may provide a troubleman with clearance, instructions,

and other information.

3-4. Circle the correct answer.

A common troubleshooting safety practice is verifying information by

a. Writing down the dispatcher's instructions

b. Telephoning other utilities to see how they would handle the situation

c. Reading all information back to the dispatcher

d. All of the above

e. Only a and c

3-5. True or False. Before performing any work on a line, a troubleman should know what the

results of the work will be.

T&D PowerSkills Lineman Training Edition II

Page 28

TROUBLESHOOTIG OVERHEAD LIES

4. Sectionalizing Primary, Part 1

When a power outage occurs, a typical procedure is to patrol the line to locate the source of the

problem, let the dispatcher know what has to be done, take the necessary steps to isolate or

correct the problem, and then close the line in to restore service. In some cases, however, a

different troubleshooting approach might be used. One such approach is sectionalizing the line.

OBJECTIVES:

Explain when it may be appropriate to close in a line that has tripped open.

Describe three ways that a line can be sectionalized.

OSHA Regulations Snap-Shot

1926.955 (as of ovember 2006)

(4)(i) If the existing line is deenergized, proper clearance authorization shall be secured and the line

grounded on both sides of the crossover or, the line being strung or removed shall be considered and

worked as energized.

(ii) When crossing over energized conductors in excess of 600 volts, rope nets or guard structures shall

be installed unless provision is made to isolate or insulate the workman or the energized conductor.

Where practical the automatic reclosing feature of the circuit interrupting device shall be made

inoperative. In addition, the line being strung shall be grounded on either side of the crossover or

considered and worked as energized.

(5) Conductors being strung in or removed shall be kept under positive control by the use of adequate

tension reels, guard structures, tielines, or other means to prevent accidental contact with energized

circuits.

T&D PowerSkills Lineman Training Edition II

Page 29

TROUBLESHOOTIG OVERHEAD LIES - PART 1

4. Sectionalizing Primary, Part 1 (continued)

4.1 Closing in a Line

Closing in a line means re-energizing a line that has tripped open. Closing in is usually done

after a problem has been found and isolated or corrected. In some cases, a line may be closed in

after it has been checked and no apparent problem has been found. Sometimes, a problem on an

overhead distribution line is temporary and will clear itself later. For example, the tree branches

shown in Figure 4-1 may brush against the lines during high winds and cause problems. Later,

after the winds calm, the cause of the problem may not be evident. The branches could be well

away from the lines, and the troubleman might not notice them.

Figure 4-1. Tree Branches ear Lines

T&D PowerSkills Lineman Training Edition II

Page 30

TROUBLESHOOTIG OVERHEAD LIES

4. Sectionalizing Primary, Part 1 (continued)

Whether or not a line is closed in if no problem is found depends on experience and company

policy. In the video example, a line that crossed a river (Figure 4-2) was reported to be out. A

troubleman determined that a fused cutout had blown open, but he did not know why. The

troubleman patrolled the line up to the point at which it crossed the river, but he found no

problem. He could have crossed the river and continued patrolling, but that would have taken a

great deal of time. The troubleman knew from his own experience that temporary problems

caused by tree branches were frequent in the area on the other side of the river, so he asked the

dispatcher for permission to re-fuse the cutout and close in the line. If it holds, customers are

without power for a much shorter time. (Note: Figure 4-2 represents a hypothetical distribution

system. Other systems may be designed differently. For example, the open cutout in Figure 4-2

may be a different device, such as a recloser, in another system.)

Figure 4-2. Distribution Line Across a River

T&D PowerSkills Lineman Training Edition II

Page 31

TROUBLESHOOTIG OVERHEAD LIES - PART 1

4. Sectionalizing Primary, Part 1 (continued)

4.2 Sectionalizing a Line

Sectionalizing a line means re-energizing it a section at a time. Sectionalizing can be used in a

number of situations, depending on the nature of the problem and company policy. In the video

example, the fused cutout failed to hold when the troubleman tried to close in the line that

crossed the river. The troubleman then decided to sectionalize the line to see if he could restore

service to at least some customers. First, the troubleman opened the line at a convenient point

near the river (Figure 4-3). He then re-fused and closed the cutout to energize the section of line

on his side of the river. If the line stayed energized, the troubleman would have restored service

to some customers and narrowed the problem down to one side of the river.

Figure 4-3. Line Opened

T&D PowerSkills Lineman Training Edition II

Page 32

TROUBLESHOOTIG OVERHEAD LIES - PART 1

4. Sectionalizing Primary, Part 1 (continued)

A line can be sectionalized in several ways. One way is to open a switch located at a convenient

point in the line. The switch could be a cutout (Figure 4-4), a gang-operated air switch, a

recloser, or any other appropriate switching device.

Figure 4-4. Fused Cutouts

T&D PowerSkills Lineman Training Edition II

Page 33

TROUBLESHOOTIG OVERHEAD LIES

4. Sectionalizing Primary, Part 1 (continued)

A line can also be sectionalized by cutting a jumper or removing a hot tap. A jumper is a

conductor that connects two lines, such as the one in Figure 4-5. A hot tap is a type of

connection that was made to join two conductors.

Figure 4-5. Installing a Jumper

OSHA Regulations Snap-Shot

TROUBLESHOOTIG OVERHEAD LIES

1910.269(j)(2) (as of ovember 2006)

Condition of tools.

(i) Each live-line tool shall be wiped clean and visually inspected for defects before use each day.

(ii) If any defect or contamination that could adversely affect the insulating qualities or mechanical integrity of

the live-line tool is present after wiping, the tool shall be removed from service and examined and tested

according to paragraph (j)(2)(iii) of this section before being returned to service.

(iii) Live-line tools used for primary employee protection shall be removed from service every 2 years and

whenever required under paragraph (j)(2)(ii) of this section for examination, cleaning, repair, and testing as

follows:

[A] Each tool shall be thoroughly examined for defects.

[B] If a defect or contamination that could adversely affect the insulating qualities or mechanical

integrity of the live-line tool is found, the tool shall be repaired and refinished or shall be permanently

removed from service. If no such defect or contamination is found, the tool shall be cleaned and waxed.

T&D PowerSkills Lineman Training Edition II

Page 34

4. Sectionalizing Primary, Part 1 (continued)

Questions

4-1. True or False. Sectionalizing a line may restore power to some customers quickly, and

also help narrow the area of the problem.

4-2. Circle the correct answer.

A line may be sectionalized by opening

a. A fused cutout

b. A gang-operated air switch

c. A recloser

d. Any of the above

4-3. True or False. Cutting a jumper is a way of sectionalizing a line.

4-4. Circle the correct answer.

A line break is usually installed when

a. There is no convenient switch to open

b. There is a recloser nearby

c. There is no convenient place to remove a hot tap or cut a jumper

d. All of the above

e. Only a and c

OTES: _____________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

T&D PowerSkills Lineman Training Edition II

Page 35

TROUBLESHOOTIG OVERHEAD LIES - (continued)

5. Sectionalizing Primary, Part 2

Sectionalizing a primary line can be an effective way to isolate a problem on a circuit and restore

power to customers. A primary line can be sectionalized in several ways, depending on the

situation and company policy. For example, a primary line may be sectionalized one relatively

small section at a time, or it may be sectionalized in larger portions, such as at the midpoint of

the line.

OBJECTIVE:

Describe the principles for locating trouble on a primary line by sectionalizing and

energizing portions of the line.

OSHA Regulations Snap-Shot

1910.269(g)(2)(v) as of July, 2006:

Fall arrest equipment, work positioning equipment, or travel restricting equipment shall be used

by employees working at elevated locations more that 4 feet (1.2 m) above the ground on poles,

towers, or similar structures if other fall protection has not been provided. Fall protection

equipment is not required to be used by a qualified employee climbing or changing location on

poles, towers or similar structures, unless conditions, such as, but not limited to, ice, high winds,

the design of the structure (for example, no provision for holding on with hands), or the presence

of contaminants on the structure, could cause the employee to loose his or her grip or footing.

Note 1: This paragraph applies to structures that support overhead electric power generation,

transmission, and distribution lines and equipment. It does not apply to portions of buildings,

such as loading docks, to electric equipment, such as transformers and capacitors, nor to aerial

lifts. Requirements for fall protection associated with walking and working surfaces are

contained in Subpart D of this Part; requirements for fall protection associated with aerial lifts are

contained in 1910.67 of this Part.

ote 2: Employees undergoing training are not considered qualified employees for the

purposes of this provision. Unqualified employees (including trainees) are required to use

fall protection any time they are more than 4 feet (1.2 m) above the ground. (emphasis

supplied).

T&D PowerSkills Lineman Training Edition II

Page 36

TROUBLESHOOTIG OVERHEAD LIES

5. Sectionalizing Primary, Part 2 (continued)

5.1 Sectionalizing a Primary by Sections

Figure 5-1 is a simplified illustration of a primary circuit. The illustration shows a substation

circuit breaker, a primary distribution line, laterals, fused cutouts, normally closed non-load-

break switches, and a load-break switch that serves as a normally open tie point. In this example,

a problem has caused the substation circuit breaker to open, de-energizing the circuit from the

circuit breaker to the open load-break switch.

Figure 5-1. Primary Circuit

Company policies often dictate how a line can be sectionalized to locate the source of a problem.

In the video demonstration, the troubleman began by patrolling the section of line between the

circuit breaker and the first switch.

T&D PowerSkills Lineman Training Edition II

Page 37

TROUBLESHOOTIG OVERHEAD LIES

5. Sectionalizing Primary, Part 2 (continued)

The troubleman found no problem on that section of line, so he asked the dispatcher for

permission to open the first switch. After receiving approval, the troubleman opened the switch

and tagged it. The troubleman observed the appropriate safety precautions by working the line as

if it were energized. After informing the dispatcher that the switch was open, the troubleman

asked the dispatcher to remotely close the circuit breaker to re-energize the section of line from

the breaker to the switch (Figure 5-2). The breaker stayed closed, so the troubleman knew that

the cause of the problem was not in that section of the line.

Figure 5-2. First Line Section Energized

Sectionalizing allows a troubleman to test a section of line, make it operational, and then move

on to another section. In the video demonstration, the troubleman made the first section of the

line operational and then proceeded to the second section of line, between the first switch and the

second switch.

T&D PowerSkills Lineman Training Edition II

Page 38

TROUBLESHOOTIG OVERHEAD LIES

5. Sectionalizing Primary, Part 2 (continued)

When the troubleman patrolled the second section of the line, he found no problem, so he opened

and tagged the second switch (1). He then returned to the first switch, which was still open. The

troubleman asked the dispatcher to open the circuit breaker (2) so that the first switch could be

closed safely. After the breaker was opened, the troubleman closed the first switch (3). The

dispatcher then closed the circuit breaker (4) and re-energized the section of line from the circuit

breaker to the second switch (Figure 5-3). Again, the breaker stayed closed, indicating that the

problem was not in the first two sections.

Figure 5-3. Line Sections 1 and 2 Energized

Sectionalizing a primary line could continue in this manner for some time. However, in the

video presentation, the troubleman found the problem in the third section. A line was down

between the second and third switches.

T&D PowerSkills Lineman Training Edition II

Page 39

TROUBLESHOOTIG OVERHEAD LIES

5. Sectionalizing Primary, Part 2 (continued)

After finding the downed line, the troubleman could have stopped patrolling and started to take

corrective action, or he could isolate the problem and continue sectionalizing to restore power to

customers on the other side of the problem area. The troubleman decided to continue

sectionalizing, so he went on to the third switch, which he opened and tagged (1). He then went

on to the normally open load-break tie switch and asked permission to close that switch. When

the switch was closed (2), the section between the third switch and the load-break tie switch was

re-energized (Figure 5-4).

Figure 5-4. Re-Energized Sections 1, 2, and 4

With three sections re-energized, only the section between the second and third switches (the

section containing the downed line) was out of service. By sectionalizing the primary line one

section at a time, the troubleman was able to isolate the problem and restore power to many of

the customers.

T&D PowerSkills Lineman Training Edition II

Page 40

TROUBLESHOOTIG OVERHEAD LIES

5. Sectionalizing Primary, Part 2 (continued)

5.2 Sectionalizing a Primary at the Midpoint

Sometimes a circuit is sectionalized at the midpoint in an attempt to restore service to more

customers in less time. For example, in the video demonstration, the troubleman could have

started troubleshooting by patrolling from the circuit breaker all the way to the second switch,

which was near the midpoint. If he found no problem, he could have opened the second switch

(1) and then asked the dispatcher to remotely close the circuit breaker (2) to re-energize the first

half of the line. Figure 5-5 shows the part of the line that could have been energized in one step

by sectionalizing at the midpoint.

Figure 5-5. Half of Circuit Energized

Not every circuit can be sectionalized at the midpoint. Company policy and other factors, such

as the layout of the circuit or the load distribution, normally dictate the procedure to follow.

T&D PowerSkills Lineman Training Edition II

Page 41

TROUBLESHOOTIG OVERHEAD LIES

5. Sectionalizing Primary, Part 2 (continued)

Questions

5-1. True or False. Sectionalizing a primary line should always start at the midpoint.

5-2. True or False. It is a good practice to patrol a section of line before opening or closing

switches.

Refer to the following illustration to answer Questions 5-3 and5-4.

5-3. Circle the correct answer.

If trouble on the line causes a substation circuit breaker to open, one logical place to

begin patrolling for the problem is

a. Between the first and second switches on the line

b. Between the last switch and a load-break tie switch

c. Between the circuit breaker and the first switch

d. On a secondary circuit near a customer's house

T&D PowerSkills Lineman Training Edition II

Page 42

TROUBLESHOOTIG OVERHEAD LIES

5. Sectionalizing Primary, Part 2 (continued)

5-4. Circle the correct answer.

If a portion of the sectionalized primary line is re-energized, and remains energized,

a. That section of line has a definite problem

b. That section may have no problem

c. That section of line must be shut down immediately

d. Both a and c

5-5. True or False. Sectionalizing a primary line near the midpoint may help restore service to

more customers in less time.

OTES: _____________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

T&D PowerSkills Lineman Training Edition II

Page 43

TROUBLESHOOTIG OVERHEAD LIES - (continued)

6. Testing Secondary, Part 1

Problems on secondary circuits are as common as problems on primary circuits. One situation

that troublemen often face on secondary circuits is a power outage report from one customer.

OBJECTIVE:

Describe how to locate trouble by testing for voltage at a customer's meter.

6.1 Visually Checking a Secondary Circuit

Troubleshooting a power outage at a customer's house typically involves testing for voltage at the

customer's meter box. A visual check of the secondary circuit leading to the meter box will

sometimes reveal the cause of the outage.

T&D PowerSkills Lineman Training Edition II

Page 44

TROUBLESHOOTIG OVERHEAD LIES

6. Testing Secondary, Part 1 (continued)

Figure 6-1 shows part of a typical secondary circuit, including the secondary main, a distribution

transformer, a fused cutout, and a service drop to a customer's house. These components are all

susceptible to problems. In the video example, the troubleman found no obvious signs of

problems on the secondary, so he made a number of voltage tests to narrow down the location of

the problem. One of the first tests he performed was to check for voltage to the house.

Figure 6-1. Part of a Typical Secondary Circuit

T&D PowerSkills Lineman Training Edition II

Page 45

6.2 Testing for Voltage at a Meter Box

The first step in testing for voltage at a meter box is to gain access to the meter box terminals.

Depending on the design of the meter box, access may be gained by removing the meter box

cover or by removing the meter.

T&D PowerSkills Lineman Training Edition II

Page 46

TROUBLESHOOTIG OVERHEAD LIES

6. Testing Secondary, Part 1 (continued)

Voltage testing can be done with a voltage tester (Figure 6-2), a voltmeter, or any other testing

device capable of handling secondary voltage levels.

Figure 6-2. Typical Voltage Tester

OSHA Regulations Snap-Shot

1910.269(I)(2) (as of ovember 2006)

(i) The employee is insulated from the energized part (insulating gloves or insulating gloves and

sleeves worn in accordance with paragraph (l)(3) of this section are considered insulation of the

employee only with regard to the energized part upon which work is being performed), or

(ii) The energized part is insulated from the employee and from any other conductive object at a

different potential.

T&D PowerSkills Lineman Training Edition II

Page 47

TROUBLESHOOTIG OVERHEAD LIES

6. Testing Secondary, Part 1 (continued)

In the video demonstration, phase-to-phase voltage was tested by connecting the two probes of

the testing device to the two source phase terminals inside the meter box (Figure 6-3). (Phase-to-

phase checks in a meter box are also referred to as line-to-line checks.) When voltage tests are

performed, care must be taken to ensure that the probes do not touch a phase terminal and the

meter box or any other grounded part at the same time. Touching a probe to both phase and

ground at the same time will result in a phase-to-ground short.

Figure 6-3. Testing Phase-to-Phase Source Voltage to a Customer's Meter Box

T&D PowerSkills Lineman Training Edition II

Page 48

TROUBLESHOOTIG OVERHEAD LIES

6. Testing Secondary, Part 1 (continued)

A normal residential phase-to-phase voltage reading should be about 240 volts. The troubleman

in the video presentation got no reading, so he knew that there was no phase-to-phase voltage to

the meter. His next step was to test the phase-to-ground voltage.

Phase-to-ground voltage is tested by connecting one probe of the voltage tester to the ground

terminal and the other probe to one phase terminal. A normal residential phase-to-ground

voltage reading should be about 120 volts. Both phases should be tested to ground. If there is no

reading on either leg, voltage is not reaching the meter, and two possible causes of the customer's

outage can usually be eliminated: (1) The problem is not likely to be in the customer's wiring or

equipment, and (2) the problem is probably not in the customer's meter.

6.3 Additional Testing

Test results of no voltage at a meter box usually indicate a problem somewhere up the line. The

problem could be in the service drop, the secondary main, the transformer, or even the primary.

If a transformer serves several customers, a quick check for voltage at a second customer's meter

box could help to further isolate the problem.

If there is normal voltage at the second customer's meter box, the problem is not likely to be in

the transformer or the secondary main. It would most likely be in the service drop to the first

customer.

If the second customer also has no voltage at the meter box, the problem is not likely to be in

either service drop. It could be in the secondary main, the transformer, the protective device for

the transformer, or the primary. Additional troubleshooting will be necessary to determine the

exact location.

T&D PowerSkills Lineman Training Edition II

Page 49

TROUBLESHOOTIG OVERHEAD LIES

6. Testing Secondary, Part 1 (continued)

Questions

6-1. True or False. Visually checking the secondary circuit leading to a customer's meter box

sometimes reveals the cause of a problem.

6-2. True or False. The first step in testing voltage at a meter box is to gain access to the

meter box terminals.

6-3. Circle the correct answer.

Testing phase-to-phase voltage in a residential area

a. Usually results in a reading of 240 volts

b. Usually results in a reading of 120 volts

c. Usually involves connecting a voltage tester to a ground terminal

d. Both b and c

6-4. True or False. Phase-to-ground voltage is tested by connecting both voltage tester probes

to the ground terminal.

6-5. Circle the correct answer.

If two customers are serviced by the same distribution transformer, and both are without

service, the problem is likely to be

a. In the service drop to the second customer

b. In the secondary main, the transformer, or before the transformer

c. In the first customer's meter box

d. In the first customer's house wiring

OTES: _____________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

T&D PowerSkills Lineman Training Edition II

Page 50

TROUBLESHOOTIG OVERHEAD LIES - (continued)

7. Testing Secondary, Part 2

In the video demonstration, the troubleman eliminated the possibility of a problem at the meter

boxes and service drops of two customers. His next step was testing at the distribution

transformer.

OBJECTIVES:

Describe how to locate trouble by testing for power output from a distribution

transformer.

Describe how to locate trouble by testing for power to a distribution transformer.

7.1 Testing Voltage Output

Voltage testing at a distribution transformer may help to isolate a secondary circuit problem. If

there is normal voltage output at the transformer, the problem could be somewhere on the

secondary main. If there is no voltage output at the transformer, the problem could be either in

the transformer or in the source circuit to the transformer.

T&D PowerSkills Lineman Training Edition II

Page 51

TROUBLESHOOTIG OVERHEAD LIES

7. Testing Secondary, Part 2 (continued)

The voltage output at a distribution transformer can be tested in the same way as the voltage at a

meter box, using a voltage tester. Phase-to-phase output voltage is checked by touching the

tester probes to the two secondary phase terminals of the transformer. Phase-to-ground tests are

made by touching the tester probes to the secondary neutral terminal of the transformer and one

of the secondary phase terminals (Figure 7-1). The probes are then placed on the secondary

neutral terminal and the other secondary phase terminal.

Figure 7-1. Testing Phase-to-Ground Transformer Output Voltage

If the tests show that there is no voltage output from the transformer, the problem causing the

customer's outage is not in the secondary main. It is either in the transformer or in the source

circuit to the transformer.

T&D PowerSkills Lineman Training Edition II

Page 52

TROUBLESHOOTIG OVERHEAD LIES

7. Testing Secondary, Part 2 (continued)

7.2 Testing Source Voltage

In the video demonstration, the troubleman checked to determine if the source circuit, or primary

line, was energized. A statiscope, such as the one shown in Figure 7-2, was used for this test.

Figure 7-2. Testing a Primary Line Using a Statiscope

Statiscope

T&D PowerSkills Lineman Training Edition II

Page 53

TROUBLESHOOTIG OVERHEAD LIES

7. Testing Secondary, Part 2 (continued)

In the video demonstration, the statiscope light lit up, indicating that the primary line was

energized. The troubleman then knew that the problem was somewhere between the primary and

the transformer or in the transformer itself. When the troubleman took a closer look at the

cutout, he noticed that the primary jumper had broken off at the connection to the cutout (Figure

7-3).

Figure 7-3. Broken Jumper

7.3 Problem Solving

Procedures for repairing a problem like the broken jumper vary, depending on company policy.

In the video demonstration, the cutout was opened to isolate the transformer. The jumper was

then moved away from the cutout and disconnected from the primary. The troubleman then

trimmed and cleaned the end of the jumper and reattached it at the top of the cutout. Finally, the

troubleman cleaned the primary, reconnected the jumper to it, and closed the cutout to re-

energize the transformer and restore power to the customers.

T&D PowerSkills Lineman Training Edition II

Page 54

TROUBLESHOOTIG OVERHEAD LIES

7. Testing Secondary, Part 2 (continued)

Questions

7-1. True or False. If a troubleman has eliminated the possibility of a problem at a customer's

meter box and in the service drop, a logical next step is to test at the distribution

transformer.

7-2. Circle the correct answer.

With the transformer fuse intact, a no voltage output reading at a distribution transformer

could indicate

a. A problem somewhere on the secondary main

b. A problem somewhere in the transformer

c. A problem somewhere in the source circuit

d. All of the above

e. Only b and c

7-3. Circle the correct answer.

With a customer outage, a normal voltage output reading at a distribution transformer

could indicate

a. A problem somewhere on the secondary main

b. A problem somewhere in the transformer

c. A problem somewhere in the source circuit

d. All of the above

e. Only b and c

7-4. True or False. When output voltage is tested at a distribution transformer, only phase-to-

phase testing is necessary.

7-5. Circle the correct answer.

A ________________ can be used to test for input voltage at a distribution transformer.

a. Meter box

b. Statiscope

c. Primary jumper

d. None of the above

T&D PowerSkills Lineman Training Edition II

Page 55

GLOSSARY

This glossary contains terms pertinent to troubleshooting overhead lines. The meanings of the

terms are given in that context.

Branch line - A line in a distribution system that taps off of a lateral

circuit.

Closing in - Re-energizing a line that has tripped open.

Hot tap - A type of connection that can be made to join two

conductors.

Jumper - A conductor that connects two lines.

Lateral - A line in a distribution system that taps off of a primary

circuit.

Outage report form - A form used by some companies on which a

troubleman documents information such as the cause of

an outage, the location of the problem, and the nature of

the repair work done.

Patrolling - Visually checking lines and equipment for signs of

damage.

Route sheet - A form used by some companies on which a

troubleman lists each stop made, the time of the stop,

and the work performed during a given shift.

Sectionalizing - Re-energizing a circuit a section at a time to determine

the location of a problem.

Troubleshooting - A systematic process of gathering information and

tracking down leads to find the source of a problem.

S-ar putea să vă placă și

- Protective relay The Ultimate Step-By-Step GuideDe la EverandProtective relay The Ultimate Step-By-Step GuideÎncă nu există evaluări

- Arc Control in Circuit Breakers: Low Contact Velocity 2nd EditionDe la EverandArc Control in Circuit Breakers: Low Contact Velocity 2nd EditionÎncă nu există evaluări

- Power Cable FundamentalsDocument1 paginăPower Cable FundamentalsBorislav VulicÎncă nu există evaluări

- Nicc802 Padmount Transformer BrochureDocument8 paginiNicc802 Padmount Transformer Brochureparas99Încă nu există evaluări

- High Voltage Distribution System For Agricultural Pumps: A Case StudyDocument9 paginiHigh Voltage Distribution System For Agricultural Pumps: A Case StudyAkshat GangwalÎncă nu există evaluări

- Electrical Engineering Safety Final ExamDocument2 paginiElectrical Engineering Safety Final ExamMarielle LopezÎncă nu există evaluări

- Pdu Lab Manual 104Document94 paginiPdu Lab Manual 104Rana FaizanÎncă nu există evaluări

- Lab 4: C A C: Lippers ND LampersDocument9 paginiLab 4: C A C: Lippers ND LampersAhmed ChÎncă nu există evaluări

- Electrician A Complete Course by Gary Price PDFDocument174 paginiElectrician A Complete Course by Gary Price PDFHamdam NazarovÎncă nu există evaluări

- BP - Res U2 Elect Symbols Outlets Note PDFDocument23 paginiBP - Res U2 Elect Symbols Outlets Note PDFyeng botzÎncă nu există evaluări

- Balancing PAC IPC PLC PDFDocument5 paginiBalancing PAC IPC PLC PDFlucasgianini100% (1)

- Advantages of Solid-State Relays Over Electro Mechanical RelaysDocument10 paginiAdvantages of Solid-State Relays Over Electro Mechanical RelaysnsadnanÎncă nu există evaluări

- Operation and Application of PLC With Ladder DiagramDocument9 paginiOperation and Application of PLC With Ladder DiagramYuva Raj50% (2)

- Power Switches and Their Applications in Power ElectronicsDocument58 paginiPower Switches and Their Applications in Power ElectronicsMuhammad NazeerÎncă nu există evaluări

- Manual de Servicio Monitor LCD Dell E190SfDocument59 paginiManual de Servicio Monitor LCD Dell E190SfAntonio Chavez100% (1)

- P34x EN AD G54Document48 paginiP34x EN AD G54Adip Chy100% (1)

- Engineering VocabularyDocument8 paginiEngineering VocabularyJoaquim Sabino PessoaÎncă nu există evaluări

- Voltage Drops - OD and Other Circuits: How An Ohmmeter WorksDocument9 paginiVoltage Drops - OD and Other Circuits: How An Ohmmeter Workshanif274Încă nu există evaluări

- FCC Accessories PDFDocument40 paginiFCC Accessories PDFSorcerer NAÎncă nu există evaluări

- ABB TransformersDocument18 paginiABB TransformersEng HamiedÎncă nu există evaluări

- 2 ACTS12kPLUSDocument34 pagini2 ACTS12kPLUSPRBÎncă nu există evaluări

- OFFSHORE CABLES CATALOGUEDocument88 paginiOFFSHORE CABLES CATALOGUEErstendrain EngÎncă nu există evaluări

- 34 5 KV Rubber Glove Work - Instructor's GuideDocument12 pagini34 5 KV Rubber Glove Work - Instructor's GuideStedroy RoacheÎncă nu există evaluări

- MODULE CODE AND TITLE: NEWNF401 Network FundamentalsDocument12 paginiMODULE CODE AND TITLE: NEWNF401 Network FundamentalsJean d'Amour ISHIMOÎncă nu există evaluări

- Distribution Standards & EstimationDocument217 paginiDistribution Standards & EstimationAkhil Krishnan100% (1)

- ENGR AE 6 CircuitAnalysisAndTroubleshootingPowerPointDocument18 paginiENGR AE 6 CircuitAnalysisAndTroubleshootingPowerPointMarvs SD RojsvelÎncă nu există evaluări

- Scilab textbook companion for digital principals and applicationsDocument217 paginiScilab textbook companion for digital principals and applicationsRadhika Agarwal50% (2)

- Electrical Works Section Table of ContentsDocument98 paginiElectrical Works Section Table of ContentssasikalaÎncă nu există evaluări

- Training Manual PDFDocument12 paginiTraining Manual PDFOwen kamazizwaÎncă nu există evaluări

- 0 - A High-Voltage Fuse Tutorial and Application GuideDocument35 pagini0 - A High-Voltage Fuse Tutorial and Application GuideFerran MunyósÎncă nu există evaluări

- AWG Catalog PDFDocument412 paginiAWG Catalog PDFgerrzen64Încă nu există evaluări

- Variable Speed Drive - IntroductionDocument6 paginiVariable Speed Drive - Introductionawhk2006Încă nu există evaluări

- SF6 Circuit Breakers - Construction, Types and WorkingDocument13 paginiSF6 Circuit Breakers - Construction, Types and WorkingSankara SubramanianÎncă nu există evaluări

- Distributed System IntroDocument30 paginiDistributed System IntroShivam KumarÎncă nu există evaluări

- Tricab Marine CablesDocument58 paginiTricab Marine CablesrahulranjanÎncă nu există evaluări

- Circuit Breaker MarkingsDocument4 paginiCircuit Breaker Markingsfarooq929Încă nu există evaluări

- Linear Solenoid GuideDocument20 paginiLinear Solenoid GuideAndrei ReventÎncă nu există evaluări

- GroundingDocument8 paginiGroundingRachit KhannaÎncă nu există evaluări

- Contactor Selection GuideDocument6 paginiContactor Selection GuideJovimarkEncarnacionManzanoÎncă nu există evaluări

- 06-POWER AND CONTROL CABLE - Rev5 PDFDocument14 pagini06-POWER AND CONTROL CABLE - Rev5 PDFSanjay RoutÎncă nu există evaluări

- UPS Power 10 KVA, 20kva, 30 Kva, 40kva Redundant UPS - Uninterruptible Power SupplyDocument4 paginiUPS Power 10 KVA, 20kva, 30 Kva, 40kva Redundant UPS - Uninterruptible Power SupplyGamatronicÎncă nu există evaluări

- Electrical Design 101 PDFDocument104 paginiElectrical Design 101 PDFjungatbuntonÎncă nu există evaluări

- 16X2 LCD Basics:: LCD Pin Description: Pin No Symbol I/O DescriptionDocument33 pagini16X2 LCD Basics:: LCD Pin Description: Pin No Symbol I/O DescriptionvaralakshmikrÎncă nu există evaluări

- Electrical Wiring HistoryDocument17 paginiElectrical Wiring Historymotowerx100% (5)

- Descriptive Bulletin 242-32Document25 paginiDescriptive Bulletin 242-32mashan98Încă nu există evaluări

- Gep 974GDocument43 paginiGep 974GalbrodzÎncă nu există evaluări

- Underground Residential Distribution Layouts GuideDocument6 paginiUnderground Residential Distribution Layouts Guidekash30Încă nu există evaluări

- EE454 PowerSystemProtection Course Outline 2016Document4 paginiEE454 PowerSystemProtection Course Outline 2016Hafsa IjazÎncă nu există evaluări

- Introduction of CablesDocument14 paginiIntroduction of CablesRanganath SriÎncă nu există evaluări

- Magnum ACB - InstructionDocument52 paginiMagnum ACB - InstructionAdrian MorenoÎncă nu există evaluări

- Control Devices PDFDocument24 paginiControl Devices PDFjonnymarin23Încă nu există evaluări

- HPED Assignment 2: DC DrivesDocument4 paginiHPED Assignment 2: DC DrivesShadÎncă nu există evaluări

- List of Books ScribdDocument4 paginiList of Books Scribdkultardeep0% (1)

- ResistorDocument12 paginiResistorShantanu ChouguleÎncă nu există evaluări

- Linear Network Theory: The Commonwealth and International Library: Applied Electricity and Electronics DivisionDe la EverandLinear Network Theory: The Commonwealth and International Library: Applied Electricity and Electronics DivisionÎncă nu există evaluări

- Knowledge is "Real Power": Introduction to Power QualityDe la EverandKnowledge is "Real Power": Introduction to Power QualityÎncă nu există evaluări

- Alstom - RPC - Switching of Shunt Capacitor BanksDocument8 paginiAlstom - RPC - Switching of Shunt Capacitor BanksSalman FaisalÎncă nu există evaluări

- Design Flow Line & H/Up for ES-PCP Well Mukhaizna-02/10Document6 paginiDesign Flow Line & H/Up for ES-PCP Well Mukhaizna-02/10Salman FaisalÎncă nu există evaluări

- Vario Part IIDocument46 paginiVario Part IISalman FaisalÎncă nu există evaluări

- 19 Experience Report enDocument6 pagini19 Experience Report envdaÎncă nu există evaluări

- Cable Testing Products PDFDocument2 paginiCable Testing Products PDFmahmoud fawzyÎncă nu există evaluări

- Code of practice for power system protection wiring and standardsDocument7 paginiCode of practice for power system protection wiring and standardsSalman FaisalÎncă nu există evaluări

- Protection Settings KTS Rev01Document136 paginiProtection Settings KTS Rev01bala86% (7)

- Acoustic Emission Properties of Partial Discharges and their DetectionDocument76 paginiAcoustic Emission Properties of Partial Discharges and their DetectionSalman FaisalÎncă nu există evaluări

- Acoustic Emission Properties of Partial Discharges and their DetectionDocument76 paginiAcoustic Emission Properties of Partial Discharges and their DetectionSalman FaisalÎncă nu există evaluări

- Design Data: Galfar Engineering Contracting LLC GEN-WI-000-003-F/02 Rev. 0Document1 paginăDesign Data: Galfar Engineering Contracting LLC GEN-WI-000-003-F/02 Rev. 0Salman FaisalÎncă nu există evaluări

- Alstom - RPC - Switching of Shunt Capacitor BanksDocument8 paginiAlstom - RPC - Switching of Shunt Capacitor BanksSalman FaisalÎncă nu există evaluări

- Cable Splicing - Part 1: Edition IIDocument0 paginiCable Splicing - Part 1: Edition IISalman FaisalÎncă nu există evaluări

- Application Form WorkDocument1 paginăApplication Form WorkSalman FaisalÎncă nu există evaluări

- Code of practice for power system protection wiring and standardsDocument7 paginiCode of practice for power system protection wiring and standardsSalman FaisalÎncă nu există evaluări

- Design Input Review Sheet: o o o o o o o oDocument1 paginăDesign Input Review Sheet: o o o o o o o oSalman FaisalÎncă nu există evaluări

- 02-15 ScopeDocument2 pagini02-15 ScopeSalman FaisalÎncă nu există evaluări

- Central Networks Eon Cable Spiking ManualDocument13 paginiCentral Networks Eon Cable Spiking ManualSalman FaisalÎncă nu există evaluări

- Cable Sizing CalculationDocument1 paginăCable Sizing CalculationhafizheryÎncă nu există evaluări

- Cable Testing Products PDFDocument2 paginiCable Testing Products PDFmahmoud fawzyÎncă nu există evaluări

- Central Networks Eon Cable Spiking ManualDocument13 paginiCentral Networks Eon Cable Spiking ManualSalman FaisalÎncă nu există evaluări

- OhlmatDocument18 paginiOhlmatSalman FaisalÎncă nu există evaluări

- Pole Top Equipment Voltage Regulators PDFDocument0 paginiPole Top Equipment Voltage Regulators PDFSalman FaisalÎncă nu există evaluări

- Central Networks Eon Cable Spiking ManualDocument13 paginiCentral Networks Eon Cable Spiking ManualSalman FaisalÎncă nu există evaluări

- Ducab Catalogue PDFDocument70 paginiDucab Catalogue PDFSalman FaisalÎncă nu există evaluări

- S-AA-CORR (Rev.0-2009)Document22 paginiS-AA-CORR (Rev.0-2009)Salman FaisalÎncă nu există evaluări

- S-AA-CORR (Rev.0-2009)Document22 paginiS-AA-CORR (Rev.0-2009)Salman FaisalÎncă nu există evaluări

- GL - gn.03 - HSEQ Requirements For Contractors GuidelinesDocument58 paginiGL - gn.03 - HSEQ Requirements For Contractors GuidelinesSalman FaisalÎncă nu există evaluări

- SP0406C01 Ver 3 Commiss Ground MNTD Dist Substn and SwitchgearDocument2 paginiSP0406C01 Ver 3 Commiss Ground MNTD Dist Substn and SwitchgearSalman FaisalÎncă nu există evaluări

- Selection of Current TrafoDocument18 paginiSelection of Current TrafoSuraj KumarÎncă nu există evaluări

- ZXONE Quick Installation Guide - V1.0Document56 paginiZXONE Quick Installation Guide - V1.0kmad100% (2)

- Adaptive ArchitectureDocument27 paginiAdaptive ArchitectureSanjeev BumbÎncă nu există evaluări

- Interaction & Bank EffectDocument6 paginiInteraction & Bank EffectAkash KandwalÎncă nu există evaluări

- The Sperry Bombsight: A Pioneering Rival to NordenDocument6 paginiThe Sperry Bombsight: A Pioneering Rival to NordenPaul DupontÎncă nu există evaluări

- List of Linkages2016Document74 paginiList of Linkages2016engrwho0% (1)

- Strength of Pressure Vessels With Ellipsoidal HeadsDocument8 paginiStrength of Pressure Vessels With Ellipsoidal Headsنصرالدين ادريسÎncă nu există evaluări

- TMC 421 PDFDocument82 paginiTMC 421 PDFJamie MooreÎncă nu există evaluări

- Experion Scada PinDocument7 paginiExperion Scada PinKhalid AliÎncă nu există evaluări

- Tabla 1 Engine ControlDocument2 paginiTabla 1 Engine Controljulio montenegroÎncă nu există evaluări

- Vehicle Air Conditioning (VAC) : System Operation and The Refrigerant CycleDocument49 paginiVehicle Air Conditioning (VAC) : System Operation and The Refrigerant CycleVarun RaizadaÎncă nu există evaluări

- Chapter-6 IscaDocument1 paginăChapter-6 IscakishorejiÎncă nu există evaluări

- STP GuideDocument2 paginiSTP GuideFlow Dynamics IndiaÎncă nu există evaluări

- Bottom Ash HopperDocument8 paginiBottom Ash HopperBhargav ChaudhariÎncă nu există evaluări

- Strength and Insulating Properties of Building Blocks Made From Waste MaterialsDocument7 paginiStrength and Insulating Properties of Building Blocks Made From Waste Materialsmjrobust05Încă nu există evaluări

- List of Projects Related To Transportation Highway and BridgesDocument5 paginiList of Projects Related To Transportation Highway and BridgesOyedotun TundeÎncă nu există evaluări

- BPCL Kochi Refinery MS BLOCK PROJECT Piping Material SpecificationDocument1 paginăBPCL Kochi Refinery MS BLOCK PROJECT Piping Material SpecificationDeepak DayalÎncă nu există evaluări

- Advantages & Disadvantages CITWDocument5 paginiAdvantages & Disadvantages CITWSreePrakashÎncă nu există evaluări

- CAD1 AssignmentDocument11 paginiCAD1 AssignmentJohn2jÎncă nu există evaluări

- 83 - Detection of Bearing Fault Using Vibration Analysis and Controlling The VibrationsDocument12 pagini83 - Detection of Bearing Fault Using Vibration Analysis and Controlling The VibrationsmaulikgadaraÎncă nu există evaluări

- TV Compatibility with Verbatim HDDsDocument2 paginiTV Compatibility with Verbatim HDDsmirciulicacatyÎncă nu există evaluări

- Ali Haider ResumeDocument3 paginiAli Haider ResumeHasnain ShakirÎncă nu există evaluări

- Feed Water and Boiler Water of Steam GeneratorsDocument2 paginiFeed Water and Boiler Water of Steam GeneratorsIvicaT0% (2)

- Design of A Fluidized Drum GranulatorDocument6 paginiDesign of A Fluidized Drum GranulatorditchcheÎncă nu există evaluări

- Supercharging: Superchargers & TurbochargersDocument11 paginiSupercharging: Superchargers & TurbochargersAkhil Here100% (1)

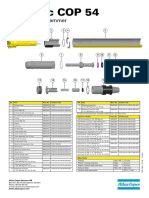

- 9853 1239 01 - COP 54 Service Poster - LOWDocument1 pagină9853 1239 01 - COP 54 Service Poster - LOWValourdos LukasÎncă nu există evaluări

- Iraqi Code for Reinforced Concrete StructuresDocument71 paginiIraqi Code for Reinforced Concrete Structuresmamandawe50% (2)

- Schneider LV Switchboard Inspection GuideDocument59 paginiSchneider LV Switchboard Inspection GuideAlp Arslan Ok100% (1)

- Solar TrackerDocument13 paginiSolar TrackerMuthuRajÎncă nu există evaluări