Documente Academic

Documente Profesional

Documente Cultură

TENSACCIAI - Slab Post-Tensioning System

Încărcat de

novakno1Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

TENSACCIAI - Slab Post-Tensioning System

Încărcat de

novakno1Drepturi de autor:

Formate disponibile

P

P

P

O

O

O

S

S

S

T

T

T

E

E

E

N

N

N

S

S

S

I

I

I

O

O

O

N

N

N

I

I

I

N

N

N

G

G

G

S

S

S

Y

Y

Y

S

S

S

T

T

T

E

E

E

M

M

M

F

F

F

O

O

O

R

R

R

S

S

S

L

L

L

A

A

A

B

B

B

S

S

S

Monostrand system

PTS system

Emission: May 2007

UT Tensacciai

Total pages: 11

Page 2 of Slab post-tensioning Technical Document

System main features

The advantages of the technique of slab post-tensioning are several and clear.

If we take as an example a car parking, we can see that, in the case of simply

reinforced concrete slab, the structure is made of a forest of pillars, with floor

thickness considerably high. In the case of post-tensioned slabs, structure is

spacious and free, facilitating traffic movements and parking. Floor thickness is

also considerably reduced (up to 1,8 times, i.e. from 40 up to 25 cm) introducing a

saving of weight, while spans reach 15 meters instead of common 7 / 8 meters.

Slab post-tensioning enables deflections and cracks under service conditions to be

kept under control.

This is why, in fact, post-tensioning increases the concrete durability, due to the

presence of concrete always under compression stresses.

The structural simplification, giving also an increase of free space, leads to an

overall reduction of costs for buildings.

This also comes from the reduction of steel placed inside slab and time needed for

construction.

Even installation equipment can be less, due to reduction of formworks through the

application of fast cycling after stressing.

The following table summarises the main advantages of slab post-tensioning.

Slab Post-tensioning system

Main features - 1

Page 3 of Slab post-tensioning Technical Document

First direct advantage Related further advantages

Reduction in slab thickness

Floor to floor distance reduction

Savings on total building height

(1 floor gained each 20 foreseen)

Reduction of construction volumes

and consequent energy needed

for heating, cooling living spaces

Different opportunities for ceiling

final finishing.

Larger spans

(and reduction of columns)

Increase of free space available

More architectural opportunities

Reduction in slab weight

Savings on vertical structural

bearing members and

foundations.

High limitation of crack widths

Improvement of durability and

concrete behavior.

D

E

S

I

G

N

High deflection limitation

Improvement of serviceability for

all structural members

Reduction of steel reinforcement and

arrangement simplification

Easier materials placing and

handling.

High deflection limitations due to

concrete shrinkage and creep

Possible earlier formworks

removal.

C

O

N

S

T

R

U

C

T

I

O

N

High repeatability from floor to floor /

quick rotation of formworks

Reduction of erection times

Reduction of formworks sets

Improvement of constructability

Slab Post-tensioning system

Main features - 2

Page 4 of Slab post-tensioning Technical Document

Mono-strand System

Live end Dead end

Coupler

Typical application

Monostrand post-tensioning

system

General overview

Page 5 of Slab post-tensioning Technical Document

Mono-strand System

Live end

Dead end

Mono-strand post-tensioning

system

Main dimensions - 1

Page 6 of Slab post-tensioning Technical Document

Mono-strand System

Coupler

Mono-strand post-tensioning

system

Main dimensions - 2

Page 7 of Slab post-tensioning Technical Document

Mono-strand System

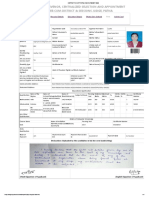

Concrete strength at

the time of stressing

b c d e

all dimensions in mm

f

cm,0 - cyl

=25 MPa 75 140 220 110

f

cm,0 - cyl

=33 MPa 65 120 200 100

f

cm,0 - cyl

=45 MPa 55 100 160 80

Mono-strand post-tensioning

system

Reinforcement and

distances

Page 8 of Slab post-tensioning Technical Document

Mono-strand System

Recess former system for mono-strand anchorage

Mono-strand post-tensioning

system

Installation details

Page 9 of Slab post-tensioning Technical Document

PTS multi-strand system

Anchorage

Coupler

PTS multi-strand system

General overview

Page 10 of Slab post-tensioning Technical Document

PTS multi-strand system

A B C D E F G H I

PTS type all dimensions in mm

3 PTS 13

(3 strands 12,7 mm)

170 75 50 125 190 45 45 72 20

3 PTS 15

(3 strands 15,2 mm)

170 75 60 155 190 45 45 72 20

4 PTS 13

(4 strands 12,7 mm)

220 75 50 160 220 45 45 72 20

4 PTS 15

(4 strands 15,2 mm)

220 75 60 205 220 45 45 72 20

5 PTS 13

(5 strands 12,7 mm)

220 75 50 200 220 45 45 72 20

5 PTS 13

(5 strands 15,2 mm)

265 75 60 250 270 45 45 92 22

PTS multi-strand system

Main dimensions - 1

Page 11 of Slab post-tensioning Technical Document

PTS multi-strand system

A B C D E F G H I

PTS type all dimensions in mm

3 PTS 13

(3 strands 12,7 mm)

170 75 44 50 190 88 190 72 20

3 PTS 15

(3 strands 15,2 mm)

170 75 44 62 190 104 220 72 20

4 PTS 13

(4 strands 12,7 mm)

220 75 50 50 220 88 160 72 20

4 PTS 15

(4 strands 15,2 mm)

220 75 53 53 220 103 250 72 20

5 PTS 13

(5 strands 12,7 mm)

220 75 50 50 220 88 242 72 20

5 PTS 13

(5 strands 15,2 mm)

265 75 53 53 270 104 295 92 22

PTS multi-strand system

Main dimensions - 2

S-ar putea să vă placă și

- Post TensionDocument56 paginiPost TensionanoopsurendranÎncă nu există evaluări

- Post-tensioning steel strands technical dataDocument28 paginiPost-tensioning steel strands technical datanovakno1Încă nu există evaluări

- Bar CouplerDocument6 paginiBar Couplerlwin_oo2435Încă nu există evaluări

- DSI ALWAG-Systems Pantex Lattice Girders EDocument8 paginiDSI ALWAG-Systems Pantex Lattice Girders Epramods_8Încă nu există evaluări

- 01 A 01 Cat PDFDocument29 pagini01 A 01 Cat PDFKrm ChariÎncă nu există evaluări

- Post-tensioned Concrete Slab SystemsDocument39 paginiPost-tensioned Concrete Slab Systemsyy2010100% (2)

- Contur KatalogDocument48 paginiContur KatalogDang Minh HuongÎncă nu există evaluări

- PT-Post Tensioning Methods&AppDocument5 paginiPT-Post Tensioning Methods&AppAanchal100% (1)

- Upvc SWR Pipes PDFDocument7 paginiUpvc SWR Pipes PDFalmig200Încă nu există evaluări

- Section 2 PT Systems: Developed by The Pti Edc-130 Education CommitteeDocument40 paginiSection 2 PT Systems: Developed by The Pti Edc-130 Education CommitteeKhaled AbdelbakiÎncă nu există evaluări

- FREYSSIBAR prestressing system overviewDocument12 paginiFREYSSIBAR prestressing system overviewFelix Untalan Ebilane JrÎncă nu există evaluări

- CFS Stone Support and RestraintDocument9 paginiCFS Stone Support and Restraintab8ccw5288Încă nu există evaluări

- 01 PTE Unbonded System 02 070909Document9 pagini01 PTE Unbonded System 02 070909Aizaz ShaikhÎncă nu există evaluări

- Case Study HighriseDocument13 paginiCase Study HighriseKhush TiwariÎncă nu există evaluări

- M50 enDocument338 paginiM50 entomwilkinsÎncă nu există evaluări

- CTT Pot BearingsDocument16 paginiCTT Pot BearingswpchengÎncă nu există evaluări

- TENSACCIAI - Rock and Soil AnchorsDocument0 paginiTENSACCIAI - Rock and Soil Anchorsnovakno1Încă nu există evaluări

- Pre StressingDocument48 paginiPre StressingRameshÎncă nu există evaluări

- EFS Post Tensioning System - Technical BrochureDocument18 paginiEFS Post Tensioning System - Technical BrochureLuan Truong VanÎncă nu există evaluări

- Con CastDocument5 paginiCon CastZubair AhmadÎncă nu există evaluări

- 060417163938preview - CP 65-1-1999+err1Document9 pagini060417163938preview - CP 65-1-1999+err1Raabbit VithyeaÎncă nu există evaluări

- MK4 Posttensioning SpecificationsDocument28 paginiMK4 Posttensioning SpecificationsshashireshÎncă nu există evaluări

- Post Tensioned SlabsDocument11 paginiPost Tensioned SlabsTlvs MurthyÎncă nu există evaluări

- Esr 2408Document41 paginiEsr 2408rolandoriÎncă nu există evaluări

- Halfen Coupler Mechanical Rebar SplicingDocument33 paginiHalfen Coupler Mechanical Rebar Splicingcarlosfilipegomes3994Încă nu există evaluări

- Screen Sand ControlDocument20 paginiScreen Sand ControlsaptagunungÎncă nu există evaluări

- Hollow Core Planks Application and Design GuideDocument46 paginiHollow Core Planks Application and Design Guidemixi1978100% (1)

- Lenton TerminatorDocument8 paginiLenton Terminatordanker1988Încă nu există evaluări

- Construction Solutions for EngineersDocument16 paginiConstruction Solutions for EngineersFida GÎncă nu există evaluări

- Lenotec 1Document20 paginiLenotec 1Graham Mark BennettÎncă nu există evaluări

- 02-Why Post Tension Floors R1Document36 pagini02-Why Post Tension Floors R1Saqlain AwanÎncă nu există evaluări

- Cast in Lifting LoopsDocument8 paginiCast in Lifting LoopsAnonymous 1js1YzeFÎncă nu există evaluări

- Technical ManualDocument36 paginiTechnical Manualneeshakothari31Încă nu există evaluări

- Flowtite Pipe Systems Technical GuideDocument36 paginiFlowtite Pipe Systems Technical Guide76027074Încă nu există evaluări

- Prestresed ConcreteDocument6 paginiPrestresed ConcreteSantoshÎncă nu există evaluări

- Tensacciaia Rock AnchorsDocument28 paginiTensacciaia Rock AnchorsjoebriffaÎncă nu există evaluări

- Composite Floor System: Better BuildingDocument84 paginiComposite Floor System: Better BuildingDuc HoangÎncă nu există evaluări

- Dywidag High Strength BarsDocument4 paginiDywidag High Strength Barsnishchint100% (1)

- GB Heco-Topix CC T Hcs BrochureDocument8 paginiGB Heco-Topix CC T Hcs BrochureBogdan PopÎncă nu există evaluări

- Steel FrameDocument16 paginiSteel FrameFernando DomeniconiÎncă nu există evaluări

- Metal Perforated CeilingDocument6 paginiMetal Perforated CeilingkripeshdubeyÎncă nu există evaluări

- PCI Bridge Manual Chapter on Precast Concrete Bridge ComponentsDocument28 paginiPCI Bridge Manual Chapter on Precast Concrete Bridge ComponentsJosue LewandowskiÎncă nu există evaluări

- Dywidag DSI Bonded PT SystemDocument44 paginiDywidag DSI Bonded PT SystemxlogicyÎncă nu există evaluări

- Freyssinet Cipec Expansion JointsDocument20 paginiFreyssinet Cipec Expansion JointsIalomiteanu DanÎncă nu există evaluări

- Gratings BrochureDocument22 paginiGratings BrochureN P Srinivasarao100% (2)

- Concrete: Testing EquipmentsDocument15 paginiConcrete: Testing EquipmentsMorched TounsiÎncă nu există evaluări

- Reinforced Concrete Buildings: Behavior and DesignDe la EverandReinforced Concrete Buildings: Behavior and DesignEvaluare: 5 din 5 stele5/5 (1)

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerDe la EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerEvaluare: 5 din 5 stele5/5 (1)

- Concrete Pipes, Bricks & Blocks World Summary: Market Values & Financials by CountryDe la EverandConcrete Pipes, Bricks & Blocks World Summary: Market Values & Financials by CountryÎncă nu există evaluări

- Weld Like a Pro: Beginning to Advanced TechniquesDe la EverandWeld Like a Pro: Beginning to Advanced TechniquesEvaluare: 4.5 din 5 stele4.5/5 (6)

- The Comprehensive Manual of Track Maintenance VOLUME 1De la EverandThe Comprehensive Manual of Track Maintenance VOLUME 1Încă nu există evaluări

- Structural Concrete: Materials; Mix Design; Plain, Reinforced and Prestressed Concrete; Design TablesDe la EverandStructural Concrete: Materials; Mix Design; Plain, Reinforced and Prestressed Concrete; Design TablesEvaluare: 3.5 din 5 stele3.5/5 (13)

- All-in-One Manual of Industrial Piping Practice and MaintenanceDe la EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceEvaluare: 5 din 5 stele5/5 (1)

- Handbook of PVC Pipe Design and Construction: (First Industrial Press Edition)De la EverandHandbook of PVC Pipe Design and Construction: (First Industrial Press Edition)Încă nu există evaluări

- F2016L00416VOL02Document20 paginiF2016L00416VOL02Hamidah Mohd HazarudinÎncă nu există evaluări

- CFDPOST KeyframeAnimation DOC PDFDocument8 paginiCFDPOST KeyframeAnimation DOC PDFOmar Lopez C.Încă nu există evaluări

- Axial Shortening Effect On Vertical ElementDocument7 paginiAxial Shortening Effect On Vertical Elementnovakno1Încă nu există evaluări

- Introduction CFDPostDocument24 paginiIntroduction CFDPostSathi MechÎncă nu există evaluări

- AutoCAD 2013-2014 DGN Hotfix ReadmeDocument3 paginiAutoCAD 2013-2014 DGN Hotfix ReadmeKodali Naveen KumarÎncă nu există evaluări

- CTT Pot BearingsDocument16 paginiCTT Pot BearingswpchengÎncă nu există evaluări

- TENSACCIAI - Stay CablesDocument0 paginiTENSACCIAI - Stay Cablesnovakno1Încă nu există evaluări

- Construction and Design of Multistorey Building by Abhimanyu ParidaDocument38 paginiConstruction and Design of Multistorey Building by Abhimanyu Paridashadz27Încă nu există evaluări

- BOF32 - Drewett - en 1504 PresentationDocument33 paginiBOF32 - Drewett - en 1504 PresentationUygar KöprücüÎncă nu există evaluări

- TENSACCIAI - Stay Cable SystemDocument0 paginiTENSACCIAI - Stay Cable Systemnovakno1Încă nu există evaluări

- Structure 201101Document60 paginiStructure 201101Ahmad Al-MusaÎncă nu există evaluări

- LRFD Composite Beam Design With Metal DeckDocument12 paginiLRFD Composite Beam Design With Metal DeckJajun IchromÎncă nu există evaluări

- An Introduction To The Network ArchDocument29 paginiAn Introduction To The Network ArchSzabolcs Attila KöllőÎncă nu există evaluări

- EN1537 Ground AnchorsDocument8 paginiEN1537 Ground AnchorsGeorg VatsellasÎncă nu există evaluări

- TENSACCIAI - Soil and Rock AnchorsDocument0 paginiTENSACCIAI - Soil and Rock Anchorsnovakno1Încă nu există evaluări

- TENSACCIAI - Rock and Soil AnchorsDocument0 paginiTENSACCIAI - Rock and Soil Anchorsnovakno1Încă nu există evaluări

- The Mathematics of Gambling (Edward O. Thorpe)Document75 paginiThe Mathematics of Gambling (Edward O. Thorpe)novakno1100% (1)

- TENSACCIAI - Post-Tensioning SystemDocument29 paginiTENSACCIAI - Post-Tensioning Systemnovakno1Încă nu există evaluări

- Linton Coupler LT0381Document20 paginiLinton Coupler LT0381Sayed Diab AlsayedÎncă nu există evaluări

- Summary Refinery Sulfur Recovery ProjectsDocument8 paginiSummary Refinery Sulfur Recovery ProjectsAli MÎncă nu există evaluări

- Springhill Suites by Marriott / Houston Brookhollow Remit To:2750 N.Loop West, Houston TX 77092 713.290.9242Document1 paginăSpringhill Suites by Marriott / Houston Brookhollow Remit To:2750 N.Loop West, Houston TX 77092 713.290.9242Josué SalazarÎncă nu există evaluări

- HandoutDocument4 paginiHandoutZack CullenÎncă nu există evaluări

- Ajwin Handbuch enDocument84 paginiAjwin Handbuch enEnzo AguilarÎncă nu există evaluări

- FloridaSharkman ProtocolsDocument14 paginiFloridaSharkman ProtocolsgurwaziÎncă nu există evaluări

- Applying Graph Theory to Map ColoringDocument25 paginiApplying Graph Theory to Map ColoringAnonymous BOreSFÎncă nu există evaluări

- Calculate Capacity of Room Air Conditioner: Room Detail Unit Electrical Appliances in The RoomDocument2 paginiCalculate Capacity of Room Air Conditioner: Room Detail Unit Electrical Appliances in The Roomzmei23Încă nu există evaluări

- Degrees of Comparison: When We Compare Two Nouns: Comparative. When We Compare Three or More Nouns: SuperlativeDocument6 paginiDegrees of Comparison: When We Compare Two Nouns: Comparative. When We Compare Three or More Nouns: SuperlativeMerlina AryantiÎncă nu există evaluări

- DISADVANTAGESDocument3 paginiDISADVANTAGESMhd MiranÎncă nu există evaluări

- Raj Priya Civil Court Clerk FinalDocument1 paginăRaj Priya Civil Court Clerk FinalRaj KamalÎncă nu există evaluări

- Reg OPSDocument26 paginiReg OPSAlexandru RusuÎncă nu există evaluări

- MRI Week3 - Signal - Processing - TheoryDocument43 paginiMRI Week3 - Signal - Processing - TheoryaboladeÎncă nu există evaluări

- 1989 Volvo 740 Instruments and ControlsDocument107 pagini1989 Volvo 740 Instruments and Controlsskyliner538Încă nu există evaluări

- Blackmagic RAW Speed TestDocument67 paginiBlackmagic RAW Speed TestLeonardo Terra CravoÎncă nu există evaluări

- Guidelines To MAS Notice 626 April 2015Document62 paginiGuidelines To MAS Notice 626 April 2015Wr OngÎncă nu există evaluări

- Certification of Psychology Specialists Application Form: Cover PageDocument3 paginiCertification of Psychology Specialists Application Form: Cover PageJona Mae MetroÎncă nu există evaluări

- 09 Lift Cylinder Drift (Bulldozer) - CheckDocument2 pagini09 Lift Cylinder Drift (Bulldozer) - CheckFredy Manrique AstoÎncă nu există evaluări

- Lesson Plan Earth & SpaceDocument5 paginiLesson Plan Earth & SpaceSol Vega PagdangananÎncă nu există evaluări

- 8510C - 15, - 50, - 100 Piezoresistive Pressure Transducer: Features DescriptionDocument3 pagini8510C - 15, - 50, - 100 Piezoresistive Pressure Transducer: Features Descriptionedward3600Încă nu există evaluări

- Asset Valuation: Debt Investments: Analysis and Valuation: 1 2 N M 1 2 N MDocument23 paginiAsset Valuation: Debt Investments: Analysis and Valuation: 1 2 N M 1 2 N MSirSmirkÎncă nu există evaluări

- Polygon shapes solve complex mechanical problemsDocument6 paginiPolygon shapes solve complex mechanical problemskristoffer_mosshedenÎncă nu există evaluări

- The Act of Proclamation of The Independence of The Filipino PeopleDocument33 paginiThe Act of Proclamation of The Independence of The Filipino PeopleJULIANA RAE CONTRERASÎncă nu există evaluări

- Epri ManualDocument62 paginiEpri Manualdrjonesg19585102Încă nu există evaluări

- CEA-2010 by ManishDocument10 paginiCEA-2010 by ManishShishpal Singh NegiÎncă nu există evaluări

- Fees Structure For Government Sponsored (KUCCPS) Students: University of Eastern Africa, BaratonDocument3 paginiFees Structure For Government Sponsored (KUCCPS) Students: University of Eastern Africa, BaratonGiddy LerionkaÎncă nu există evaluări

- UNIT- 5 IRSDocument78 paginiUNIT- 5 IRSganeshjaggineni1927Încă nu există evaluări

- New Microsoft Word DocumentDocument1 paginăNew Microsoft Word Documentshubhangiw17Încă nu există evaluări

- Berserker - Lifting Wood and Stone Like A Viking Strongman Bodybuilding Functional StrengthDocument10 paginiBerserker - Lifting Wood and Stone Like A Viking Strongman Bodybuilding Functional Strengthluciferr71Încă nu există evaluări

- Pirates and Privateers of the Caribbean: A Guide to the GameDocument25 paginiPirates and Privateers of the Caribbean: A Guide to the GameLunargypsyÎncă nu există evaluări

- Subtracting-Fractions-Unlike DenominatorsDocument2 paginiSubtracting-Fractions-Unlike Denominatorsapi-3953531900% (1)