Documente Academic

Documente Profesional

Documente Cultură

Series: Cylinder With Lock

Încărcat de

martc35Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Series: Cylinder With Lock

Încărcat de

martc35Drepturi de autor:

Formate disponibile

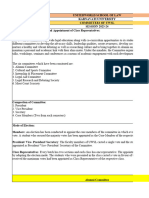

Cylinder with Lock

Series CNS/ 125, 140, 160

A locking cylinder ideal for intermediate stops, emergency stops and drop prevention.

CL MLG CNA CNG MNB CNS CLS CB CV/MVG CXW CXS CXT MX MXU MXH MXS MXQ MXF MXW MXP MG MGP MGQ

Series Variations

Standard variations Series Action Model Built-in auto switch magnets With rod boot Lock type Spring locking Standard Bore size stroke (mm) (mm)

MGG MGC MGF MGZ CY MY

3.6-1

Cylinder with lock

Series CNS

Double acting

Single rod

Series CNS

125 140 160

Maximum 1600

A locking cylinder ideal f emergency stops an

Cylinder with Lock

Simple construction

Steel balls

A force magnifying mechanism is employed based on the wedge effect of a taper ring and steel balls.

Taper ring

Series

CNS

f R R

Enhanced locking efficiency

Greater locking efficiency as well as stable locking and unlocking operation has been achieved by arranging a large number of steel ball bearings in circular rows. The floating taper ring provides alignment and stable locking force with respect to piston rod eccentricity. (Unlocking pressure of 0.25MPa ...... 0.05MPa lower than conventional SMC products)

Greater reliability and stable holding force

Outstanding durability and stable holding force are maintained through the use of a substantially lengthened brake shoe which provides superior wear resistance. (Double that of a conventional SMC product)

A metal rod scraper is standard

3.6-2

Resistance against welding process spatter and other external contaminants is achieved by providing a metal rod scraper as standard.

CL

for intermediate stops, nd drop prevention.

Maximum piston speed: 500mm/s

CL MLG CNA CNG MNB CNS CLS CB CV/MVG CXW CXS CXT MX MXU MXH MXS MXQ MXF MXW MXP MG MGP MGQ MGG MGC

Standard variations Series Action Model Built-in auto switch magnets With rod boot Lock type Spring locking Bore size (mm) Standard stroke (mm) Maximum 1600

Within the allowable kinetic energy range, speeds between 50 to 500mm/s can be achieved.

In the event that the air supply is cut off or unavailable, unlocking can be performed with a commercially available tool. The fail safe mechanism locks again when the manual override is released.

Simple manual override

Enclosed construction minimizes influences of poor air quality

Separation of the lock mechanism and the unlocking piston chamber produces a structure which is resistant to moisture and drainage in compressed air.

Compact lock unit saves space

The lock unit is extremely compact, without a large overhang.

Can be locked in both directions

Holding force is equal on either extend or retract.

Series Variations

MGF MGZ CY MY

Cylinder with lock

Series CNS

Double acting

Single rod

Series CNS

125 140 160

CL

3.6-3

Cylinder with Lock

Double Acting: Single Rod

Series

CNS L CDNS L

Tubing material

Nil Aluminum tubing Steel tubing

125, 140, 160

125 125

CNS

100 100 D D A53

Cylinder unit auto switch type

Nil Without auto switch

Select applicable auto switch models from the table below.

How to Order

Standard Type With Auto Switch

With auto switch Mounting brackets

B L F G C D T

Basic type Foot type Front flange type Rear flange type Single clevis type Double clevis type Centre trunnion type

Locking direction

D Both directions

Steel tubing is not available with auto switches.

Number of auto switches Cylinder

Rod boot Nil 2 pcs. 1 pc. "n" pcs.

J K

Nil

Nylon tarpaulin Heat resistant tarpaulin Rubber bumper at both ends Without bumpers With front bumper With rear bumper

S n

Bore size

125 140 160

125mm 140mm 160mm

Cushion

N R H

Cylinder stroke (mm)

Refer to the maximum stroke table on page 3.6-5

Indicate in alphabetical order when 2 or more symbols are applicable.

Internal magnet cylinder part numbers

In the case of internal magnets with no auto switches, the auto switch type symbol is "Nil". (Example) CDNSL140-100-D

Applicable auto switches

Indicator light Load voltage Wiring (output) 3 wire (NPN equiv.) Yes Grommet Terminal conduit DIN terminal Diagnostic indication (2 colour indicator) Grommet 3 wire (NPN) Grommet 3 wire (PNP) 2 wire Terminal conduit Diagnostic indication (2 colour indicator)

Water resistant (2 colour indicator)

Type

Special function

Electrical entry

Auto switch models Tie-rod Band mount mount

Lead wire length (m) 0.5 (Nil) 3 5 (L) (Z) None IC circuit IC circuit IC circuit IC circuit Relay, PLC Applicable loads

DC 5V 12V 12V 5V, 12V

AC 100V, 200V

A56 A53 A54 A67 A64

Solid state switches

IC circuit IC circuit

PLC Relay, PLC PLC Relay, PLC PLC Relay, PLC

Mounting brackets/ Part numbers

Refer to page 3.6-6 for the part numbers of mounting brackets for other than the basic air cylinder.

No 2 wire Yes 24V

5V, 12V 200V or less 12V

A33 A34 A44

100V, 200V 100V, 200V

A59W F59 F5P J51 J59

24V 5V, 12V 12V 5V, 12V 12V 5V, 12V 24V

Reed switches

3 wire (NPN) 2 wire Yes 3 wire (NPN) 3 wire (PNP)

G39 K39

F59W

F5PW J59W F5BAL F5NTL F59F F5LF

Grommet

2 wire 3 wire (NPN) 4 wire (NPN)

12V 5V, 12V

With timer

With diagnostic output (2 colour indicator) Latch type with diagnostic output (2 colour indicator)

Lead wire length symbols 0.5m .... Nil (Example) A53 3m ....... L A53L 5m ....... Z A53Z

Auto switches marked with a "" are produced upon receipt of order.

Auto switch mounting bracket part nos.

Auto switch models D-A5/A6/A59W/F5/J5/F5NTL D-F5W/J59W/F5BA/F59F D-A3/A44/G39/K39 Bore size (mm) 125 BT-12 BS1-125 140 BT-12 BS1-140 160 BT-16 BS1-160

Stainless Steel Mounting Screw Kit The following stainless steel mounting screw kit (including set screws) has been prepared for use depending upon the operating environment. (Mounting brackets are not included, and must be ordered separately.) BBA1: For D-A5/A6/F5/J5 The above stainless steel switches are used when a cylinder is shipped with D-F5BAL type switches mounted. BBA1 is also included when switches are shipped separately.

3.6-4

Cylinder with Lock

Double Acting: Single Rod

Models

Series Type Non-lube type Action Double acting

Series

CNS

Bore size (mm) 125, 140, 160

Locking Spring locking

CNS CDNS

Cylinder Specifications

Type Fluid Proof pressure Maximum operating pressure Minimum operating pressure Piston speed Non-lube type Air 1.46MPa {14.9kgf/cm} 0.97MPa {9.9kgf/cm} 0.08MPa {0.82kgf/cm} 50 to 500mm/s Without auto switch: 0C to 70C With auto switch : 0C to 60C Yes

1.0 1.4 + 2.2 to 250: + 0 , 251 to 1000: + 0 , 1001 to 1500: + 1.8 0 , 1501 to 1600: 0

CL MLG CNA CNG MNB CNS CLS CB CV/MVG CXW CXS CXT MX MXU MXH

Unit: mm

Symbol

Ambient and fluid temperature Cushion Stroke length tolerance Mounting brackets

(With no freezing)

Basic type, Axial foot type, Front flange type, Rear flange type, Single clevis type, Double clevis type, Centre trunnion type

There are load limitations depending on the piston speed when locked, the mounting orientation and the operating pressure.

Lock Specifications

Locking Unlocking pressure Locking pressure Maximum operating pressure Locking direction Spring locking (exhaust locking) 0.25MPa {2.5kgf/cm} or more 0.20MPa {2.0kgf/cm} or less 0.25 to 0.7MPa {2.5 to 7.1kgf/cm} Both directions

) are for steel tubing.

Maximum Stroke Table/Numbers inside (

Bore size (mm)

Maximum stroke Basic type, Rear flange type, Single clevis type, Double clevis type, Centre trunnion type to 1000 (to 1000) to 1200 (to 1200) Foot type, Front flange type to 1400 (to 1600) to 1400 (to 1600)

MXS MXQ MXF MXW MXP MG MGP MGQ MGG MGC MGF MGZ CY MY

125, 140 160

Auto switches are not available with steel tubing.

Stopping Accuracy

Unit: mm

Locking

Spring locking

Piston speed (mm/s) 100 0.5 300 1.0 500 2.0

Conditions/Horizontal, supply pressure P = 0.5MPa {5kgf/cm} Load weight Upper limit of allowed values Solenoid valve for locking Mounted directly to unlocking port Maximum value taken from the range of 100 measured stopping positions

Holding force for Spring Locking (Maximum Static Load)

Bore size (mm) Holding force KN {kgf}

125

8.4 {859}

140

10.5 {1077}

160

13.8 {1407}

Be sure to make cylinder selections in accordance with the method given on page 3.6-17

3.6-5

Cylinder with Lock

Double Acting: Single Rod

Mounting Brackets/Part Numbers

Bore size (mm) Foot type

Note 1) Note 2)

Series

CNS

60C

Rod Boot Materials

160

CS1-L16 CS1-F16 CS1-C16 CS1-D16 Symbol Material Nylon tarpaulin Heat resistant tarpaulin Maximum ambient temperature 100C

125

CS1-L12 CS1-F12 CS1-C12 CS1-D12

140

CS1-L14 CS1-F14 CS1-C14 CS1-D14

J K

Flange type

Single clevis type Double clevis type

Note 3)

Maximum ambient temperature for the rod boot itself.

Note 1) When ordering foot brackets, 2 pcs. should be ordered for each cylinder. Note 2) 125 to 160 front flange types use Series CS1 long stroke flanges. Note 3) A clevis pin, flat washer and cotter pin are packed with the double clevis type.

Accessories

Mounting brackets Standard equipment Clevis pin Rod end nut Options Single knuckle joint Double knuckle joint (with pin) With rod boot Basic type Foot type Front flange type Rear flange type Single clevis type Double clevis type Centre trunnion type

Weight Table/Numbers inside (

Bore size (mm) Lock unit weight Basic type Foot type Flange type Basic weight Single clevis type Double clevis type

(includes clevis pin & cotter pin)

) are for steel tubing (kg)

Auto Switch Weight Table

(kg) Auto switch type Model D-A5/A6 D-A59W Reed switch D-A3 D-A4 D-A9 D-F5/J5 Solid state D-G39/K39 switch D-F9 Lead wire Switch Switch + Mounting bracket length Unit 125 140 160 0.5m 3 m 0.5m 3 m 0.5m 3 m 0.5m 3 m 0.024 0.080 0.116 0.114 0.008 0.041 0.023 0.081 0.116 0.007 0.037 0.037 0.095 0.156 0.037 0.095 0.160 0.042 0.098 0.165 0.038 0.094 0.156 0.154 0.038 0.094 0.160 0.158 0.041 0.097 0.165 0.163

125

14.40 28.79 (30.26) 30.42 (31.89) 31.47 (32.94) 31.86 (33.33) 32.32 (33.79) 32.92 (34.39) 1.77 (2.66) 0.91 1.37 0.16

140

20.20 37.67 (39.48) 40.19 (42.00) 42.67 (44.48) 41.96 (43.77) 42.71 (44.52) 43.40 (45.21) 1.96 (3.01) 1.16 1.81 0.16

160

30.60 55.31 (57.52) 58.11 (60.32) 61.70 (63.91) 60.80 (63.01) 61.65 (63.86) 62.71 (64.92) 2.39 (3.58) 1.56 2.48 0.23

Trunnion type Additional weight per 100mm of stroke Single knuckle Accessories Double knuckle (with pin) Rod end nut

Calculation (Ex.) CNSL140-100

Basic weight 40.19 (foot type, 140) Additional weight 1.96/100 stroke Cylinder stroke 100mm stroke 40.19 + 1.96 x 100/100 = 42.15kg

Construction Principle

Brake shoe holder Brake shoe Release piston Air pressure exhaust Air pressure supply Steel balls Ball retainer Taper ring Brake spring

A

Spring Locking (Exhaust Locking) The spring force which acts upon the taper ring is magnified by a wedge effect, and is conveyed to all of the numerous steel balls which are arranged in two circles. These act on the brake shoe holder and brake, which locks the piston rod by tightening against it with a large force. Unlocking is accomplished when air pressure is supplied to the unlocking port. The release piston and taper ring oppose the spring force, moving to the right side, and the ball retainer strikes the cover section A. The braking force is released as the steel balls are removed from the taper ring by the ball retainer.

Locked condition

Unlocked condition

3.6-6

Series

CNS

Construction

CL MLG CNA CNG MNB CNS CLS CB

Parts list

No. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 Description Cover A Cover B Rod cover Head cover Cylinder tube Piston rod Piston Release piston Cushion ring A Cushion ring B Retaining plate B Tie-rod A Unit holding tie-rod Bushing Brake spring Pre-load spring Clip A Clip B Cushion valve Valve guide Taper ring Ball retainer Tooth ring Brake shoe Brake shoe holder Piston guide Coil scraper mounting plate Bumper Washer Material Aluminum alloy Aluminum alloy Rolled steel plate Rolled steel plate Aluminum alloy Carbon steel Aluminum alloy casting Aluminum alloy Rolled steel Rolled steel Bronze casting Carbon steel Carbon steel Lead bronze casting Steel wire Steel wire Stainless steel wire Stainless steel wire Rolled steel Brass Carbon steel Aluminum alloy Stainless steel Special friction material Special steel Carbon steel Aluminum alloy Polyurethane rubber Carbon steel Note Hard anodized & coated Hard anodized & coated Black coated Black coated Hard anodized Hard chrome plated Chromated Chromated Zinc chromated Zinc chromated Chromated Chromated Black coated Zinc chromated

Parts list

No. 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 Description Unlocking cam Wing nut Steel ball A Steel ball B

C type snap ring for shaft (for taper ring)

C type snap ring for shaft (for unlocking cam)

CV/MVG

Material Carbon steel Carbon steel Note Zinc chromated 125,140 nickel plated 160 black zinc chromated

CXW CXS CXT MX MXU MXH MXS MXQ MXF MXW MXP MG MGP MGQ MGG

Bushing (for release piston)

Hexagon socket head cap screw Hexagon socket head cap screw

Electroless nickel plated Heat treated

Heat treated Zinc chromated Anodized Colorless zinc chromated

Conical spring washer Conical spring washer Spring washer Hexagon nut Wear ring BC element Coil scraper Wiper ring Cushion seal Rod seal Piston seal 0-ring (for release piston) 0-ring (for piston guide) 0-ring (for unlocking cam) Valve seal Retaining plate gasket Piston gasket Guide gasket Tube gasket

Carbon steel Carbon steel Carbon steel Black oxide finish Carbon steel Nickel plated Lead bronze casting Chromium molybdenum steel Nickel plated Chromium molybdenum steel Nickel plated Nickel plated Spring steel Nickel plated Spring steel Steel wire Black zinc chromated Rolled steel Black zinc chromated Resin Phosphor bronze NBR NBR NBR NBR NBR NBR NBR NBR NBR NBR NBR NBR

Replacement parts/Seal kits

Bore size (mm) Seal kit CS1N125A-PS CS1N125A-PS CS1N125A-PS Contents A set of above Nos. 46, 48, 49, 53, 54, 57

125 140 160

MGC MGF MGZ CY MY

3.6-7

Since the lock section for Series CNS is normally replaced as a unit, replacement seal kits are for the cylinder section only. Order using the seal kit for each bore size. Seal kits are sets consisting of items 46, 48, 49, 53, 54 and 57, which can be ordered using the seal kit for each cylinder bore size.

Series

CNS

Dimensions

Basic type/CNSB

2-MA Effective thread depth R M

Width across flats KA

GA Rc(PT) BP Unlocking port

Rc(PT) BQ Plug with breathing hole BC element G 2-Rc(PT) P Cylinder port G

CL T GR GL

FA GB

MM

E EA D

AL A

VA K H F

BN ZZ + Stroke

N S + Stroke

N M

C B

4-J

With rod boot

75

15 h+l

40

ZZ1 + l + Stroke

(mm) Bore size (mm) Stroke range (mm) to 1000 to 1000 to 1200

A

50 50 56

AL

47 47 53

B

145 161 182

BN

205 245 290

BP

1/2 1/2 1/2

BQ

3/8 3/8 3/8

C

115 128 144

CL

120 136 144

D

36 36 40

E

90 90 90

EA

63 63 63

F

35 35 43

FA

14 14 14

G

16 16 18.5

GA

155 180 215 (mm)

GB

23 28 35

GL

25 30 35

GR

30 30 35

J

M14 x 1.5 M14 x 1.5 M16 x 1.5

125 140 160

Bore size (mm)

K

15 15 17

KA

31 31 36

M

27 27 30.5

MA

M12 x 1.75 M12 x 1.75 M12 x 1.75

MM

M30 x 1.5 M30 x 1.5 M36 x 1.5 (mm)

N

35 35 39

P

1/2 1/2 3/4

Q

85.5 93.5 104

R

25 25 25

S

303 343

T

87.5 95

V

20 20 25

VA

23 28 35

ZZ

125 140 160

110 440 110 480 120 546.5

396 109

With rod boot

Bore size (mm) Stroke range (mm) to 1000 to 1000 to 1200

ZZ1

463 503 567.5

l

0.2 stroke 0.2 stroke 0.2 stroke

h

133 133 141

125 140 160

3.6-8

Cylinder with Lock

Double Acting: Single Rod

Foot type/CNSL

A AL H K GA F GB FA Rc(PT)BP Unlocking port Rc(PT)BQ Plug with breathing hole BC element 2-Rc(PT)P G G Cylinder port

Series

CNS

4-J

2-MA Effective thread depth R

CL T GR GL

MM

CL

Q LY

E EA D

MLG

V LH

Width across flats KA

4-LD

CNA CNG MNB CNS CLS CB CV/MVG CXW CXS

LT

VA Y X

BN

N S + Stroke LS + Stroke ZZ + Stroke

N X Y

LX C B

With rod boot

75

15

40

h+l ZZ1 + l + Stroke Rc(PT) BQ Plug with breathing hole A AL H K GA F GB Rc(PT) BP FA Unlocking port BC element 2-Rc(PT) P G Cylinder port

Long strokes

2-MA Effective thread depth R CL T GR GL 4-J

CXT MX MXU

MM

E EA D

RY

MXH MXS MXQ MXF MXW

(mm)

LY

Width across flats KA

VA LT Y X

BN

N S + Stroke LS + Stroke ZZ + Stroke

RT

N X Y

LH

4-LD

LX C B

Bore size (mm)

Stroke range (mm) to 1400 to 1400 to 1400

A

50 50 56

AL

47 47 53

B

145 161 182

BN

205 245 290

BP

1/2 1/2 1/2

BQ

3/8 3/8 3/8

C

115 128 144

CL

120 136 144

D

36 36 40

E

90 90 90

EA

63 63 63

F

35 35 43

FA

14 14 14

G

16 16 18.5

GA

155 180 215

GB

23 28 35

GL

25 30 35

GR

30 30 35

J

M14 x 1.5 M14 x 1.5 M16 x 1.5 (mm)

MXP MG MGP MGQ MGG MGC MGF MGZ CY MY

125 140 160

Bore size (mm)

K

15 15 17

KA

31 31 36

LD

19 19 19

LH

85 100 106

LS

393 433 496

LT

8 9 9 (mm)

LX

100 112 118

LY

157.5 180.5 197

MM

M30 x 1.5 M30 x 1.5 M36 x 1.5

N

35 35 39

P

1/2 1/2 3/4

Q

85.5 93.5 104

R

25 25 25

S

303 343

T

87.5 95

V

20 20 25

VA

23 28 35

X

45 45 50

Y

20 30 25

H

110 110 120

ZZ

478 528 591

125 140 160

396 109

With rod boot

Bore size (mm) Stroke range (mm) to 1400 to 1400 to 1400

For long strokes

Bore size (mm) Stroke range (mm) 1401 to 1600 1401 to 1600 1401 to 1600

(mm)

ZZ1

501 551 612

l

0.2 stroke 0.2 stroke 0.2 stroke

h

133 133 141

RT

36 36 45

RY

164 184 204

125 140 160

125 140 160

Not available with auto switches.

3.6-9

Series

CNS

Dimensions

Front flange type/CNSF

M T GL GR 4-J 4-FD FA

Width across flats KA

GA GB Rc(PT) BP Unlocking port

Rc(PT) BQ Plug with breathing hole BC element 2-Rc(PT) P G G Cylinder port

MM Q

FY BF

E EA D

C B FX FZ

AL A

FT K H F

VA BN N S + Stroke ZZ + Stroke N M

With rod boot

75

15

40

h+l ZZ1 + l + Stroke

Long strokes

T GL GR 4-J 4-FD

Width across flats KA

M FA GB

GA Rc(PT) BP Unlocking port

MM

Rc(PT) BQ Plug with breathing hole BC element 2-Rc(PT) P G G Cylinder port

FY BF

E EA D

C B FX FZ

AL A

K H

FT F

VA BN N S + Stroke ZZ + Stroke RT N M

RY

(mm) Bore size (mm) Stroke range (mm) to 1400 to 1400 to 1400

A

50 50 56

AL

47 47 53

B

145 161 182

BF

145 160 180

BN

205 245 290

BP

1/2 1/2 1/2

BQ

3/8 3/8 3/8

C

115 128 144

D

36 36 40

E

90 90 90

EA

63 63 63

F

35 35 43

FA

14 14 14

FD

19 19 19

FT

14 20 20

FX

190 212 236

FY

100 112 118 (mm)

FZ

230 255 275

G

16 16 18.5

GA

155 180 215

125 140 160

Bore size (mm)

GB

23 28 35

GL

25 30 35

GR

30 30 35

J

M14 x 1.5 M14 x 1.5 M16 x 1.5

K

15 15 17 (mm)

KA

31 31 36

M

19 19 22

MM

M30 x 1.5 M30 x 1.5 M36 x 1.5

N

35 35 39

P

1/2 1/2 3/4

Q

85.5 93.5 104

S

303 343 396 (mm)

T

87.5 95 109

V

20 20 25

VA

23 28 35

H

110 110 120

ZZ

432 472 538

125 140 160

With rod boot

Bore size (mm) Stroke range (mm) to 1400 to 1400 to 1400

For long strokes

Bore size (mm) Stroke range (mm) 1401 to 1600 1401 to 1600 1401 to 1600

ZZ1

455 495 559

l

0.2 stroke 0.2 stroke 0.2 stroke

h

133 133 141

RT

36 36 45

RY

164 184 204

125 140 160

125 140 160

Not available with auto switches.

3.6-10

Cylinder with Lock

Double Acting: Single Rod

Series

CNS

Rear flange type/CNSG

M FA GB

Width across flats KA

GA Rc(PT) BP Unlocking port

Rc(PT) BQ Plug with breathing hole BC element 2-Rc(PT) P G G Cylinder port

2-MA Effective thread depth R 4-FD

CL T GR GL

4-J

CL MLG CNA CNG MNB CNS CLS CB CV/MVG CXW CXS CXT MX

Q

MM

E EA D

BF FY

AL A

VA K H F BN N S + Stroke ZZ + Stroke N FT

C B FX FZ

With rod boot

75

15 h+l

40

MXU MXH MXS MXQ MXF MXW

(mm)

ZZ1 + l + Stroke

Bore size (mm)

Stroke range (mm) to 1000 to 1000 to 1200

A

50 50 56

AL

47 47 53

B 145 161 182

BF

145 160 180

BN

205 245 290

BP

1/2 1/2 1/2

BQ

3/8 3/8 3/8

C 115 128 144

CL

120 136 144

D

36 36 40

E

90 90 90

EA

63 63 63

F

35 35 43

FA

14 14 14

FD

19 19 19

FT

14 20 20

FX

190 212 236

FY

100 112 118

FZ

230 255 275

G

16 16 18.5 (mm)

GA

155 180 215

MXP MG MGP MGQ MGG MGC MGF MGZ CY MY

125 140 160

Bore size (mm)

GB

23 28 35

GL

25 30 35

GR

30 30 35

J

M14 x 1.5 M14 x 1.5 M16 x 1.5

K

15 15 17

KA

31 31 36

M

19 19 22

MA

M12 x 1.75 M12 x 1.75 M12 x 1.75

MM

M30 x 1.5 M30 x 1.5 M36 x 1.5

N

35 35 39

P

1/2 1/2 3/4

Q

85.5 93.5 104

R

25 25 25

S

303 343

T

87.5 95

V

20 20 25

VA

23 28 35

H

110 110 120

ZZ

427 473 536

125 140 160

396 109

With rod boot

Bore size (mm) Stroke range (mm) to 1000 to 1000 to 1200

(mm)

ZZ1

450 496 557

l

0.2 stroke 0.2 stroke 0.2 stroke

h

133 133 141

125 140 160

3.6-11

Series

CNS

Dimensions

Single clevis type/CNSC

M FA

Width across flats KA

GA GB Rc(PT) BP Unlocking port

Rc(PT) BQ Plug with breathing hole BC element 2-Rc(PT) P G G Cylinder port

CD Hole H10 Shaft d9

MM

E EA D

CX

AL A

VA K H F BN N S + Stroke Z + Stroke ZZ + Stroke N CT L U RR

CL T GR GL

2-MA Effective thread depth R

With rod boot

Q

75

C B

4-J

15

40

h+l Z1 + l + Stroke ZZ1 + l + Stroke

(mm) Bore size Stroke range (mm) (mm)

A

50 50 56

AL

47 47 53

B

145 161 182

BN

205 245 290

BP

1/2 1/2 1/2

BQ

3/8 3/8 3/8

C

115 128 144

CDH10

0.084 25 + 0 0.084 28 + 0 0.100 32 + 0

CL

120 136 144

CT

17 17 20

CX

0.1 32 0.3 0.1 36 0.3 0.1 40 0.3

D

36 36 40

E

90 90 90

EA

63 63 63

F

35 35 43

FA

14 14 14

G

16 16 18.5

GA GB

155 180 215 23 28 35

GL

25 30 35 (mm)

125 140 160

to 1000 to 1000 to 1200

Bore size (mm)

GR

30 30 35

J

M14 x 1.5 M14 x 1.5 M16 x 1.5

K

15 15 17

KA

31 31 36

L

65 75 80

M

19 19 22

MA

M12 x 1.75 M12 x 1.75 M12 x 1.75 (mm)

MM

M30 x 1.5 M30 x 1.5 M36 x 1.5

N

35 35 39

P

1/2 1/2

Q

85.5 93.5

R

25 25 25

RR

29 32 36

S

303 343

T

87.5 95

U

35 40 45

V

20 20 25

VA

23 28 35

H

110 110 120

Z

478 528 596

ZZ

507 560 632

125 140 160

3/4 104

396 109

With rod boot

Bore size Stroke range (mm) (mm)

Z1

501 551 617

ZZ1

530 583 653

l

0.2 stroke 0.2 stroke 0.2 stroke

h

133 133 141

125 140 160

to 1000 to 1000 to 1200

3.6-12

Cylinder with Lock

Double Acting: Single Rod

Series

CNS

Double clevis type/CNSD

M

Width across flats KA

GA GB Rc(PT) BP Unlocking port

FA

Rc(PT) BQ Plug with breathing hole BC element G G 2-Rc(PT) P Cylinder port

CD Hole H10 Shaft d9

CL MLG CNA CNG MNB

MM

EA D

CX CZ

AL A K H F

VA BN N S + Stroke Z + Stroke ZZ + Stroke N CT L RR U

CNS CLS CB CV/MVG

CL T GR GL

2-MA Effective thread depth R

With rod boot

Q

CXW CXS CXT

75

C B

15 4-J

40

MX MXU MXH MXS MXQ MXF MXW

(mm)

h+l Z1 + l + Stroke ZZ1 + l + Stroke

Bore size (mm)

Stroke range (mm) to 1000 to 1000 to 1200

A

50 50 56

AL

47 47 53

B

145 161 182

BN

205 245 290

BP

1/2 1/2 1/2

BQ

3/8 3/8 3/8

C

115 128 144

CDH10

0.084 25 + 0 + 0.084 0

CL

120 136 144

CT

17 17 20

CX

0.3 32 + + 0.1 + 0.3 + 0.1

CZ

0 640.2 0 720.2 0 800.2

D

36 36 40

E

90 90 90

EA

63 63 63

F

35 35 43

FA

14 14 14 (mm)

MXP MG MGP MGQ MGG MGC MGF MGZ CY MY

125 140 160

28

36

0.100 32 + 0

0.3 40 + + 0.1

Bore size (mm)

G

16 16 18.5

GA

155 180 215

GB

23 28 35

GL

25 30 35

GR

30 30 35

J

M14 x 1.5 M14 x 1.5 M16 x 1.5 (mm)

K

15 15 17

KA

31 31 36

L

65 75 80

M

19 19 22

MA

M12 x 1.75 M12 x 1.75 M12 x 1.75

MM

M30 x 1.5 M30 x 1.5 M36 x 1.5

N

35 35 39

P

1/2 1/2 3/4

Q

85.5 93.5 104

R

25 25 25

RR

29 32 36

S

303 343 396

T

87.5 95 109

125 140 160

With rod boot

Bore size (mm) Stroke range (mm) to 1000 to 1000 to 1200

(mm)

Bore size (mm)

U

35 40 45

V

20 20 25

VA

23 28 35

H

110 110 120

Z

478 528 596

ZZ

507 560 632

Z1

501 551 617

ZZ1

530 583 653

l

0.2 stroke 0.2 stroke 0.2 stroke

h

133 133 141

125 140 160

125 140 160

Packed with clevis pin, flat washer and cotter pin.

3.6-13

Series

CNS

Dimensions

Centre trunnion type/CNST

Z + 1/2 stroke M FA

Width across flats KA

GA GB Rc(PT) BP Unlocking port

Rc(PT) BQ Plug with breathing hole BC element G

2-Rc(PT) P Cylinder port G

2-MA Effective thread depth R

CL T GR GL

4-J

MM e8

E EA D

TY

TD

AL A

VA K H F BN S + Stroke ZZ + Stroke N TT N M

C B TX TZ

With rod boot

Z1 + l + 1/2 stroke

75

15 h+l

40

ZZ1 + l + Stroke

Bore size (mm)

Stroke range (mm) 25 to 1000 30 to 1000 35 to 1200

A

50 50 56

AL

47 47 53

B

145 161 182

BN

205 245 290

BP

1/2 1/2 1/2

BQ

3/8 3/8 3/8

C

115 128 144

CL

120 136 144

D

36 36 40

E

90 90 90

EA

63 63 63

F

35 35 43

FA

14 14 14

G

16 16 18.5

GA GB

155 180 215 23 28 35

GL

25 30 35

GR

30 30 35

J

M14 x 1.5 M14 x 1.5 M16 x 1.5

K

15 15 17 (mm)

125 140 160

Bore size (mm)

M

19 19 22

MA

M12 x 1.75 M12 x 1.75 M12 x 1.75

MM

M30 x 1.5 M30 x 1.5 M36 x 1.5

N

35 35 39

P

1/2 1/2

Q

85.5 93.5

R

25 25 25

R1

1 1.5 1.5

S

303 343

T

87.5 95

TDe8

0.050 32 0.089 0.050 36 0.089

TT

50 55 60

TX

170 190 212

TY

164 184 204

TZ

234 262 292

V

20 20 25

VA

23 28 35

H

110 110 120

Z

364 404 463

ZZ

432 472 538

125 140 160

3/4 104 (mm)

396 109

40 0.089

0.050

With rod boot

Bore size Stroke range (mm) (mm)

Z1

387 427 484

ZZ1

455 495 559

l

0.2 stroke 0.2 stroke 0.2 stroke

h

133 133 141

125 140 160

25 to 1000 30 to 1000 35 to 1200

3.6-14

R1

(mm)

KA

31 31 36

Series CNS

Accessory Dimensions

Y Type Double Knuckle Joint

H10 ND Hole Shaftd 9

Pins and snap rings for double clevis and double knuckle joint are included when shipped.

MM

8 Material: Cast iron

Applicable Part No. bore size (mm) (mm)

CL MLG CNA CNG MNB CNS CLS CB CV/MVG CXW

Material: Carbon steel

(mm) Part No. Applicable bore size (mm)

E1

NZ NX

E1

46 48 55

L1

100 105 110

MM

M30 x 1.5 M30 x 1.5 M36 x 1.5

NDH10

25 + 0.084 0 28 + 0.084 0 32 + 0.1 0

NX

+ 0.3 32 + 0.1 + 0.3 36 + 0.1 + 0.3 40 + 0.1

NZ

0.1 64 0.3 0.1 72 0.3 0.1 80 0.3

RR1

27 30 34

U1

42 47 46

U1

1 RR

L1

Y-12 Y-14 Y-16

125 140 160

Clevis Pin/Knuckle Pin

L

5

Dd9

Dd9

0.065 25 0.117 0.065 28 0.117 0.080 32 0.142

L

79.5 86.5 94.5

l

69.5 76.5 84.5

Cotter pin 4 x 40l 4 x 40l 4 x 40l

CXS CXT MX MXU MXH MXS

2-d

IY-12 IY-14 IY-16

125 140 160

I Type Single Knuckle Joint

NDH10 NX A2 MM 8 E1

Material: Cast iron

Part No. Applicable bore size (mm)

(mm)

A2

54 54 60

E1

46 48 55

L1

100 105 110

MM

M30 x 1.5 M30 x 1.5 M36 x 1.5

NDH10

25 + 0.084 0 28 + 0.084 0 32 + 0.1 0

NX

0.1 32 0.3 0.1 36 0.3 0.1 40 0.3

RR1

27 30 34

U1

33 39 39

MXQ MXF MXW MXP MG MGP MGQ MGG

U1

RR 1

L1

I-12 I-14 I-16

125 140 160

Rod End Nut

30

d Material: Rolled steel

Part No. Applicable bore size (mm) (mm)

MGC MGF MGZ CY MY

3.6-15

d

M30 x 1.5 M36 x 1.5

H

18 21

B

46 55

C

53.1 63.5

D

44 53

NT-12 NT-16

125, 140 160

Series CNS

Accessory Dimensions

Single/Double Knuckle Joint Mounting

H A 3.5

Bore size (mm)

(mm)

Symbol

H

110 110 120

A

50 50 56

L1

100 105 110

H1

156.5 161.5 170.5

Applicable knuckle joint part nos. I type single knuckle Y type double knuckle I-12 I-14 I-16 Y-12 Y-14 Y-16

L1 H1

125 140 160

A, H dimensions when single/double knuckle joint and rod end nut are mounted together

Bore size (mm)

A

65 65 76

H

125 125 140

125 140 160

Single knuckle joint and double knuckle joint should be used separately. ( Fasten by screwing completely into the rod end threads.) When using a single/double knuckle joint together with a rod end nut, the A and H dimensions should be extended. (For extension of the A and H dimensions, refer to the table above and specify the order made product -XAO.)

3.6-16

Series CNS

Model Selection

Precautions on Model Selection Step 1 Find the maximum load speed: V

Load movement time: t (S)

1. In order that the originally selected maximum speed is not exceeded, be certain to use a speed controller to adjust the total movement distance of the load so that movement takes place in no less than the applicable movement time. The movement time is the time that is necessary for the load to travel the total movement distance from the start without any intermediate stops. 2. In cases where the cylinder stroke and the movement distance of the load are different (double speed mechanism, etc.), use the movement distance of the load for selection purposes.

Caution

Find the maximum load speed: V(mm/s) from the load movement time: t(s) and the movement distance: st(mm).

CL MLG CNA CNG MNB CNS CLS CB CV/MVG CXW CXS CXT MX MXU MXH MXS MXQ MXF MXW MXP MG MGP MGQ MGG MGC MGF MGZ CY MY

Graph 1

30 20 10 5 4 3 2 1 0.5 0.4 0.3 0.2 280 200 300 400 500 1600st 1400st 1200st 1000st 800st 600st 500st 400st 300st 200st 100st

Example)

V' V W

Cylinder stroke

0.1 100

Maximum speed: V(mm/s)

Step 2

Find the cylinder bore size.

Movement distance of load

Select a graph based upon the load condition and operating pressure, and then find the point of intersection for the maximum speed found in Step 1 and the load weight. Select the bore size on the line above the point of intersection.

Selection Example

Load weight: m = 320kg Movement distance: st = 400mm Movement time: t = 2s Load condition: Vertical downward = Load in direction of rod extension Operating pressure: P = 0.4MPa

Step 1: From graph 1 find the maximum movement speed of the load Maximum speed V: approx. 280mm/s Step 2: Select Graph 6 based upon the load condition and operating pressure, and then from the intersection of the maximum speed V = 280mm/s found in Step 1, and the load weight m = 320kg 140 select a CNS140 or larger bore size.

Load condition

Direction of load at right angle to rod ( Being held by a guide)

Operating pressure

from 0.3MPa

Graph 2

m

F

from 0.4MPa

Graph 3

from 0.5MPa

Graph 4

Load in direction of rod extension Load in direction of rod retraction

m

F

from 0.3MPa

Graph 5

from 0.4MPa

Graph 6

m

F

from 0.5MPa

Graph 7

3.6-17

Series

CNS

0.3MPaP<0.4MPa

Selection Graphs

Graph 2

3000 2000

Graph 5

3000 2000

0.3MPaP<0.4MPa

Load weight: m(kg)

140 125 P

400 300 200

Load weight: m(kg)

1000 900 800 700 600 500

160

1000 900 800 700 600 500 400 300 200

160 140 125

100 100

200

300

400

500

100 100

200

300

400

500

Maximum speed: V(mm/s)

Maximum speed: V(mm/s) 0.4MPaP<0.5MPa

Graph 3

3000 2000

Graph 6

3000 2000

0.4MPaP<0.5MPa

160

Load weight: m(kg) Load weight: m(kg)

1000 900 800 700 600 500 400 300 200

140 125

1000 900 800 700 600 500 400 300 200 320

160 140 125

280 100 100 200 300 400 500 100 100 200 300 400 500

Maximum speed: V(mm/s)

Maximum speed: V(mm/s) 0.5MPaP

Graph 4

3000 2000

Graph 7

3000 2000

0.5MPaP

160 140 125

Load weight: m(kg)

Load weight: m(kg)

1000 900 800 700 600 500 400 300 200

1000 900 800 700 600 500 400 300 200

160 140 125

100 100

200

300

400

500

100 100

200

300

400

500

Maximum speed: V(mm/s)

Maximum speed: V(mm/s)

3.6-18

Series CNS

Auto Switch Specifications

Refer to p. 5.3-2 for further information on auto switch single body.

Applicable Auto Switch Models Specific Product Precautions

Be sure to read before handling. Refer to pages 0-39 to 0-46 for auto switch precautions.

Auto switch type Auto switch model Electrical entry Band mount Tie-rod mount Band mount Terminal conduit DIN terminal Grommet Grommet Terminal conduit Grommet Tie-rod mount Grommet Grommet Grommet Grommet Function 2 color indication With timer 2 colour indication 2 colour indication/water resistant 2 colour indication/with diagnostic output

D-A3

Reed switch

CL MLG CNA CNG MNB CNS CLS CB

D-A44 D-A5/A6 D-A59W D-G39/K39 D-F5/J5

Solid state switch

D-F5NTL D-F5W/J59W D-F5BAL D-F5F

Reed Switch Specifications

Auto switch part no. Load current Max. load current or Indicator light Contact protection load current range (mA) (lights when ON) circuit Application

CV/MVG CXW CXS CXT MX MXU MXH MXS MXQ MXF MXW MXP MG MGP MGQ MGG MGC MGF MGZ CY MY

D-A53 D-A54 D-A56 D-A64 D-A67 D-A59W D-A33 D-A34 D-A44

24VDC 24VDC 100VAC 200VAC 4 to 8VDC 24VAC/DC or less 100VAC 200VAC Max. 24VDC 24VDC 24VDC 24VDC 100VAC 200VAC

5 to 50 5 to 50 5 to 25 5 to 12.5 20 50 25 12.5 30 5 to 40 5 to 50 5 to 50 5 to 25 5 to 12.5

None None (2 colour indication)

None None None None

PLC Relay, PLC IC circuit Relay, PLC IC circuit, PLC Relay, PLC PLC Relay, PLC

In the case of D-A59W, the red indicator light goes on when at a sensing position, and the green indicator light goes on at the position of maximum sensitivity.

Solid State Switch Specifications

Auto switch part no. Wiring output 3 wire NPN 2 wire 2 wire Load voltage 28VDC or less Max. load Internal voltage Indicator light current or load drop at load (lights current range current of 10mA when ON) 40mA or less 0.8V or less 4V or less Function Application IC circuit, Relay, PLC 24VDC relay AC relay IC circuit, Relay, PLC

D-F59 D-F5P D-J59 D-J51

3 wire PNP 5, 12, 24VDC (4.5 to 28VDC) 80mA or less 24VDC (10 to 28VDC) 5 to 40mA 80 to 260VAC 28VDC or less 24VDC (10 to 28VDC) 26VDC or less 28VDC or less 28VDC or less 28VDC or less 40mA

5 to 80mA 14V or less 0.8V or less

D-F59W 3 wire NPN D-J59W D-F5BAL D-F5LF D-F59F D-G39 D-K39

D-F5PW 3 wire PNP 5, 12, 24VDC (4.5 to 28VDC) 80mA or less

2 wire 4 wire NPN 5 to 40mA

4V or less

(2 colour 24VDC relay, indication) Water resistant PLC Latch type with

diagnostic output

40mA or less 0.8V or less 80mA or less 0.8V or less 40mA or less 0.8V or less 4V or less

With diagnostic output

D-F5NTL 3 wire NPN

3 wire PNP 2 wire

Built-in OFF delay timer

IC circuit, Relay, PLC 24VDC relay, PLC

24VDC (10 to 28VDC) 5 to 40mA

The red indicator light goes on when at a sensing position , and the green indicator light goes on at the position of maximum sensitivity.

3.6-19

Series

CNS

Cylinder Unit Auto Switch Mounting Brackets/Part Nos.

Auto switch models Bore size (mm) n: Quantity Number of auto switches mounted

2 pcs.(different side, same side), 1pc.

Minimum Strokes for Mounting of Cylinder Unit Auto Switches

Auto switch models Brackets other than centre trunnion 25 25 + 55

(n - 2)

Centre trunnion type

125

125

(n - 4)

140

135 2 135 + 55

160

(n - 4)

125

140

160

D-A5, A6 D-A59W D-F5, J5

"n" pcs. (same side)

n = 2, 4, 6, 8

125 + 55

n = 4, 8, 12, 16

n = 4, 8, 12, 16

D-F5W, J59W 2 pcs.(different side, 35 same side), 1 pc. D-F5BAL D-F59F "n" pcs. (same side) 35 + 55 D-F5NTL

2 pcs. Different side Same side Different side Same side 1pc. 2 pcs. Different side Same side Different side Same side 1 pc.

D-A5/A6/A59W/ F5/J5/F5NTL F5W/J59W/ F5BAL/F5F D-A3/A4/G39/K39

BT-12

BT-12

BT-16

145

(n - 2)

155

(n - 4)

n = 2, 4, 6, 8

145 + 55

n = 4, 8, 12, 16

155 + 55 110 110

(n - 4)

BS1-125 BS1-140 BS1-160

n = 4, 8, 12, 16

[Stainless Steel Mounting Screw Kit]

The stainless steel mounting screw kit (including set screws) shown below has been prepared for use depending on the operating environment. (The mounting brackets are not included and must be ordered separately.) BBA1: For use with D-A5, A6, F5, J5 The above stainless steel screws are used when DF5BAL type switches are mounted on a cylinder at the time of shipment. BBA1 is also included when switches are shipped separately.

35 100 35 + 30 (n - 2) 100 + 100 (n - 2) 15 35 55 35 + 30 (n - 2) 55 + 55 (n - 2) 15

D-A3 D-G39 D-K39

"n" pcs.

110 + 30 (n - 2) n = 2, 4, 6, 8 110 + 100 (n - 2) n = 2, 4, 6, 8 110 110 110 110 + 30 (n - 2) n = 2, 4, 6, 8 110 + 50 (n - 2) n = 2, 4, 6, 8 110

D-A44

"n" pcs.

Cylinder Unit Auto Switches/Proper Mounting Position and Height for Stroke End Detection

<Band Mount Type>

D-A3 D-G3/K3

G(PF) 1/2 (compatible cable O.D. 6.8-9.6)

<Tie-rod mount type>

D-F5/J5/D-F5NTL D-F5BAL/F5F D-F5W/J59W

A

49

B

Approx. Ht Approx. Ht

Auto switch

56 34

36 Approx. Hs Auto switch

A 30

Approx. Hs

(33)

Numbers in ( ) are for type D-F5LF.

D-A4

G(PF)1/2 (compatible cable O.D. 6.8-11.5) 34.5

D-A5/A6

Auto switch Approx. Ht Approx. Ht

56

Approx. Hs

36

B

Auto switch (mm)

A

Approx. Hs

33

Proper auto switch mounting positions

Auto switch models

Auto switch mounting height

Auto switch models

(mm)

D-A5/A6 D-A3 D-A44 D-G39 D-K39 A

0 0 0

D-A59W

D-F5W D-J59W D-F5BAL D-F5 D-J5 A

4.5 4.5 4.5

D-F5F

D-F5NTL

D-A3 D-G39 D-K39 Hs

116 124 134.5

D-A44

D-A5 D-A6 D-A59W Hs

75.5 81 89

Bore size (mm)

B

0 0 0

A

2 2 2

B

2 2 2

B

4.5 4.5 4.5

A

8.5 8.5 8.5

B

8.5 8.5 8.5

A

9.5 9.5 9.5

B

9.5 9.5 9.5

Bore size (mm)

D-F5 D-J5 D-F5W D-J59W D-F5BAL D-F5F D-F5NTL Hs

74.5 80 88

Hs

126 134 144.5

Ht

69.5 76.5 87.5

Ht

70 76.5 87.5

125 140 160

125 140 160

3.6-20

Series CNS

Specific Product Precautions 1

Be sure to read before handling.

Design of Equipment & Machinery

Selection

1. Construct so that the human body will not come into direct contact with driven objects or the moving parts of locking cylinders.

Devise a safe structure by attaching protective covers that prevent direct contact with the human body, or in cases where there is a danger of contact, provide sensors or other devices to perform an emergency stop, etc. before contact occurs.

Warning

3. In order to further improve stopping CL accuracy, the time from the stop signal to the operation of the lock should be shortened as MLG much as possible.

To accomplish this, use a device such as a highly responsive electric control circuit or solenoid valve driven by direct current, and place the solenoid valve as close as possible to the cylinder.

Warning

CNA

2. Use a balance circuit, taking cylinder lurching into consideration.

In cases such as an intermediate stop, where a lock is operated at a desired position within the stroke and air pressure is applied from only one side of the cylinder, the piston will lurch at high speed when the lock is released. In such situations, there is a danger of causing human injury by having hands or feet, etc. caught, and also a danger of causing damage to the equipment. In order to prevent this lurching, a balance circuit such as the recommended air pressure circuits (p. 3.6-22) should be used.

CNG CNS CLS CB CV/MVG CXW CXS MX

4. Note that stopping accuracy will be influenced MNB by changes in piston speed.

When piston speed changes during the course of the cylinder stroke due to variations in the load or disturbances, etc., the dispersion of stopping positions will increase. Therefore, consideration should be given to establishing a standard speed for the piston just before it reaches the stopping position. Moreover, the dispersion of stopping positions will increase during the cushioned portion of the stroke and during the accelerating portion of the stroke after the start of operation, due to the large changes in piston speed.

Selection

Warning

1. When in a locked condition, do not apply a load accompanied by an impact shock, strong vibration or turning force, etc.

Use caution, because an external action such as an impacting load, strong vibration or turning force, may damage the locking mechanism or reduce its life.

Mounting

Warning

If connected when in the locked condition, a load greater than the turning force or holding force may operate on the piston rod and cause damage to the lock mechanism. The CNS series is equipped with an emergency unlocking mechanism, however, when connecting the rod end to the load this should be done with the lock released by simply connecting an air line to the unlocking port and supplying air pressure of 0.25MPa {2.5kgf/cm2} or more.

1. Be certain to connect the rod end to the load CXT with the lock released.

2. Consider stopping accuracy and the amount of overrun when an intermediate stop is performed.

Due to the nature of a mechanical lock, there is a momentary lag with respect to the stop signal, and a time delay occurs before stopping. The cylinder stroke resulting from this delay is the overrun amount. The difference between the maximum and minimum overrun amounts is the stopping accuracy. Place a limit switch before the desired stopping position, at a distance equal to the overrun amount. The limit switch must have a detection length (dog length) of the overrun amount + . SMC's auto switches have operating ranges from 8 to 14mm (depending on the switch model). When the overrun amount exceeds this range, self-holding of the contact should be performed at the switch load side. Refer to page 3.6-5 regarding stopping accuracy.

MXU MXH MXS MXQ MXF MXW MXP MG MGP MGQ MGG MGC MGF MGZ CY MY

2. Do not apply an offset load to the piston rod.

Particular care should be taken to match the load's centre of gravity with the centre of the cylinder shaft. When there is a large discrepancy, the piston rod may be subjected to uneven wear or damage due to the inertial moment during locking stops.

X Load centre of gravity and cylinder shaft centre are not matched.

Load centre of gravity and cylinder shaft centre are matched.

Stop signal Amount of overrun Note) Can be used if all of the generated moment is absorbed by an effective guide.

3.6-21

Series CNS

Specific Product Precautions 2

Be sure to read before handling.

Mounting

Air Pressure Circuits

Caution

1. Precautions when using the base unit and when changing bracket positions, etc.

The lock unit and cylinder rod cover are assembled as shown in the drawing below. For this reason, it cannot be installed as in the case of common air cylinders, by using the basic type and screwing the cylinder tie-rods directly into machinery. Furthermore, when brackets are replaced, the unit holding tie-rods may become loose and they should be retightened.

Unit holding tie-rod Lock unit Cylinder tie-rod Rod cover

Warning

2. Use a solenoid valve for unlocking which has a large effective sectional area, as a rule 50% or more of the effective sectional area of the cylinder drive solenoid valve.

The larger the effective sectional area is, the shorter the locking time will be (the overrun amount will be shorter), and stopping accuracy will be improved.

3. Place the solenoid valve for unlocking close to the cylinder, and no farther than the cylinder drive solenoid valve.

The less distance there is from the cylinder (the shorter the piping), the shorter the overrun amount will be, and stopping accuracy will be improved.

4. Allow at least 0.5 seconds from a locked stop (intermediate stop of the cylinder) until release of the lock.

Tie-rod nut, spring washer Wing nut Conical spring washer

When the locked stop time is too short, the piston rod (and load) may lurch at a speed greater than the control speed of the speed controller.

Bore size (mm)

Tie-rod nut JIS B1181 Class 2 M14 x 1.5 JIS B1181 Class 2 M16 x 1.5

Width across flats 22 24

Socket JIS B4636 12 point socket 22 JIS B4636 12 point socket 24

125 140 160

5. When restarting, control the switching signal for the unlocking solenoid valve so that it acts before or at the same time as the cylinder drive solenoid valve.

If the signal is delayed, the piston rod (and load) may lurch at a speed greater than the control speed of the speed controller.

Adjustment

6. Basic circuits.

1. [Horizontal]

Forward

Caution

1. Adjust the cylinder's air balance.

Balance the load by adjusting the air pressure in the front and rear sides of the cylinder with the load connected to the cylinder and the lock released. Lurching of the cylinder when unlocked can be prevented by carefully adjusting this air balance.

W

Backward

2. Adjust the mounting positions of the detectors on auto switches, etc.

When intermediate stops are to be performed, adjust the mounting positions of detectors on auto switches, etc., taking into consideration the overrun amount with respect to the desired stopping positions.

3 ports normally closed SOL.A SOL.C

SOL.A SOL.B ON ON Regulator OFF OFF w/check ON OFF valve ON ON Pressure ON OFF center OFF OFF SOL.B ON OFF ON OFF

SOL.C OFF OFF OFF OFF ON OFF OFF ON

Action Forward Locked stop Unlocked Forward Backward Locked stop Unlocked Backward

0.5s or more 0 to 0.5s

0.5s or more 0 to 0.5s

2. [Vertical] in direction [ Load of rod extension ]

in direction [ Load of rod retraction ]

W

Air Pressure Circuits

Warning

1. Be certain to use an air pressure circuit which will apply balancing pressure to both sides of the piston when in a locked stop.

In order to prevent cylinder lurching after a locked stop, when restarting or when manually unlocking, a circuit should be used which will apply balancing pressure to both sides of the piston, thereby canceling the force generated by the load in the direction of piston movement.

SOL.C SOL.B SOL.A SOL.A SOL.C SOL.B

3.6-22

Series CNS

Specific Product Precautions 3

Be sure to read before handling.

Air Pressure Circuit

Manual Unlocking

Caution

1. A 3 position pressure center solenoid valve and regulator with check valve can be replaced with two 3 port normally open valves and a regulator with relief function.

Cylinder side Cylinder side

3. Take measures to prevent the load from CL dropping when unlocking is performed.

Perform work with the load in its lowest position. Use supports, etc. to prevent the load from dropping. Confirm that balanced pressure is applied to both sides of the piston.

Warning

MLG CNA CNG MNB CNS CLS CB CV/MVG

Caution

[Example] 1. [Horizontal]

W

3 ports normally open SOL.C SOL.B Regulator with relief function

SOL.A 3 ports normally closed

1. The unlocking cam is an emergency unlocking mechanism only. During an emergency when the air supply is stopped or cut off, this is used to alleviate a problem by forcibly pushing back the release piston and brake spring to release the lock. 2. When installing the cylinder into equipment or performing adjustments, etc., be sure to apply air pressure of 0.25MPa or more to the unlocking port, and do not perform work using the unlocking cam. 3. When releasing the lock with the unlocking cam, it must be noted that the sliding resistance of the cylinder will be high, unlike normal unlocking with air pressure.

Cylinder sliding Cam unlocking Bore size resistance torque (standard) Width across (mm) (kgf) Nm {kgfcm} flats (mm) Socket JISB4636 12 point socket 16 JISB4636 12 point socket 18 JISB4636 12 point socket 21

CXW CXS CXT MX MXU MXH MXS MXQ MXF MXW MXP MG MGP MGQ MGG MGC MGF MGZ CY MY

2. [Vertical] [Load in direction of rod extension] [Load in direction of rod retraction]

W

SOL.C SOL.C SOL.B SOL.A SOL.A SOL.B

125 140 160

98 124 161

68.6 { 700} 78.4 { 800} 156.8 {1600}

16 18 21

Manual Unlocking

4. Do not turn the unlocking cam (the arrow or mark on the unlocking cam head) past the position marked FREE. If it is turned too far, there is a danger of damaging the unlocking cam. 5. For safety reasons, the unlocking cam is constructed so that it cannot be fixed in the unlocked condition.

Locked condition Manually unlocked condition

Unlocking cam Release piston

Warning

1. Never operate the unlocking cam until safety has been confirmed. (Do not turn to the FREE side.)

When unlocking is performed with air pressure applied to only one side of the cylinder, the moving parts of the cylinder will lurch at high speed causing a serious hazard. When unlocking is performed, be sure to confirm that personnel are not within the load movement range and that no other problems will occur if the load moves.

2. Before operating the unlocking cam, exhaust any residual pressure which is in the system.

[Principle] If the unlocking cam is turned clockwise with an adjustable angle wrench or socket wrench, etc., the release piston is pushed back and the lock is released. Since the lever will return to its original position and become locked again when it is released, it should be held in this position for as long as unlocking is required.

3.6-23

Series CNS

Specific Product Precautions 4

Be sure to read before handling.

Maintenance

Caution

1. The lock units for the CNS series are replaceable. To order replacement lock units for the CNS series, use the order numbers given in the table below.

Bore size (mm) Lock unit order number CNS125D-UA CNS140D-UA CNS160D-UA

3) Similarly, apply compressed air of 0.3MPa or more to the unlocking port of the new lock unit, and replace the sympodium with the cylinder piston rod.

(New)

Sympodium

125 140 160

P0.3MPa

2. Replacement of lock units. 1) Loosen the tie-rod nuts (4 pcs.) on the front side of the cylinder using a socket wrench. Refer to the table below for the applicable socket.

Bore size (mm) Nut JIS B1181 Class 2 M14 x 1.5 JIS B1181 Class 2 M16 x 1.5 Width across flats 22 24 Socket JIS B4636 12 point socket 22 JIS B4636 12 point socket 24

125,140 160

4) Tighten the tie-rod nuts (4 pcs.) on the front side of the cylinder using a socket wrench.

2) Apply compressed air of 0.3MPa or more to the unlocking port, and remove the lock unit.

(Old)

P0.3MPa

Warning

Never disassemble a CNS series lock unit.

1) Since a heavy duty spring is contained in the unit, there is a serious hazard, such as the possibility of parts being ejected, if disassembly is performed incorrectly. Therefore, do not loosen or remove the hexagon socket head cap screws which secure cover A and cover B. 2) Be sure to contact SMC regarding disassembly or repair, etc.

3.6-24

S-ar putea să vă placă și

- MBB50 50Document45 paginiMBB50 50dgfggfhghgdfhtÎncă nu există evaluări

- Electrovalva SMC - Eng 3 - 1 - 2 - 1 - SY3000-5000-7000-9000Document234 paginiElectrovalva SMC - Eng 3 - 1 - 2 - 1 - SY3000-5000-7000-9000Canea Mihai CaiusÎncă nu există evaluări

- % Lighter: Air CylinderDocument34 pagini% Lighter: Air CylinderRuri ApridianoÎncă nu există evaluări

- Catalogo Pistones SMCDocument151 paginiCatalogo Pistones SMCCarlos Gonzalez100% (1)

- Acm Series (KCC)Document13 paginiAcm Series (KCC)Hendar KristÎncă nu există evaluări

- C 316SFeb2008Document2 paginiC 316SFeb2008Mano NegraÎncă nu există evaluări

- 160S 1Document51 pagini160S 1Ahmad Mustaghfiri AsrarÎncă nu există evaluări

- Technical Specifications For Centrifugal Pumps PDFDocument12 paginiTechnical Specifications For Centrifugal Pumps PDFVicky GautamÎncă nu există evaluări

- Air Cylinder CM2Document169 paginiAir Cylinder CM2icarus_fallenÎncă nu există evaluări

- Compact Cylinder: SeriesDocument22 paginiCompact Cylinder: SeriesNguyễn ThếÎncă nu există evaluări

- 70 A HydraulicDocument148 pagini70 A HydraulicMauricio MpintoÎncă nu există evaluări

- CH2Document37 paginiCH2Jigar M. UpadhyayÎncă nu există evaluări

- Base Mounted VQ Series SpecificationsDocument84 paginiBase Mounted VQ Series SpecificationsmeritnoorÎncă nu există evaluări

- Cilindros Neumaticos SMC CQ2 - ZDocument239 paginiCilindros Neumaticos SMC CQ2 - ZluisaliasÎncă nu există evaluări

- Mallard LevelInstrumentationDocument24 paginiMallard LevelInstrumentationtechdocuÎncă nu există evaluări

- Modular Dual Line SystemDocument6 paginiModular Dual Line Systemangela_draguÎncă nu există evaluări

- Data Sheet Tag 180-Pu-011eDocument8 paginiData Sheet Tag 180-Pu-011eSarah PerezÎncă nu există evaluări

- Low Noise Solenoid Relief ValvesDocument4 paginiLow Noise Solenoid Relief ValvesReinaldo RuskeÎncă nu există evaluări

- TTM Post TensioningDocument103 paginiTTM Post Tensioninghorea67100% (2)

- Monoflanges VariAS BlocksDocument20 paginiMonoflanges VariAS BlocksamuihÎncă nu există evaluări

- INSULATED SHAFT TYPEDocument5 paginiINSULATED SHAFT TYPEshyhuÎncă nu există evaluări

- 3/4" - 2" Cartridge Style Liquid Turbine Meter: Features/BenefitsDocument2 pagini3/4" - 2" Cartridge Style Liquid Turbine Meter: Features/Benefitssrmedinac2122Încă nu există evaluări

- 10mm Size Hollow Shaft Type: A Series of Compact and Long-Life Encoders With Unique Hollow Shaft DesignDocument3 pagini10mm Size Hollow Shaft Type: A Series of Compact and Long-Life Encoders With Unique Hollow Shaft DesignshyhuÎncă nu există evaluări

- 10Z 3Document95 pagini10Z 3ZMCONTROLÎncă nu există evaluări

- Dyadic Systems 2011 CatalogDocument16 paginiDyadic Systems 2011 CatalogServo2GoÎncă nu există evaluări

- CL-kompl EDocument6 paginiCL-kompl EpecqroÎncă nu există evaluări

- SN Series Screw PumpsDocument12 paginiSN Series Screw PumpsAlexis Ernesto Cardenas BeltranÎncă nu există evaluări

- Flow Meters, Flow Switches and Flow Transmitters: A Medium Vane-Style For Corrosive FluidsDocument6 paginiFlow Meters, Flow Switches and Flow Transmitters: A Medium Vane-Style For Corrosive FluidsSIPNETÎncă nu există evaluări

- C95 Eu PDFDocument36 paginiC95 Eu PDFMihaela PopÎncă nu există evaluări

- Switch de Presión SMA 8 4S C HCDocument2 paginiSwitch de Presión SMA 8 4S C HCFigueroa JoseÎncă nu există evaluări

- H1000e K FJDocument8 paginiH1000e K FJSyarif HidayatullahÎncă nu există evaluări

- CQ2 New Series PDFDocument210 paginiCQ2 New Series PDFsumit_waghmareÎncă nu există evaluări

- Iai Rca Ss5d SpecsheetDocument2 paginiIai Rca Ss5d SpecsheetElectromateÎncă nu există evaluări

- Dyadic Systems 2011 CatalogDocument16 paginiDyadic Systems 2011 CatalogElectromateÎncă nu există evaluări

- 06 SCT Extended PDFDocument40 pagini06 SCT Extended PDFSlobodan Antic100% (2)

- KVC 01Document35 paginiKVC 01hamidreza_m85Încă nu există evaluări

- Jai Balaji Limit SwitchesDocument2 paginiJai Balaji Limit Switchesnavinchopra1986Încă nu există evaluări

- Filter Regulator SMC PDFDocument27 paginiFilter Regulator SMC PDFTuấn Anh NguyễnÎncă nu există evaluări

- MAXROY Series A, B & D DatasheetDocument4 paginiMAXROY Series A, B & D Datasheetnguyenquoc1988Încă nu există evaluări

- ABS Submersible Wastewater Pump AS 0530-0841: ApplicationsDocument4 paginiABS Submersible Wastewater Pump AS 0530-0841: Applicationsas3ateÎncă nu există evaluări

- EC18A 18mm Insulated Shaft EncoderDocument4 paginiEC18A 18mm Insulated Shaft EncodershyhuÎncă nu există evaluări

- 4 Snubber and Rigid StrutDocument8 pagini4 Snubber and Rigid StrutkysucoÎncă nu există evaluări

- MPVN BrochureDocument32 paginiMPVN Brochurefernando_naciamentÎncă nu există evaluări

- List of Varieties: Detector Slide Push RotaryDocument5 paginiList of Varieties: Detector Slide Push RotaryshyhuÎncă nu există evaluări

- Catalog - Essential Guide of Control Panel PDFDocument172 paginiCatalog - Essential Guide of Control Panel PDFMircea MurarÎncă nu există evaluări

- Steam TrapDocument2 paginiSteam TrapAmpornchai PhupolÎncă nu există evaluări

- SWGDocument25 paginiSWGBilly ZununÎncă nu există evaluări

- CVP 90spec InformacionDocument7 paginiCVP 90spec InformacionvictorÎncă nu există evaluări

- G12MF TypeDocument1 paginăG12MF Typeosto72Încă nu există evaluări

- Solenoid ValvesDocument71 paginiSolenoid ValvesAlberto De la Cruz100% (1)

- Series: Dual Rod CylinderDocument22 paginiSeries: Dual Rod CylinderAnonymous A55PY1bÎncă nu există evaluări

- Weld Like a Pro: Beginning to Advanced TechniquesDe la EverandWeld Like a Pro: Beginning to Advanced TechniquesEvaluare: 4.5 din 5 stele4.5/5 (6)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsDe la EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsÎncă nu există evaluări

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsDe la EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsEvaluare: 4.5 din 5 stele4.5/5 (10)

- 6 Restrained Beams HandoutDocument2 pagini6 Restrained Beams HandoutHakan EzcanÎncă nu există evaluări

- Au Ma34 2 PDFDocument22 paginiAu Ma34 2 PDFmartc35Încă nu există evaluări

- Catalogo RHPDocument83 paginiCatalogo RHPLuisNovoaRivera100% (1)

- Uma Unimaster 70 250 Dust CollectorsDocument12 paginiUma Unimaster 70 250 Dust Collectorsmartc35Încă nu există evaluări

- DetailingDocument1 paginăDetailingRaymond JacksonÎncă nu există evaluări

- Belt Tensioning White Paper PDFDocument13 paginiBelt Tensioning White Paper PDFPetros IosifidisÎncă nu există evaluări

- Teseo HBS Pipework CatalogueDocument28 paginiTeseo HBS Pipework Cataloguemartc35Încă nu există evaluări

- Ten Steps To An Effective Bin Design - AIChEDocument8 paginiTen Steps To An Effective Bin Design - AIChEhwang2Încă nu există evaluări

- PCI Pulley Selection Guide 2014Document32 paginiPCI Pulley Selection Guide 2014Akram FerchichiÎncă nu există evaluări

- Costing Steelwork 2Document7 paginiCosting Steelwork 2martc35Încă nu există evaluări

- ModellingDocument1 paginăModellingmartc35Încă nu există evaluări

- Conveyor Chain and SprocketsDocument5 paginiConveyor Chain and Sprocketsmartc35Încă nu există evaluări

- Grade efficiency and particle classificationDocument11 paginiGrade efficiency and particle classificationmartc35Încă nu există evaluări

- EN DEMAG PogledajDocument158 paginiEN DEMAG PogledajNenad TabandzelicÎncă nu există evaluări

- Ballscrew MachiningDocument3 paginiBallscrew Machiningmartc35Încă nu există evaluări

- Weekly External Plant & Equip ReturnDocument1 paginăWeekly External Plant & Equip Returnmartc35Încă nu există evaluări

- Air Reservoirs enDocument6 paginiAir Reservoirs enmartc35Încă nu există evaluări

- A - Piping Joint HandbookDocument161 paginiA - Piping Joint HandbookCharles Tauk100% (30)

- Antique Toasting ForkDocument6 paginiAntique Toasting Forkmartc35Încă nu există evaluări

- Iso GD&TDocument39 paginiIso GD&TSanjay Kumar SinghÎncă nu există evaluări

- Solids flow modes and hopper design principlesDocument14 paginiSolids flow modes and hopper design principlesHogar Belo HorizonteÎncă nu există evaluări

- Pipe Flange BoltingDocument8 paginiPipe Flange BoltingayoungaÎncă nu există evaluări

- F 17 Report of Inspections of Lifting Equipment and Safe Load IndicatorsDocument1 paginăF 17 Report of Inspections of Lifting Equipment and Safe Load Indicatorsmartc35Încă nu există evaluări

- F 16 PPE Issue-Return LogDocument1 paginăF 16 PPE Issue-Return Logmartc35Încă nu există evaluări

- F 18 Record of Work EquipmentDocument1 paginăF 18 Record of Work Equipmentmartc35Încă nu există evaluări

- ACAD12 Tips OnlineDocument21 paginiACAD12 Tips OnlineEnrique ZGÎncă nu există evaluări

- F 19 Employees PPE Issue-Return LogDocument1 paginăF 19 Employees PPE Issue-Return Logmartc35Încă nu există evaluări

- Spray Guide and Jig Table GA-1Document1 paginăSpray Guide and Jig Table GA-1martc35Încă nu există evaluări

- Designer information for silo bin usersDocument2 paginiDesigner information for silo bin usersmartc35Încă nu există evaluări

- Class XII PHY - EDDocument7 paginiClass XII PHY - EDsampoornaswayamÎncă nu există evaluări

- First Gospel of The Infancy of Jesus ChristDocument16 paginiFirst Gospel of The Infancy of Jesus ChristOdracir OiravlacÎncă nu există evaluări

- Sally Su-Ac96e320a429130Document5 paginiSally Su-Ac96e320a429130marlys justiceÎncă nu există evaluări

- IIT Ropar Calculus Tutorial Sheet 1Document2 paginiIIT Ropar Calculus Tutorial Sheet 1jagpreetÎncă nu există evaluări

- Math 20053 Calculus 2: Unit Test 1Document2 paginiMath 20053 Calculus 2: Unit Test 1mark rafolsÎncă nu există evaluări

- Assess White PaperDocument6 paginiAssess White PaperCristian ColicoÎncă nu există evaluări

- Reading SkillsDocument37 paginiReading SkillsShafinaz ZhumaÎncă nu există evaluări

- Housekeeping ProcedureDocument3 paginiHousekeeping ProcedureJeda Lyn100% (1)

- Bulletin 13.9.22Document4 paginiBulletin 13.9.22dbq088sÎncă nu există evaluări

- Form 2 Physics HandbookDocument90 paginiForm 2 Physics Handbookmosomifred29Încă nu există evaluări

- Compiled Lecture in Engineering Economy PDFDocument78 paginiCompiled Lecture in Engineering Economy PDFLJ dela PazÎncă nu există evaluări

- SQL QuestionsDocument297 paginiSQL Questionskeysp75% (4)

- Past Progressive WorksheetDocument3 paginiPast Progressive WorksheetSantiago VargasÎncă nu există evaluări

- Globalisation Shobhit NirwanDocument12 paginiGlobalisation Shobhit NirwankrshraichandÎncă nu există evaluări

- Experiment 1 Tensile Testing (Universal Tester) : RD THDocument23 paginiExperiment 1 Tensile Testing (Universal Tester) : RD THShangkaran RadakrishnanÎncă nu există evaluări

- 9th Science Term 3 Model Question Paper English MediumDocument3 pagini9th Science Term 3 Model Question Paper English MediumStalin JesudossÎncă nu există evaluări

- Models - Acdc.pm Motor 3dDocument52 paginiModels - Acdc.pm Motor 3dAmadou KonfeÎncă nu există evaluări

- Eye Floaters Cure - Natural Treatment For Eye FloatersDocument34 paginiEye Floaters Cure - Natural Treatment For Eye FloatersVilluri Venkata Kannaapparao50% (2)

- Committees of UWSLDocument10 paginiCommittees of UWSLVanshika ChoudharyÎncă nu există evaluări

- REINFORCED CONCRETE DESIGNDocument22 paginiREINFORCED CONCRETE DESIGNEMIL JOHN P. ANTONIOÎncă nu există evaluări

- Political Education and Voting Behaviour in Nigeria: A Case Study of Ogbadibo Local Government Area of Benue StateDocument24 paginiPolitical Education and Voting Behaviour in Nigeria: A Case Study of Ogbadibo Local Government Area of Benue StateMohd Noor FakhrullahÎncă nu există evaluări

- EHV AC Transmission System Design and AnalysisDocument104 paginiEHV AC Transmission System Design and Analysispraveenmande100% (1)

- Parameter ranges and attenuation values for RRH configurationsDocument121 paginiParameter ranges and attenuation values for RRH configurationscharantejaÎncă nu există evaluări

- Osmaan Shamsiddeen: Work History Personal InfoDocument1 paginăOsmaan Shamsiddeen: Work History Personal InfoOsmaan ShamsiddeenÎncă nu există evaluări

- BIO125 Syllabus Spring 2020Document3 paginiBIO125 Syllabus Spring 2020Joncarlo EsquivelÎncă nu există evaluări

- Expanded-Internet-Art-Twenty-First-Century-Artistic-Practice-and-the-Informational-Milieu-Ceci-Moss-z-lib.orgDocument169 paginiExpanded-Internet-Art-Twenty-First-Century-Artistic-Practice-and-the-Informational-Milieu-Ceci-Moss-z-lib.orgxx2gkt72c7Încă nu există evaluări

- MAAA-Unit 3B - Examples of Insects, CRPT 100 For BSADocument147 paginiMAAA-Unit 3B - Examples of Insects, CRPT 100 For BSAKosme DumpÎncă nu există evaluări

- CHAPTER 7development StrategiesDocument29 paginiCHAPTER 7development StrategiesOngHongTeckÎncă nu există evaluări

- DECIDE ChecklistDocument2 paginiDECIDE ChecklistGuilioÎncă nu există evaluări

- Trinity Rescue Kit 3.4 GuideDocument108 paginiTrinity Rescue Kit 3.4 GuideTimothy Stockholm50% (2)