Documente Academic

Documente Profesional

Documente Cultură

Intro Lecture Part 3 Chapter 7 Text

Încărcat de

gail_johnson76Descriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Intro Lecture Part 3 Chapter 7 Text

Încărcat de

gail_johnson76Drepturi de autor:

Formate disponibile

Lecture Part 3 Chapter 7 InFashion: Fun! Fame! Fortune!

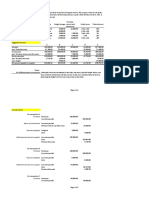

2nd Edition by Elaine Stone In Part Three we will look at the Secondary LevelThe Producers of Fashion (or Who makes all this stuff?) Chapter Seven Product Development: If you think it looks like they are having fun in this picture. You are correct. Exercising your creativity is fun. When you sell the products you created for a profit then you are in business. Slide 4 Key Concepts The major advantages and disadvantages of the contractor system The six-stage process of developing and producing a line of apparel The details, colors, fabrics, silhouettes, styles, trims will change with every season but the process remains the same regardless of whether you are making something basic like a tee shirt or an intricately cut gown and jacket. In part 4 we will look the same cycles for accessories, cosmetics, home furnishings and even fragrance. Chapter 8 talks about some of the specifics of mens womens and children. The major industry practices of licensing, brand extension, private label and specification buying, offshore production, CAD/CAM, PLM, use of factors, chargebacks, and SIC/NAICS codes The supply chain management movement and the mass customization theory and their effects on the product development chain How bar codes, scanners, and RFID are integral parts of supply chain management. The visuals on the slide are the Anatomy of the barcode showing what the digits stand for and the bar code below is a little tongue in CHIC version of the barcode. : ) Slide 5 Introduction Product development is the teaming of market and trend research, with the merchandising, design, and technical processes that develop a final product. "Peclers Fashion Trend Books", a trend forecasting publication used in the fashion industry showing real fabrics of the trend is depicted in the slide. This is one of the tools that a company might purchase to

give them information on the upcoming trends. Some trend forecasting companies put out general information and others create more specific or targeted information for specific fashion industries Slide 6 What Is a Product Line, and Who Develops It? Line is the word used to describe the product line that is created for wholesale presentation several times or seasons per year. These presentations are held during market week, a time when the new line is presented to the buyers. When I was working in the fashion industry we had 5 markets per year so you were always planning and creating for the next market. Some industries may have fewer markets. Examples of the seasons might be Spring, Fall, Resort/ Holiday and you might have preview markets as well. These seasonal lines would be presented in time for the buyers to see the line, place their orders, production of the garments to be completed and the garments to be shipped to the stores in time for the season. Collection means the same thing as line but specifies that it is an expensive line. Groups Lines are divided into groups. These groups would have some commonality such as color, fabric or style or it might be items that would work well together. The idea being that stores would buy groups and merchandise them together in their stores. http://www.coroflot.com/kimberly_jamison/LINE-SHEET-EXAMPLES This is a portfolio I found on line that I would like you to take a look at. It will give you an idea of some of the work that goes into creating a line. Click on all the different options to see more. Line-for-line designs are copied from original designs but made in cheaper fabrics according to the size specs for the individual company. In the United States there is no copyrighting of designs nothing to protect the creativity of any given designer. As you would imagine this makes it very important to always be developing something new. Anchors are designs which originated in a previous season but have been reworked in a different color or fabric. It saves money if designers/companies do not have to completely reinvent the entire line. Do any of you have a favorite pair of jeans that you go back to and look to buy this seasons version? If you find something that fits and it fits and wears consistently it makes it easier for you the consumer also. Knockoffs are copies an item at a lower price. You might also knock off something your competition is offering at the same price to try and get some of their business. If you copy your competitor you might have a factory that could make it cheaper or maybe you are vertical and make your own fabric, which would also allow you to sell it cheaper. Slide 7 What Is a Product Line, and Who Develops It?

If it is a very small company one person might do it all but their ability to create very much product is limited. Generally more people are required to put out a line of any size. In some cases the designer and merchandiser may be one in the same and will perform the duties as described. Role of the Merchandiser Your book mentions this position as the glue that holds together the process of product development. Merchandisers have to look at the big picture of the process from concept through design, and production to the sale of the merchandise. They will insure that the links between all of these flow. The Role of the Designer is to create the new styles. Designers conceive their ideas by sketching, using CAD Computer Aided Design or working directly on the dress form with fabric. They must consider: trends, the target customer, the selling price range that the company works in and the factorys abilities. Although the artistic expression is key if you dont create a garment that can made for the price your company needs to sell it for it is useless. When I first started designing one of the more senior designers told me if you want 5 buttons put 8 on because when they start working the price down you might need to give something up. Good advicethanks Joanne! This will not be as critical if you are designing very expensive items as in the moderate market. Role of the Producer Apparel Manufacturers are the producers who handle all the steps of the production. Designs are created by in house or freelance designers. The designs are costed and production patterns are made. This requires fittings and insuring that the patterns use the fabric efficiently. Fabric and trimming is purchased. Companies have purchasing agents whose job it is to negotiate the best price on fabric/ trim and follow up with orders to be sure that they are delivered on time. Companies may have their own factories to produce the garments or they may use a contractor whose business it is to make garments. The companys sales force sells the merchandise and it is shipped by the traffic department. Apparel Jobbers handle all of the phases of production except for the sewing and sometimes the cutting. Contractors may sew cut work from the manufacturers or jobbers or they may cut and sew from patterns which are submitted. The contractors are responsible for sewing, finishing, inspection, pressing, and hanging or packaging the garments. Manufacturers and contractors rely on each other and having a good relationship is important.

Slide 8 The Product Development Process Stage 1: Planning a line The designers or product development team start with research. Not only do they look at trend information but also at sales records to understand what has and has not sold. They come up with ideas of what the line is going to look like. They may also shop fabric and trim suppliers to see what is being offered. At this stage they may create mood, inspiration or trend boards as you see in the upper right corner of this slide. Stage 2: Creating the design concept This is the birth of the individual garments that become part of groups and the line. Usually the designs are sketched or developed in muslin. Sketches are more cost effective than muslin because they require less time and expense. Experienced designers would have an idea of whether the designs are in the price range of their company when they sketch them. It is important to have an understanding of construction such that the garments are able to be made in their manufacturing plant. On my first job I had sketched a sleeve that was not something they had made previously. The patternmaker grumbled that the sleeve was going to be too difficult and expensive to make. I had an idea when I sketched it of how it could be made in the factory with minimal labor. The sleeve was very doable in our factory but if I had not had an idea of HOW it was to be made it would have been negated at that time. Slide 9 The Product Development Process Stage 3: Developing the designs From the initial designs the styles which look the most promising will be made up in fabric. These are called sample garments and they are created in sample size which is determined by the company. Usually someone who is the sample size will try them on. It may be someone who works at the company and is the correct size or a fit model who comes in to fit the production styles. The photo on the top shows someone fitting a sweater. Your book says that the patternmaker makes a production pattern at this time. That has never been my experience which doesnt mean it is untrue. At this point a first pattern is made and a design number is assigned to track the style. A designer may make their own first patterns or the sketches may be given to an assistant for them to create the first pattern. The people who sew the samples in the design room are the samplehands. It is important to treat everyone with respect as samplehands and assistants can make a designers work look good or not.

Costing the garment requires the yardage needed to make the garment and the cost of the labor. The fabric and all other components are the materials required and the labor is how much it costs to make the style. Costing engineers estimate how much it will cost at the factory to make the garment Some companies complete this step with offshore design and sample services. The red fabric shown in the lower picture shows a number of samples being cut at one time. The layers of fabric are stacked up and cut with a vertical cutting machine that looks like a saw. If you have a sales force or need garments to send to customers you will need multiples of the samples. Computer-Aided Design If you are strong on computers you may enjoy creating styles or print patterns on the computers. Due to the advances in technology you can create a 3 D image on the screen making changes with just a click rather than cutting another garment. These images can be used to show styles in merchandising and sales presentations. The creation of samples is more costly than a printed computer image. Linked CAD/CAM/CIM Computer Aided Design can be linked with Computer AidedManufacturing CAM and CIM computer integrated manufacturing. These systems allow the information to be shared around the world.

Stage 4: Planning production The question of where the garments will be made needs to be answered before a final cost sheet can be completed. It is much more expensive to make a garment in NYC than in Bangladesh for example and a company needs to know the cost before they can decide how much to sell it for.

Also, the source for the components is usually established at the time of costing. If a garment is too expensive they may continue to look for a cheaper source for the components. Companies establish minimum orders that they will accept from buyers just as fabric manufacturers may have minimum purchase amounts. The buyers look at the lines during the seasonal shows and based on their feedback the manufacturer may decide to drop something from the line if there is no interest. Slide10 The Product Development Process Stage 5: Production is making many of the style which has been adopted and sold. How many is determined by the number of orders you have. Cutting Before you are ready to cut the production pattern must be created. This is a perfect pattern which fits the body, is comfortable and it sews together with no mismatches. It is also notched with all the notches required in order for it to be sewn together easily. In some industries the designer is responsible for creating the production pattern in others there is a production patternmaker. The patterns (not the garments as is indicated in the book) need to be graded not with an A, B, or C but sloped to every size that will be cut. For example the sample size

might be a size 8 and the size range that the style is cut in might be 4- 16. The size 8 would be graded up and down to the size specifications

This is one example of a cutting machine. The blade goes up and down to slice through the layers of fabric.

This picture shows hard patterns hanging in a design or pattern room.

The drawing above is an example of graded patterns. If any of you sew and have used a multi sized pattern this will look familiar. Markers are the arrangement of all the pattern pieces that need to be cut and are fit together tightly so they look like puzzles. The tighter the patterns can be laid the more efficient the marker is and therefore less waste. It is very important to know the width of the fabric you are buying so that your marker is accurate. When fabric is shipped to the manufacturer it is always checked for quality before it is cut.

Markers will include all of the sizes that are being cut in the ratio that they are being cut. The customer history of sales may show that they sell more size 12 than size 2 so they will cut accordingly.

Sewing is done on industrial machines which sew much faster than home machines that you might own. They are usually set up to do one particular type of operation. Some are set up to sew the seams, other the hems and some are specific machines such as buttonhole machines or embroidery machines. The bundles of garments would move through an assembly line style or modular manufacturing designed for maximum efficiency.

Finishing the Product includes turning them right side out, sewing labels in and buttons and buttonholes. Pressing, hanging or bagging and making them floor ready. Inspecting the Product is not a onetime event. The fabric is checked on the way in, cutting and bundling is checked and sewing is inspected along the way.

Stage 6: Distributing the line If any of you work in the retail environment you know there is more work to be done here. In order to be sold the sales ticket including the bar codes must be attached. As I mentioned above the manufacturer often does this in order to save time. The availability of the electronic tracking allows this to be a possibility. Garments have to be transported and may be shipped a multitude of ways. Consider garments coming to the United States may have been shipped via sea, air, rail or truck or a combination of. The following picture is from a showroom in the California Mart in Los Angeles.

Slide 11 Specializing by Product the apparel industry in the U.S has been divided into 3 categories mens womens and childrens. We will look at these in more detail in chapter 8. Within these categories manufacturers will be even more specialized. For example: Tailored clothing, Active sportswear, Dressy dresses, Junior sportswear, Boys casual and the list goes on. Brands and Labels National/designer brand The most recognized top 4 in the United States are Calvin Klein, Ralph Lauren, Donna Karan and Tommy Hilfiger (according to your book) Click on the link in your PowerPoint to see a Fall 2013 Calvin Klein advertisement. Notice how the image or feeling that is created is almost more important than the clothes themselves.

Many other name designers are working and making a very successful living. Designer labels can live on after the original designer has died or retired. Some examples of these are Halston, Bill Blass and Calvin Klein. Private label is big business and because it store specific it may not be as easily noticed. One of the companies that I worked for all they did was Private Label and it was a 90 million dollar division of a larger company. We serviced different accounts and created merchandise specifically for them. You develop close relationships with your buyers when you work with them in this capacity Retail store brand The Gap, The Limited, Talbots are all examples of this branding. Almost if not everything in the store is this brand. Click on this link to see a clip of the Victorias Secret fashion show http://www.youtube.com/watch?v=PSjhOOX1gqw Other brands This is the group that doesnt fit into the categories above and it is often licensed goods. Nonbrands These non brands are probably not on your radar. They are found in discount and off price stores and do very little advertising.

Slide 12 Industry Practices Manufacturers Acting as Retailers As you would imagine this gives them much more control if they control the environment for their clothing. Ralph Lauren was unhappy with the way that stores were presenting his merchandise and opened his first store in 1971. Many designers have followed since then as it not only allows them to present their vision in its entirety as they see it but it gives them greater profit when they sell directly to the customer. Licensing How many of you cannot afford Dolce and Gabbana jeans but may be able to purchase a D&G fragrance or sunglasses? Licensing relies on the name recognition to create demand for other items. Examples would be sunglasses, fragrance, tee shirts and more Designers or Designer level companies license their name to other manufacturers who make items they make well. It is always important to maintain the level of quality your customer expects. The designers are paid royalties of somewhere between 2-15% on each item sold. This type of agreement can be a win-win for both sides. Brand Extensions Private Label and Specification Buying are close cousins. Private label manufacturers may be allowed to design the merchandise for the retailer who in this case is the customer of the private label manufacturer. This would require a strong understanding of the customer needs and requirements.

Specification buying is when the retailers provide all of the specifications they require to the private label manufacturer. Offshore Production is generally used to lower production costs but also may also give you the opportunity to have some special handwork which would be prohibitive in the States. You have already had look at the tags inside your garments to see some to the different countries of origin. I just looked in the label of 3 garments to see Vietnam, Bangladesh and China. Use of Factors Factors are companies that work in the financial world and they purchase a manufacturers accounts receivable (the money that is owed them by their customers) or they may offer a cash advance. In order to create products manufacturers have to lay out cash up front to buy the fabric and trim, to create the patterns and sew the garments. Understandably they do not receive compensation for this until the goods are delivered. The factors do this for an interest fee and usually charge higher interest rates than a bank. Due to the high risk factors some banks are not willing to loan money to manufacturers. Credit insurance companies are used widely in Europe and they protect a manufacturer from losing money as a result of late payments or customer bankruptcy Chargebacks are not a good thing for manufacturers. This is money that is charged back by the retailer. Chargebacks can be for mistakes in purchase orders, ticketing, late shipments or even for something that didnt sell which the retailer selected. Aiming for perfect quality control all along the chain can help but it the retailers want to chargeback for something they will look for a fault on the part of the designer/ manufacturer. Ouch!! These can hurt! SIC/NAICS Codes Stand for Standard Industrial Classification/ North American Industry Classification System. These codes identify businesses and what they do. By identifying different businesses it become easier to track information and see trends in business. Slide 13 Advanced Technologies and Strategies Computer-Integrated Manufacturing and Product-Lifecycle Management Programmable sewing, patternmaking and cutting machines. Having every step linked with all the information available to all of the parties allows for immediacy in decision making. Supply Chain Management Quick Response (QR) delivering the right product at the right time. This also links all the parts of the pipeline and connects the manufacturer, supplier, retailer and consumer more closely.

Bar Codes, Scanners, and Radio Frequency Identification (RFID) these automatically identify items when they are scanned. Bar codes are specific patterns of dark bars and white space of varying widths. These identify the item and the price is added at the register for the individual stores. In this way it can easily be changed as something goes on sale or has a discount applied. Universal product code (UPC)

Electronic Data Interchange (EDI) Mass Customization Body Scanning Slide Globalization Globalization of the marketplacefinding both foreign competitors and foreign customershas happened to a wide range of U.S. manufacturing products Slide 15 This chapter is a hefty one as you will see by 2 slides of Trade Talk terms. Trade Talk anchor apparel contractor apparel jobber apparel manufacturer bundling chargeback collection computer-aided design (CAD) computer-aided manufacturing (CAM) computer integrated manufacturing (CIM)

corporate licensing electronic data interchange (EDI) factor floor ready graded group item house line line-for-line Trade Talk Slide 16 marker mass customization offshore production outside shop piece work private label product development product lifecycle management (PLM) product manager quality assurance (QA) quick response (QR) radio frequency identification (RFID) sample hand section work

specification buying specification manager spreader supply chain management (SCM) universal product code (UPC)

S-ar putea să vă placă și

- Chapter 13 FINALDocument11 paginiChapter 13 FINALgail_johnson76Încă nu există evaluări

- Test 4 Study GuideDocument1 paginăTest 4 Study Guidegail_johnson76Încă nu există evaluări

- Final Project Fashn Hist Notebook Then-NowDocument2 paginiFinal Project Fashn Hist Notebook Then-Nowgail_johnson76Încă nu există evaluări

- Intro Fashion Career ProjectDocument1 paginăIntro Fashion Career Projectgail_johnson76100% (1)

- Infashion: Fun! Fame! Fortune! 2 Edition: Elaine StoneDocument14 paginiInfashion: Fun! Fame! Fortune! 2 Edition: Elaine Stonegail_johnson76Încă nu există evaluări

- Extra Credit Movie Fashion HistoryDocument1 paginăExtra Credit Movie Fashion Historygail_johnson76Încă nu există evaluări

- Infashion: Fun! Fame! Fortune! 2 Edition: Elaine StoneDocument15 paginiInfashion: Fun! Fame! Fortune! 2 Edition: Elaine Stonegail_johnson76Încă nu există evaluări

- Slide 3: Introduction To Fashion Chapter 6 Text LectureDocument8 paginiSlide 3: Introduction To Fashion Chapter 6 Text Lecturegail_johnson76Încă nu există evaluări

- Review Quiz 6 Crino, Bustle, Edwardian, WWIDocument4 paginiReview Quiz 6 Crino, Bustle, Edwardian, WWIgail_johnson76Încă nu există evaluări

- Intro Lecture Chapter 9 Text VersionDocument24 paginiIntro Lecture Chapter 9 Text Versiongail_johnson76Încă nu există evaluări

- Unit 3 Study GuideDocument1 paginăUnit 3 Study Guidegail_johnson76Încă nu există evaluări

- Unit 3 Study GuideDocument1 paginăUnit 3 Study Guidegail_johnson76Încă nu există evaluări

- Unit 3 Study GuideDocument1 paginăUnit 3 Study Guidegail_johnson76Încă nu există evaluări

- Intro Lecture Chapter 8 Text Version Fashion ApparelDocument19 paginiIntro Lecture Chapter 8 Text Version Fashion Apparelgail_johnson76Încă nu există evaluări

- Slide 3: Introduction To Fashion Chapter 6 Text LectureDocument8 paginiSlide 3: Introduction To Fashion Chapter 6 Text Lecturegail_johnson76Încă nu există evaluări

- Infashion: Fun! Fame! Fortune! 2 Edition: Elaine StoneDocument20 paginiInfashion: Fun! Fame! Fortune! 2 Edition: Elaine Stonegail_johnson76Încă nu există evaluări

- Intro Lecture Chapter 5 Text VersionDocument11 paginiIntro Lecture Chapter 5 Text Versiongail_johnson76Încă nu există evaluări

- Chapter 9 FINALDocument10 paginiChapter 9 FINALgail_johnson76Încă nu există evaluări

- Stone - Chapter 5 Updated TUDocument19 paginiStone - Chapter 5 Updated TUgail_johnson76Încă nu există evaluări

- Review Quiz 4 17th & !8th CDocument2 paginiReview Quiz 4 17th & !8th Cgail_johnson76Încă nu există evaluări

- Final Project Fashn Hist Notebook Then-NowDocument2 paginiFinal Project Fashn Hist Notebook Then-Nowgail_johnson76Încă nu există evaluări

- Chapter 10 FINALDocument13 paginiChapter 10 FINALgail_johnson76Încă nu există evaluări

- Review Quiz 5 CH 11-12 UpdatedDocument2 paginiReview Quiz 5 CH 11-12 Updatedgail_johnson76Încă nu există evaluări

- Intro Time Era Report OnlineDocument1 paginăIntro Time Era Report Onlinegail_johnson76Încă nu există evaluări

- Slide 3: Introduction To Fashion Chapter 6 Text LectureDocument8 paginiSlide 3: Introduction To Fashion Chapter 6 Text Lecturegail_johnson76Încă nu există evaluări

- Chapter 12 FINALDocument11 paginiChapter 12 FINALgail_johnson76Încă nu există evaluări

- Chapter 11 FINALDocument11 paginiChapter 11 FINALgail_johnson76Încă nu există evaluări

- Chapter 10 2013Document43 paginiChapter 10 2013gail_johnson76Încă nu există evaluări

- Intro Lecture Part 3 Chapter 7 TextDocument15 paginiIntro Lecture Part 3 Chapter 7 Textgail_johnson76Încă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- GundamDocument25 paginiGundamBattlecruiser ScharnhorstÎncă nu există evaluări

- Selling AIESEC To Your TargetsDocument7 paginiSelling AIESEC To Your TargetspijoowiseÎncă nu există evaluări

- Term Paper - 2022964Document17 paginiTerm Paper - 2022964Md. Ahbab HasanÎncă nu există evaluări

- Determining Load Ratios For Technical Rescue Systems and EquipmentDocument2 paginiDetermining Load Ratios For Technical Rescue Systems and EquipmentAhmad Zubair Rasuly0% (1)

- Shower Tapware: For More Information and Detailed Specifications Please Refer To Our Website: WWW - Plumbline.co - NZDocument11 paginiShower Tapware: For More Information and Detailed Specifications Please Refer To Our Website: WWW - Plumbline.co - NZNoman KhanÎncă nu există evaluări

- Facility Layout Case StudyDocument8 paginiFacility Layout Case StudyHitesh SinglaÎncă nu există evaluări

- Baptismal DelayDocument20 paginiBaptismal DelayfiohdiohhodoÎncă nu există evaluări

- Accomplishment Report Filipino Values MonthDocument4 paginiAccomplishment Report Filipino Values MonthIan Santos B. Salinas100% (10)

- Culture NegotiationsDocument17 paginiCulture NegotiationsShikha SharmaÎncă nu există evaluări

- Altium Designer Training For Schematic Capture and PCB EditingDocument248 paginiAltium Designer Training For Schematic Capture and PCB EditingAntonio Dx80% (5)

- Handout No. 03 - Purchase TransactionsDocument4 paginiHandout No. 03 - Purchase TransactionsApril SasamÎncă nu există evaluări

- Thetford c250 InstallationDocument19 paginiThetford c250 InstallationCatalin Bejan100% (1)

- E650E650M-17 Guía Estándar para El Montaje de Sensores Piezoeléctricos de Emisión Acústica1Document4 paginiE650E650M-17 Guía Estándar para El Montaje de Sensores Piezoeléctricos de Emisión Acústica1fredy lopezÎncă nu există evaluări

- Term Paper Gender RolesDocument5 paginiTerm Paper Gender Rolesea8d1b6n100% (1)

- Free Vibration of SDOFDocument2 paginiFree Vibration of SDOFjajajajÎncă nu există evaluări

- Navigation - Star FinderDocument31 paginiNavigation - Star FinderPrasadtÎncă nu există evaluări

- DBL10 - Sapporo X Schematics Document: Compal ConfidentialDocument50 paginiDBL10 - Sapporo X Schematics Document: Compal ConfidentialEvgeniy BaranovskiyÎncă nu există evaluări

- SIDPAC Standard Data Channels: Ch. No. Symbols Description UnitsDocument2 paginiSIDPAC Standard Data Channels: Ch. No. Symbols Description UnitsRGFEÎncă nu există evaluări

- Upsa Y5 2023Document8 paginiUpsa Y5 2023Faizal AzrinÎncă nu există evaluări

- N Mon Visualizer OverviewDocument27 paginiN Mon Visualizer OverviewClaudioQuinterosCarreñoÎncă nu există evaluări

- Samsung LN55C610N1FXZA Fast Track Guide (SM)Document4 paginiSamsung LN55C610N1FXZA Fast Track Guide (SM)Carlos OdilonÎncă nu există evaluări

- Otis C. Mitchell - Hitler-s-Stormtroopers-and-the-Attack-on-the-German-Republic-1919-1933 PDFDocument201 paginiOtis C. Mitchell - Hitler-s-Stormtroopers-and-the-Attack-on-the-German-Republic-1919-1933 PDFbodyfull100% (2)

- Heat Cured ElastomersDocument40 paginiHeat Cured ElastomerslberrierÎncă nu există evaluări

- Xafsa 1Document19 paginiXafsa 1Heitham OmarÎncă nu există evaluări

- North-South Railway Project - South LineDocument49 paginiNorth-South Railway Project - South LinesuperÎncă nu există evaluări

- Another Look at Pistis ChristouDocument17 paginiAnother Look at Pistis Christouakimel100% (1)

- Student Exploration: Magnetism (Find Gizmo Icon On Eclass)Document4 paginiStudent Exploration: Magnetism (Find Gizmo Icon On Eclass)Abdel Majeed Tuffaha0% (1)

- Historic Trial of Ali Brothers and Shankaracharya-1921Document276 paginiHistoric Trial of Ali Brothers and Shankaracharya-1921Sampath Bulusu100% (3)

- Net June 2013Document22 paginiNet June 2013Sunil PandeyÎncă nu există evaluări

- ACI 318M-11 RC Bracket and Corbel Design - v0.03 - 2017-04-10Document5 paginiACI 318M-11 RC Bracket and Corbel Design - v0.03 - 2017-04-10arken123Încă nu există evaluări