Documente Academic

Documente Profesional

Documente Cultură

NIC Components NSPE-T Series

Încărcat de

NICCompDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

NIC Components NSPE-T Series

Încărcat de

NICCompDrepturi de autor:

Formate disponibile

Hybrid Aluminum Electrolytic Capacitors NSPE-T Series

• CYLINDRICAL V-CHIP CONSTRUCTION FOR SURFACE MOUNTING

• EXTENDED LOAD LIFE AT HIGH TEMPERTURE (2,000 ~ 3,000 HOURS @ +125°C)

• HIGH VOLTAGE RATINGS (25 ~ 100VDC)

• LOW ESR AND HIGH RIPPLE CURRENT RATINGS

• 6.3x8mm ~ 10x10.8mm CASE SIZES Expanded

• REFLOW SOLDERING RATED TO +260°C (+250°C 80V & 100V) 80V & 100V

Values

CHARACTERISTICS

Rated Voltage Range 25 ~ 100Vdc

Rated Capacitance Range 3.9 ~ 270μF

Operating Temp. Range -55 ~ +125°C

Capacitance Tolerance ±20% (M)

Max. Leakage Current Less than 0.05CV or 100μA

After 2 Minutes @ 20°C whichever is greater

W.V. (Vdc) 25 35 50 63 80 100

Working and Surge Voltage Ratings

S.V. (Vdc) 32 44 63 79 100 125

Tan δ @ 120Hz/20°C 0.16

Z -55°C/Z +20°C 1 ~ 2.5

Impedance Ratio

Z +125°C/Z +20°C 0.6 ~ 1.0

W.V. (Vdc) 25 35 50 63 80 100

φ6.3mm 2000 hrs.

Case Dia.

φ8 & 10mm 3000 hrs.

Load Life Test @ 125°C

Capacitance Change Within ±30% of initial measured value

and Rated Voltage

Tan δ and ESR Less than 200% of specified max. value

Leakage Current Less than specified max. value

ESR Less than 200% of specified max. value

Hot Plate at +250°C for 30 seconds with electrodes facing downward

Capacitance Change Within ±10% of the initial measured value

Resistance to Soldering Heat

Dissipation Factor Less than the initial limit

Leakage Current Less then the initial limit

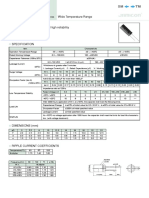

STANDARD PRODUCTS AND CASE SIZES Dφ x L (mm)

Cap. Working Case Size Max. Tan δ Max. ESR (mΩ) Max. Ripple Current (mA rms) Load Life

PART NUMBER

(μF) Voltage (D X L) mm 120Hz/20°C AT 100kHz/20°C AT 100KHz/125°C Hours (+125°C)

NSPE-T680M25V6.3X8NBYF 68 6.3X8 0.16 45 980 2000

NSPE-T151M25V8X10.8NBYF 150 25 8X10.8 0.16 27 1330 3000

NSPE-T271M25V10X10.8NBYF 270 10X10.8 0.16 22 1520 3000

NSPE-T470M35V6.3X8NBYF 47 6.3X8 0.16 60 910 2000

NSPE-T101M35V8X10.8NBYF 100 35 8X10.8 0.16 30 1260 3000

NSPE-T151M35V10X10.8NBYF 150 10X10.8 0.16 23 1480 3000

NSPE-T100M50V6.3X8NBYF 10 6.3X8 0.16 80 840 2000

NSPE-T330M50V8X10.8NBYF 33 50 8X10.8 0.16 35 1170 3000

NSPE-T560M50V10X10.8NBYF 56 10X10.8 0.16 25 1390 3000

NSPE-T3R9M63V6.3X8NBYF 3.9 6.3X8 0.16 100 740 2000

NSPE-T220M63V8X10.8NBYF 22 63 8X10.8 0.16 40 1090 3000

NSPE-T330M63V10X10.8NBYF 33 10X10.8 0.16 30 1260 3000

NSPE-T120M80V10X10.8LBYF 12 80 10X10.8 0.16 70 900 3000

NSPE-T100M100V10X10.8LBYF 10 100 10X10.8 0.16 80 870 3000

New Values

NIC COMPONENTS CORP. www.niccomp.com www.lowESR.com www.RFpassives.com www.SMTmagnetics.com

34

Hybrid Aluminum Electrolytic Capacitors NSPE-T Series

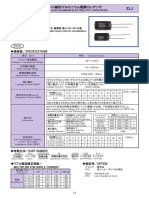

DIMENSIONS (mm)

Part Marking

Case Size Dφ ±0.5 L max. A, B ±0.2 W I ±0.2 P ±0.2

6.3x8 6.3 8.0 6.6 0.5 ~ 0.8 2.5 2.2 Series Code

8x10.8 8.0 10.8 8.3 0.7 ~ 1.0 2.9 3.2

10x10.8 10 10.8 10.3 1.0 ~ 1.4 3.2 4.6

Lot Code

Dφ + -

I I

W T__

3R9 Capacitance Value

L A

0.3mm max. 63V

P

Voltage

B

PART NUMBER SYSTEM

NSPE-T 220 M 63V 8x10.8 N B Y F

RoHS Compliant

Sn-Bi Finish, 13" Reel

Reflow Temp. Code (N=+260°C)

Size in mm

Working Voltage

Tolerance Code M=20%

Capacitance Code in μF, first 2 digits are significant

Third digit is no. of zeros, “R” indicates decimal for

values under 10μF

Series

Suitable for automotive equipment, sourced to special

production and inspection at TS-16949 certified production site

RECOMMENDED REFLOW SOLDERING PROFILE* LAND PATTERN DIM. (mm)

Peak Temperature Case Dia. A B P

(260°C/5 seconds) 6.3 3.5 1.8 2.1

260

Temperature - Deg. C

8 4.1 2.1 2.8

230 Time Above 230°C

10 4.4 2.5 4.3

(40 seconds max.)

200

150 Time Above 200°C

(80 seconds max.) + -

100 Preheat - 120 seconds max.

(+150°C ~ +190°C)

50 B

Time (Seconds)

PEAK TEMPERATURE AND DURATION A P A

Time Above Time Above Peak Time Above

Diameter

+200°C +217°C Temperature +230°C

6.3 ~ 63V +260°C (5 sec. max.)

100 sec. max. 80 sec. max. 40 sec. max.

80 ~ 100V +250°C (5 sec. max.)

*Two reflow passes are permissible with a cool down to room temperature required between

the first and second pass.

NIC COMPONENTS CORP. www.niccomp.com www.lowESR.com www.RFpassives.com www.SMTmagnetics.com

35

Hybrid Aluminum Electrolytic Capacitors NSPE-T Series

TAPING SPECIFICATIONS (mm)

1. Both Leader and Trailer tape: Minimum 40mm (1.57") empty carrier tape pockets.

2. Leader tape: Approximately 20cm of cover tape at leader. 1.75 + 0.15

4 + 0.1 1.5∅ +0.1/-

1.5φ+0.1/-0 1.75 ± t

3. Connection: Maximum 3 connections (slices) per reel.

A B C D P T t -

Case Size

D

±0.5 ±0.5 ±0.3 ±0.1 ±0.1 ±0.2 max.

C

6.3x8 7.0 7.0 16.0 7.5 12.0 8.2 0.6

B

8x10.8 8.7 8.7 24.0 11.5 16.0 11.0 0.6

10x10.8 10.7 10.7 24.0 11.5 16.0 11.0 0.6 +

A P Feeding T

REEL DIMENSIONS (mm) 2mm ± 0.5mm

W Qty per Reel

Case Size

±1.0 13" (330mm)

φ13mm ± 0.5mm

6.3x8 18 500

φ50mm min.

8x10.5 26 300

10x10.5 26 300

φ21mm ± 0.8mm

3mm

φ330mm ± 2.0mm W

or φ380mm ± 2.0mm

PRECAUTIONS

Please review the notes on correct use, safety and precautions found on pages T10 & T11

of NIC’s Electrolytic Capacitor catalog.

Also found at www.niccomp.com/precautions

If in doubt or uncertainty, please review your specific application - process details with

® NIC’s technical support personnel: tpmg@niccomp.com

NIC COMPONENTS CORP. www.niccomp.com www.lowESR.com www.RFpassives.com www.SMTmagnetics.com

36

S-ar putea să vă placă și

- NIC Components NSPE-H SeriesDocument3 paginiNIC Components NSPE-H SeriesNICCompÎncă nu există evaluări

- TE SeriesDocument8 paginiTE SeriesANIL ŞENÎncă nu există evaluări

- электролитические конденсаторы ECRDocument4 paginiэлектролитические конденсаторы ECRНиколай филюкÎncă nu există evaluări

- E Uhw 883813Document5 paginiE Uhw 883813Allyfranhy Nunes AlvesÎncă nu există evaluări

- NIC Components NRE-LW SeriesDocument5 paginiNIC Components NRE-LW SeriesNICCompÎncă nu există evaluări

- Surface Mount Aluminum Electrolytic Capacitors: NACE SeriesDocument5 paginiSurface Mount Aluminum Electrolytic Capacitors: NACE SeriesNICCompÎncă nu există evaluări

- Miniature Aluminum Electrolytic Capacitors Spec SheetDocument3 paginiMiniature Aluminum Electrolytic Capacitors Spec SheetOliver NeroÎncă nu există evaluări

- NIC Components NATK SeriesDocument4 paginiNIC Components NATK SeriesNICCompÎncă nu există evaluări

- NIC Components NRE-FLDocument7 paginiNIC Components NRE-FLNICCompÎncă nu există evaluări

- CD288/CD288H SERIES: Aluminum Electrolytic CapacitorsDocument2 paginiCD288/CD288H SERIES: Aluminum Electrolytic CapacitorsAlbert Laydee Molina TorresÎncă nu există evaluări

- NIC Components NRE-HS SeriesDocument6 paginiNIC Components NRE-HS SeriesNICCompÎncă nu există evaluări

- NIC Components NSP SeriesDocument6 paginiNIC Components NSP SeriesNICCompÎncă nu există evaluări

- NIC Components NRE-LX SeriesDocument6 paginiNIC Components NRE-LX SeriesNICCompÎncă nu există evaluări

- NIC Components NPC SeriesDocument4 paginiNIC Components NPC SeriesNICCompÎncă nu există evaluări

- Capacitor Lifetime Value Estimation With RecordsDocument6 paginiCapacitor Lifetime Value Estimation With RecordsVivekÎncă nu există evaluări

- NIC Components NRE-WY SeriesDocument7 paginiNIC Components NRE-WY SeriesNICCompÎncă nu există evaluări

- NIC Components NRSS SeriesDocument6 paginiNIC Components NRSS SeriesNICCompÎncă nu există evaluări

- NIC Components NRSX SeriesDocument9 paginiNIC Components NRSX SeriesNICCompÎncă nu există evaluări

- NIC Components NSRZ SeriesDocument4 paginiNIC Components NSRZ SeriesNICCompÎncă nu există evaluări

- MWR CapsDocument4 paginiMWR CapsMartien BakkerÎncă nu există evaluări

- SERIES - Lead Terminal: FeaturesDocument4 paginiSERIES - Lead Terminal: FeaturesVenu Gopal Rao AggressÎncă nu există evaluări

- Aluminum Electrolytic Capacitors: SpecificationsDocument5 paginiAluminum Electrolytic Capacitors: Specificationsm3y54mÎncă nu există evaluări

- NIC Components NRLR SeriesDocument11 paginiNIC Components NRLR SeriesNICCompÎncă nu există evaluări

- Teapo SZDocument2 paginiTeapo SZZainudin GhozaliÎncă nu există evaluări

- Beryl (Radial Thru-Hole) RT SeriesDocument2 paginiBeryl (Radial Thru-Hole) RT Seriesester853Încă nu există evaluări

- Series: High Voltage 63V.DC), Ultra Low ESR FeaturesDocument2 paginiSeries: High Voltage 63V.DC), Ultra Low ESR FeaturesMac RodrigoÎncă nu există evaluări

- Cel47uf250v CDocument3 paginiCel47uf250v CJean Marc BEAUMONTÎncă nu există evaluări

- Aluminum Electrolytic Capacitors: RXW SeriesDocument3 paginiAluminum Electrolytic Capacitors: RXW SeriesSuki ChanÎncă nu există evaluări

- NIC Components NRE-HW SeriesDocument6 paginiNIC Components NRE-HW SeriesNICCompÎncă nu există evaluări

- NIC Components NRSZ SeriesDocument8 paginiNIC Components NRSZ SeriesNICCompÎncă nu există evaluări

- NIC Components NRWP SeriesDocument6 paginiNIC Components NRWP SeriesNICCompÎncă nu există evaluări

- NIC Components NRLM SeriesDocument5 paginiNIC Components NRLM SeriesNICCompÎncă nu există evaluări

- E ZLHDocument3 paginiE ZLHJoe CrabshawÎncă nu există evaluări

- SR Passives T910Document1 paginăSR Passives T910Gato KurroÎncă nu există evaluări

- SBD20C100T/F - Datasheet: 20A, 100V Schottky RectifierDocument7 paginiSBD20C100T/F - Datasheet: 20A, 100V Schottky RectifierFreddy CamposÎncă nu există evaluări

- NIC Component Series NACKADocument4 paginiNIC Component Series NACKANICCompÎncă nu există evaluări

- NIC Components NCC SeriesDocument3 paginiNIC Components NCC SeriesNICCompÎncă nu există evaluări

- Elite (Radial Thru-Hole) ED SeriesDocument3 paginiElite (Radial Thru-Hole) ED Seriesgideilsonborges50Încă nu există evaluări

- Capxon (Polymer) 2011 PH SeriesDocument2 paginiCapxon (Polymer) 2011 PH Serieshes545Încă nu există evaluări

- Series: 23456specificationsDocument4 paginiSeries: 23456specificationsRamot SimbolonÎncă nu există evaluări

- Tta 2944741 PDFDocument4 paginiTta 2944741 PDFDhaval PatelÎncă nu există evaluări

- Jameco Part Number 95038ISOCOM: Distributed byDocument4 paginiJameco Part Number 95038ISOCOM: Distributed bymejmakÎncă nu există evaluări

- Capacitor ElcoDocument5 paginiCapacitor ElcoRazi QurrahmanÎncă nu există evaluări

- Beryl (Radial Thru-Hole) HU SeriesDocument3 paginiBeryl (Radial Thru-Hole) HU Seriesester853Încă nu există evaluări

- Datasheet 10D471K Varistor Maq de Lavar PDFDocument11 paginiDatasheet 10D471K Varistor Maq de Lavar PDFRenato MartinsÎncă nu există evaluări

- Beryl (Radial Thru-Hole) RG SeriesDocument2 paginiBeryl (Radial Thru-Hole) RG Seriesester853Încă nu există evaluări

- Crydom TD2410 DatasheetDocument5 paginiCrydom TD2410 DatasheetAdityaJayakarÎncă nu există evaluări

- NIC Components NRSH SeriesDocument8 paginiNIC Components NRSH SeriesNICCompÎncă nu există evaluări

- SMT Gate Drive TransformersDocument6 paginiSMT Gate Drive TransformersRig 25 Sr. ElectricianÎncă nu există evaluări

- Beryl (Radial Thru-Hole) TC SeriesDocument2 paginiBeryl (Radial Thru-Hole) TC Seriesester853Încă nu există evaluări

- Capa Panasonic Low EsrDocument5 paginiCapa Panasonic Low EsrClovis APOVOÎncă nu există evaluări

- Acon (Radial Thru-Hole) GFL SeriesDocument2 paginiAcon (Radial Thru-Hole) GFL Seriesxyz99Încă nu există evaluări

- Acon (Radial Thru-Hole) GFE SeriesDocument2 paginiAcon (Radial Thru-Hole) GFE Seriesxyz99Încă nu există evaluări

- NCC Nippon Chemi Con EMVY500ADA470MF80G - C2162911Document2 paginiNCC Nippon Chemi Con EMVY500ADA470MF80G - C2162911Milad MazaheriÎncă nu există evaluări

- Optically coupled bilateral switch non-zero crossing triac datasheetDocument3 paginiOptically coupled bilateral switch non-zero crossing triac datasheetElectronicos CaldasÎncă nu există evaluări

- NIC Components NRLFW SeriesDocument2 paginiNIC Components NRLFW SeriesNICCompÎncă nu există evaluări

- NIC Components NRE-WX SeriesDocument1 paginăNIC Components NRE-WX SeriesNICCompÎncă nu există evaluări

- NIC Components NRSG SeriesDocument8 paginiNIC Components NRSG SeriesNICCompÎncă nu există evaluări

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsDe la EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsÎncă nu există evaluări

- Surface Mount Aluminum Electrolytic Capacitors: NACE SeriesDocument5 paginiSurface Mount Aluminum Electrolytic Capacitors: NACE SeriesNICCompÎncă nu există evaluări

- NIC Components NCB-H SeriesDocument3 paginiNIC Components NCB-H SeriesNICCompÎncă nu există evaluări

- NIC Components NCSP SeriesDocument2 paginiNIC Components NCSP SeriesNICCompÎncă nu există evaluări

- Surface Mount Aluminum Electrolytic Capacitors: NACE SeriesDocument5 paginiSurface Mount Aluminum Electrolytic Capacitors: NACE SeriesNICCompÎncă nu există evaluări

- NIC Components NSPE-Y SeriesDocument2 paginiNIC Components NSPE-Y SeriesNICCompÎncă nu există evaluări

- NIC Press Release NSPE x0210Document2 paginiNIC Press Release NSPE x0210NICCompÎncă nu există evaluări

- NIC Component Series NTC-R NTP-RDocument3 paginiNIC Component Series NTC-R NTP-RNICCompÎncă nu există evaluări

- NIC Component Series NPIS - LSDocument11 paginiNIC Component Series NPIS - LSNICCompÎncă nu există evaluări

- NIC Component Series NTIDocument4 paginiNIC Component Series NTINICCompÎncă nu există evaluări

- Technical Support: TPMG@Document1 paginăTechnical Support: TPMG@NICCompÎncă nu există evaluări

- RoHS Makes Impact On Circuit DesignDocument3 paginiRoHS Makes Impact On Circuit DesignNICCompÎncă nu există evaluări

- NIC Components NRSNE SeriesDocument2 paginiNIC Components NRSNE SeriesNICCompÎncă nu există evaluări

- NIC Component Series NACKADocument4 paginiNIC Component Series NACKANICCompÎncă nu există evaluări

- NIC Components Corp.Document4 paginiNIC Components Corp.NICCompÎncă nu există evaluări

- HTTP:WWW - Niccomp.com Technical Inquiries: TPMG@Document2 paginiHTTP:WWW - Niccomp.com Technical Inquiries: TPMG@NICCompÎncă nu există evaluări

- Web Exclusive: An Introduction To Low ESRDocument3 paginiWeb Exclusive: An Introduction To Low ESRNICCompÎncă nu există evaluări

- NIC Components NACH SeriesDocument3 paginiNIC Components NACH SeriesNICCompÎncă nu există evaluări

- NIC Components NRE-HS SeriesDocument6 paginiNIC Components NRE-HS SeriesNICCompÎncă nu există evaluări

- NIC Components Current Sensing Resistor GuideDocument1 paginăNIC Components Current Sensing Resistor GuideNICCompÎncă nu există evaluări

- NIC Components NSPE-U SeriesDocument2 paginiNIC Components NSPE-U SeriesNICComp100% (2)

- NIC Components NACH SeriesDocument3 paginiNIC Components NACH SeriesNICCompÎncă nu există evaluări

- NIC Components NRE-WY SeriesDocument7 paginiNIC Components NRE-WY SeriesNICCompÎncă nu există evaluări

- NIC Components NMC-Q SeriesDocument7 paginiNIC Components NMC-Q SeriesNICCompÎncă nu există evaluări

- NIC Components NSPE-S SeriesDocument3 paginiNIC Components NSPE-S SeriesNICCompÎncă nu există evaluări

- NIC Components NACEN SeriesDocument3 paginiNIC Components NACEN SeriesNICCompÎncă nu există evaluări

- Guide To Hand SolderingDocument1 paginăGuide To Hand SolderingNICComp100% (1)

- NIC Components NMC-H X2/Y3 SeriesDocument2 paginiNIC Components NMC-H X2/Y3 SeriesNICCompÎncă nu există evaluări

- NIC Components NPIM - C SeriesDocument6 paginiNIC Components NPIM - C SeriesNICCompÎncă nu există evaluări

- Spare Parts Catalog: Machine Type: Vip Ii 46 / Vip Ii 47 Gaming Platform: Various Game Software: VariousDocument14 paginiSpare Parts Catalog: Machine Type: Vip Ii 46 / Vip Ii 47 Gaming Platform: Various Game Software: VariousMitica ScurtuÎncă nu există evaluări

- PIC Wire & Cable: For S22089Document1 paginăPIC Wire & Cable: For S22089Vidhu SrikumaranÎncă nu există evaluări

- Establishment of Paramedics College & Male Nursing College in Lakki Marwat - Bill of Quantities Package - 4Document12 paginiEstablishment of Paramedics College & Male Nursing College in Lakki Marwat - Bill of Quantities Package - 4Farhan AshrafÎncă nu există evaluări

- Setting Up ShopDocument242 paginiSetting Up ShopFredy Alvarez Lucas100% (15)

- Philips Core Pro LED Bulbs PDFDocument20 paginiPhilips Core Pro LED Bulbs PDFsalekojicÎncă nu există evaluări

- Catalogo Ricambi Spares Parts List Catalogue Pieces Detachees Ersatzteilkatalog Catálogo de Piezas de RecambioDocument8 paginiCatalogo Ricambi Spares Parts List Catalogue Pieces Detachees Ersatzteilkatalog Catálogo de Piezas de RecambioMohammad AslamÎncă nu există evaluări

- What Is TRIAC - Symbol, Construction, Working and ApplicationsDocument20 paginiWhat Is TRIAC - Symbol, Construction, Working and ApplicationsgezahegnÎncă nu există evaluări

- Amenity English 2003octDocument6 paginiAmenity English 2003octapi-3725711Încă nu există evaluări

- M3.6-Pure Solar-Add 3xZXD3000+3tech DG+DCPD7 and LTE-M3.6-Pure Solar Add 3xZXD3000+3techDG+2xMCB - 20181129 - V1.0Document26 paginiM3.6-Pure Solar-Add 3xZXD3000+3tech DG+DCPD7 and LTE-M3.6-Pure Solar Add 3xZXD3000+3techDG+2xMCB - 20181129 - V1.0Kyaw Kyaw WinÎncă nu există evaluări

- Dimensional drawing of MX612 Junction Box installation guideDocument2 paginiDimensional drawing of MX612 Junction Box installation guideBruno MirandaÎncă nu există evaluări

- Bobcat Online Parts Catalog - Engine & Attaching Parts (Engine Mounts) - S450 - 22-08-2023 16-54-10Document3 paginiBobcat Online Parts Catalog - Engine & Attaching Parts (Engine Mounts) - S450 - 22-08-2023 16-54-10Gabriel Pereira SilvaÎncă nu există evaluări

- t-030f Spanish p35-48Document4 paginit-030f Spanish p35-48Juan ContrerasÎncă nu există evaluări

- ASHRAE 90.1 Building Envelope RequirementsDocument51 paginiASHRAE 90.1 Building Envelope RequirementsRam RamisettiÎncă nu există evaluări

- Hager Protection Devices TechnicalDocument70 paginiHager Protection Devices TechnicalerreagaaÎncă nu există evaluări

- Form 2: Residential Loads Feeder 1: Use: 100 KVADocument38 paginiForm 2: Residential Loads Feeder 1: Use: 100 KVAZaul tatingÎncă nu există evaluări

- FFUS2613LS4 Frigidaire Refrigerator Wiring 240389639Document2 paginiFFUS2613LS4 Frigidaire Refrigerator Wiring 240389639aderloch100% (1)

- Vexica Vex-Miniline-Sqr-DsDocument2 paginiVexica Vex-Miniline-Sqr-DsUmeshÎncă nu există evaluări

- VW T-Cross 2019+ - Connector ViewsDocument220 paginiVW T-Cross 2019+ - Connector ViewsMucowera AshaÎncă nu există evaluări

- Catalog Product Osram LED Superstar MR16Document4 paginiCatalog Product Osram LED Superstar MR16Rialdy TewuhÎncă nu există evaluări

- Geep 114Document5 paginiGeep 114friendkwtÎncă nu există evaluări

- Rain Alarm ProjectDocument28 paginiRain Alarm Projectrinkoo067% (6)

- Siemens LLC: Earth Switch ClosedDocument2 paginiSiemens LLC: Earth Switch ClosedBala MÎncă nu există evaluări

- RCC folded plate slab detailsDocument1 paginăRCC folded plate slab detailsVinita KumariÎncă nu există evaluări

- Restraint System Diagnostics and DTC ReferenceDocument88 paginiRestraint System Diagnostics and DTC ReferencechrideerÎncă nu există evaluări

- Handbook For Handi-Lift 7: CAMA Lift Aps. Ellehammervej 6 DK - 9900 FrederikshavnDocument21 paginiHandbook For Handi-Lift 7: CAMA Lift Aps. Ellehammervej 6 DK - 9900 FrederikshavnNick VanderauweraÎncă nu există evaluări

- Block Diagram For AC To DC Converter (Power Supply)Document28 paginiBlock Diagram For AC To DC Converter (Power Supply)Piyush DubeyÎncă nu există evaluări

- KT-1703V Parts List and SpecificationsDocument22 paginiKT-1703V Parts List and Specificationsvico21hÎncă nu există evaluări

- Beginners Guide To LEDsDocument8 paginiBeginners Guide To LEDsnjaydopeÎncă nu există evaluări

- Service Manual Yamaha Scorpio Chapter 3 Inspection AdjustmentDocument35 paginiService Manual Yamaha Scorpio Chapter 3 Inspection Adjustmentjolang46Încă nu există evaluări

- Installation Manual: Sliding Gate OpenerDocument22 paginiInstallation Manual: Sliding Gate OpenerLuis Alfaro CasasÎncă nu există evaluări