Documente Academic

Documente Profesional

Documente Cultură

CO2 Mitigation Through The Use of Hybrid Solar-Combined Cycles

Încărcat de

Hamza MoussaDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

CO2 Mitigation Through The Use of Hybrid Solar-Combined Cycles

Încărcat de

Hamza MoussaDrepturi de autor:

Formate disponibile

~

Pergamon

1997ElsevierScienceLtd. All rights reserved Printed in Great Britain PII: S0196-8904(97)00012-5 0196-8904/97 $17.00+ 0.00

Energy Convers. Mgmt Vol. 38, Suppl., pp. $661-S667, 1997

COz MITIGATION THROUGH THE USE OF HYBRID SOLAR-COMBINED CYCLES Y. Allani COGENER, Parc Scientifique, EPFL CH- 1015 Lausanne, Switzerland D. Favrat and M. R. yon Spakovsky Laboratoire d'Energ6tique Indnstrielle, Ecole Polytechnique F&t6rale de Lausanne (EPFL) CH- 1015 Lausanne, Switzerland

ABSTRACT The integration of a solar collector field generating steam into a conventional combined cycle in order to partially replace the fossil fuel required by the latter results in a substantial reduction in greenhouse gases, in an increase in the return on investments associated with the solar field and in an almost complete elimination of the need for solar energy storage. This paper discusses the design of such an integrated hybrid solar-fossil combined cycle with maximum daily and nightly power outputs of 88 MWe and 58 MWe, respectively. This cycle is currently being evaluated from a technical and economic risk feasibility standpoint for possible implementation as a pilot plant in Tunisia 1. This paper outlines pertinent design considerations utilized in the thermoeconomic optimization approach employed for developing the hybrid combined cycle proposed here. The approach shows that there are several advantages to this type of design when compared with a purely solar steam cycle or any of the several other hybrid solar concepts which exist today. In addition to these advantages, the design presented revolves around the definition of a number of degrees of freedom which allow the solar energy part of the cycle to be highly integrated into the conventional part A discussion of them is given. Finally, from an environmental standpoint, the obvious advantage of this type of cycle is that due to the substitution of fossil fuel, there is a marked mitigation in CO 2 and NO x emissions when compared to a conventional cycle and to other hybrid concepts. Pertinent results for these reductions are presented. 1997 Elsevier Science Ltd

KEYWORDS integrated solar-fossil combined cycle; hybrid solar-fossil combined cycle; solar generated electricity; thermoeconomic optimization; CO: mitigation; pilot plant; Tunisia. INTRODUCTION It is obvious that increased reliance on renewable energies such as solar for the production of electricity has a high potential for CO~ mitigation. However, the inherent variability and daily intermptibility of solar radiation are major hindrances to its broader economic use, Nevertheless, large scale thermal solar power plants have been shown to be the most economic of the solar technologies in use today (Cohen et al., 1995; MttUer and Hennecke, 1993; Klaiss and Staiss, 1992).

The primary ways of compensating for these solar radiation drawbacks are either through the extensive use of thermal storage which turns out to be extremely expensive or through a coupling with fossil fuel equipment as proposed in this paper. This type of fuel though inherently the cheapest energy storage form known today

This work is bei.'ngcloneby COGENERandLENI-EPH~ in collaboration with ELEKTROWATr (Ztirich), KJC (Kramer on cotporatton,Washington, D.C.) and STEG (Soci6t~Tunisienne de l'~.lectricit6et du Craz,Tunisia) and its industrial patam'sandis beingfinancedby an ageacy of the Swiss governmentthe DDC (Direction du D6vdoppementet de la

~tion,

Berae).

$661

$662

ALLANI et al.: HYBRID SOLAR-COMBINED CYCLES

must, nonetheless, be used with care primarily due to its associated environmental effects. When employed in connection with solar energy, fossil fuel must be utilized as effectively as possible in order to maximize the solar and fossil energy potential while minimizing the negatives associated with both energy forms. Hence the concept of the integrated hybrid solar-natural gas combined cycle under study by the authors (AUani, 1995; Allani, 1992; Allani and Favrat, 1991) and by others (e.g., Ktinstle (1994)) since the early 1990s. This concept guaranties a constant power availability and alleviates some of the perceived risks associated with the use of large solar concentrator fields. These characteristics provide the major arguments for convincing a large utility from one of the sun belt countries (Tunisia) to jointly investigate integration alternatives for a more sustainable power production through the increased use of indigenous energy sources and a progressive substitution of fossil fuels. HYBRID COMBINED CYCLE CONCEPT One of the integrated concepts proposed is shown in Fig 1. It consists of a field of cylindrical-parabolic concentrators feeding hot oil to a buffer tank and to an oil-steam boiler which is itself connected in parallel to the main steam boiler of the combined cycle. The combined cycle consists of two gas turbines (for reliability and for increased efficiency at partial load), one or two heat recovery steam generators and one steam turbine. A possible alternative design not yet mature consists of a partial generation of steam directly in the collector

ext

g~

coolingsystem Fig, 1. Proposed integrated hybrid solar-fossil combined cycle.

tubes (Lippke, 1994), thus, reducing the number of components and better exploiting the exergy potential of the working fluid. For larger plants, natural gas, oil or gas from coal gasification can be used as fossil fuel candidates. For smaller plants, biomass derived fuels comprise additional candidates with still further improvements in CO 2 mitigation. In these concepts, solar energy can only be considered as an additional energy source to the fossil fuel power plant. However, the concepts' advantage is that they provide a high solar conversion efficiency at a lower invest/nent cost. Of course, care must be taken to not excessively penalize the fuel efficiency of the primary (o~ fossil) combined cycle. The basic idea for the proposed integrated plant is to have a steam turbine generator which is oversized when operated without solar input. As solar heating increases, the additional steam produced is fed to the turbine until its full capacity is reached. Fossil fuel consumption is then progressively reduced by decreasing the gas turbine load while keeping the steam turbine at full load.

ALLANI HYBRID SOLAR-COMBINED CYCLES

et al.:

$663

concepts.

It is clear from a thermodynamic standpoint that ideally one would use the solar energy directly in the toppinggas turbine cycle rather than in the bottoming steam cycle. However, present day technology for heating towers (judged not mature enough for heating compressed gases) as well as the inherent complexity of heater integration within standard gas turbines are major hindrances to the introduction of such advatred

THERMOECONOMIC DESIGN CONSIDERATIONS The thermoeconomic design of such integrated hybrid plants is considerably more complex than for conventional plants since one must take into account variations in solar energy availability throughout the year as well as match it with the electricity rate structure. Solar energy availability for a typical site in Tunisia is shown in Fig. 2 above. It shows the cumulative duration expected for the various classes of solar radiation in a representative year and the corresponding usable energy per square meter. The choice of design radiation value is an important parameter in the thermoeconomic / environomic (von Spakovsky and Frangopoulos, 1996) assessment. If a design value too high is chosen, then the solar field will be small leading to correspondingly lower investments but an excessive reliance on fossil fuel throughout the year. Choosing a value too small results in excessive investments with the additional drawback of needing to defocalize the collector field to avoid overload on peak summer days. Additional design parameters or degrees of freedom which are of importance are: 1. 2. 3. 4. the number of gas turbines used, e.g., the use of two gas turbines provides a necessary flexibility in the operation of the cycle when solar energy is substituted for fossil; a minimum partial load level for the gas turbines; the level of operational losses associated with the combustion gases; minimum and maximum non-nominal load levels for the steam turbines.

These design parameters are linked to two major operational strategies: a) a maximum power strategy by which power is maximized in any given time interval without consideration for fossil fuel use or CO 2 emissions; b) a maximum efficiency strategy whereby overall fuel efficiency is maximized in any given time interval. The strategies used must be matched to national grid dispatching requirements, although, because of its inherently higher efficiency level, such a hybrid power plant is likely to benefit from a higher dispatching priority. With regards to CO 2 mitigation, another possibility for this type of plant is to stop operation during

350

~0

'

55AI"

~

J opera,on

.

night

o .o

200 150

50

4I M

350~

I

500 l l : ? /

~' !ad!tl! 1! eII!ty!W!m9,!~ 1

IOcum .te hours non rgyr ciov (kWh)I

Fig. 2. Available solar radiation at a typical site in Gabes/Tunisia; duration and energy received are classed by radiation intensity,

heat rate (MW),,_

i0

200

Fig. 3. Pinch technology (temperature-heat rate) diagram for a dual pressure steam cycle design operating under the two extremes described in the text.

$664

ALLAN1 et al.:

HYBRID S O L A R - C O M B I N E D

CYCLES

the lower rate hours of the night, resulting in an improved fuel efficiency at reduced cost penalties. The choice of any of the above strategies has a definite impact on the design values linked to the combined cycle itself. Figure 3 above illustrates, using a pinch technology (temperature-heat rate) diagram, the situation for a dual pressure steam cycle design operating under the following two extremes: a) the composites for night Operation with only the exhaust gases from the gas turbines generating steam; b) the composites for a peak summer day with the combined heat of the exhaust gases and the solar heated oil generating steam.

Sliding steam pressure strategies are used to acx~mmodate these various operating conditions at the steam turbine while verifying the law of cones for the steam turbine design (Kehlhofer, 1991). PRELIMINARY RESULTS Some optimal designs for several different plant configurations linked to the pilot plant project in Tunisia were determined using a quasi-stationary thermoeconomic approach which uses a hierarchical sgucture to determine system synthesis (configuration), component design (size and performance) and system operation in the following manner. i) Two system configurations each with a steam cycle larger than that which would be found in a conventional combined cycle of the same size are evaluated. The amount of collector surface for the solar field which corresponds to each configuration is determined statistically based on the most often observed solar radiation events occurring during a typical year. ii) For each configuration and size evaluated, two optimal command strategies are determined which maximize for each steady-state interval of operation (quasi-stationary approach) either the global electric power output or the global efficiency of the hybrid solar combined cycle. iii) For each of the optimal command strategies, two operational policies are evaluated. They are based on an electricity rate structure which corresponds either to continuous (full time) operation or to operating only during the day and at peak nighttime hours, i.e. in Tunisia, the price of electricity is based on a daytime (middle), nighttime (low) and nighttime peak (high) rate structure. Table 1 summarizes some preliminary results for two configurations with the same gas turbines but two different steam turbine sizes. Each column corresponds to the hierarchy outlined above: a particular configuration, optimal command strategy and rate-based operational policy. It is important to note that the numbers given result from an integration over time of steady-state operations for a typical year. For example, all plant simulations of the type shown in Fig. 42 are integrated over time and the results presented in Fig. 5 as monotonic curves. The integration is accomplished by determining levels of power production throughout the year along with the number of operating hours at each level and then in decreasing order determining the energy produced at each level in order to arrive at the curves shown in Fig. 5. The areas underneath the curves, thus, represent annual levels of electricity produced (solar and total). This type of approach is used, for example, by STEG not only for planning purposes but as a means for determining an operational policy for an existing plant. In this case, the monotonic curves are calculated on a specific basis. Looking at Table I once more, the most economic plant corresponds to the smallest solar collector field and the longest operating time since the latter distributes the amortization over a larger energy output. However, the difference in C/kWh for the concepts examined and for the same number of operating hours is small. Also, note that the costs for the conventional part of the plant are based on Swiss prices and, therefore, somewhat elevated over the norm primarily due to civil engineering and a more reslrietive regulatory environment. Thus, specific production costs could decrease by as much as I to 2 C/kWh in developing countries such as Tunisia. In terms of the environment, CO 2 production for our hybrid concepts was compared to a conventional power plant with a 50% yearly mean conversion efficiency and the tons and percentage of CO 2 mitigated calculated. As shown in Table 1, the relative mitigation varies between 17% and 13% for continuous operation (left-handside of Fig. 4). These numbers can be pushed to 25% and more for a solar coverage of over 30% by stopping

line

2 Note in this figure that during winte~ operations, the gas turbine operates at part load and for this reason can also act as an c e backup s y s t e m w h e n insatbilities occur due to solar radiation flucmafiom.

ALLANI et

al.:

HYBRID SOLAR-COMBINED CYCLES

$665

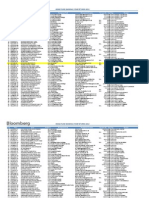

Table 1. Summary of preliminary results for the designs of the pilot plant project in Tunisia. 67.5 MW steam cycle 51,5 MW steam cycle (overdim by a factor of 4) (overdim, by a factor of 3) max power max efficien- max power max efficienstrategy c), strateg3( strategy cy strategy [h/y] 7880 4930 7880 4930 7880 4930 7880 4930

Operating time

ENERGY

mean plant efficiency [%] 60.2 67.1 60.3 68.9 57. 62.4 57.3 63.0 mean conventional efficiency [%] 49.4 49.7 48.1 47.4 49.8 49.9 48.6 47.9 part of solar elec.on total production [%] 18.0 26.0 20.3 31.2 13.4 20.0 15.1 24.0 solar field surface [103.m 2] 344.2 344.2 344.2 344.2 244.4 244.4 244.4"'244.4 specific gas consumption (day) [-] 1.26 1.26 1,13 1.13 1.41 1.41 1.32 1.32 specific gas consumption (night) [-] 2.04 2.04 2.04 2.04 2.02 2.02 2.02 2.02 specific gas consumption (mean) [-] 1.66 1.49 1,66 1.45 1.74 1.60 1.75 1.59 annual solar electric output [GWh] 98.5 98,5 98,1 98,1 70.1 70.1 69.8 69.8 annual conventional electric output [GWh] 450,0 280.9 385.9 216.8 451.7 280.5"393.0 22i.7 t0talannual electric output [GWh] 548.5 379.4 484.0 314.9 521.8 350.6 462.8 291.6

CO z MITIGATION*

CO2 Production by solar (X2 [103.t/y] 192.3 119.3 169.4 96.4 191.5 118.6 170.6 97.6 co2 Production by conventional plant[103.t/y] 231.5 160.1 204.3 132.9 220.3 148.0 195.4 123.1 (50% eff.) annual COs mitigation [ 103.t/y] 39.2 40.8 34.9 36.4 28.7 29.4 24.8 25.4 annual CO2 mitigation [%] ' 17 25 17 27 13 20 13 21 O~amitigation per installed collector [kg/m2] ce 114 118 101 106 117 120 101 104

ECONOMY**

solar investment costs total investment costs i~avest./total installed capacity annual invest. (20 years, 8%) operating and maintenance costs ~gasconsumption specific electric, prod. cost electric cost with internalized costs(2.42/k~COz) electric cost with internalized costs (60 /k~CO~)

[mio$] 105 [mio$] 251 [$JkW] 2303 [mio$] "25".1 21.5 [mio$] 5.70 4.01 5.70 4.01 [mio$] 7.84 4.87 6.90 3.93 [C/kWh] 7.04 8.96 7.79 10.49 CO2[/kWh] 7.89 COz[/kWh] 9.72 8.63 11.23

74

215"

2310 5.37 7.81 6.64 7.53 3.66 4.83 8'.55 9.37 5.37 6.95 7,30 3.66 3.98 9,99

8.19 10.80

28.08 27,83 28.67 28.87 28.67 28.85 29.42 30.01

(*) The percentagein annual mitigation of CO2 is calculatedrelative to a conventionalec~bin~ eyrie with the ~ to~ energy output as that of the hybrid solar combinedeyrie conceptstudied (**) The costs for the conventionalpart of the plant m'e based on Swiss prices an& therefore, somewhat elevated over the norm primarily due to civil engineeringand a moreresU'ictiveregulatoryeavironment plant operalion during nighttime hours (right-hand-side of Fig. 5). In Fig. 5, the solar electric power contribution is depicted by the dotted lines which monotonically correlate with the solar radiation availability. It is interesting to note that even if the maximum efficiency strategy improves the yearly solar coverage figure, it does not significantly improve the yearly mean efficiency or the mitigation of CO 2. If the reduction in kilograms of CO 2 per square meter installed of collector surface is calculated, the maximum power strategy again beats the maximum efficiency strategy with 114 to 120 kg/m 2 for maximum power against 101 to 106 kg/m 2 for maximum efficiency. Finally, the lowest specific CO s production corresponds to the highest electricity cost and even internalizing the CO: cost on the basis of 0.0242 $/kg CO2 (Goswami, 1993) would not significantly change the comparative figures. It would require a considerably higher CO 2 tax to invert this trend. Note, however, that the cost for

ECM 38/SUPI

$666

A L L A N 1 et al.:

HYBRID SOLAR-COMBINED CYCLES

atput profile for a partly cloudy winter day ax efficiency strategy)

] 130.~

I

l

120.~ 110 (E,

,

l 100.~ i 90.0% i80.0%

70.0%

i

"60.0% "50.0% ' . . . . . . . t 40.0% 9 1"1 ~ 1~5 17 19 21 23

hour

ant elec. ou ut - - - - lant eft.

Fig. 4. Two examples for plant electric output over a single winter or summer day. solar and total yearly plant output for continuous operation

90~00 80"OOO

m-m

solar and total yearly plant output for operating during daytime hours and nighttime peak hours

90'OO0

70'000

S0"O00

~1------

I~

to~al p~m!power

SOlarelecmc power I ]

70'000 ~'~ 60'000

~ ayooo

0

%

..~ 40'001) ,~ 30'000 20'000

d-ayfime !

o 40D00 ..__~ 30'000 20JO00 10"000

i

I

_ _ _ _ _ . _ _ _ _

10'000

| ~-"- "~-I

2000

4000

6000

8000

2000

4000

6000

8000

cumulative hours

Fig. 5.

cumdative hours

Solar and total yearly electricity production at maximum efficiency and for two different rate-based operational strategies.

for CO2 mitigation with hybrid solar-fossil combined cycle plants are only of the order of a few cents per kWh which is significantly cheaper than other CO 2 mitigation technologies based on renewable energies. CONCLUSIONS There are several advantages to the integrated hybrid solar-fossil combined cycle designs proposed in this pa.per when compared with a purely solar steam cycle or any of the several other hybrid solar concepts which exist today. The advantages are that

ALLANI et al.: HYBRID SOLAR-COMBINED CYCLES 1.

$667

2. 3.

the conventional combined cycle part of our hybrid concepts operate at base load, guaranteeing a minimum of power. This leads to an increase in overall availability for the plant as compared to the other cycles mentioned above, to an increase in the return on investment for the solar part and to a better integration of the plant into the utility grid or network; our hybrid cycle concepts have a higher dispatching priority from the standpoint of its annual average and peak efficiencies; our concepts utilize the solar equipment better when compared to the other concepts mentioned above.

In addition, hybrid solar-fossil combined cycle plants have in general a high potential for CO L mitigation at reasonable costs. However, the strategies used in achieving reductions is imporlanr. For example, even if the maximum efficiency strategy improves the yearly solar coverage figure, it does not significantly improve the yearly mean efficiency or CO Lmitigation. If the reduction in kilograms of CO: per square meter installed of collector surface is calculated, the maximum power strategy beats the maximum efficiency strategy with 114 to 120 kg/m2 for maximum power against 101 to 106 kg/m2 for maximum efficiency. Finally, simple internalization of CO Lproduction costs are unlikely to be sufficient for helping to identify the most sustainable path for achieving the major reduction targets which are likely to be needed in the future. More complex thermoeconomic / environomic optimization approaches (von Spakovsky and Frangopoulos, 1996) will have to be used. REFERENCES Allani, Y. (1995). PAESI Projet d'amtnagement 6nergttique solaire inttgrt:Rtsultats majeures de l'ttude de faisabilit6 technico-tconomique et environnemental d'une nouvelle cenWale 61ectro-thermo-solaire ~ cycle combine bi-combustible, Journdes lnternationales de Thermiques J1TH '95, Marmkech. Allani, Y. (1992). A Global Concept of a New Type of Solar Combined Cycle Duel Fuel, Proceedings of the 6th International Symposium on Solar Thermal Concentrating Technologies, 9/28- 10/2, v. II, p. 939-943. Allani, Y. and Favrat, D. (1991). Concept Global d'une Nouvelle Centmle Solaire ~ Cycle Combin6 Dual-Fuel, Entropie, 27, n 164/165, pp121-122. Cohen, G., Kearney, D.W. and Gable, R.G. (1995). Recent Improvements and Performance Experience at the Kramer Junction SEGS Plants, Symposium: Solarthermische Kraftwerkw 11(VD1),9 - 12 OcL, Stuttgart. Goswami, D.Y. (1993). Solar Energy and the Environment, International Conference on Energy Systems and Ecology: ENSEC '93,J. Szargut and G. Tsatsaronis editors, ASME, pp. 77-85, Poland. Kehlhofer, R. (1991). Combined-Cycle Gas & Steam Turbine Power Plants, The Fairmount Press Inc. Klaiss, H. and Stalss, F. (1992). Solarthermische Kraftwerkejear den Mittelmeerraum, Bd. 2, DLR, SpringerVeflag. Ktinstle, tC, I.ezuo, A. and Reiter, K. (1994). Solar Powered Combined Cycle Plant, Power Gen Europ '94, Cologne, 17-19 May. Lippke, F. (1994). Numerische Simulation des Absorberdynamik yon Parabolrinnen-Solar-Kraftwerken mit Direkter Dampferzeugung, Energieerzeugung, VDI-Verlag N'307, Reihe 6. Mtiller, M. and Hermecke, K. (1993). Solare Farmkraftwerke und Dimktverdampfung in Parabolinnen Kollektoren, Forschungsverbund Sonnenergie, pp 57-64, Themen 93/94. von Spakovsky, MoR. and Frangopoulos, C.A. (1996). Environomic Modeling and Optimization of a Gas Turbine Cycle with Cogeneration, Journal of Energy Resources Technology, ASME, accepted for publication.

S-ar putea să vă placă și

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Adsorption Equilibrium of Water On Silica GelDocument4 paginiAdsorption Equilibrium of Water On Silica GelHamza MoussaÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Review of Solid Adsorption Refrigerator I An Overview of The Refrigeration CycleDocument12 paginiReview of Solid Adsorption Refrigerator I An Overview of The Refrigeration CycleHamza MoussaÎncă nu există evaluări

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Experiment On A Continuous Heat Regenerative Adsorption Refrigerator Using Spiral Plate Heat Exchanger As AdsorbersDocument11 paginiExperiment On A Continuous Heat Regenerative Adsorption Refrigerator Using Spiral Plate Heat Exchanger As AdsorbersHamza MoussaÎncă nu există evaluări

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Object XMLDocumentDocument27 paginiObject XMLDocumentHamza MoussaÎncă nu există evaluări

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- 06 Electric Power Generation and Utilization (Scientific, Technical)Document1 pagină06 Electric Power Generation and Utilization (Scientific, Technical)Hamza MoussaÎncă nu există evaluări

- CoolingDocument8 paginiCoolingHamza MoussaÎncă nu există evaluări

- PERFORDocument12 paginiPERFORHamza MoussaÎncă nu există evaluări

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- A New Approach To The Exergy Analysis of Absorption Refrigeration Machines - SDDocument18 paginiA New Approach To The Exergy Analysis of Absorption Refrigeration Machines - SDHamza MoussaÎncă nu există evaluări

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Measurement While Drilling (MWD)Document14 paginiMeasurement While Drilling (MWD)Hamza Moussa100% (1)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Corporate Social Responsibility in Bangladesh:: A Comparative Study of Commercial Banks of BangladeshDocument12 paginiCorporate Social Responsibility in Bangladesh:: A Comparative Study of Commercial Banks of BangladeshSaima Binte IkramÎncă nu există evaluări

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Why Some Platforms Thrive and Others Don'tDocument11 paginiWhy Some Platforms Thrive and Others Don'tmahipal singhÎncă nu există evaluări

- Weavers, Iron Smelters and Factory Owners NewDocument0 paginiWeavers, Iron Smelters and Factory Owners NewWilliam CookÎncă nu există evaluări

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- John 5:31-47Document5 paginiJohn 5:31-47John ShearhartÎncă nu există evaluări

- Sample TosDocument7 paginiSample TosJenelin EneroÎncă nu există evaluări

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- DramaturgyDocument4 paginiDramaturgyThirumalaiappan MuthukumaraswamyÎncă nu există evaluări

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- The Role of Women in Trade Unions and Nation BuildingDocument18 paginiThe Role of Women in Trade Unions and Nation BuildingSneha KanitCar Kango100% (1)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- PS2082 VleDocument82 paginiPS2082 Vlebillymambo0% (1)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- Presentation On Ethics in ManagementDocument20 paginiPresentation On Ethics in Managementnasif al islamÎncă nu există evaluări

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Pup LawDocument144 paginiPup LawSheena ValenzuelaÎncă nu există evaluări

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Unit 7:: Intellectual PropertyDocument52 paginiUnit 7:: Intellectual Propertyمحمد فائزÎncă nu există evaluări

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- TS4F01-1 Unit 3 - Master DataDocument59 paginiTS4F01-1 Unit 3 - Master DataLuki1233332100% (1)

- Proposal Teen Age PregnancyDocument2 paginiProposal Teen Age Pregnancymountain girlÎncă nu există evaluări

- Technical AnalysisDocument4 paginiTechnical AnalysisShaira Ellyxa Mae VergaraÎncă nu există evaluări

- Risk AssessmentDocument11 paginiRisk AssessmentRutha KidaneÎncă nu există evaluări

- Ciplaqcil Qcil ProfileDocument8 paginiCiplaqcil Qcil ProfileJohn R. MungeÎncă nu există evaluări

- Oracle Fusion Global Human Resources Payroll Costing GuideDocument90 paginiOracle Fusion Global Human Resources Payroll Costing GuideoracleappshrmsÎncă nu există evaluări

- Itinerary KigaliDocument2 paginiItinerary KigaliDaniel Kyeyune Muwanga100% (1)

- Scupin and DeCorse Chapter 20Document29 paginiScupin and DeCorse Chapter 20Sana FarshbafiÎncă nu există evaluări

- Assessment Task-2Document7 paginiAssessment Task-2Parash RijalÎncă nu există evaluări

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Invoice: Page 1 of 2Document2 paginiInvoice: Page 1 of 2Gergo JuhaszÎncă nu există evaluări

- Albert EinsteinDocument3 paginiAlbert EinsteinAgus GLÎncă nu există evaluări

- Chapter 8: ETHICS: Mores Laws Morality and EthicsDocument3 paginiChapter 8: ETHICS: Mores Laws Morality and EthicsJohn Rey BandongÎncă nu există evaluări

- Rizal FamilyDocument3 paginiRizal FamilyPamela MarquezÎncă nu există evaluări

- Hedge Fund Ranking 1yr 2012Document53 paginiHedge Fund Ranking 1yr 2012Finser GroupÎncă nu există evaluări

- Blcok 5 MCO 7 Unit 2Document12 paginiBlcok 5 MCO 7 Unit 2Tushar SharmaÎncă nu există evaluări

- ECONOMÍA UNIT 5 NDocument6 paginiECONOMÍA UNIT 5 NANDREA SERRANO GARCÍAÎncă nu există evaluări

- Gillette vs. EnergizerDocument5 paginiGillette vs. EnergizerAshish Singh RainuÎncă nu există evaluări

- Employee Shift ScheduleDocument32 paginiEmployee Shift ScheduleRishane RajapakseÎncă nu există evaluări

- Become A Living God - 7 Steps For Using Spirit Sigils To Get Anything PDFDocument10 paginiBecome A Living God - 7 Steps For Using Spirit Sigils To Get Anything PDFVas Ra25% (4)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)